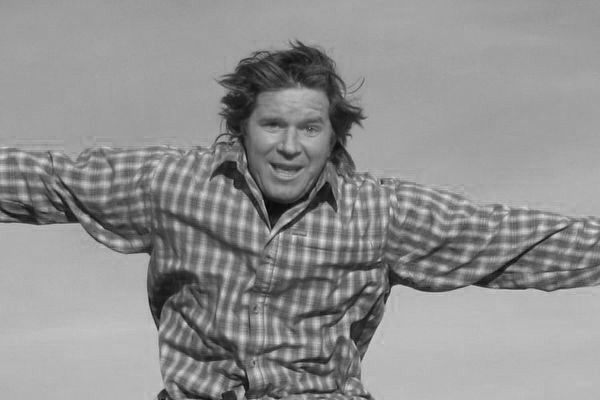

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

There are many different ways to upgrade your truck's brake system: bigger calipers, aftermarket master cylinders, hydro boost, and larger rotors all come to mind. But a quick and easy upgrade is better brake pads and rotors. EBC is a British-based company with nearly 30 years of experience making performance disc-brake pads for motorcycles, mountain bikes, mining equipment, autos, and trucks. So when EBC offered to let us test a set of its performance pads and rotors we jumped at the chance.

The old rotors and pads on our 7,700-pound '91 Chevy worked, but were nothing to write home about. We had learned to leave a fair distance between us and the other crazy drivers in front of us, but that didn't account for the many brainless individuals who nonchalantly cut us off and then come to a screeching halt for no apparent reason. It's almost funny how many people do not realize that when you cut off a big truck with 37-inch tires and a massive front bumper, it may not be able to stop all that quickly and could end up on top of you. Plus this big monster has become a weekend camping rig used for exploring lots of mountain trails, and the curving winding scenic byways are so much nicer when you know you can slow down the momentum quickly and not go sailing off a cliff. Thus you can see our desire for brakes we can depend on, and so we took a short afternoon of wrenching to swap in the EBC pads and rotors in our driveway.