A reasonable definition of a street rod is a vintage car modernized with improved performance for today's roads and travel speeds. Of course if you're reading this you already knew that, but while installing modern suspension, brakes, and updated motors was once all it took, today you must also deal with the ever-changing landscape called technology. One such challenge is how and if "modern" E10 gasoline is affecting your vintage carbureted hot rod.

We say modern, but actually ethanol pre-dates the automobile and has been around since the Civil War. Many hot rodders are unaware that the Ford Model T was originally designed to run on ethanol or gasoline. Henry Ford was a huge advocate of bio-fuels with a vision of converting crop waste to alcohol to fuel his factories and the cars he built. Through a series of twists, turns, legislation, and power brokers, alcohol has come and gone several times over the past 100 years, but it now appears E10 is here to stay.

There are two serious concerns with ethanol blends: too-high RVP (Reid Vapor Pressure) causing vapor lock behavior and percolation of the fuel. The second problem arises when fuel sits for a period of time, the technical name is water-induced phase separation. For automotive use, vaporlock concerns vanished with modern electronic fuel injection. The E10 gasoline was designed for and works perfectly well in a modern car with fuel injection and the associated fuel pump and return line. Since the fuel circulates continuously, it never gets hot enough to vaporize, and thus never vaporlocks. Even if there were vapor in this system, with the fuel flowing in a loop it would simply be pushed through the line, much like bleeding brakes.

The problems begin with a vintage fuel system that employs a dead-head pump and float bowls where the fuel can heat up and percolate. This problem is particularly acute after running the engine for a sustained period of time at highway speeds, then suddenly coming into stop-and-go traffic. The associated heat sink effect will elevate the temperature of the carburetor and the fuel will boil in the bowl. This can lead to serious flooding on some cars and hard starting problems when hot in other vehicles, while many other cars may notice rough idle characteristics.

Not being a pure substance, gasoline has no single boiling point. Instead, the lighter fractions start boiling out at 90-100 degrees F, with more and more evaporated as the liquid temperature increases, until the final, heaviest fractions evaporate in the 300-400 degrees F range. This behavior is called the "distillation curve." Ethanol boils at 178.5 degrees F, while water boils at 212 degrees F. The trick in a carburetor is to make the fuel evaporate into fumes when atomized without lowering the boiling point.

To prevent the fuel from boiling in the carburetor or fuel lines you should insulate the carburetor base to prevent unwanted heat sink. A heat shield will also help to reflect radiant heat away from the carburetor bowls, while insulating fuel lines will help prevent pre-heating the fuel. If there is no heat shield available for your carburetor you can either fabricate one yourself or you might try putting some of the hi-tech heat reflective tapes directly on the bottom of the fuel bowl of the carburetor. It will also pay to insulate incoming fuel lines and exhaust pipes that exit under the gas tank or close to fuel lines.

The second potential problem is also not likely to affect new cars. Water-induced phase separation is caused by alcohol's natural tendency to absorb moisture. If you fill and consume the fuel in your tank on a regular basis this problem is rare as the fuel does not have time to absorb substantial water. However, most street rods sit for more days than they are driven, and all the while they are sitting in the garage the alcohol is busy absorbing water from the air. At some point the water separates from the alcohol and your street rod is now running unintentional and intermittent water injection; this is not a good thing. These pockets of water cause misfires when running, but worse yet that water and alcohol has become a corrosive agent that is busy eating your pot metal carburetor and rusting that steel fuel tank. Storing the car with a full tank helps reduce the amount of air in the tank and you should also introduce a fuel additive to stabilize the fuel.

Ethanol reduces emissions, and that my friend is a good thing. On a down note ethanol also attacks unprotected aluminum and pot metal. Yes, that means your carburetor is under attack. Ethanol has been used in varying amounts since the 1970s as an octane enhancer, but it wasn't until the '90s that the levels were elevated to the 10 percent ratio of E10 gasoline.

Here are some materials that cannot be used with ethanol but can be used with pure gasoline. Do not use old-time lacquered cork carburetor floats, the antique zinc-based "pot metal" castings for fuel pumps and carburetors, and Lexan or Plexiglas if there is warm vapor contact with ethanol fuels. Of course you can change the floats and hoses but that carburetor is pot metal so it will require some protection; we'll get to that shortly.

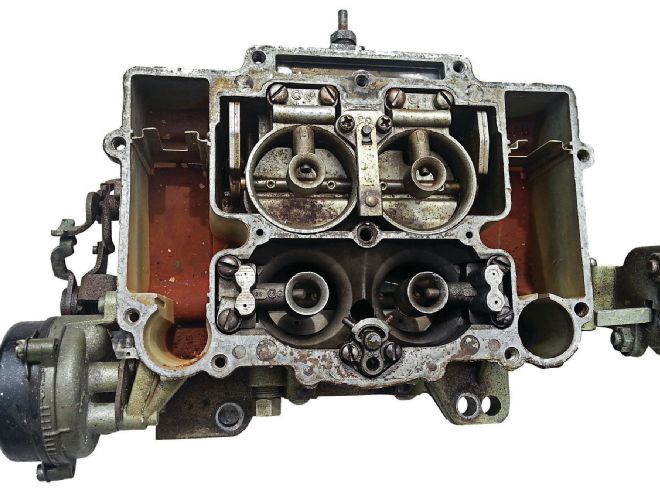

1. Ethanol can be highly corrosive, and one look inside this carburetor tells us something in the fuel system is rusting—most likely the steel tank itself. Fine rust sediment has lined the bottom of the carburetor bowls.

2. Oxidation and phase separation of the fuel itself will lead to this type of deposit, which of course leads to poor performance and possible flooding if sediment becomes lodged between the needle and seat inside the carburetor. Even with a good filter the untreated fuel can produce sludge in the carburetor.

3. AMSOIL INC. Quickshot is a premium fuel additive formulated to thoroughly clean and restore peak performance in automotive and small-engine fuel systems. It also stabilizes fuel between uses and during short-term storage. Its revolutionary technology focuses on three major fuel-related issues plaguing these applications: Ethanol, water, and dirty pump gas. When an ethanol/water mixture is pulled into the engine, it creates a lean burn situation that increases combustion chamber temperatures and can lead to engine damage. AMSOIL INC. Quickshot is designed to keep water dispersed throughout the fuel tank, moving it out as a normal part of operation and decreasing the chance of ethanol separating from the gasoline. AMSOIL INC. Quickshot was tested in fuel containing 10 percent ethanol. Controlled plugging of injectors showed a 70 percent flow improvement, while oxidation stability improved 44 percent over untreated fuel.

4. Driven’s Carb Defender Fuel Additive is specifically formulated to protect against ethanol corrosion and induction deposits. Special corrosion inhibitors work to prevent expensive repairs and diminished performance caused by ethanol-blended pump gasoline and the moisture it attracts. High levels of ethanol dilution in motor oil can lead to rust and other corrosion problems in the fuel system and inside the engine. This new additive, however, controls combustion chamber residue, plus cleans and protects surfaces of the fuel system and intake tract. The additive treats up to 25 gallons of ethanol-blended gas, and should be used with each and every fill-up. Driven Racing Oil Carb Defender Fuel Additive keeps the carburetor functioning properly and is designed for the unique needs of classic vehicles that spend much of their lives in storage between cruises and special events.

5. Eastwood’s Fuel Guard additive prevents the harmful effects caused by ethanol and prevents corrosion, gumming, and resin buildup. Use Fuel Guard Protection formula with every fill-up and Fuel Stabilizer formula for storage up to 12 months to prevent ethanol phase separation and corrosion. Fuel Guard also keeps carburetors and injectors clean and the formula contains no harmful alcohol or hydroscopic additives.

Most blended fuel problems can be traced to seasonal equipment, such as lawn mowers and street rods, which often sit for months at a time. Phase separation can occur in large amounts of fuel or small and it is best to drain the fuel system before long-term storage. That works well for things like a lawn mower but is not so easy or safe with cars with larger tanks. Three main problems occur in stored fuel of any type: evaporation, oxidation, and moisture absorption. The by-products of oxidation are gum and varnish...that brownish stuff that can clog various small orifices in your fuel system. Oxidation never sleeps, so the longer you allow untreated fuel to remain in your system the more likely the metals will produce scale and corrosion. UV light and exposure to air hastens oxidation and exposure to air also hastens evaporation. The light aromatics, those visible and highly explosive vapors that rise off an open container of gas, are what make the fuel burn well and especially with a carbureted car that relies on fuel atomization for smooth running. These components are lost rapidly, including the ethanol component of E10.

Finally, moisture comes into play. Entering a vented fuel tank from outside air, the severity of the problem will vary according to your location as dry air versus humid air affects the degree of water in the fuel. Phase separation from moist air alone is uncommon, but combined with temperature change and condensation you have a problem. Water condenses in the air pocket at the top of a vented tank and drops into the fuel. Water can also come from poorly maintained storage tanks at gas stations. In straight gas, the moisture separates and collects at the bottom of the tank. E10 fuel absorbs moisture until it reaches the phase separation point. At that point water drops out and begins to accumulate on the bottom of the tank.

The cure for storage problems begins with an airtight container. Plugging the vent in your gas tank is probably not easily accomplished but try to maintain a high tank level to minimize the volume of air in the tank. Next add a fuel stabilizer that will address the three major problems in stored E10 fuel. A quality fuel stabilizer contains high levels of antioxidants that will slow oxidation to a crawl. Second, a quality additive enhances the ability of the fuel to absorb water and resist phase separation. Fuel additives should also contain corrosion preventers to neutralize the corrosive tendencies and metal deactivators to prevent the chemical reactions between the fuel and metals like zinc, brass, aluminum, and iron. Finally a quality fuel additive will have about twice as much detergent as the best top tier gasoline to keep the fuel system clean all the way to the intake valve.

Fuel additives cannot entirely prevent evaporation, nor can they restore phase-separated fuel. The goal is to prevent phase separation. If you have a street rod with phase separated fuel, the best cure is to drain the fuel and start over. A second option is to drain off the water/ethanol and top off with fresh fuel. There are some products that can re-emulsify the water but that merely allows more inert material to go through the fuel system.

Armed with this knowledge we decided to venture into the world of fuel additives and see exactly how they should be used. As it turns out it is cheap insurance against ethanol fuel problems when using the additives as directed.

We would recommend using an additive in the summer months to help prevent fuel boiling problems. Using fuel additive with every fill-up is a good idea, but if you plan on consuming the entire tank of fuel on your trip and the weather is cooler you can probably run less additive. However, be sure to add the fuel additive with the last fill-up before you park the car for an extended period of time. Be certain to run the engine so the fuel additive is in your carburetor bowls providing the all-important protection. Now let's take a look at some of the better fuel additives and insulation materials on the market today.

6. STA-BIL Ethanol Fuel Treatment and Stabilizer protects against corrosion, helps remove water, cleans fuel system, and stabilizes fuel. Perfect for use in your everyday driving vehicle, such as your car, truck, SUV, or minivan, and also great for your small gasoline-powered equipment, such as lawn mowers.

Keeping Fuel Cool

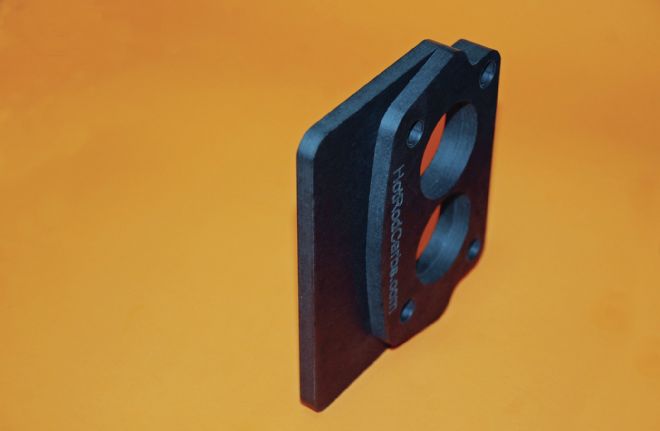

7. Trans-Dapt offers insulating carburetor spacers in both plastic and canvas phenolic materials for Holley/AFB 4 BBL carburetors. They offer a range of PCV and non-PCV port-equipped models that range in thicknesses from 3/8 inch up to 2 inches. To accommodate both street and track-bound applications, they also include open and ported plenum designs. Many of the ported spacer models are also available with Trans-Dapt’s proprietary mixture-motion groove that enhances air/fuel atomization without reducing plenum volume. The Swirl-Torque technology used on these spacers improves low-to-midrange rpm torque, giving your engine better low-end throttle response. All Trans-Dapt carburetor spacers include the gaskets and hardware necessary for installation. The spacers are available in either phenolic or synthetic composition.

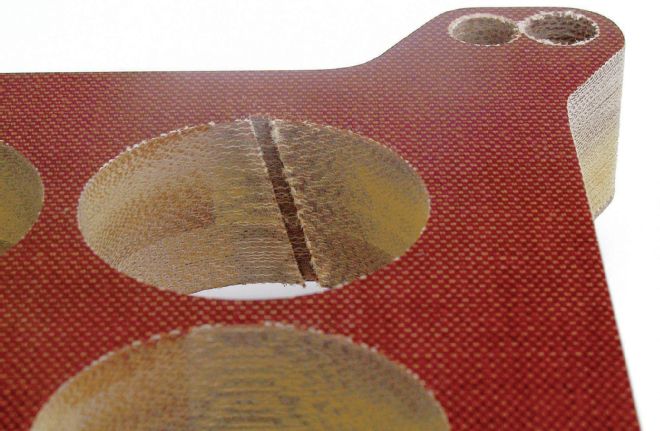

8. Having experienced substantial percolation problems on my own Tri-power–equipped 327 Chevy motor I went looking for some heat insulator spacers for the popular three Rochester setup. Hot Rod Carbs offers an insulator spacer and they also offer this combination heat shield and spacer that provides both insulation and a reflective shield to stop radiant heat from the intake manifold from pre-heating the float bowl.

9. Cool Carb offers insulated spacers in several different thicknesses. The spacers are constructed with a poly core sandwiched between two pieces of aluminum. They offer insulating spacers for most popular two- and four-barrel carburetors.

10. A quality carburetor spacer will prevent heat from being absorbed directly from the intake manifold, but there is also radiant heat to deal with. We decided to apply a piece of reflective gold foil to the bottom of our carburetor bowls; DEI offers this high-quality reflective material in sheets or rolls.

11. When the carburetor is installed you won’t see the foil, but it should be effective in repelling radiant heat coming off the engine. This will work on Holley-style four-barrels and any two-barrel carb with exposed fuel bowls.

12. Preheating the fuel before it gets to the carburetor or injector is also a problem. Once again DEI offers a solution in the form of aluminized fuel line insulation. This is the sewn style that must be slipped over the fuel line prior to the final connections.

13. If your fuel lines are already installed they can be insulated easily by using the DEI Velcro fuel line insulation. Simply wrap the insulation around the fuel tubing and press the Velcro closed.

14. Speaking of fuel lines, be certain that all of your rubber fuel lines are certified bio-fuel safe. Older rubber and neoprene lines that are not designed for ethanol fuels can break down, causing dangerous leaks or rubber residue in the fuel system.

Typical Installation of a Heat Spacer

15. Installing the Hot Rod Carbs heat shield and spacer was as simple as removing the carbs and replacing the studs with new Mr. Gasket 2-inch studs sourced from Summit Racing. The new stud is in the foreground.

16. Replacement studs are available in different lengths; for use with the Hot Rod Carbs spacer and heat shield a 2-inch stud works perfectly.

17. The heat shield and spacer provide double protection from heat transfer and radiant heat. This view shows the bottom side of the unit. Use the proper gasket on both sides of the spacer.

18. Of course with Tri-power you will need three of everything, three sets of studs, three spacers, the proper gaskets are provided with these spacers.

19. Our Offenhauser intake has a lower carburetor pad so we had to grind a bit off the front shield where it contacted the thermostat housing. This modification is not required on an Edelbrock intake. In the end we beat the heat and the spacers blend in nicely with the intake manifold.