Once on the road a street rod's gas tank is one of those parts seldom thought about until it's time to pay for filling it up. But when a car is under construction it's a good idea to give the gas tank some thought.

Basically there are three choices when deciding on a gas tank: build a one-off gas tank to fit the space available, use the original, or find a substitute. In the Nov. 2013 issue of STREET RODDER we showed how to build a custom gas tank with Rock Valley. (We should point out we incorrectly stated in that article that 1 gallon of gas measures 231 square inches when it should have read 231 cubic inches.) This time around we'll look at some other gas tank options and related parts.

Tanks

It makes sense to use the car's original gas tank when possible, however carefully check its condition before putting it in service. Old fuel turns into something akin to molasses mixed with concrete, and rust can be an issue as well. There are a variety of methods to clean a nasty fuel tank. One old trick was to toss in screws, nuts, nails, or even gravel and shake the tank vigorously (the Tex Smith method was to throw it in the back of a pickup and drive around with it for a week or so). There are a variety of chemicals available for cleaning gas tanks and if you choose that option follow the instructions to the letter, particularly when it comes to disposing of the used material. Be aware there are a number of scary concoctions that have been tried to clean old gas tanks; some can be dangerous so stick with the commercially available variety. Another option may be your local radiator shop, as many of them clean and repair gas tanks.

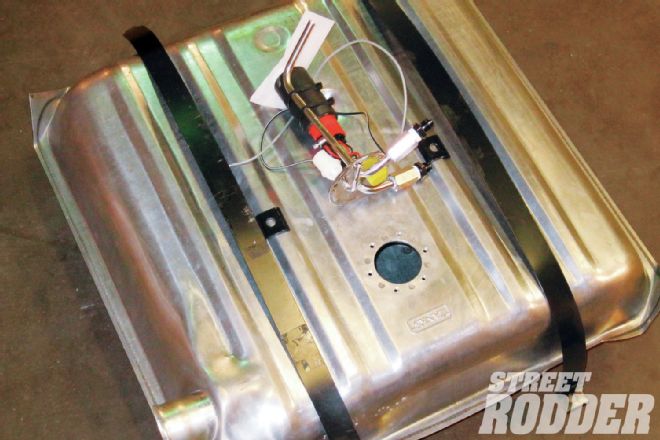

Replacement gas tanks are available for a variety of early cars. This one from Tanks accepts an internal electric fuel pump.

Replacement gas tanks are available for a variety of early cars. This one from Tanks accepts an internal electric fuel pump.

Caps and Vents

Gas tanks require a vent—atmospheric pressure must be allowed to enter the tank to prevent creating a vacuum as fuel is removed from the tank. However there is a problem with gas tank vents. They work both ways: They let air in and they can also let gasoline vapor out. As a result, some gas caps are equipped with a one-way valve, air can come in but vapor can't get out.

One of the oldest emission control devices found on automobiles is the vapor canister—essentially it's a container that acts as a vent for the fuel tank when the engine is running and collects vapor from the fuel system when the engine is off. While most street rodders aren't anxious to add emission control devices to their cars, if your garage smells like gas it's likely the fumes from your pride and joy not the newer car or truck parked next to it. To stifle the stink, Hot Rods by Dean recently introduced a vapor recovery tank that looks great and traps escaping vapor. Soon as the engine is running and fuel is pulled out of the tank the canister is purged. A good thing for the environment, it also saves a little fuel and it will keep the garage from smelling like gasoline.

In some cases saving an original tank is the best option; this one may be beyond help. It’s been fiberglassed, epoxied, brazed, and it still leaked and was full of rust.

In some cases saving an original tank is the best option; this one may be beyond help. It’s been fiberglassed, epoxied, brazed, and it still leaked and was full of rust.

Fuel Pumps

While mechanical fuel pumps are still used, electric fuel pumps are not only popular, but also necessary with electronic fuel injection.

There are two common types of electric fuel pumps, the T style and the inline. T-style pumps use a motor to drive a sliding-vane type pump with an internal bypass to regulate pressure. When the outlet pressure reaches a preset point (Aeromotive HO Fuel Pumps PN 11209 are internally regulated to 7 psi), a spring-loaded poppet valve opens and sends fuel from the outlet side of the pump back to the inlet via an internal passage. As the engine's fuel demands increase less fuel is bypassed.

The classic T-style fuel pump from Aeromotive. Simple and reliable, they’re available in configurations to suit anything from a street cruiser to a Pro Mod.

The classic T-style fuel pump from Aeromotive. Simple and reliable, they’re available in configurations to suit anything from a street cruiser to a Pro Mod.

Inline fuel pumps are often thought of as being applicable to fuel injection systems only, however they work with carburetors as well. Pumps like the Aeromotive A1000 are continuous-duty fuel pumps that produce a constant flow of fuel and can be used in low-pressure carbureted or high-pressure EFI systems with the proper regulator. In all cases the regulator must be the bypass-style, which means a return line to the tank is required.

Another type of inline pump is the in-tank style. Submerging the pump has a number of advantages, not the least of which is the large volume of fuel keeps the pump cool, which extends its operating life. As the pump runs cooler it won't transfer heat to the fuel, which can contribute to vapor lock. An added bonus is the fuel muffles the sound of the pump, which makes them quieter than external designs.

Fuel Filters

Filters are rated by the size of contaminates they will trap (a micron is 1⁄1,000 of a millimeter or 0.00003937 of an inch). Most electric fuel pumps are more forgiving of small particles passing through them than that are of a restriction in the supply line from the tank (electric pumps are said to get "angry" because they growl when they have to pull harder than they push). Aeromotive recommends a coarse 100-micron stainless steel pre-pump filter and a finer 10-micron linen filter after the pump. As the saying goes, suck through stainless push through paper.

Aeromotive offers inline filters with replaceable 10- or 100-micron elements.

Aeromotive offers inline filters with replaceable 10- or 100-micron elements.

Fuel Tank Sending Units

The fuel level sending consists of a float connected to a variable resistor that grounds the gauge. As the float moves up and down the resistance is changed and the needle on the gauge moves. Some gauges use senders with low resistance to indicate empty and higher resistance for full; others are the opposite. In either case the gauge and sender must be compatible.

Classic Instruments manufactures several tank senders to conform to most OEM (original equipment manufacturers) electrical resistance specifications. They also offer a variety of fuel gauges to read correctly when connected to the original or stock tank sender. When using an aftermarket fuel tank, Classic Instruments recommends a 240-ohm (empty) to a 33-ohm (full) adjustable sending unit.

This style bolt-in fuel level sender is often used with fuel cells. It has a float inside the vertical tube and is used with gauges that have a 240- to 33-ohm range.

This style bolt-in fuel level sender is often used with fuel cells. It has a float inside the vertical tube and is used with gauges that have a 240- to 33-ohm range.

To ensure reliable operation Classic Instruments recommends the installation of an extra ground from the top of the sending unit to the chassis; don't rely on the support straps that are often rubber lined. In addition, they recommend testing the sending unit's calibration for the depth of the tank before installation. "Simply have a pal in the car turn the key to the run position to power up your instruments and make sure the ground and sending unit wire are attached, then swing the float to the top. You should see the instrument read full; swing the float to the bottom and it should move to empty. We always recommend leaving a little reserve in the bottom of the tank, so when the instrument reads empty you have a 1/2-gallon or so left in the bottom for ‘get to the nearest gas station' insurance."

If the Gauge is Ohms Empty Ohms Full Use Classic Sender GMC 1964 or earlier 0 30 Sender SN36 GMC 1966 and later 0 90 Sender SN38 Ford 1987 and later(unleaded fuel only) 16 158 OE Only Ford (pre-1987); AMC 73 10 Sender SN39 Stewart-Warner 240 33 Sender SN33 or SN35 Auto Meter 240 33 Sender SN33 or SN35

For original tanks that can be brought back to life, Eastwood offers a complete kit with cleaner, metal prep, and fuel tank sealer.

For original tanks that can be brought back to life, Eastwood offers a complete kit with cleaner, metal prep, and fuel tank sealer.