Everyone who races uses some form of harness to keep them securely in his or her race car. They have saved countless lives, and many times, go overlooked in the grand scheme of the car. Especially when you think about belts from technology point of view. There is a lot to a set of racing harnesses -- the belts themselves, the clamps and brackets that attach them to the car, the latching device, and whatever form adjustability they may have. Though it sounds fairly simple, each component must be strong enough on its own to hold you in under some extreme forces.

Seatbelts are subject to extreme loads when put to the test in a crash situation. When a car impacts a wall, or another car for that matter, the car sees and sudden decrease in velocity, or sometimes a sudden stop from very high speeds. While the vehicle may slow down or stop, the driver’s body wants to stay in motion. The harnesses are what slow down and eventually stop the driver’s body in a crash. Because of this, seatbelts have to be constructed from materials strong enough to withstand as much as 200 times the weight of the driver. They also need to stretch enough to absorb some of the energy of the driver, while still limiting movement of the driver’s body.

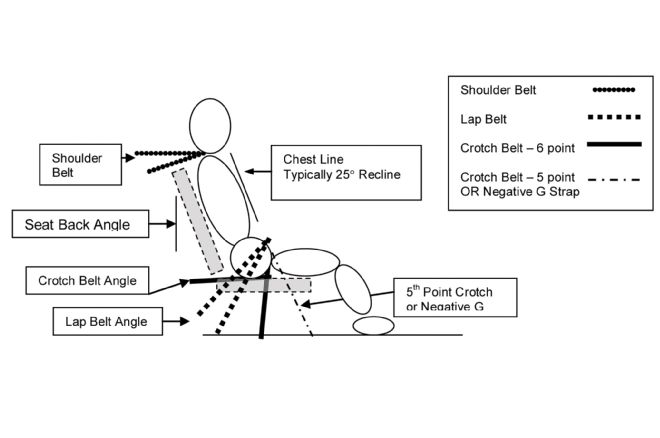

Shoulder belt angle should be 0- to -20-degrees (-10-degrees optimum) from horizontal. There should be a clear passage of webbing from the top of the driver’s shoulders (or head-and-neck restraint) back to the harness bar or mounting point without any interference of the seat openings. Belts should be as short as possible to the mounting points.

Double Shoulder Belt (Over/Under Belt):

Upper belt (2-inch belts) should be mounted at 0 to -10 degrees (-10 degrees optimum). Body belts (3-inch belts) should be mounted -10 to -30 degrees (-20 degrees optimum). Separation between upper and lower belts should be 1 to 2 inches. Upper belts should be mounted to line up with the inside edge (closer to the neck) of the body belts.

Lap Belts

Lap belt angle should be -45 to -80 degrees from the horizontal. Belts should ride within the curvature of the pelvic bone, preferably just below the iliac crest. There should be a clear passage through the seat opening without the webbing being corded or binding on the edges of the seat openings with a direct path to the mounting point. The webbing should not ride against any hardware, such as seat mounting brackets, bolts, or tabs. Lap belt adjusters should be clear of the seat openings. Pull-up adjusters, if outside the seat opening, should be a minimum of 2 inches below the opening when the lap belt is tightened. Belts to the mounting point should be as short as possible mounted beside the seat and never behind the seat. Lap belt should be allowed to pivot freely at the mounting point. Webbing should be allowed to pull on hardware in plane (straight).

Position of the Cam Lock or Latch and Link

Centered on the body 1 to 2 inches below the belly button when all belts are tightened.

Crotch Belt -- Six-Point

Sports Car “Shell Type Seat” and aluminum seats with a single crotch belt hole 10 to 12 inches forward of the inside seat back (seats with a single hole positioned more than 12 inches from the inside seat back are designed for five-point belt installations and may not be as effective for six-point installations) should use a crotch belt angle of -20 degrees (2 inches rearward) through the hole with two separate anchors 4 to 6 inches apart.

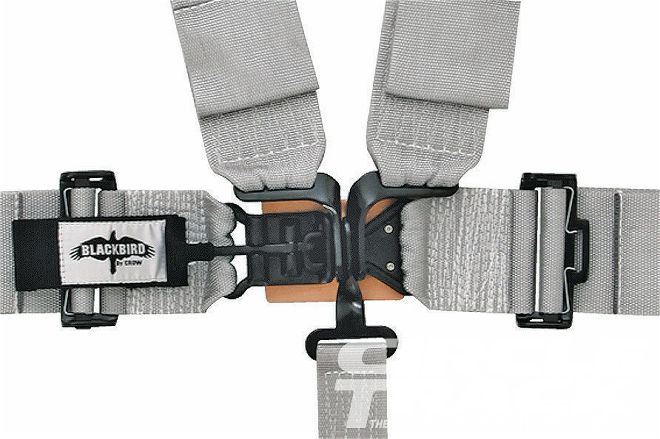

Crow Enterprizes’ Blackbird belts are the latest from the safety company. The Blackbird Series belts feature all Black hardware a standard latch and link five-way restraint, 50-inch seatbelts with individual harness floor mount, anti-sub belt bolt in, pull down adjustment, and SFI 16-1 approval They are available in red, blue, black, purple, and gray for $112.

Crow Enterprizes’ Blackbird belts are the latest from the safety company. The Blackbird Series belts feature all Black hardware a standard latch and link five-way restraint, 50-inch seatbelts with individual harness floor mount, anti-sub belt bolt in, pull down adjustment, and SFI 16-1 approval They are available in red, blue, black, purple, and gray for $112.

Containment seats with crotch belt mounting directly to seat bottom or through holes provided at the back of the seat bottom (driver is sitting on the crotch belts) should have a crotch belt angle of -10 to -20 degrees from perpendicular just in front of the crotch with anchors 4 to 6 inches apart. Routing of the crotch belts should have a clear and unobstructed path to the mounting point.

Crotch Belt -- Five-Point

Sports Car “Shell Type Seat” and aluminum seats with single crotch belt hole 11 to 13 inches forward of the inside seat back should have a crotch belt angle of 20 degrees from the chest line through the hole. Crotch belts should never wrap around the front of the seat -- there should be a pass through as it is used only to maintain position of the lap belt.

Negative G Belt -- 7th Point

Negative G strap angle should be 20 to 25 dgerees (chest line extension on a 25-degree seat back angle), and used in conjunction with a six-point crotch belt system as an additional point to maintain the position of the lap belt in “Negative G” or rollovers. This may sound rather scary, and it is. But this is the reality of what we do. To learn more about one of the most basic safety device, we talked to some of the biggest names in the racing harness world to show you the latest and greatest in seatbelt technology.

Simpson Racing Products’ top of the line harnesses are its Platinum Series belts. The company’s focus with restraint development is to load the driver earlier in the crash through the use of proper mounting, six-point restraints, and improved webbing, as used in the Platinum Series. Through testing, Simpson has found that there is a delicate balance between force and elongation of the webbing. Traditional standard nylon webbing has elongation (stretch) of approximately 15- to 17-percent at 2,500 pounds. Its new Platinum Series webbing, made primarily of polyester, is both stronger (in excess of 20 percent) and has less elongation (7- to 9-percent less at 2,500 pounds) than nylon webbing. It also has better resilience to abrasion, moisture and chemical deterioration over time. These properties help ensure that the driver is properly positioned and restrained earlier in the crash equation.

The standard latch and link system can be slightly more cumbersome when strapping in, but a flip of the lever releases the belts.

The standard latch and link system can be slightly more cumbersome when strapping in, but a flip of the lever releases the belts.

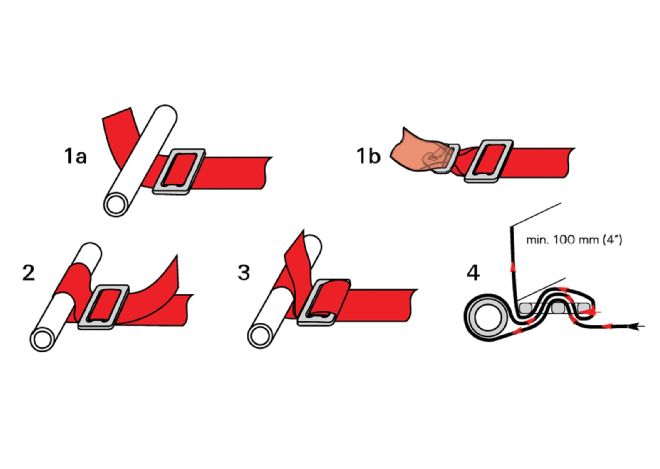

The best belts in world mean nothing if they aren’t mounted properly. According to G-Force Racing Gear there is no step-by-step instruction manual for installing belts into your race car. They do include a general instruction form with each set of belts, which can be found on the company’s website. G-Force gives you option when it comes to mounting its belts. They can be used in a wrap-around or bolt-in configuration by simply removing the clasp at the end of each belt. This allows the belts to be extremely versatile for a wide array of different race cars. Snap-in hardware can also be purchased from G-Force.

Harnesses and Head-and-Neck Restraints

With all of the advancements in head-and-neck restraint technology, harnesses are following with new features suited specifically for HNRs. Schroth Racing has a new feature, which ARCA driver Will Kimmel uses. The shoulder belts actually have two sets of belts that sandwich the head-and-neck restraint, keeping it in place. The system works like a regular harness. You tighten the shoulder belts down prior to putting you HNR on. After putting it on, a second set of shoulder harnesses go over the HNR, keeping it tightly in place.

With head-and-neck restraints become mandatory in many race series, safety companies are designing belts to work specifically with these restraint devices. Schroth Racing has its new belts designed for HNRs. The shoulder harnesses have two straps that sandwich the HNR. The first belts go directly on the driver’s shoulders before the HNR. After installing the HNR, the top belts sandwich the HNR to the lower belts. This allows the driver to pull the belts tight on his or her shoulders, not the HNR. The HNR is then tightened after. This also ensures the HNR stay in place during a crash.

With head-and-neck restraints become mandatory in many race series, safety companies are designing belts to work specifically with these restraint devices. Schroth Racing has its new belts designed for HNRs. The shoulder harnesses have two straps that sandwich the HNR. The first belts go directly on the driver’s shoulders before the HNR. After installing the HNR, the top belts sandwich the HNR to the lower belts. This allows the driver to pull the belts tight on his or her shoulders, not the HNR. The HNR is then tightened after. This also ensures the HNR stay in place during a crash.

“The belts are definitely more comfortable and give you a tighter feel in the seat,” explains Kimmel. “The setup pulls you back and down into the seat more so then pulling down on you shoulders with the HNR.”

Another advancement that has followed HNR popularity is tapered shoulder belts. Companies are taking their 3-inch shoulder belts and tapering them to 2-inch belts where the belts contact the HNR. This allows for a sturdier, more comfortable fit for the driver.

Think Safety

The effectiveness of harnesses, like any other piece of safety equipment, is up to you. If they are not installed properly, damaged, or just plain old, the odds of failure increase dramatically. This can lead to serious injury, or even death. Be sure your belts are installed correctly. If you aren’t sure, ask another racer who’s done it before. There is plenty of information on the internet to show you everything you need to know about proper installation and maintenance. Now pull those belts down tight and go fast!