You'd have to be new to this hobby, or a little inattentive, to not be aware of the excellent choice and availability of aftermarket air conditioning and heating systems we enjoy today. In fact we have just such an install coming up on the project '49 Chevy in the not-too-distant future. But what if you have a Fifties or Sixties car and don't want to go to the expense of ripping out the factory air conditioning to replace it with a modern aftermarket version? Is your old A/C system viable nowadays? Can it be upgraded? What's this about Freon becoming unavailable?

Whoa, let's take a step back and we'll answer those questions and more after we explain a little more about refrigerants, availability, and the Environmental Protection Agency. Older A/C systems use a refrigerant commonly known as Freon, the DuPont trade name for R-12. After studies proved R-12 to be damaging to the ozone layer, the EPA phased out its use and then banned its manufacture in 1996 with its replacement, R-134a, first being used in new cars in 1992, and used almost exclusively by '95. Which means that 'our' type of cars all use an obsolete, and now scarce refrigerant. The problem is R-12 and R-134a don't mix, and while the former is still available, it may not be for much longer. Occasionally, though you may not be aware of it, any R-12 you can get may have been smuggled from outside the US or is an illegally manufactured blend, as reserves of R-12 manufactured prior to the EPA ban are getting low.

As R-12 cannot be mixed with any other refrigerant, converting to R-134a involves removing the R-12 using approved recovery equipment, as venting into the atmosphere is forbidden, before new refrigerant can be added. If your cooling system is working efficiently and holds its charge there is currently no reason to retrofit it for R-134a as an R-12 system is designed to work with that refrigerant and offers its best performance with it, and while supplies last, staying with R-12 is logical. Even if it leaks, or requires minor repair, recharging it with R-12 is probably still the preferred option, as converting to its successor will typically see the cooling performance reduced. However, repair may not be an option if the parts are no longer available, though there are suppliers that can help. Old Air Products specializes in vintage and antique A/C systems and may be able to supply heater valves, expansion valves, receiver/driers, evaporator coils, blower motors, compressors, switches and reservoirs for many early models from various manufacturers. They even carry rare NOS parts for Ford and GM cars, as well as offering complete new retro-looking underdash A/C units.

While it's possible to retrofit an older A/C system to take R-134a, sometimes seals, hoses, the compressor, receiver-drier, and even the condenser need to be changed. The components in the A/C system are comprised of the compressor, condenser, evaporator, orifice tube, thermal expansion valve, receiver-drier and accumulator. If your car has an orifice tube, it will not have a thermal expansion valve, as these two devices serve the same purpose. Also, the system will use either a receiver-drier or an accumulator.

A compressor designed to run with R-12 may not be compatible with R-134a. The different refrigerants have different chemical properties, with R-12 using a mineral oil to lubricate the compressor and R-134a using a PAG oil (polyaklylene glycol lubricant). OEM compressors including some Keihin, Panasonic and Tecumseh versions cannot be retrofitted because of this. Also, because R-134a raises the discharge pressure from the compressor, some lightweight versions will not work for long using R-134a.

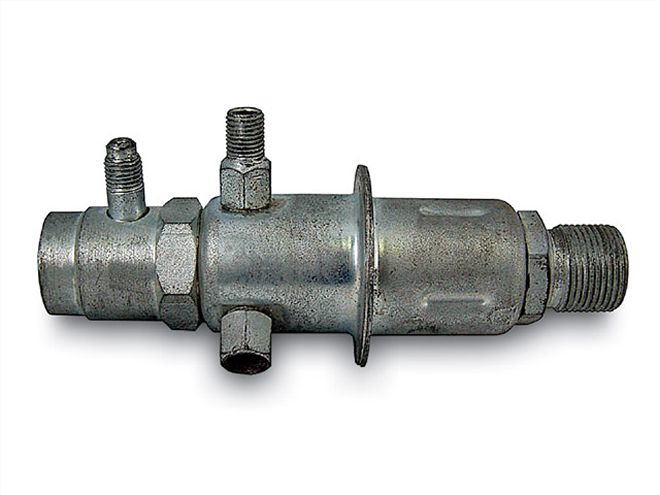

POA valves are typically found on '65-73 GM vehicles as well as '70-80 Fords. Activated by pressure they don't work properly with R-134a owing to higher system pressures associated with the newer refrigerant.

POA valves are typically found on '65-73 GM vehicles as well as '70-80 Fords. Activated by pressure they don't work properly with R-134a owing to higher system pressures associated with the newer refrigerant.

Rick Love of Vintage Air told us that the molecules in R-134a are smaller than those of its predecessor, and as such over time may leak from old-style flare fittings, which is why new systems employ O-rings. He also mentioned that the pressure/temperature curve is different between the refrigerants, and with GM products from the Sixties in particular, a temperature cycling switch may be required to replace the POA valve (Pilot Operated Valve-replaced by a Valve In Receiver valve, or VIR, in '73), which keeps the evaporator coil from freezing. Also, if an expansion valve is part of the system, a new one recalibrated to work with R-134a will be needed too. Of course Vintage Air manufactures new A/C systems, so their interest lies in replacing rather than retrofitting, but Rick knows many will want to keep the original system and has even retrofitted a few himself in the past.

Shane at Southern Air reiterated Rick Love's comments about swapping out the compressor, condenser, drier and hoses, saying many of their customers with older cars fit a new system using the factory evaporator and controls, and disguise the converted controls with a new fascia plate in the interior. This is something we'll be doing in our project '49, using the factory heat and air controls to operate the new A/C system from Vintage Air.

But we're discussing retrofitting here, so how's it done? As a general rule of thumb, the old mineral oil has to be removed from the system, the accumulator or drier should be replaced with one containing X-7 desiccant, a new orifice tube or recalibrated expansion valve will need to be fitted as will a high pressure cutout switch, and the O-rings will have to be replaced. A more efficient condenser may also be needed. The hoses should also be changed to a barrier hose, which contains a nitrile rubber inner tube and neoprene cover that prevents water from entering or refrigerant from leaking through the actual hose walls. Then PAG oil can be added and the system recharged with R-134a to around 80 percent of its original capacity. You're also required by Federal law to install R-134a fittings on the high and low service ports which will identify the system as containing that refrigerant and reduce contamination in the future.

Clint Millican at Old Air Products told us that while much retrofitting is model-specific, all will need, as a minimum, a new receiver/dryer, oil change and system flush, as well as new service parts according to the new refrigerant. Other additions will then depend on the vehicle. For instance '59-61 GM vehicles use a hot gas bypass valve that contains rubber parts and diaphragms that are not compatible with R-134a, and as such should continue to use R-12 if originality is required, while from '62 to '65 the STV (Suction throttling valve) should be updated to a CCOT, or cycling clutch valve, as the higher pressures at which R-134a works will force the STV to close before the temperature drops to where it should be. Old Air Products also offers an eliminator kit to convert '73-76 GM VIR assemblies to an orifice tube. Variable orifice tubes allow the flow rate to change to provide improved cooling at low speeds and in stationary traffic.

If you're converting a GM, Ford or Chrysler A/C system from the Sixties, however, you may experience slightly higher temperatures with the A/C running after switching to R-134a because these systems are controlled by the low side pressure, and R-134a produces lower pressure at a given temperature than R-12.

In addition to the components required to retrofit an A/C system to use R-134a, it should be noted that as R-134a has a different pressure/temperature curve than R-12 there will be more pressure at a given temperature in the high pressure side of the system, often requiring a larger and more efficient condenser, or at the very least increased airflow over the condenser core to dissipate the heat generated. Equate this to the radiator in your cooling system and you'll see why an electric fan and shroud is important to help boost the performance of the A/C system.

The Future

Though in Europe R-134a will start to be phased out by 2010 in new cars, and disappear completely by 2017 (as it is a greenhouse gas that contributes to global warming when released into the atmosphere, even though it doesn't harm the ozone layer) American and Japanese automakers will continue to use it, though A/C systems will be redesigned to use less refrigerant, reduce leakage and improve efficiency. However, at some point R-134a will likely be replaced worldwide. CO2 (R-744 when used as a refrigerant) and HFC-152a are possible alternatives, along with HFO-1234yf. A refrigerant developed by DuPont and Honeywell, the latter meets the new European Union regulations which will require a refrigerant to have a global warming potential (GWP) of less than 150. HFO-1234yf has a GWP of 4 compared to 1430 for R-134a and looks to be the safest and easiest replacement, especially as there are no major alterations required to use it in an R-134a system.