Now that the cruising season is just about over for most of us, maintenance and rebuild season is just beginning. Because cruising is usually limited to late Spring through early Fall, we don’t want to lose valuable driving time having our cars down for non-essential repairs. For instance, if the heater is broken and it’s August, there’s no reason to rip apart the car to fix it immediately. If we can get by without it, why park the Dodge while the weather is still nice?

One item that didn’t seem to be essential when we were younger is air conditioning. I remember very distinctly removing the factory A/C system from my first car in an attempt to lighten the front end and pick up a few extra horsepower. A futile effort in a 4,000 pound car, but logic doesn’t always come into play when you’re 16. At the time, it seemed to make even more sense because there was a problem with the system, and I didn’t have the money to fix it.

Now that many of us are driving our cars a lot more than the occasional Sunday evening drive, having cold air conditioning is becoming less of a luxury and more of a necessity when it comes to enjoying our time behind the wheel. So now that Fall is here, maybe it’s time to give the A/C system a thorough going through and get it working again.

R-12 or R-134a?

When our Mopars rolled out of the factory’s doors, their A/C systems were charged with Refrigerant 12—Freon. Unfortunately, freon is a chlouroflourocarbon (CFC), and CFCs have since been determined by the scientific community to be a contributor to the depletion of the ozone layer. There has been a lot of debate among different political camps as to whether or not CFCs actually contribute to the depletion, whether or not the hole in the ozone is a naturally occurring event, and even whether or not the hole actually exists, but that debate isn’t for these pages. The only fact we need to concern ourselves with is that R-12 is no longer manufactured in this country, and that the government has mandated that R-12 be replaced with R-134a. That’s the law, and it isn’t going to change.

However, if your R-12 system still performs well, R-12 will be legal and available until the year 2030. That’s the good news. Unfortunately, right now you can expect to pay around $40 per pound for R-12, as opposed to about $8 per pound for R-134a. And domestic production of R-12 only ceased in 1994—think what future prices will be!

When R-134a was first introduced, there was a lot of complaining that it wasn’t as efficient at cooling as R-12. There were concerns that it would hurt systems that were designed for R-12. What that panic and concern boiled down to was that people don’t like change and they don’t like the government telling them they have to change. Since the introduction of R-134a, all the differences have been worked out between R-12 and R-134a, so that an R-134a system is as efficient, and will blow air as cold (or within two to three degrees at the dash vents) as an R-12 system. As for component failure, since the introduction of R-134a, the hoses and mechanicals in well-maintained A/C systems have not been shown to suffer failures as a result of using R-134a in place of R-12.

Notice we said well-maintained—if an R-12 system already has a problem, R-134a isn’t going to hasten it’s demise, but it isn’t going to help, either. Because of this, often when a recently-converted system fails, blame is unfairly placed on the new refrigerant when, in reality, the system probably had never been serviced in its life. Also, and this is important, the filter/drier on your system should be considered a service replacement item, just like any other filter on your car. It should be replaced to rid your system of impurities and debris which it has trapped, whether or not you are converting. If you are converting, the drier needs to be replaced because the desiccant in original R-12 units is not compatible with R-134a—the desiccant pellets will turn to mush and plug the filter, which will damage other components in the system. There are desiccants that are compatible with either coolant, as well as R-134a-specific desiccants.

Everything is bead-blasted, and then the parts that originally came plated are buffed and replated in-house, while the other pieces are prepped for paint.

Everything is bead-blasted, and then the parts that originally came plated are buffed and replated in-house, while the other pieces are prepped for paint.

What about everybody’s complaint that R-12 systems are colder than R-134a? Al Sedita, owner of Classic Auto Air in Tampa, Florida, told us that when R-134a first came out a few years ago, that was in fact the case. But over time they found out that the industry was suggesting that R-134a systems should be charged with 90 percent as much refrigerant as the R-12 systems were charged with. They’ve since found that most systems actually require only 60-75 percent as much R-134a as the R-12 charge specs. “The systems were overcharged, so they weren’t as efficient,” says Al.

If It Ain’t Broke...

So when’s the time to convert your R-12 system to R-134a? The old axiom “If it ain’t broke, don’t fix it” applies. If your A/C system blows cold don’t worry about it. R-12 will still be available for a long time, and buying a pound every couple of years will be cheaper than converting. However, if you have a major component failure and you have to dump a bunch of money into it, you may as well add a little more and convert it at the same time.

Not all hose crimps are the same. Chrysler, GM, and Ford all used different styles of crimps to attach the hard lines and fittings to the rubber hoses on their A/C system. On top of that, Chrysler used a couple of different styles itself, depending on the year of your car. Classic Auto Air has the dyes to put the correct crimps on the hose fittings. Here, Rob is using their crimping machine to install the fittings on the ends of the rubber hoses.

Not all hose crimps are the same. Chrysler, GM, and Ford all used different styles of crimps to attach the hard lines and fittings to the rubber hoses on their A/C system. On top of that, Chrysler used a couple of different styles itself, depending on the year of your car. Classic Auto Air has the dyes to put the correct crimps on the hose fittings. Here, Rob is using their crimping machine to install the fittings on the ends of the rubber hoses.

The major component differences between an R-12 and an R-134a system are the hoses, O-ring seals, the service ports (where the refrigerant is put into and evacuated from the system), lubricating oil, the expansion pressure relief valve (which acts as the thermostat that turns the compressor on and off to keep it from freezing up), and the desiccant in the filter/dryer.

If you are using fresh hoses, the difference between the two is that there is an extra barrier liner on the inside of R-134a hoses. You can use fresh R-134a hoses on an R-12 system, but you cannot use fresh R-12 hoses on a R-134a system. However, if you are converting an existing R-12 system to R-134a, your old hoses are fine to use with the new R-134a refrigerant because the R-12 hoses have “seasoned,” so they will suffer no adverse affects from the new refrigerant. Because of this, it is virtually impossible to get standard R-12 style hoses (without the barrier lining) anymore, so this isn’t much of a concern. If you replace the hoses on your car, they will likely be the R-134a type.

The service ports are different mainly as a safety feature to ensure that service centers don’t mix the two refrigerants when filling or recycling the coolant. Lubricating oils have come a long way in the last 30 years, and many of them are compatible with both types of refrigerant, so if you’re rebuilding your own system, make sure to check the label.

Next, they turn their attention to the filter/ drier. Because NOS filter/dryers are hard to come by, Classic Auto Air has developed a process to actually recondition, rebuild, and restore your original. Here, Rob starts by removing the sight glass and seals, the low pressure cut-out switch, and high pressure relief valve, all found on top of the filter/drier canister.

Next, they turn their attention to the filter/ drier. Because NOS filter/dryers are hard to come by, Classic Auto Air has developed a process to actually recondition, rebuild, and restore your original. Here, Rob starts by removing the sight glass and seals, the low pressure cut-out switch, and high pressure relief valve, all found on top of the filter/drier canister.

With the help of Classic Auto Air, we recently completely restored an entire A/C system out of a ’70 Challenger. We followed along with them as they rebuilt the plenum box and compressor, as well as replaced the lines, custom-reproduced the fittings, and rebuilt the filter/drier.

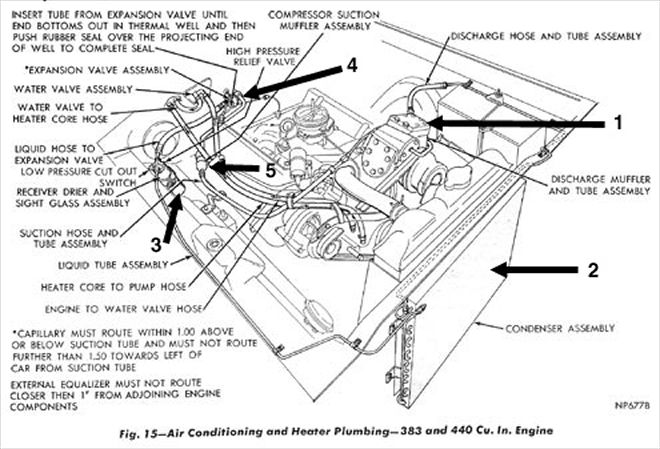

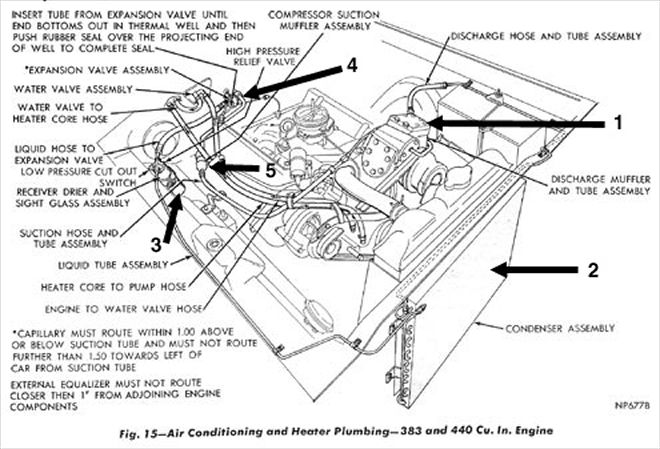

For the compressor and plenum box, Classic Auto Air will sell you the individual parts to replace any broken or missing pieces if you choose to do the work yourself, or you can send them the components and they will do it for you. If you are going to do the work yourself, it is important to have a service manual for the year and make of car you are working on. For illustration purposes, we used diagrams taken out of a reproduction ’70 manual we got from Year One.

In this story, we’re following along as Classic Auto Air restores the muffler, filter/drier, and the lines and fittings. By the time you read this, they will be able to completely re-create all the hard lines, rather than cutting the old hose fittings off and re-using them. In Parts II and III, we’ll walk you through restoring a plenum box and completely rebuilding the compressor.

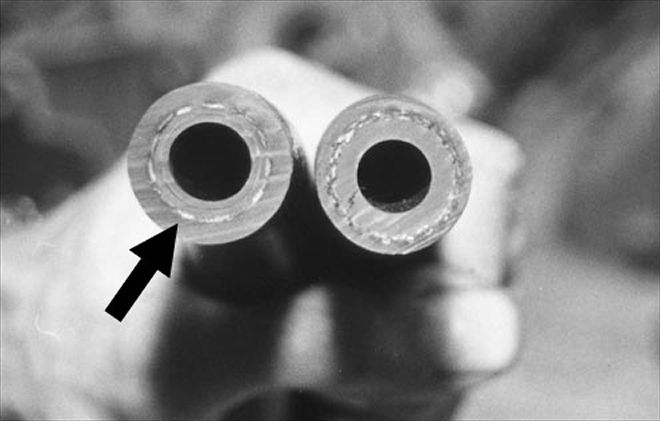

The hose on the left is the new-style R-134a compatible A/C hose, the one on the right is the old R-12 style. If you look closely (arrow), you can see the additional inner barrier lining on the R-134a-style hose.

The hose on the left is the new-style R-134a compatible A/C hose, the one on the right is the old R-12 style. If you look closely (arrow), you can see the additional inner barrier lining on the R-134a-style hose.

R-12 and R-134a vs. The Rest

One problem that’s developed as substitutes for R-12 have been tried is the “chemical soup” created by the blending of various types of dissimilar and incompatible products marketed as refrigerants.

“It sets up a very advanced corrosion that’s faster than even a salt-spray corrosion test,” explains Al Sedita, owner of Classic Auto Air in Tampa, Florida. “The EPA approves refrigerants from a toxicity standpoint, not performance or longevity. There have been about a dozen approved by EPA as alternative refrigerants, but that does not mean that they’re good, safe, and efficient to use in an automotive air conditioner.” In fact, many of these substitutes are legal replacements only in industrial or commercial applications, and not automotive. “About the time these products were hitting the market, we also saw oil additives introduced that claimed to not only increase system longevity, but make the system colder, some claimed by as much as 8-10 degrees,” says Al. “But tests done by some of the compressor and O-ring manufacturers show that there’s a cross-contamination situation that can create compressor failure in months rather than years.”

On the left is the old-style R-12 service port, on the right is the new-style R-134a port. These ports, or valves, are where the coolant system is charged and evacuated during service. The fittings above the R-12 piece are adapters that can be permanently installed on R-12’s high side (“fill”) and low side (“evacuation”) fittings to convert them to R-134a.

On the left is the old-style R-12 service port, on the right is the new-style R-134a port. These ports, or valves, are where the coolant system is charged and evacuated during service. The fittings above the R-12 piece are adapters that can be permanently installed on R-12’s high side (“fill”) and low side (“evacuation”) fittings to convert them to R-134a.

When R-12 began to be subject to sales restrictions, some auto parts stores began to put R-22—a refrigerant used in household refrigerators and central air conditioners—on that same spot on the shelf. Al says, “We saw a lot of hobbyists use it, then their system doesn’t work right, so they go to a shop that doesn’t have refrigeration identification equipment and it gets sucked into their refrigerant recovery machine. Some other guy comes in and he’s got some other refrigerant. Before you know it we’ve got “chemical soup” in that recovery machine that gets put into 20 or 30 other cars. Then those cars have problems and they go to a different shop and the contamination begins to snowball.”

Refrigerant identifier technology has improved, and now most bigger shops use them. But manufacturers of parts, seals, and O-rings will not warranty their products for any refrigerant other than R-12 or R-134a. That includes oil additives.

Stick with industry-approved products and your system will hold up—and stay cool—over the long haul.

To fully understand what components you’re dealing with, it helps to know where they fit in the system, their functions and how they work. We pulled this diagram from our reproduced ’70 Charger/Coronet service manual from Year One. The diagram illustrates a system used on 383-440 engines, and while the shape of the individual components may differ depending on which size engine you have, their functions are the same regardless of engine options.

1. Hot refrigerant, in vaporized form, leaves the compressor and travels to the condenser via a high-pressure hose.

2. At the condenser, the vaporized refrigerant, which is much hotter than the outside air, is cooled and returns to a liquid state.

3. From the condenser, the cooled refrigerant goes into the filter/dryer. The filter/dryer serves three purposes: It filters the refrigerant, removing little particles of metal that occur from internal corrosion; it uses a desiccant pack to remove small amounts of moisture from the refrigerant; and it acts as a reservoir for the cooled refrigerant that’s returned to a liquid state. This should be treated as a service replacement part, just as any other filter on your vehicle. And contrary to what your local garage might tell you, it cannot be serviced by simply putting it in the oven and “baking” the moisture out of the desiccant! Besides any water moisture trapped in the desiccant there is also a small amount of oil, but more importantly, there is a lot of debris trapped by the filter that must be removed from the system.

4. A high-pressure hose carries liquefied refrigerant from the filter/dryer to the expansion valve. The expansion valve, located at the evaporator inlet, has a tiny hole in it, typically .018-.020-inch in diameter. The compressor is sucking against that tiny hole, creating low pressure throughout the evaporator. As refrigerant flows through the hole, it expands rapidly in this low pressure zone and becomes a hot, low-pressure vapor again. It now enters the evaporator (the smaller, radiator-type coils mounted in the plenum box under the dash). As warm air from the car’s interior is blown over the evaporator, the refrigerant absorbs the heat, and the interior air, having the heat removed, is returned to the passenger compartment.

5. The heat-laden refrigerant runs through a low pressure line to the compressor muffler, then back to the compressor to repeat the cycle.