Barry Grant has made a career out of feeding fuel to engines but in his off hours he's still a hot rodder. As an enthusiast he cruises one of his hot rods to several events each year and it soon became quite obvious to him that old-school engines and induction systems were showing no signs of losing popularity. However, with regard to the induction systems, he knew little attention had been given to improving their function, serviceability, or appearance.

He took it upon himself, with some prompting from Skratch of Skratch's Garage, to see what he could come up with and it wasn't too long before he developed the Demon 98. From the start Barry knew the carburetor had to have a retro style that would blend in sitting atop a Flathead, Y-block, Hemi, Nailhead, or any vintage engine. But at the same time it would need to offer modern-day performance. Special attention was also given to serviceability, as it becomes increasing difficult to obtain service parts for older carburetors. The Demon 98 employs standard fuel bowl and metering-block gaskets, jets, power valve, needle-and-seat assemblies, and air bleeds.

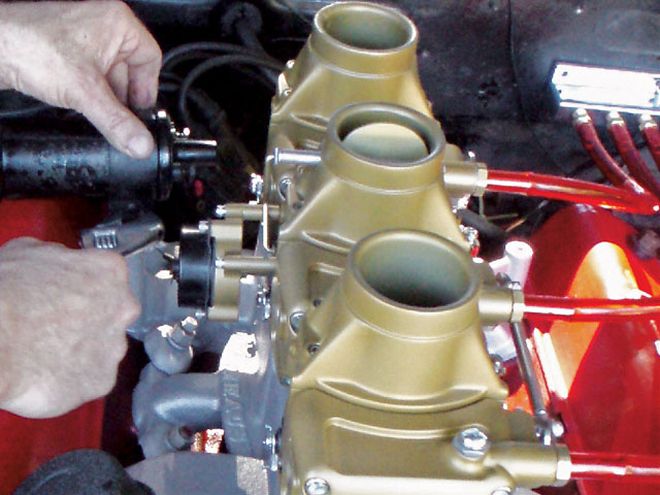

The 98 carburetor body is sandwiched between the tower, which mounts the air cleaner, and the base plate, which contains the throttle plates and idle-metering discharge ports.

The 98 carburetor body is sandwiched between the tower, which mounts the air cleaner, and the base plate, which contains the throttle plates and idle-metering discharge ports.

The "98" achieves higher performance by using modern-day designs of air-entries, air-fuel circuits, and boost venturis. Accelerator-pump circuits have interchangeable nozzles (squirters); the wilder the camshaft, the greater the need for larger accelerator-pump nozzles. Adjustable air-bleeds provide the guy who really wants to tweak and tune a means to correct or adjust fuel curves and improve throttle response, fuel economy, and power output.

Each venturi of the Demon 98 carburetor measures 1 1/16-inches. In common with American downdraft carburetor convention, the Demon 98 features an idle circuit, a main circuit, and an accelerator-pump circuit. The idle and main circuits draw their air supplies through the idle air-bleeds and high-speed air-bleeds, located on top of each carburetor main body. Idle and main fuel supplies are, naturally, taken from the fuel bowls. The resulting idle air-fuel mixture is dispersed through an idle discharge port and transfer slot, located in the base plate of each carburetor. Main circuit air-fuel mixtures are discharged via boost venturis. The chief differences between the Stromberg 97 and the Demon 98 include the design of the accelerator-pump mechanism and the operating fuel pressure-the Demon 98 accelerator-pump arrangement has interchangeable nozzles, which encourages tuning; the operating fuel pressure of the Demon 98 is around 6 to 7 psi compared 3 to 4 psi of the Stromberg.

The carbs shown here are still prototypes. Barry tells us that production of the Demon 98s should start late summer or early fall of this year. When that happens, we'll see if we can get our hands on one or two and put them to a real test under the hood and out on the road.