Dyno testing can deliver some deceiving numbers if you're not well versed on how dynos work. In order for this magazine to be competitive on the newsstand and for us not to look like dorks to the Internet critics, we have to play the same game that the other magazines force everyone to play.

Dyno testing can deliver some deceiving numbers if you're not well versed on how dynos work. In order for this magazine to be competitive on the newsstand and for us not to look like dorks to the Internet critics, we have to play the same game that the other magazines force everyone to play.

Dyno Rat Tricks

Brady Turley, via Car Craft e-mail: I am planning on building my motor soon and would like some advice. I want something that will rev to 6,500 rpm without a problem, and I'm also looking for around 700 hp. It would be something similar to your 700hp-for-$6,720 big-block (May '07) since I already have a 454 block that I plan on putting a four-bolt main kit into, stroking it to a 496 with all forged internals and running good heads. I want it to be fairly streetable, but I am running a five-speed and hydroboost brakes, so a big cam is OK. I also want to reuse my Edelbrock RPM intake if possible and stay with oval port heads that have the exhaust ports in the same location so I can reuse my current headers. Is there a way to make a nice, normally aspirated street package out of this? I will also be running full exhaust and converters to boot, just because I can. I am expecting that 700 hp to turn into around 660. If it helps, it will be dropped into a '71 Nova with 3.42 gears, hopefully weighing in around 3,300 pounds.

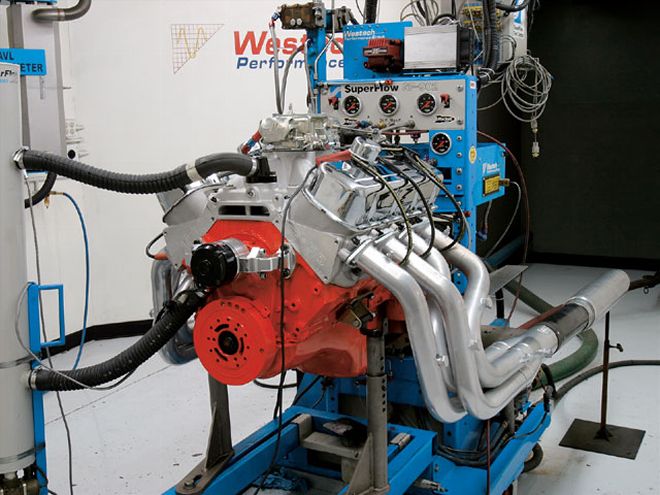

Jeff Smith: Let's start with a reality check, Brady. If you want to run oval portheads and an Edelbrock RPM dual-plane intake manifold, you can forget about 700 or 660 fully streetable horsepower. Let's first deal with a concept I'll call optimized horsepower. This is a number that only exists on an engine dynamometer. If you believe the Internet forum critics (and there are a lot of 'em!), all the dynos that Car Craft uses are optimistic by at least 5 percent (which would be a ridiculous 35 hp at 700 hp). The reality is that the 707hp number we made with our 496 was created with the benefit of idealized dyno headers and 4-inch-diameter mufflers that are sound dampers in name only and present very little restriction to power. Next, for quick setup, we used an electric water pump rather than an engine-driven pump. The engine had no accessory drive and no air cleaner and was operating at 165 or 170 degrees of water temperature with an oil temperature of 220-plus degrees. Also, any engine dyno number you read is corrected to 60 degrees' inlet air temperature, zero humidity, and an atmospheric pressure equal to sea level at 29.92 inches of mercury. Those are hardly typical at your local dragstrip. Now put that same engine in a car with a muffled 211/42-inch exhaust system, an engine-driven water pump and fan, and all the other stuff that makes up a truly streetable engine package; test it on a chassis dyno and remove the parasitic losses from the trans and rearend, and you're looking at perhaps 625 hp. Rear-wheel horsepower with this engine in a car with a TH400 trans and loose converter we'd estimate at roughly 525 hp.

Our ultimate job is to sell magazines. One way to do that is based on big horsepower numbers. They are honest, but not necessarily real-world. This is the story behind the story that nobody wants to talk about. Why? Because most people who read this magazine want to believe that their engine makes 700 hp. It makes for great bragging rights. But the truth is that once you get that 700hp engine in the car, it is barely making 650 at the flywheel. What we haven't even talked about are the custom headers at $1,500 a set necessary to fit those raised exhaust ports. There's the truth.

'Cc Quickies <strong>'Cc Quickies</strong><br>Maybe this Pirates of the Caribbean thing has gone too far.

<strong>'Cc Quickies</strong><br>Maybe this Pirates of the Caribbean thing has gone too far.

But all is not negative, Brady. You might make 600 hp from a dual-plane 496ci Rat motor with oval port heads if the moon and stars are perfectly aligned and your name is David Reher, Warren Johnson, or Ken Duttweiler, to name a few. We simulated a 10.0:1 compression 496 with a set of Brodix Race-Rite oval port Rat heads (PN 2061001 from summitracing.com, $1,929 a pair) and a Comp hydraulic roller 270 cam spec'ing 218/224 at 0.050 with 0.510 lift, small headers, and a 750 carburetor, and the simulation said 590 hp at 5,500 and 626 lb-ft of torque at 4,000. Yes, that's a very conservative camshaft. We chose that duration figure in order to keep the peak rpm below 6,000. That would be an outstanding combination, but again, these numbers are closer to optimized horsepower than real-world power numbers. Subtract 50 hp from that and you're close to what you could make in the car on an average day. These are not optimized horsepower numbers, but they are excellent and reliable levels for an extremely streetable Rat motor.

If you want to make more peak horsepower, you will need to run a camshaft with more duration and lift. The problem then becomes the restriction of the dual-plane intake manifold and the small carburetor. A single-plane intake and a bigger carb will make more horsepower, but you have to spin the engine up over 6,000 to achieve that goal. This is still a safe rpm, but anytime you start revving above 6,000 on a consistent basis you'd better have really good parts, because Rat motors are famous for abusing valvetrains due to both heavy parts and angled pushrods.

We're not sure why you would want to run catalytic converters in an early car like this. If low emissions is your real goal, this is the wrong combination for that. The problem with even "high-flow" catalytic converters is the restriction of power in the upper horsepower range. As a wild guess, we'd tag the loss at around 20 hp, perhaps more. That's a great reason not to run cats, especially on a big-inch big-block.

As far as the rest of the car is concerned, plan on using sticky tires that are the largest you can stuff under the stock '71 Nova wheelwell, because this motor will make gobs of torque. That equates to lots of tire spin at lower speeds even on the dragstrip. With a five-speed it will be difficult to bang gears without spinning the tires. But if that's your goal, then this will deliver the goods. It would be fun to drive! We talked to one of the tech guys from World Products about a 598ci Rat motor customer. The guy complained that he had already shredded one pair of rear tires because of the massive torque the engine made and wanted to know what to do about it. Our advice is the same as theirs-buy bigger tires. This actually sounds like a great engine package if you can hook it up. Just don't put catalytic converters on it.

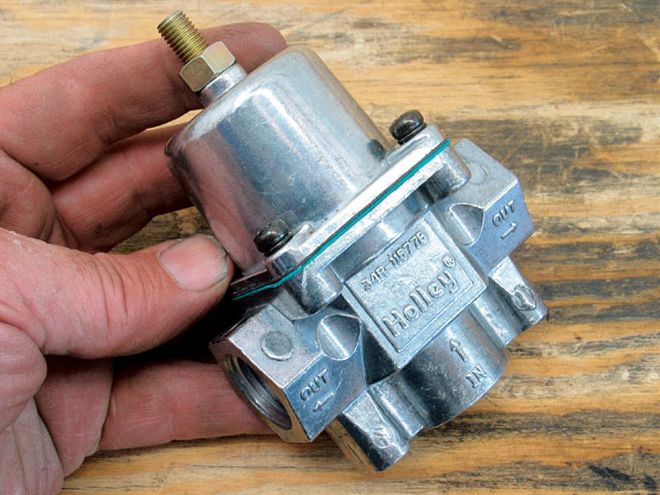

Pressure regulators use restrictions to flow to establish the correct downstream fuel pressure. Properly sizing the restriction in the pressure regulator to meet the flow demands of your engine is the best way to choose a regulator.

Pressure regulators use restrictions to flow to establish the correct downstream fuel pressure. Properly sizing the restriction in the pressure regulator to meet the flow demands of your engine is the best way to choose a regulator.

A Question Of Restriction

Bill Roth, Adams, WI: Why do you need a large-diameter fuel line of 31/48 or 11/42 inch to supply a fuel regulator that has a 71/432-inch (0.219-inch) hole feeding your carburetor? That small hole is even smaller if you subtract the pin diameter that goes through the hole to unseat the check ball. It seems like a regulator would kill your volume.

Jeff Smith: Great question, Bill, and you're absolutely right. Pressure and volume are inversely proportional. That means that as pressure increases, volume decreases. The classic example is a garden hose. Open up the spigot valve, let the water run out of the end of the hose, and you have lots of volume but little pressure. Restrict the end of the hose with your thumb, and the pressure increases in the line but the volume decreases.

All pressure regulators are designed to limit the amount of fuel pressure that is applied to the carburetor inlet bowls. This is because most high-volume pumps can create more line pressure than a typical Holley can tolerate. Generally, the maximum fuel pressure a Holley can stand is between 6 and 8 psi. Excessive pressure will overpower the needle and seat and flood the bowls. This usually results in fuel shooting out the vent tubes-not good. Recent testing by the guys at Aeromotive indicates that even 8 psi is too much pressure, creating bubbles and foam in the float bowl, causing erratic fuel delivery from the carburetor.

But to get back to your question, Bill, the original Holley blue regulator (PN 12-803, $26.95 at summitracing.com) you mentioned does, in fact, have a very small, 71/432-inch (0.219-inch)-diameter ball restrictor. I'm guessing here, but I think the regulator was sized that way because it was only designed to feed a single Holley dual-feed carburetor with two needle and seat diameters of between 0.097 and 0.100 inch, so a 0.219-inch-diameter ball would not be any more of a restriction than the combination of the two needles and seats. I checked this theory by computing the area of a 0.219-inch-diameter ball, which is 0.0376 inch. The flow area of two 0.100-inch-diameter needles and seats comes out to only 0.0157 inch, or less than half the area of the regulator.

Where you can get into trouble is when you use this single small regulator to feed a pair of Holley carburetors. Then the regulator might be a restriction, even though the area calculation indicates that it would not. The newer lineup of larger carbureted pressure regulators offers less restriction, such as Holley's PN 12-707 ($145.50, summitracing.com), which has an internal flow diameter of 0.437 inch, or a flow area of 0.149 square inches, roughly four times that of the 12-803 regulator.

'Cc Quickies <strong>'Cc Quickies</strong><br>This is a classic example of a Pro Street Camaro that has likely remained untouched since the mid-'80s. Enjoy the M/T Sportsman tires, graphics package, and Outlaw wheels. We wonder if there is a Trick Racing Gasoline sticker on the fuel cell in the trunk.

<strong>'Cc Quickies</strong><br>This is a classic example of a Pro Street Camaro that has likely remained untouched since the mid-'80s. Enjoy the M/T Sportsman tires, graphics package, and Outlaw wheels. We wonder if there is a Trick Racing Gasoline sticker on the fuel cell in the trunk.

That's a long way around to answer your question, Bill, but to drill down to it, you need a good pump to ensure that there is both plenty of fuel volume and pressure heading into the regulator, so that even with a 15-foot-long feed line between the rear-mounted pump and the front-mounted regulator there is sufficient fuel volume and pressure to feed the carb under a high-g launch.

A common misconception is that a larger-diameter fuel line, like 11/42 inch, from the pump forward will create a greater pressure drop due to its larger area when attempting to pump fuel forward under a high-g, dragstrip-style launch. The reality is that the diameter is not the culprit-it's the length of the line. Let's use an example to test that statement.

Assume that we have a large swimming pool full of water and we submerge two lengths of 10-foot-long tubing vertically. One is 11/42 inch in diameter and the other is 31/48 inch in diameter. The pressure of the weight of a column of standing water 10 feet deep is the same at any point on the bottom of the pool, including the base of both our 31/48-inch and 11/42-inch lines. If we reduce the depth of the pool from 10 feet to 5 feet, the pressure at the bottom of the pool will be lower because we reduced the height of the standing column of water. The point is that the diameter of the fuel line is not important, but the length is critical. Increasing the length of the fuel line that the pump must push the fuel through creates a greater pressure drop under acceleration. This requires additional pump pressure to overcome the static load of a long fuel line. In this case, longer is not better. That's why you'll see many race cars running a small fuel tank (assuming it's legal) in the front of the engine compartment with a very short feed line running to the carburetors. This system uses the g-force of acceleration to help the fuel pump deliver fuel to the regulator, instead of the pump having to fight against the force of acceleration. Even with a rear-mounted tank and pump, it's still wise to mount the fuel pressure regulator ahead of the carburetor, so that the reduced pressure is using the force of acceleration to help push the fuel from the regulator to the carburetor.

To boil it all down, a shorter, larger-diameter fuel delivery line to the regulator is best, aided by a relatively low fuel pressure into the carburetor to prevent aeration of the fuel in the float bowls. While this is also subject to continuing debate, most manufacturers point out that a full-flow return system is superior to a deadhead system where the fuel pump bangs up against the regulator. But I'll wait for another letter to talk about the inside info on full-flow systems. It's good stuff.

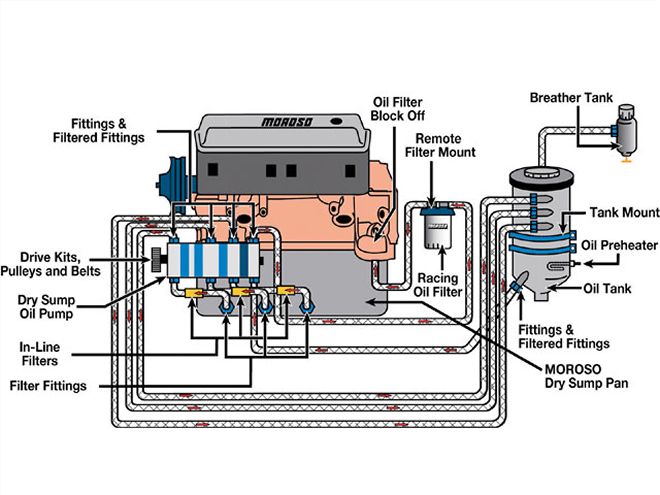

This Moroso drawing illustrates the complexity of a typical four-stage dry-sump system with three suction stages and 1 pressure.

This Moroso drawing illustrates the complexity of a typical four-stage dry-sump system with three suction stages and 1 pressure.

Wet Or Dry

Paul Serna, Delano, CA: In the Horsepower section of the Jan. '07 issue, you displayed a kick-butt dry-sump Pro Stock-style engine. My question is: What is it that makes a dry-sump application capable of such high rpm? I know through reading your magazine that the rule of thumb is 10 psi per 1,000 rpm unless you're running synthetic oil, in which case it could be less pressure. But what are the operating differences between dry-sump and wet-sump systems?

Jeff Smith: The engine you mention, Paul, is actually a 762ci Reher-Morrison nitrous Rat that unfortunately wouldn't be legal for NHRA Pro Stock racing's 500ci displacement limit. This engine is actually intended for unlimited heads-up racing. The reason dry-sumps have become popular is as much for reliability and endurance as for increased horsepower. Let's deal with the reliability factor first. A wet-sump engine stores oil in the oil pan. Most production V-8 engines use a typical 4-quart reservoir with an additional quart in the oil filter. In high-rpm drag race or corner-turning situations, the oil is subjected to high g-forces that can easily force it away from the oil pump pickup. This causes the oil pressure to take an immediate nosedive, generally at the same time that the engine is heavily loaded, which is a bad combination. Solutions to this problem include typical items such as deeper oil sumps with greater capacity oil pans, one-way swinging trap doors in the sump, windage trays, oil scrapers, and many other tools used to keep the oil pump pickup submerged in oil at all times.

Dry-sump oil systems are really not a new idea. The idea probably dates back to early '20s race engines. Our research turned up that Aviaid, started by the late Tom Davis, was the first aftermarket company to build dry-sump lubrication systems for V-8 production competition engines in 1968. The simplest dry-sump consists of a two-stage system with one suction or scavenge side and one pressure side with a remote reservoir to store the oil. There are several advantages to a dry-sump system. The most important is the remote storage tank, usually located near the engine. Moving the oil reservoir to a separate tank ensures that the inlet to the oil pump will always have oil, eliminating pressure fluctuations since the tank holds a large enough volume to feed the pressure side of the system at all times. Another advantage is that the reservoir is also an oil-air separator. A large percentage of the volume returned to the tank is actually air bubbles. The tank is designed to allow the oil to rest, which gives the air time to leave the liquid in much the same way that bubbles rise to the top of your favorite carbonated beverage. Wet-sump systems unfortunately subject the oil to far more turbulence, which does not give the oil time to displace the air, causing problems.

'Cc Quickies <strong>'Cc Quickies</strong><br>Enough already! Pirelli revealed this bit of madness on its Web site with 30-inch tires on a donky dinkmeister. Or is that a dinky donktail or maybe a, uh .never mind.

<strong>'Cc Quickies</strong><br>Enough already! Pirelli revealed this bit of madness on its Web site with 30-inch tires on a donky dinkmeister. Or is that a dinky donktail or maybe a, uh .never mind.

Creating an external storage location allows the engine builder to use a very shallow pan with no reservoir, since multiple suction locations remove oil from the engine as soon as it has done its job. Often you will see four to five separate suction lines as well as a high-pressure feed line into the engine. These multiple scavenge points ensure that the oil is evacuated out of the engine as quickly as possible. Additional suction points also create vacuum inside the oil pan, which reduces crankcase pressure and uncovers a little horsepower. Reducing the amount of oil bouncing around the crankshaft also improves horsepower, especially at race engine speeds. These are all good reasons why dry-sumps are so popular with race engine builders. The only real disadvantages are cost, at $2,000 and more for a professional-grade dry-sump system, and complexity, with all those hoses and extra plumbing.

As an interesting aside, the latest LS7 Gen IV 427ci engine used in the '07 ZO6 Corvette also employs a factory-built dry-sump system. As far as we know, that is the first production dry-sump lubrication system for a domestic car. While dry-sump systems are a bit of overkill for the street-as handling improves at well over a g lateral acceleration and pulling 1.5 g's or more on the starting line with the front bumper 4 feet in the air-wet-sump systems can be easily pushed beyond their limits. This is where an add-on accumulator tank can really be handy. An accumulator (such as the Moroso 3-quart unit, PN 23900, $185.95 at summitracing.com) is a cylinder connected via a small oil line to a main oil galley in the engine. Inside the accumulator is a piston. The accumulator is filled with several quarts of oil and uses engine pressure to pressurize the system. Should pressure drop when the oil pickup is uncovered, the pressure in the accumulator will automatically push oil into the engine to keep the bearings lubed until oil pressure is restored. Then oil pressure pushes the oil back into the accumulator.This is a very slick way of avoiding those zero-oil-pressure blues.

Also, your point about the "10 psi per 1,000 rpm" rule of thumb is valid, but the truth is that with a good lubrication system and synthetic or synthetic-blend oil, it's possible to run less oil pressure. We routinely run 45 to 50 psi in our 550hp, 420ci small-block at 6,000 rpm with absolutely no lubrication problems. This means we run a well-designed standard-pressure, standard-volume pump with tight clearances and have never had a problem.

Tuned Port InductionBrandon Munden, Sugar Land, TX: I have a standard 283-block with AFR heads. Will a newer TPI manifold bolt on?

Jeff Smith: You're in luck, Brandon. The Tuned Port Induction (TPI) system was first used in Corvettes and 305ci Camaros and Firebirds in 1985. The '86-and-later Corvette manifolds used in conjunction with aluminum heads employed the standard small-block Chevy intake manifold bolt pattern. This was true only for the TPI manifolds on Corvette aluminum heads, however. The Camaro and Firebird 305 and 350 TPI engines all employed iron heads that had a different bolt pattern for the two center bolts on each side. These center bolts used a different, more vertical angle to attach to the cylinder head. If you have one of these manifolds, it can be used on an earlier small-block, but you will have to modify the manifold to accept the older bolt angle.

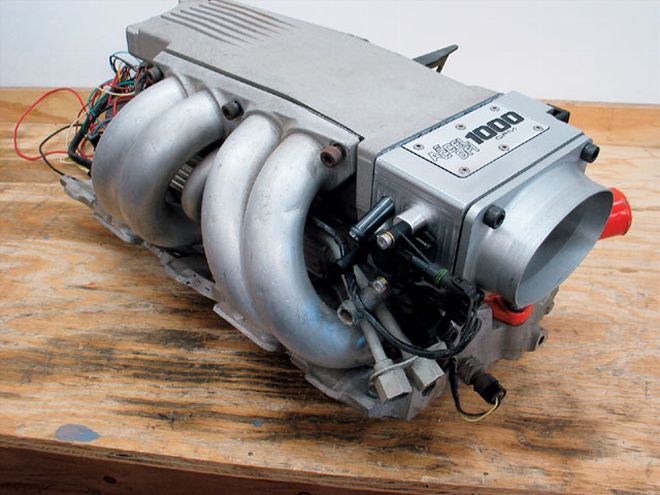

Adding a TPI intake to an early engine isn't that difficult, but may require larger injectors if the plan is to exceed 300 hp. The stock 350 TPI engine injectors may be large enough for a 302ci engine making 300 hp, especially if you raise the fuel pressure to 60 psi. That's an ACCEL 1,000-cfm throttle body on the TPI, which is worth some power over the stock throttle body on bigger engines.

Adding a TPI intake to an early engine isn't that difficult, but may require larger injectors if the plan is to exceed 300 hp. The stock 350 TPI engine injectors may be large enough for a 302ci engine making 300 hp, especially if you raise the fuel pressure to 60 psi. That's an ACCEL 1,000-cfm throttle body on the TPI, which is worth some power over the stock throttle body on bigger engines.

Your idea of putting a TPI on a 283 is something we kicked around at a Car Craft bench racing session a while ago. The concept was to build a small-displacement small-block with a TPI manifold to pump up the torque for a daily driver engine controlled by a budget aftermarket EFI unit like the MegaSquirt or the private label version called the eMS-pro from Spectre Performance. The EFI would maintain the air-fuel ratio at 14.7:1 running down the road to get good gas mileage. Vortec iron cylinder heads would be a great choice, but the cost would go up because you'd need a Scoggin-Dickey Vortec TPI manifold (PN 12498060, $399.95 at spdc2000.com). Other alternatives for heads had to be those with 64cc chambers to keep the compression up. The least expensive new iron heads would probably be the World Products S/R Torquer iron heads with 2.02/1.60-inch valves (PN 042660-1, $799.98/pair, sdpc2000.com). Last month we tested a pair of the new Patriot Freedom Series 64cc aluminum heads that sell complete for $795 a pair from Patriot (patriot-performance.com), so you might want to check that test as well. We compared them to a set of Vortec iron heads as the baseline and they came in just shy of the Vortec heads in terms of overall power; nevertheless they are decent aluminum heads for under $800 that would accept a TPI manifold.

One problem is that even with a 64cc chamber, 4.00-inch bore, 3.00-inch stroke, 0.040-inch head composition gasket, and 0.005-inch piston deck height, this will only generate 8.79:1 compression. This assumes boring the little 283 out with a 0.125-inch to a 302ci engine. Most 283- blocks will handle this additional 0.125-inch bore increase and still have decent wall thickness. To make more compression, you would have to go to a slightly domed piston.

For a cam, we'd go with a short-duration hydraulic flat tappet cam of around 210 degrees at 0.050-inch tappet lift again to make good cylinder pressure at lower engine speeds, where the engine could make some decent torque. Along with the TPI intake, this would be a great combination for torque and fuel mileage. It's an interesting idea for someone looking for a mileage-oriented small-block that would look cool and knock down 25-plus miles per gallon.

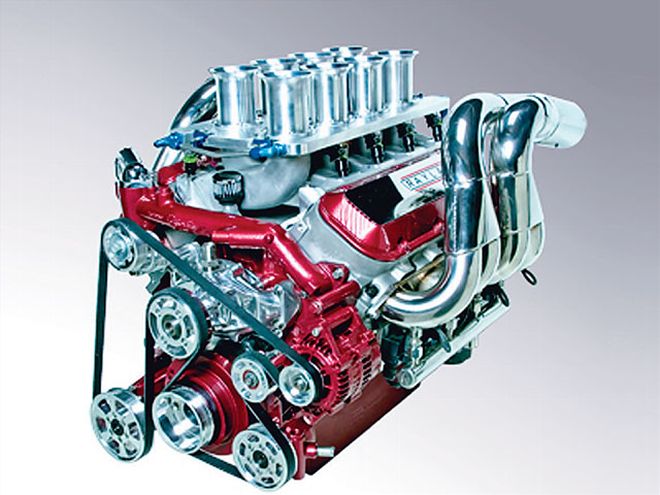

This is one of Raylar's trick EFI'd 8.1L GM engines. Note the custom individual ram induction system. We couldn't afford to ask how much this costs.

This is one of Raylar's trick EFI'd 8.1L GM engines. Note the custom individual ram induction system. We couldn't afford to ask how much this costs.

This is one of Raylar's trick EFI'd 8.1L GM engines. Note the custom individual ram induction system. We couldn't afford to ask how much this costs.

This is one of Raylar's trick EFI'd 8.1L GM engines. Note the custom individual ram induction system. We couldn't afford to ask how much this costs.

New Rat On The Block

Trevor Knill, via Car Craft e-mail: I have an 8.1L big-block out of an '04 Chevy HD truck. I would like to know if anyone makes an intake manifold for this engine. I would like to run a carburetor on it. I have noticed there is a block-off plate under the intake where the distributor would go, covering the distributor gear. I assume I can run a regular distributor in this motor. Any info would be greatly appreciated.

Jeff Smith: There's good news and bad news here, Trevor. The good news is that this 8.1L (496ci) Rat motor is going to become more and more prevalent in the junkyards as the years slip by because this is the new, GM large-displacement big-block. But for right now, that's about as far as the good news goes. We started digging into this engine and only found one shop that specializes in building these engines, a company called Raylar out of San Diego. We spoke with Raylar owner Ray Brogey, and he filled us in on the engine's details. The motor is based on the old Mark IV bore centers, and the bellhousing pattern is still the same, so you could bolt this big-block into a Chevelle or Nova. We hesitate to call it a Rat, but it still could be considered a part of the rodent family. The bad news is that the cylinder heads use an increased 18-bolt pattern that is different from the original MK IV, so the heads won't interchange, and beyond that, the intake manifold is also different because the intake port arrangement is symmetrical, like the Gen III/LS1 engines. No one makes a carbureted intake manifold for this engine, although Raylar does make a high-performance electronic fuel injection manifold for its marine applications.

The stock 8.1 employs a cast crank, forged 6.693-inch rods, and cast pistons with a 4.25-inch bore and a 4.37-inch stroke. Compression is 9.1:1 with an iron block and heads. The fuel-injection system is sequential, but Brogey says it's designed to make torque, and the heads are pretty tame right down to the net lash system. The motor comes with a hydraulic roller cam, but it also is different from the old Rat motor stuff since the firing order has been changed to the Gen III firing order (1-8-7-2-6-5-4-3). According to Brogey, if you want to start tuning on these engines, all the EFI and spark table information is set up just like the Gen III engines.

Raylar specializes in marine applications and sells several normally aspirated power packages that are designed to be incredibly durable and would be virtually indestructible on the street. Raylar also offers the only forged steel 4.50-inch (510ci) stroker crank for this engine along with Mahle forged pistons. Flow numbers on the Raylar aluminum head measure up to 370 cfm at 0.500-inch lift. Raylar engine packages can make 500-600 hp and upwards of 700 lb-ft of torque. Remember, these engines are designed to make power at around 5,000 rpm because they have to be able to run reliably at WOT all day long.

While all these parts are cool, because of the limited demand they will cost more than comparable Rat motor parts. As for a carbureted intake manifold, Brogey says your only real alternative is a custom aluminum sheetmetal manifold. They aren't cheap and are frankly a bit of overkill considering that the 8.1L cylinder heads are nothing special. Stock valve sizes for the 8.1L heads are 2.19/1.72. Our suggestion would be to sell this motor to somebody who could put it to good use as a replacement engine for his truck, and go out and buy a real Rat motor. In the long run, you'll make more power for a lot less money.

You've Got Problems?

We've Got Solutions!

CarCraft@primedia.com

CarCraft.com

Car Craft Mag

6420 Wilshire Blvd.

Los Angeles, CA 90048