It's one of the biggest challenges in engine building, getting the most power from each octane point of fuel. If you think these considerations are something new, you'd be surprised--it's a topic that's been at the forefront of internal combustion engine research since the early days of the automotive engine. Making the most of an engine combination is a lot more involved than just running as much compression ratio as you think you can get away with. When you look at what's happening in an engine, the power output is directly linked to cylinder pressure applied during the power stroke, and there are many factors affecting this directly. The best measure of this force is the BMEP, or Brake Mean Effective Pressure, and if you spend much time on the dyno, you'll notice the BMEP moves in almost lockstep with the torque curve. What puts a ceiling on the BMEP? Usually, it's the engine's detonation limit of the fuel being used.

The exhaust gas crossover is designed to add heat--good for vaporizing fuel when driving in cold weather, but murder on octane requirement in hot weather. Consider that aluminum transfers heat at five times the rate of cast iron, and you might be tempted to block the crossover in your aluminum intake if performance is the ultimate goal.

The exhaust gas crossover is designed to add heat--good for vaporizing fuel when driving in cold weather, but murder on octane requirement in hot weather. Consider that aluminum transfers heat at five times the rate of cast iron, and you might be tempted to block the crossover in your aluminum intake if performance is the ultimate goal.

Detonation

The topic of detonation has generated some interest, since power output can only be increased until it's capped by detonation. We're always looking to make more power, so if we're limited to pump gas, we need to build engines that will go further up the BMEP scale, and make more power before detonation. Just what is detonation? It is accepted that detonation is the result of autoignition of the end gas, which is the part of the air/fuel charge that has not yet been consumed by the normal flame travel. The expanding combustion gases involved in the normal propagation of the flame front raise the pressure and temperature of the remaining gases to a point where the end gas auto-ignites. If the autoignition is violent and encompasses a significant portion of the remaining mixture, you've got full-fledged detonation. With detonation will come a very high-pressure spike in the combustion chamber, producing a pressure wave and temperature rise that damages engine parts in a hurry.

Fortunately, there are a number of factors we can control when building an engine that pushes the detonation tolerance upward. Let's first look at what past scientific research has proven to be fundamentally true when it comes to combustion theory, and then dig into how that theory can be practically applied to our performance cars.

Race-style intake manifolds feature divorced runners, with a separate valley plate isolating the passages from the hot valley below. No exhaust crossover to be found here. Cooler air is denser, adding power, while lower temperatures reduce the tendency to detonate.

Race-style intake manifolds feature divorced runners, with a separate valley plate isolating the passages from the hot valley below. No exhaust crossover to be found here. Cooler air is denser, adding power, while lower temperatures reduce the tendency to detonate.

Inlet Charge Temperature

Initial temperature has a direct influence on the detonation limit, with a higher initial charge temperature resulting in a greater tendency towards detonation. As the temperature of the inlet charge increases, the temperature of the end gas in the combustion process increases at a given pressure, making the engine more prone to detonate. You can see the practical application of combating this effect in practically any newer vehicle, as nearly all are equipped with some form of cold air induction. A cold air induction provides a dual benefit in performance applications, increasing the charge density for greater power, while allowing the engine to tolerate higher cylinder pressures with a given fuel. In the old days, most vehicles would gulp nothing but underhood air, and it is surprising how many performance cars are set up in exactly the same way today. A cold-air induction system can drop the inlet air temperature from a typical figure of around 180 degrees, to a much more digestible 100 degrees, or lower.

While the air inlet temperature is a factor, it isn't exactly the same thing as inlet charge temperature in the combustion chamber. The thing to consider here is keeping the charge cool once it finds its way past the carburetor or throttle body. Where are the potential sources of heat gain? The biggest potential culprit is the exhaust crossover originally found in many older vehicles, and also built into quite a few aftermarket performance manifolds. The exhaust crossover passage plumbs a constant flow of exhaust gas right through the center of the manifold, often with a substantial area in the passage directly below the manifold's plenum. Imagine the heating effect to the inlet charge of plumbing exhaust gasses of up to 1,000 degrees right through the manifold. In fact, transferring heat to the induction charge is precisely the reason the exhaust crossover was put there in the first place. The heat helps vaporize the fuel for better cold distribution, and actually warms the manifold to prevent part-throttle carb icing in very cold climates. If maximum pump gas performance is the goal, the exhaust crossover is really working against the effort.

While the crossover is an obvious source of manifold heat that is quickly soaked by the induction system, there are other sources of heat that also play a part. The manifold of most V8 engines also serves as the cover for the lifter valley, making the intake subject to all the heat cooking up in the engine's lifter valley. Racers identified this as a potential power loss, and various heat shields have been available to help diminish the effect. Better still, a design originally applied to race manifolds, and showing up more and more on performance street intakes is the divorced runner, with a separate valley plate isolating the valley, and the runners open to the air from below. Examples here include many race single-planes, and Edelbrock's AirGap series of two-planes. While we've covered the most obvious offenders for heat transfer into the induction charge, there are other more subtle heat sources that can be considered. In looking to minimize the heat reaching the intake, we've seen competitors in the Engine Masters Challenge experiment with heat transfer resistant materials for intake manifold gaskets, and even seeking to minimize the heat transfer from the intake manifold and carb fasteners. More conventionally, spacers or isolators under the carb can contribute to reduced charge temperature. Any temperature reduction here will help in making power on pump gas.

Minimizing coolant temperature helps in the pursuit of power, and raises the detonation limit. A high-quality aftermarket radiator can substantially decrease operating temperature. Flex-a-lite's internal fins perform as heat sinks absorbing heat more quickly from the engine coolant, then radiating it through external fins to dissipate heat twice as efficiently.

Minimizing coolant temperature helps in the pursuit of power, and raises the detonation limit. A high-quality aftermarket radiator can substantially decrease operating temperature. Flex-a-lite's internal fins perform as heat sinks absorbing heat more quickly from the engine coolant, then radiating it through external fins to dissipate heat twice as efficiently.

Keep it Cool

The effect of coolant temperature on detonation is similar to that of inlet temperature, and the reason is strangely the same: lower end-gas temperature. Here the direction is pretty clear: minimize the coolant temperature, and the potential is there to make more power on pump gas. Anyone who has had the experienced of driving an under-cooled but edgy performance powerplant in scalding weather is pretty familiar with the result. Here the goal is to maximize the efficiency of the cooling system, which by itself will increase power, while allowing more power to be produced on pump gas.

There are also a couple of other considerations often missed when considering cooling. Hot-rodded engines make more power and are almost always tougher to keep cool than a stocker. Most of us have rebuilt, over-bored engines, which are generally harder to keep cool, depending on the remaining cylinder wall thickness. Finally, perhaps more than 95 percent of engines rebuilt are simply hot tanked or jet-cleaned, which does nothing to clean the surface rust scale inside the water jacket beyond the loose crust. Acid-dipping is about the only effective means to really clean the jackets of a used engine, an operation seldom performed. The rust layer is an effective thermal insulator, making it tougher to transfer heat out of the engine and into the cooling system.

All of this adds up to a real need for an exceptional cooling system. The most obvious component here is the radiator. The secret to effective cooling is effective heat transfer, and the path to getting there is capacity. The radiator is the workhorse of the cooling system, with the job of dissipating the heat carried by the coolant into the air. To do its job, an effective fan is a must, along with a shroud. Radiators are not all created equal, and can vary in their construction, size and efficiency. Until recent years, automotive radiators were of copper/brass tube-and-fin construction, and most manufacturers varied the cooling capacity of different models by radiator size, both in cross-sectional size, and in core thickness. The rule for selection here is a no-brainer: bigger is better both in cross section and thickness.

What's happening in the water jackets is an important aspect in cooling efficiency. For optimal heat transfer, the water jackets should be clean of scale at the time of a rebuild if a used block is used. An additive like Royal Purple's Purple Ice helps heat transfer from metal engine components into the coolant.

What's happening in the water jackets is an important aspect in cooling efficiency. For optimal heat transfer, the water jackets should be clean of scale at the time of a rebuild if a used block is used. An additive like Royal Purple's Purple Ice helps heat transfer from metal engine components into the coolant.

Aluminum radiators have become quite popular in recent years, and for good reason. Aluminum radiators look good, are lighter, and have been found to be very efficient in cooling. Technically, the rate of heat dissipation for brass is higher than aluminum, however one of the primary advantages of aluminum is mechanical. Aluminum is much stronger than brass, allowing for the tubes to be built with a much more efficient elongated shape. This is a primary reason for their outstanding cooling capabilities.

The radiator and fan don't work alone when it comes to keeping the engine cool. The water pump is another part that needs consideration. The stock water pump is fine for a stock or mild engine, but there are circumstances where an upgrade can be an advantage. High-compression, increased cylinder pressure, rpm, and power output all increase the demands on the cooling system. A high-efficiency water pump is an effective way to increase the cooling capacity under such compromised conditions. The increased coolant flow and pressure will help "scrub" heat from localized hot spots, improving cooling. There are a number of manufacturers that produce high-capacity replacement water pumps, including Milodon, Edelbrock, and Weiand, which move significantly more water at lower rpm, and are designed to lessen the impeller cavitation at higher engine speeds. A cooling system needs a system control, and that's handled by the thermostat. Thermostats are rated by temperature at the point when they begin to open. As the engine's temperature rises, the `stat opens to allow more coolant flow through the engine. A lower rated `stat won't make the engine run cooler if the rest of the system can't dissipate the heat fast enough. However, if the capacity is there, a cooler thermostat will result in a cooler-running engine. Generally, a 180-degree thermostat is the recommended piece for a street engine, though a cooler 160-degree unit can result in a slight power increase, and reduced tendency toward detonation, if the cooling system has the capacity to keep the temperature down.

Conventional reverse-poppet valve thermostats are designed in such a way that the valve opens against the flow of the engine. This creates a situation wherein the coolant flow pressure has an effect on the thermostat's opening. With high-flow water pumps, the pressure differential can be enough to cause a change in the operational opening rate of the thermostat. Improved "balanced flow" `stats utilize a balanced sleeve design, which results in equal pressure at both sides of the valve, so that its operation is solely regulated by coolant temperature. A balanced sleeve thermostat, like one of those offered by Milodon, is highly recommended with a high-flow water pump, since the added pressure can try to hold a conventional thermostat's valve closed.

Lighting It Off

It's impossible to try and make the most of pump gas power without considering the time factor. Ignition timing has a pronounced effect on both power and how much power can be made without detonating. There is an optimal ignition point for max power, reflective of the cylinder pressure versus crank angle in the running engine. However, the optimal timing may never be achievable, if the engine wants to detonate. As rpm rises, cycle-to-cycle time is decreased, and the time available for the end gasses to auto-ignite and propagate is progressively lower. For detonation to be possible in an engine, the reaction time of the unburned mixture must be shorter than the time for normal flame travel through the mixture, again a reduced likelihood as rpm increases. What does this mean to the hot rodder? Simply put, at higher rpm, detonation becomes less of an issue, and the engine can operate at higher cylinder pressures and power levels. One of the main reasons for advance in a spark ignition engine is to lower the octane requirement at lower engine speeds.

Whether or not the end gas auto-ignites is primarily a question of end-gas temperature and compression time. The influence of end-gas pressure is secondary and a much smaller factor in itself, outside of the resultant heat gain of the end gasses through the compression process itself. Since the propagation of the normal combustion front is the primary compressive factor on the end gasses, the ignition timing can control the compression time of the end gasses, reducing the tendency to detonate. This control is especially attractive at lower rpm, where the potential for detonation is most acute. With fine control of the engine's advance curve, the overall output can be optimized. The best examples here are some of the OE engine management systems in modern performance cars, where the timing is constantly adjusted to just under the point at which the engine will detonate. A feedback system like this is pretty difficult to compete with when working with mechanical springs and weights in a conventional distributor, however, skilled tuning of the advance curve is a sure path to making more power with pump gas.

A more recent development is the electronic programmable ignition system found on high-end ignitions such as the MSD Digital 7. With a box like this the advance rate can be tuned to any imaginable curve, and adjusted electronically. Tuning it for the maximum advantage requires trial and error testing, preferably with some dyno time, but it provides a level of flexibility in optimizing an engine package unavailable with conventional ignitions.

Fuel Management

Changes in air/fuel ratios have a direct effect on the flame speed and temperature, as well as the reaction time of the end gasses, all factors in the detonation tolerance of an engine. These facts point out that the mixture is an important factor in making the most power with a given octane fuel. The first thing to consider is what the actual air/fuel ratio is in the cylinder. Rich mixtures do tend to suppress detonation, but at the price of reduced fuel efficiency, and that isn't usually a good trade-off for a street performance application. The factor often overlooked here is the mixture distribution. Considering an eight-cylinder engine, there are quite a few holes getting filled every time the crank turns, and the mixture reaching each of these holes can vary substantially. Detonation will occur in the lean cylinders, so to compensate, the mixture has to be richer overall.

Now consider what can happen if a finer range of mixture control is achieved. Without having to go richer overall to bring the lean cylinders into the zone, the power is increased, and the detonation limit is raised at the same time. Fuel injection is the most accurate means of evening up the distribution, and better distribution will equate to more output from a gallon of gasoline. A carbureted engine can also benefit from improved distribution, and in fact we've heard from some of our top Engine Masters competitors that getting the cylinder-to-cylinder distribution dialed-in was a major part of their development effort. The emphasis there obviously had nothing to do with economy, rather the effort was aimed at making the most power overall. With distribution held in a narrow range from cylinder to cylinder, the mixture could be optimized for the engine, without some overly rich cylinders dragging down power while compensating for some lean holes that would otherwise tend to detonate. Distribution with a carburetor and wet intake manifold is very tricky to optimize, even with a Lambda sensor in each hole, while with EFI it's practically a given.

Getting Inside

Up until this point we have been discussing factors to maximize the pump-gas potential of an engine, without even getting inside the powerplant. Things like temperature management and precise control of the fuel and ignition systems can readily be employed on an existing engine. There are significant gains in pump gas performance up for grabs when the engine is being built. Again, if maximum power is to be had from a given fuel octane quality, the cylinder pressure potential of the powerplant has to be at the maximum tolerable, short of detonation. This limit can clearly be pushed up, if the tendency to detonate is reduced. There are numerous steps that can be taken when coming up with an engine combination to make it less likely to encounter detonation.

Cylinder head design is an area where all the players are not created equal. Just by going to an aluminum cylinder head, a useful increase in compression ratio of up to a full ratio point of compression can be employed. Beyond the material itself, there are other factors in the cylinder head design that increase detonation tolerance and allow higher compression ratios. The combustion chamber design is the biggest factor here, with compact chambers featuring small volumes and plugs moved inward to a more central position in the cylinder generally able to get more power out of an octane point. The major reason once again is time. These designs tend to provide a faster burn rate, propagating the burn more quickly, decreasing the potential for end gas light-off. It's not at all unusual for an efficient aftermarket head to require substantially less total timing to give maximum power, a direct indication that the burn rate is materially quicker. Small, closed chambers, which are the norm in today's heads, provide another benefit: increased quench area.

Quench It If You Can

The quench effect on engine efficiency has been well documented and researched since early in the last century. What is the quench effect, you ask? Simply put, it is designing in a close clearance between a substantial portion of the piston area and the bottom of the cylinder head when the piston is at top dead center. A closed-chamber head has a large flat area, the quench surface, over a substantial portion of the bore. It has been found that if the piston rises to within .050 inch or closer to the flat of the head, good things happen in the combustion process. The effects here are multifaceted. First, is the squish effect, wherein as the piston closes the gap in the quench portion of the head as it approaches TDC the combustible mix in this portion of the chamber is rapidly displaced, creating combustion-promoting turbulence, speeding the burn. In the compression process, the gasses in the chamber reach a very high temperature. As the propagating flame front expands, the pressure can get high enough to auto-ignite the end gas at the far side of the chamber. Since with a tight quench clearance, most of these end gasses are squeezed out near TDC, the chances of auto-ignition (detonation) are greatly reduced. The temperature of autoignition is approximately 1,375 F. Clearly, the cylinder head temperature is significantly cooler than the end gas temperature at or near autoignition levels. Due to the temperature differential, the thin layer of detonation-prone gasses at the extremities of the chamber are actually cooled by the proximity to the head, further diminishing the tendency to detonate. It is from this cooling effect that the term "quench" is derived.

An engine with an effective quench will be more detonation resistant, and it is typical for surprisingly substantial improvements in torque to result from the more efficient combustion. Most builders consider .040 inch or so to be an effective target for piston-to-quench-area clearance, a spec easily obtained with a closed-chamber head, a piston at zero deck, and a standard FelPro .039-inch compressed thickness gasket.

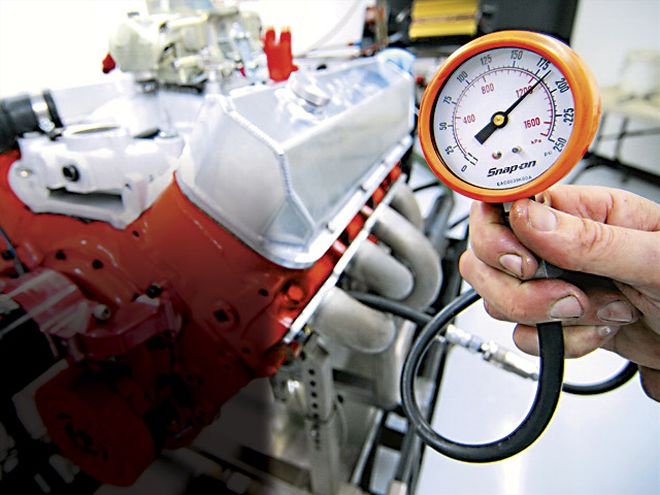

How much cylinder pressure can be run on pump gas? Commonly, a cranking compression of 180 psi is considered pretty good. We've seen engines built with attention to most of the factors discussed here run 200 psi successfully. Would you believe we are experimenting with pressures as high as 220 psi? It might work, using every trick in the book.

How much cylinder pressure can be run on pump gas? Commonly, a cranking compression of 180 psi is considered pretty good. We've seen engines built with attention to most of the factors discussed here run 200 psi successfully. Would you believe we are experimenting with pressures as high as 220 psi? It might work, using every trick in the book.

Quench It If You Can

The quench effect on engine efficiency has been well documented and researched since early in the last century. What is the quench effect, you ask? Simply put, it is designing in a close clearance between a substantial portion of the piston area and the bottom of the cylinder head when the piston is at top dead center. A closed-chamber head has a large flat area, the quench surface, over a substantial portion of the bore. It has been found that if the piston rises to within .050 inch or closer to the flat of the head, good things happen in the combustion process. The effects here are multifaceted. First, is the squish effect, wherein as the piston closes the gap in the quench portion of the head as it approaches TDC the combustible mix in this portion of the chamber is rapidly displaced, creating combustion-promoting turbulence, speeding the burn. In the compression process, the gasses in the chamber reach a very high temperature. As the propagating flame front expands, the pressure can get high enough to auto-ignite the end gas at the far side of the chamber. Since with a tight quench clearance, most of these end gasses are squeezed out near TDC, the chances of auto-ignition (detonation) are greatly reduced. The temperature of autoignition is approximately 1,375 F. Clearly, the cylinder head temperature is significantly cooler than the end gas temperature at or near autoignition levels. Due to the temperature differential, the thin layer of detonation-prone gasses at the extremities of the chamber are actually cooled by the proximity to the head, further diminishing the tendency to detonate. It is from this cooling effect that the term "quench" is derived.

An engine with an effective quench will be more detonation resistant, and it is typical for surprisingly substantial improvements in torque to result from the more efficient combustion. Most builders consider .040 inch or so to be an effective target for piston-to-quench-area clearance, a spec easily obtained with a closed-chamber head, a piston at zero deck, and a standard FelPro .039-inch compressed thickness gasket.

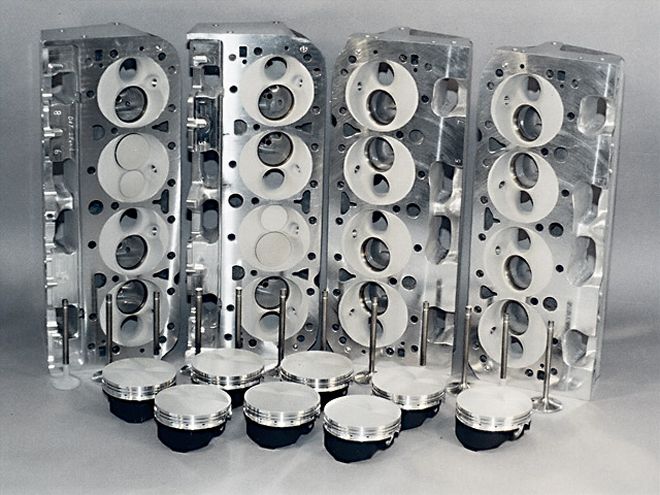

An engine's detonation point and power output can be raised with thermal barrier coatings applied to the cylinder heads. Coating the valves and ports reduces the heat transfer to the charge, while the chamber coating helps normalize the surface temperature distribution. This package of heads and pistons was fully prepped by Swain, a specialist in the field.

An engine's detonation point and power output can be raised with thermal barrier coatings applied to the cylinder heads. Coating the valves and ports reduces the heat transfer to the charge, while the chamber coating helps normalize the surface temperature distribution. This package of heads and pistons was fully prepped by Swain, a specialist in the field.

Mechanical Configuration

We've discussed how the cylinder heads at the top end of the engine can provide a substantial benefit to pump gas power, but what about the basic mechanical configuration of the bottom end? There are numerous theories and opinions, but in most instances, little empirical data. Testing at MIT clearly established a relationship between bore size and octane requirements, and the results indicated larger bores increased combustion time and temperature, increasing the tendency to detonate. However, that testing covered substantial variations in bore size, from 2.5 to 6 inches. We doubt there is significant enough an effect to warrant consideration in the range of bore sizes typical of high-performance street engines.

Another aspect of engine configuration that has gained a following is the use of shorter rods. Shorter rods will result in quicker piston motion in the vicinity of TDC. Proponents of the short rod theory claim there is an advantage to be had by the accelerated volume gain away from TDC as combustion propagates, though we wonder if there are losses due to accelerated pressure decay. We've seen no empirical data to quantify these theories. We do know that shorter rods increase internal friction, and cylinder wall loading. The bottom line is we wouldn't lose any sleep over trying to find an edge in unusual engine configurations.

These Indy Cylinder Head Hemi pistons received a thermal barrier coating on the crown, and a friction-reducing coating on the skirt. Thermal barrier coatings can improve power, since retaining heat in the combustion process means getting more efficiency from the charge in the cylinder.

These Indy Cylinder Head Hemi pistons received a thermal barrier coating on the crown, and a friction-reducing coating on the skirt. Thermal barrier coatings can improve power, since retaining heat in the combustion process means getting more efficiency from the charge in the cylinder.

Coatings Can Help

There are several types of coatings that have gained popularity in recent years, and it's for good reason: they work. From the standpoint of making the most power with pump gas, Thermal Barriers Coatings (TBCs) are right on target. TBCs are designed to reduce the transference of heat. That characteristic can be put to effective use inside an engine in a number of ways. Heat is energy and energy is power, so it follows that keeping heat in the combustion space has the potential for an enhancement in power. Aluminum is a very effective heat conductor, and also happens to define a large portion of an engine's combustion surface area. Barrier coatings applied to piston crowns have become popular in an effort to retain more of the combustion energy in producing power, rather than being lost through absorption through the piston. Similarly, TBCs are commonly used to coat the combustion chambers of aluminum heads, again to curb heat loss.

These are the rods and pistons from a normally aspirated 700-plus hp street/strip small-block Chevy that PHR tech contributor David Vizard built. Not one to leave power potential untapped, everything is coated.

These are the rods and pistons from a normally aspirated 700-plus hp street/strip small-block Chevy that PHR tech contributor David Vizard built. Not one to leave power potential untapped, everything is coated.

Heat transfer is a two-way street, and sometimes a TBC is just as valuable in keeping heat out as it is in keeping heat in. Valves, having limited means to transfer heat via the seats and guides, tend to be among the hottest component inside an engine. Intake valves are cooled considerably by the air/fuel charge rushing past. While the valves are being cooled, the induction charge is being heated, and we've already discussed the negative effects of that. At the other side of the chamber, the exhaust valves get little relief from heat. Temperature builds in the exhaust valve, making it the hottest component in the combustion space. Exhaust valve heat has been found to be a major contributor to end-gas temperature rise, and the resultant detonation.

Thermal barrier coating can reduce the ingress of combustion heat into the valves, with the promise of cooler surface temperatures. Coating the combustion face of the valves has become popular to reduce the valve's operating temperatures, and our own experience has indicated a genuine reduction in the tendency for the engine to detonate. While valves, pistons, and chambers are the most common applications for TBCs, port surfaces and intake manifolds are among other areas where some builders are employing these coatings.

Valve Timing Variables

We all know that pressure in the cylinder plays a critical role in making power, but we also realize that too much pressure will contribute to the onset of detonation. The camshaft plays a vital role in determining just what operating pressure the engine will see. Obviously, if the camshaft keeps the valves open all the time, the pistons will go up and down and there won't be any compression happening at all. Given that fact, it's clear that the cam has a substantial effect on the cylinder pressure. So how does cam timing relate to detonation tolerance, power, and cylinder pressure? We'll examine some of the key points.From the standpoint of cylinder pressure, the most relevant event in cam timing is the intake valve closing point. The intake valve closes while the piston is on its way up on the compression stroke, and there isn't any compressing going on until the intake valve closes. Long-duration camshafts will open the intake valve earlier, and correspondingly close the intake valve later, which reduces the cylinder pressure at lower rpm. With long-duration camshafts, the compression ratio should be increased to compensate. Other aspects of the camshaft alter the intake valve closing point, and therefore have a direct affect on cylinder pressure. At a given duration level, a wider lobe separation angle will close the intake valve later, bleeding off some of the cylinder pressure. Similarly, when the installed centerline is altered, the cam timing will change. Advancing the camshaft will increase the pressure, while retarding it will close the intake valve later and reduce it.

So what is the way to go with camshaft events if maximum pump gas power is the goal? The answer here is too specific to the infinite variety of engine combinations possible to make a blanket recommendation. There is an effective way to experiment with different combinations, without the need to try a dozen cams. The trick is to use one of the many engine simulation software programs available, to model the effects of various cam profiles. With a program like Dynomation's Engine Analyzer Pro, any changes of cam timing events can be simulated, and the resultant changes to cylinder pressure are estimated with a good degree of accuracy.

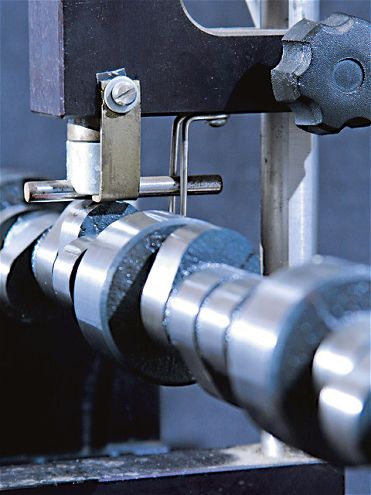

Cam timing and compression ratio are integral to cylinder pressure. Computer modeling can predict the effects of a variety of cam events to zero-in on an effective combination.

Cam timing and compression ratio are integral to cylinder pressure. Computer modeling can predict the effects of a variety of cam events to zero-in on an effective combination.

The Compression Ratio

With all this talk about pressure and detonation, we've purposely left the topic of compression ratio for last. There is no doubt that compression ratios have been trending up, with OEMs now building engines with ratios on the same level as during the high-octane musclecar days of the late `60s. High compression serves up many benefits, helping to achieve high torque and power numbers, increasing fuel efficiency, and improving throttle response, while the reduced clearance volume also aids in cleaning up the idle. Modern OEM engines are pushing ever closer to the 11:1 mark, with Chevrolet's new LS7 Corvette plant actually at that level now.

Beginning decades ago, when available fuel octane first began to rapidly decline, the trend was to lower compression ratio to 9:1 or even less. These days much higher ratios are again becoming commonplace in high-performance builds. The improvements in technology, particularly in the areas discussed, allow higher compression ratio to be tolerated on pump gas. Building an engine with all of these tricks makes it possible.