Some of you may recall our Hot Rod Hauler project that began in Custom Classic Trucksmagazine. The premise of the series was to build a vintage ¾-ton or heavier pickup into a cool-looking workhorse; ours was based on a 1973 Ford F-350. We installed dropped twin I-beam axles, airbags all around, and built a FAST EZ EFI fuel-injected 545-inch engine based on a bored and stroked 460 backed by a Gearstar 4R70W overdrive automatic transmission. One of the last chores we were faced with to get the truck back on the road was revamping the fuel system.

There were two major challenges when selecting the components to feed fuel to our big-block—first was the fact the engine was now fuel-injected and that would require a new fuel pump and complicated the plumbing due to the dual tanks. The other issue was finding a way to deal with the difficulty of filling those factory gas tanks. As this truck was built in the days of leaded fuel, the modern no-spill unleaded fuel nozzles of today don't work well with our vintage truck. Topping off the tanks took forever and resulted in gas running down the bedside, which didn't help the paint and was a waste of money. To solve our problems at the pump we had Boyd Welding fabricate a new aluminum fuel tank that mounts in the front of the bed. With its 40-gallon capacity we have plenty of range when towing and the tank is easy to fill without any spillage. Eventually a tonneau cover with a flap to gain access to the gas cap will conceal the tank.

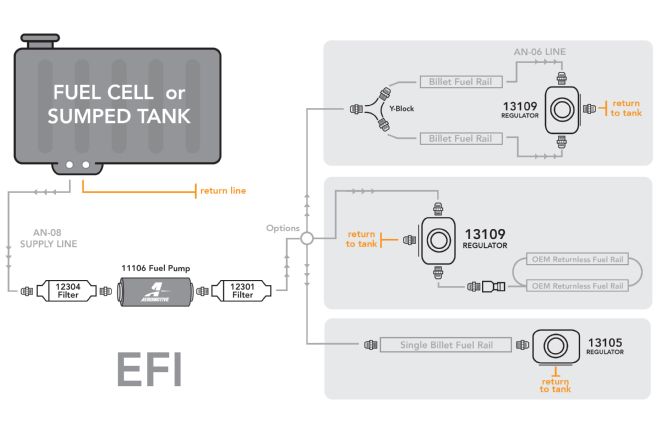

While converting to electronic fuel-injection is simple enough, an appropriate electric pump is required. There are inline pumps for that purpose, but a much better alternative is one that mounts inside the fuel tank. Mounting the pump in the tank has several advantages—with the pump submerged in fuel it runs cooler, which translates into longer life and pump noise is reduced dramatically. Keep in mind, in-tank pumps may also be used with carbureted systems. Depending on the pump used a fuel-pressure regulator may be required. Most low-pressure pumps for carbureted systems are internally regulated to around 7 psi. High-pressure pumps for carburetor or fuel-injection applications often require a regulator—most are adjustable to provide the proper pressure for the application. The system for the Hot Rod Hauler has an Aeromotive 340 in-tank fuel pump with a regulator that includes a return line and a port for a pressure gauge.

With the tank, pump, and regulator issues solved, the next consideration is filtration. Filters are rated by the size of contaminates they will trap (a micron is 1⁄1000 of a millimeter or 0.00003937 of an inch). Aeromotive recommends that 100-micron stainless steel filter elements be used on the suction side of the fuel pump. On the outlet Aeromotive recommends a 10-micron fabric filter (the saying is suck through stainless, push through paper). The reasoning behind this is simple. Electric fuel pumps are fairly forgiving of small particles, but what they don't like is pulling against restrictions to flow. That causes the pump to cavitate, which normally results in a noisy pump that growls in protest and wears out quickly.

When it comes to fuel system components Aeromotive can supply all the parts required to feed any engine.

When it comes to fuel system components Aeromotive can supply all the parts required to feed any engine.

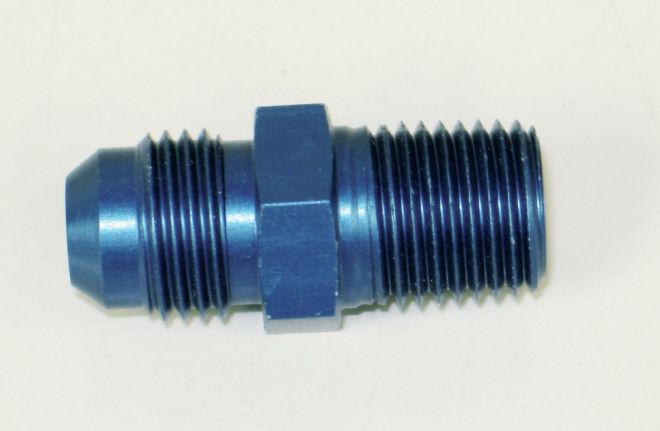

Once all the components are decided on, it's time to figure out hot to connect them all. There are several ways to go—standard automotive rigid lines, fuel hose, inverted flare, and pipe fittings are the most economical, AN fittings and braided hose are a little more spendy, but trick looking (the reference "AN" stands for Army/Navy and it was a system devised by the government to ensure interchangeability and compatibility of parts made by various manufacturers). In many cases (ours included) a combination of these components will be used so it is critical that the connections are compatible. Conventional automotive lines use 45-degree double flares and inverted flare fittings while AN lines and fittings use 37-degree single flares (another application of 37-degree flares will be found on JIC hydraulic fittings). AN fittings are often found in combination with pipe and inverted flare fittings, which means special adapters readily available from Aeromotive will be required.

Another important distinction when using AN fittings is port threads, such as those that may be found on filters and other components, are not NPT or "pipe thread." These connections have straight threads (like any normal fastener) and use SAE O-ring Boss (ORB) technology for sealing. ORB ports and adapter fittings are measured in inch/fractional sizes. AN system lines and fittings are identified by a system that uses a dash and number, such as -6. The number after the dash indicates the internal size of the components in increments of 1⁄16 inch. As an example a -6 line is 6⁄16, or 3⁄8 inch.

No discussion of plumbing any kind of a fluid system would be complete without including Teflon tape. Teflon tape or Teflon-based sealing compound is often used on pipe threads as it can prevent leaks, make it easier to tighten fittings and disassemble them later. In addition it can reduce/eliminate thread galling and protect fasteners made from corrosion. However, properly flared and installed SAE and AN fittings should seal by themselves and Teflon tape should not be used. In such cases the flared components make the seal, not the threads.

Selecting fuel system components is a critical step when building or updating a classic truck. Use quality components, mount them securely away from sharp edges and sources of heat, and allow for movement between the tank and frame-mounted lines and the frame and engine. Don't forget the filters, and above all make sure the system is leak free.

01 Aeromotive offers a variety of inline fuel pumps for carbureted applications. They are available with ports for pipe fittings or ORB.

02 We opted for an in-tank pump for our fuel-injected Ford. The pump mounts to the pickup tube with a hose clamp. The pumps inlet is fitted with a mesh filter.

03 The current draw for electric fuel pumps vary, however, all installations should include a relay and a circuit breaker.

04 Fuel pressure adjustments are accomplished with a regulator. They are available for carbureted and fuel-injected applications.

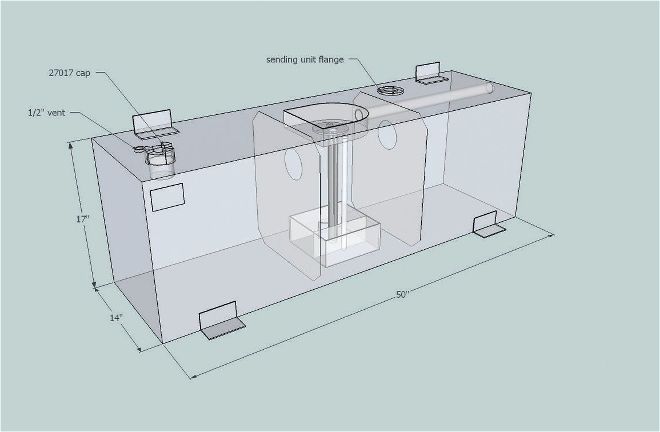

05 To fit our needs Boyd Welding fabricated an aluminum gas tank that fits in the bed of our F-350. Note the baffles and the sump that ensure the pump stays submerged.

06 The fuel pump and gauge sender mount in a recess in the top of the tank. The fuel lines and wiring harness run through a tube inside the tank and exit on the right side.

07 A removable cover protects the wiring and hose fittings. The four brackets anchor the tank to the head gate and bed floor.

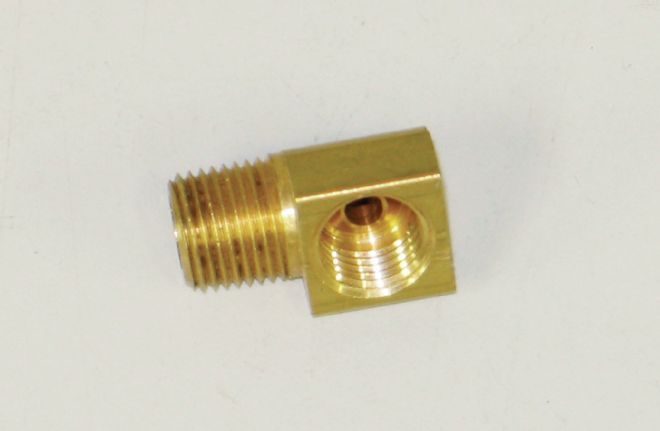

08 When plumbing a fuel system eliminate 90-degree fittings whenever possible as they can restrict flow.

09 A much better choice to go around a corner with a fuel line is a sweep. The gentle bend and consistent internal diameter won’t restrict flow. Aeromotive offers 45-, 90-, and 180-degree fittings.

10 Braided hose looks cool, but be aware that not all hose is created equal. Make sure to use hose that is compatible with today’s fuel additives.

11 Stainless steel lines are often used to plumb fuel systems. They use a single 37-degree flare, a reinforcement sleeve and a nut with female threads.

12 This adapter joins AN 37-degree flare to pipe threads. Aeromotive can supply adapters to connect all common types of fittings.

13 Here is steel line with an SAE 45-degree double flare and male nut. Such lines are readily available from most parts stores.

14 This is a common automotive fitting that can be used to plumb a fuel system—inverted flare for an SAE line on one end, pipe threads on the other.

15 Aeromotive offers this filter with a cleanable stainless steel element. We like the canister type as a pre-pump filter because they also act as a water and sediment trap.

16 This Aeromotive filter has a replaceable 100-micron element making it ideal to put in line after the fuel pump.

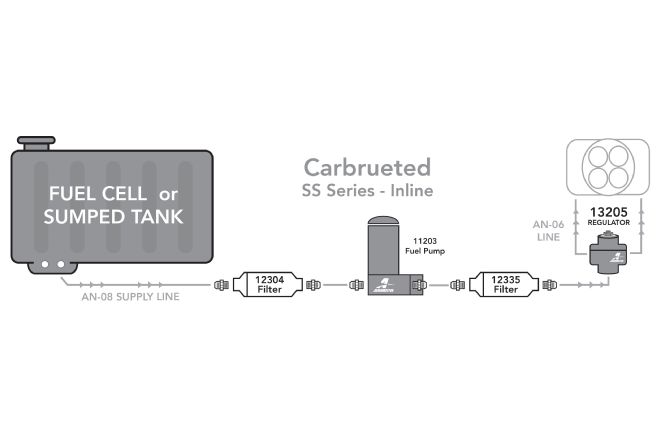

There are a number of methods to plumb a fuel system—here are some examples from Aeromotive.