Two months ago, we showed you the custom-built frame of a 1932 Ford three-window coupe like nobody's ever seen before.

In case you missed it, the influence for the car—designed by Eric Black and under construction at Hollywood Hot Rods—comes from early European sports cars, vintage American race cars, and traditional hot rods. It has to look cool and it has to work right because it's going to get seen and it's going to get driven. And it's the platform for some creative suspension engineering. Not new. And not unproven. Just something you may have never seen before.

"We have been trying to use quarter-elliptic springs in different ways for a while," said Troy Ladd, owner of Hollywood Hot Rods (HHR). Several years ago, HHR used quarter-elliptic leaf springs as lower links on the four-link rear suspension of a customer's Model T coupe. It works really well. Since then, Ladd's been eager to take the concept a step or two further—building a version with dual quarter-elliptics as both the upper and lower links in a front four-bar setup. Now he's done it.

During the course of planning the suspension, Ladd discovered that his idea was not as new as he thought. In the late '20s Harry Miller was using a very similar design on his famously successful race cars. "I like the idea that there is a vintage race heritage that we unconsciously tied into, because it validates what we're doing with the '32," Ladd said. "In addition to using them as springs, we're using the quarter-elliptics to locate the front axle." To function like radius rods in this application, the springs are directly attached to the hangers on the axle, without shackles. "You end up with a four-link like you'd use on a contemporary street rod but the links are sprung! You get your axle location and your spring in one assembly."

Yeah, but does it work?

Every hot rod comes under scrutiny—and unfamiliar engineering invites the greatest amount. When the in-progress coupe made its debut at the 2015 Grand National Roadster Show, the out-of-the-ordinary suspension design (using the springs to locate the axle instead of a familiar four-link or traditional radius rod systems like wishbones and hairpins) had some spectators asking questions about whether the cool, creative design can actually work likes it's supposed to. Like many shops, Hollywood Hot Rods builds high-level show-quality cars for customers who are really going to drive them. So in addition to looking cool, they have to work. The suspension on this Deuce is an engineering experiment that has been researched and tested to make sure that engineering is right.

A common question regarding the front suspension is whether or not the leaf springs can control lateral movement without the use of a Panhard bar.

Troy Ladd explained that, unlike a conventional four-bar system, the short, flat shape of the quarter-elliptic leafs—and the bracket holding them—makes them more resistant to lateral deflection. Just to test that, HHR loaded the car with 500 pounds of weight, put a dial indicator on the chassis between the axle and the frame, then literally pulled the car sideways across the ground to induce lateral movement. The dial indicator measured less than 0.090 inch of lateral deflection between the axle and the frame—a good sign of enough resistance to lateral movement for the '32 to operate on the street with no problem. HHR plans to do comparison testing on similar hot rods equipped with a Panhard bar; they expect that the readings will not differ significantly from this coupe.

The next test will be done driving the car on the street. If the results show an unacceptable level of lateral movement with the quarter-elliptics, a Panhard bar will be added. No sweat.

The rear suspension was similarly tested and also showed very little lateral deflection. A bigger concern in the rear is the strength of the upper frame where the wishbone connects to the top of the tall driveshaft loop. If the mechanical advantage (increased force) at the upper portion of the loop requires reinforcement, struts from that position to lower points on the frame will be added to reinforce it.

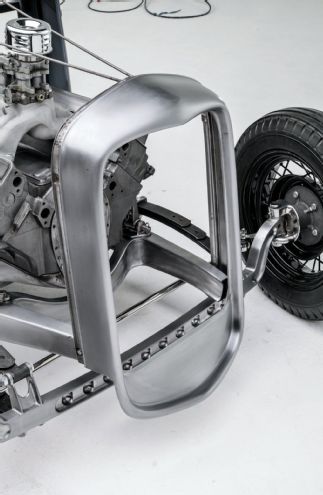

1. You saw these extraordinary handbuilt framerails in Street Rodder a couple of month ago. Since then, Hollywood Hot Rods has added motor mounts, axles, and a remarkable suspension. The drivetrain includes a '49 Cadillac, Borg-Warner five-speed transmission, and quick-change rearend. Vintage Hartford friction shocks from England will be added soon.

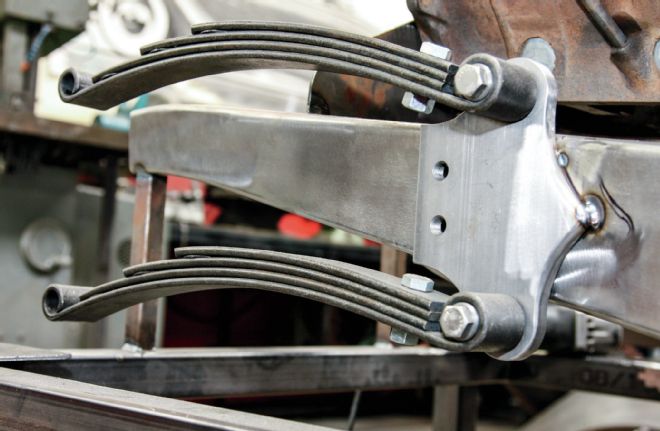

2. There is no split wishbone, hairpins, or typical four-link suspension on the coupe. These quarter-elliptics take the place of that in the front and rear.

3. On the '32 coupe's front four-link setup, quarter-elliptic leafs are doing double duty as springs and as upper and lower links. It looks cool, it's unusual, it has historical race car precedence, and it actually works. The plate shown here mounts the rear of the upper and lower springs to the frame.

4. This bracket links the upper and lower springs so that they move up and down together the exact same amount. The slotted D-shaped piece allows for adjustment. These parts were created with a waterjet cutter and then machined to add details, giving them the appearance of cast pieces.

5. Here is the completed assembly, showing the spring hangers on the axle (no shackles) and the finished link bracket at the rear of the springs. A pair of bolts in the slotted D-shaped piece (arrow) fastens the bracket to the frame and prevents it from moving.

6. To change the spring pivot points, loose those two bolts and turn the screw jack at the top of the assembly (arrow) to fine-tune adjust the springs. When the precise desired position is reached, the two side bolts are re-tightened to lock the springs.

7. The Perform-O-Adjust scale is an imaginative design detail that will be incorporated at the rear of the front spring assemblies. The decorative brass plates are intended to serve as a scale, with the point on the bracket serving as an indicator of the spring setting.

8-9. The front axle is a forged dropped I-beam from SO-CAL Speed Shop, treated to a bunch of modifications. Part of the recessed center portion was filled where the custom-fabricated, cast-appearing hangers were welded. Spring perch mounting holes were filled.

10. The center of the axle was dimpled and cupped to match the look of the inner sides of the framerails. The I-beam recess on the back side of the axle was filled. The axle will eventually be nickel plated.

11-12. In our previous story on the frame, the front of the 'rails had not been boxed. The boxing plates have a convex face to match the front crossmember. The front of the frame has been narrowed 5 inches and stops at the axle, instead of the framehorns continuing beyond the grille shell.

13. The custom engine mounts continue the forged parts look. The mounting flanges were stylishly shaped similar to the trans mount flanges. The pull pins and lanyards continue the European sports car theme. In the original applications, quick-release pins were a necessity for pulling engines at a race; here it's a cool design detail. The door and decklid hinges will get the same treatment.

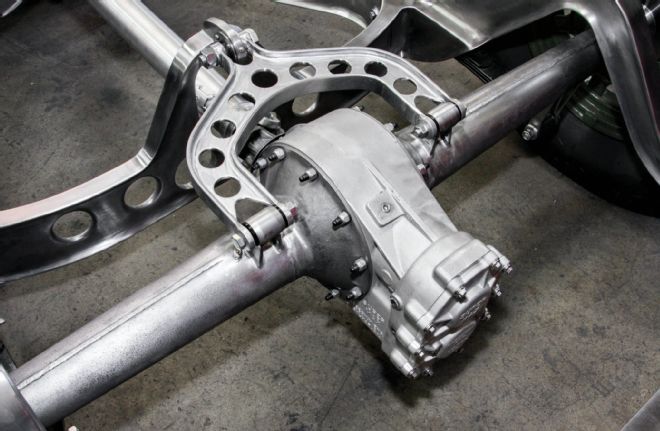

14. The rear suspension is essentially a triangulated three-link setup with quarter-elliptics working as the lower links while also acting as springs.

15-16. As in the front, there are no spring shackles. Instead, custom hangers solidly mount the springs to the rear axle housing of a Speedway quick-change rearend.

17. Each spring is adjusted with a large bolt in the top of the frame at its pivot point, as on a typical quarter-elliptic application. Hollywood Hot Rods may cut a window into each side of the 'rails and install a small scale, like they did on the front springs.

18-19. This small piece of hardware, found at a military surplus store and believe to be from a plane, inspired the design of the clevis fastener where the wishbone links to the top of the driveshaft loop. The wishbone swivels on polyurethane bushings.

20. This wishbone is the upper link on the rear three-link setup, and also acts like a Panhard bar by controlling side-to-side sway of the rearend. The dimpled, I-beam wishbone was fabricated from 10 separate pieces of steel. Heavy-duty bosses strengthen the piece by adding surface area. This upper wishbone three-link concept is similar to systems used in Pro Touring and 4x4 off-road applications, where rearends are under extreme conditions of force you'll never experience—in all likelihood—on the street.