When our '59 Chevrolet hit the showrooms it was advanced in a number of areas. The styling certainly pushed the envelope, from the "jet plane"–inspired intakes in the hood to the broad fins and "cat's eye" taillights in the rear. Under the hood performance options included a fuel-injected small-block or a 348, and either engine could be found backed by a four-speed transmission. But while there were a number of factors that make '59s really cool to this day, driving one makes them less so. Compared to contemporary cars the Chevy has all the handling characteristics one would expect from a car of this vintage—the ride is soft and squishy, which results in so much body roll in sharp corners it seems as though the rocker panels are dragging on the ground. And in today's traffic the brake's shortcomings are evident; bringing 3,500 pounds of Impala to a halt from freeway speeds with the original drum brakes is an eye-opening experience.

To ready our AMSOIL/STREET RODDER Chevy for the 2014 Road Tour, and to perform at a level we deemed necessary, Hot Rods By Dean (HRBD) swapped the stock chassis for a Roadster Shop perimeter frame with front and rear independent suspension (see the February and March SR for details). With the ride and handling issues addressed, the next consideration was updating the brakes. As we have in the past, we turned to Wilwood for their expertise.

Wilwood began doing business in 1977 and quickly became one of the predominant aftermarket brake companies supplying the race and street/performance markets. Wilwood brakes can be found in NASCAR, drag racing, dirt track, and just about every other form of motorized competition. In addition to motorsports Wilwood also manufactures brake systems and components for agricultural equipment, industrial applications, utility vehicles, snowmobiles, quads, motorcycles, and military vehicles. Of course they also have a vast array of street rod components and kits. The Roadster Shop chassis under our '59 uses C6 Corvette spindles up front, so we chose Wilwood's brake kit for that application (PN140-8921). Included in the kit are massive Billet Superlite 6R six-piston calipers (PN 120-11778/79). The fully CNC machined billet bodies have six stainless steel pistons (three per side) with what is called a differential bore configuration. Adapted from Wilwood's racing brakes, it means that the piston sizes are staggered, in pairs, along the length of the caliper body. According to Wilwood, "Clamping pressure is proportionately distributed to provide balanced pad loading with even wear properties at all loads and temperatures. Pad life is extended and performance is measurably improved." These new versions of the venerable Superlite caliper series are available with radial mounting provisions. This style of mount allows the caliper to be adjusted on two planes—closer to or further away from the centerline of the spindle and in or out in relation to the center of the rotors' braking surfaces.

Rotors in the kit are 13.06x1.25-inch thick, drilled, slotted and carry PN 160-7798/99. As Wilwood describes them, "These rotors feature a specially engineered directional cross drill and face slot pattern that improve brake response and pad performance throughout the entire range of light to heavy braking. The venting and cleaning action of the holes and slots will reduce pad glaze and disperse gases and heat generated during the pad-to-rotor interface. The holes and slots also inhibit irregular pad compound buildup on the rotor faces resulting in smoother engagement and improved pedal response in all conditions. The material removed also contributes to lower rotating and unsprung suspension weight."

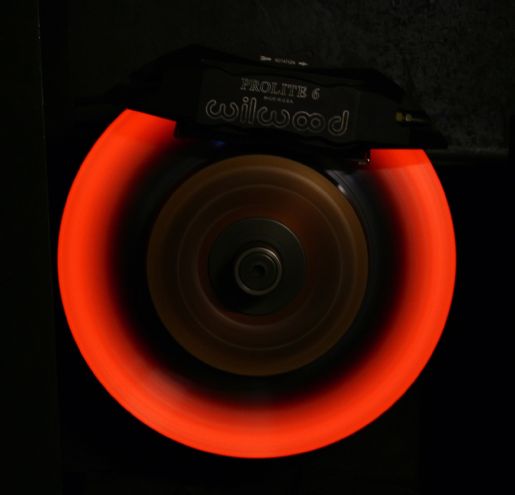

If you think the brakes on your street rod are abused it’s nothing compared to the torture tests Wilwood puts their products through.

If you think the brakes on your street rod are abused it’s nothing compared to the torture tests Wilwood puts their products through.

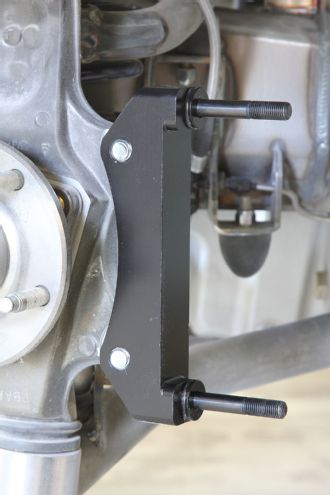

Dean Livermore of Hot Rods By Dean (HRBD), builders of the 2014 AMSOIL/STREET RODDER Road Tour Chevy, does a test-fit of the a Wilwood rear rotor and caliper.

Dean Livermore of Hot Rods By Dean (HRBD), builders of the 2014 AMSOIL/STREET RODDER Road Tour Chevy, does a test-fit of the a Wilwood rear rotor and caliper.

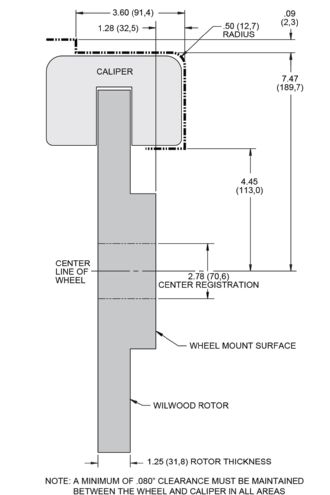

With large-diameter brakes wheel fitment can be an issue, these beauties are 19-inchers from Circle Racing Wheels; in the rear 20-inch wheels will be used. Wilwood has fitment diagrams for most brake kits on their website.

With large-diameter brakes wheel fitment can be an issue, these beauties are 19-inchers from Circle Racing Wheels; in the rear 20-inch wheels will be used. Wilwood has fitment diagrams for most brake kits on their website.

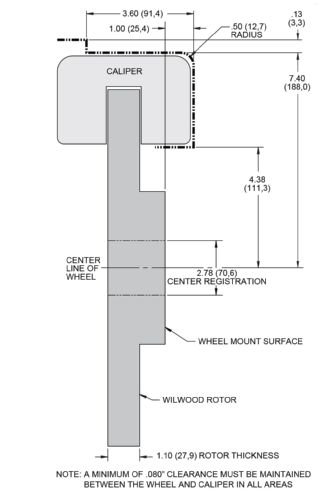

To aide in wheel selection, this diagram from Wilwood gives the dimensions of the 140-8921 brake kit.

To aide in wheel selection, this diagram from Wilwood gives the dimensions of the 140-8921 brake kit.

The front rotors are certainly impressive looking, note the chamfered holes, the directional slots, and the ends of the screws that hold the rotor to the hat.

The front rotors are certainly impressive looking, note the chamfered holes, the directional slots, and the ends of the screws that hold the rotor to the hat.

Securing the front hubs to the hats are 12-point screws that also act as the wheel studs. The hubs are drilled and tapped for 5-on-4.5 and 5-on-4.75 bolt circles.

Securing the front hubs to the hats are 12-point screws that also act as the wheel studs. The hubs are drilled and tapped for 5-on-4.5 and 5-on-4.75 bolt circles.

These are the 12-point screws that secure rotors to the hats. They are drilled to accept safety wire.

These are the 12-point screws that secure rotors to the hats. They are drilled to accept safety wire.

During assembly HRBD applied high-strength thread locker to the rotor screws then torqued them to Wilwood’s specs.

During assembly HRBD applied high-strength thread locker to the rotor screws then torqued them to Wilwood’s specs.

We used stainless steel safety wire—these pliers spin to make winding the wire easy (and it looks cool).

We used stainless steel safety wire—these pliers spin to make winding the wire easy (and it looks cool).

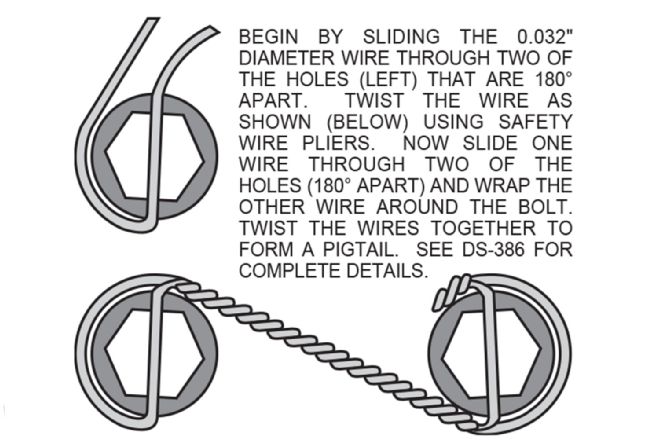

Wilwood shows fasteners wired in pairs; safety wire is put through one fastener, twisted, then put through the next one and secured.

Wilwood shows fasteners wired in pairs; safety wire is put through one fastener, twisted, then put through the next one and secured.

This is Wilwood’s suggested method of safety wiring the rotor screws.

This is Wilwood’s suggested method of safety wiring the rotor screws.

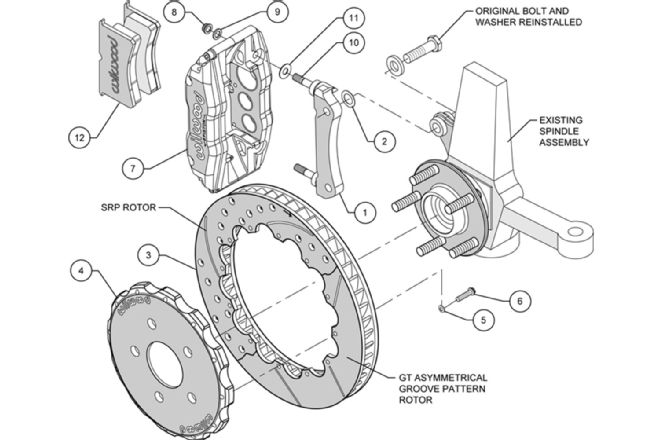

In this exploded view the staggered bores of the front calipers can be seen.

In this exploded view the staggered bores of the front calipers can be seen.

In this exploded view the staggered bores of the front calipers can be seen.

In this exploded view the staggered bores of the front calipers can be seen.

The Roadster Shop's IRS also uses some Corvette components in the rear, namely the hubs and carriers. All the brake components for that application were found in Wilwood's rear brake kit for C5/C6 Corvettes (PN 140-8032). It includes Superlite four-piston calipers that are also made from billet aluminum. These four-piston calipers are said to have the highest clamping efficiency and the lowest deflection of any caliper in its class and are equipped with radial mounts. For this particular application Wilwood's unique rotor hats with integral drums (PN 170-8169) were used to accommodate the stock Corvette internal expanding parking brakes. A special feature of both the front and rear brake kits are the two-piece hats and rotors that are held together with a series of 12-point screws. These fasteners are drilled for safety wire and it is critical they are secured in the fashion shown here (for more on safety wiring, check this month's Shop Manual column on page 132) along with a quality thread-locking compound. Dean Livermore and the crew at HRBD in Phoenix have made amazing progress on the AMSOIL/STREET RODDER '59 Chevrolet. With the new Roaster Shop chassis there's no doubt the Impala's ride and handling will be superb, and with Wilwood discs at all four corners, bringing the Chevy to a stop will require considerably less real estate than the original drums required. Watch future issues of SR for more updates and check out streetrodder.com for more information on the car and the 2014 AMSOIL/STREET RODDER Road Tour.

Safety Wire Tips From Wilwood

•Using standard (0.032-inch-diameter) stainless steel safety wire, begin by sliding the wire through two of the holes that are 180 degrees apart (see upper diagram). The twists should be six per inch, minimum, with a maximum of 12 twists per inch. Also, only safety wire bolts in pairs, as shown in the bottom diagram. Do not string along.

•Note: Safety wire (also known as lock wire) is used to prevent a fastening device from coming loose. It is not a substitute for a secure fastener.

•Safety wire must always tend to tighten the bolt. For a bolt or screw that is tightened by turning it in a clockwise direction, the installed safety wire must tend to pull in a clockwise direction. Select the bolt head holes that would best produce this tightening effect.

•Safety wire must be tight when installed.

•Safety wire must be the proper size.

•Safety wire must never be over stressed. Care must be taken when twisting safety wire together or pulling it tight, not to tighten it so much that it will break under even a light load. Making sharp bends or kinks in the wire must be avoided because they produce stress points in the wire and could cause it to break.

•Always use safety wire pliers to twist the safety wire.

•Safety wire ends must be secured. When installation is complete, the remaining ends are twisted together to form a pigtail (see upper diagram). It is standard procedure to wrap the pigtail around the part being safety wired and tucked down out of the way. Begin by sliding the wire through two of the holes (left) that are 180 degrees apart. Twist the wire as shown (below) using safety wire pliers. Now slide one wire through two of the holes (180 degrees apart) and wrap the other wire around the bolt. Twist the wires together to form a pigtail.

•Torque values must never be changed to obtain an ideal safety wire position!

•Never reuse safety wire. If you make a mistake, throw that piece away and try again. Safety wire is cheap.

Like the front rotors, the rears fasteners had thread locker applied, were torqued to specs, and then safety wired.

Like the front rotors, the rears fasteners had thread locker applied, were torqued to specs, and then safety wired.

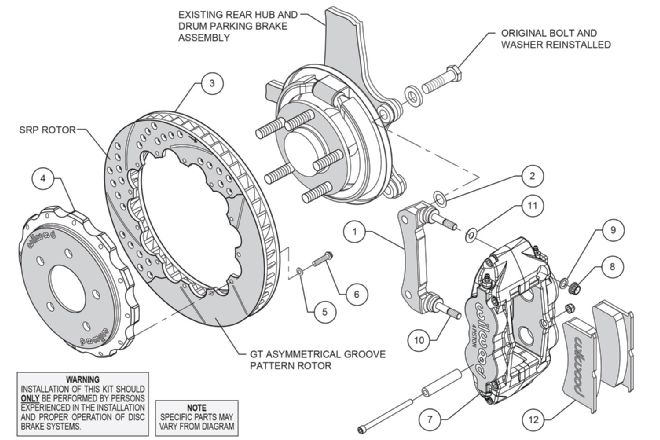

This is an exploded view of the rear brakes. Note the parking brake assembly and the caliper has four pistons, two per side.

This is an exploded view of the rear brakes. Note the parking brake assembly and the caliper has four pistons, two per side.

To aide in selecting wheels, this diagram provides the dimensions of the 140-382 rear brake kit.

To aide in selecting wheels, this diagram provides the dimensions of the 140-382 rear brake kit.

This is the OEM Corvette parking brake assembly from the drum side. Note the adjuster and that both friction surfaces are attached to one steel shoe.

This is the OEM Corvette parking brake assembly from the drum side. Note the adjuster and that both friction surfaces are attached to one steel shoe.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

From the back, the bracket for the parking brake cable and the actuating lever can be seen.

Here a six-piston front caliper is being installed; by adding or subtracting shims from the studs the pads can be located properly in relation to the rotor’s friction surface.

Here a six-piston front caliper is being installed; by adding or subtracting shims from the studs the pads can be located properly in relation to the rotor’s friction surface.

Here a six-piston front caliper is being installed; by adding or subtracting shims from the studs the pads can be located properly in relation to the rotor’s friction surface.

Here a six-piston front caliper is being installed; by adding or subtracting shims from the studs the pads can be located properly in relation to the rotor’s friction surface.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

Our Roadster Shop chassis came plumbed for brake lines, but for those who fabricate their own consider investing in an Eastwood flaring tool. It makes forming leak-free flares in steel and stainless steel lines quick and easy.

The common types of flares can be made with the Eastwood tool—37 degree for AN fittings, bubble flares found on many imports, and 45-degree double flares.

The common types of flares can be made with the Eastwood tool—37 degree for AN fittings, bubble flares found on many imports, and 45-degree double flares.