Our all-steel tub is taking shape, and the bare-metal body has been covered in clear for now. As usual, Editor Brian Brennan is on the phone, and the rest of the SRM staff is hiding out.

Our all-steel tub is taking shape, and the bare-metal body has been covered in clear for now. As usual, Editor Brian Brennan is on the phone, and the rest of the SRM staff is hiding out.

Last month, we introduced the '34 phaeton from Kelvin Waddington's Australian Ute Company (see the May '08 issue of STREET RODDER for a full report) that we're building to drive to various summertime events and to tag along with Jerry Dixey on a few of the Road Tour legs.

There were several specific goals when the project began. First and foremost, we wanted a car that was a no-hassle driver, something that road and handled well, was simple and reliable, and that could be easily duplicated by anyone building a street rod at home. For those reasons, under that new all-steel tub body is a traditional solid axle chassis from Pete & Jake's. In our first installment, we documented the assembly of the front suspension, and this time we installed the rear suspension and plumbed the chassis.

A street rod's suspension doesn't have to be complicated to work well. Our Pete and Jake's chassis uses ladder bars and a Panhard rod to locate the rearend, while suspension is via Viper adjustable damping coilovers.

A street rod's suspension doesn't have to be complicated to work well. Our Pete and Jake's chassis uses ladder bars and a Panhard rod to locate the rearend, while suspension is via Viper adjustable damping coilovers.

We've always believed the simple approach is often best when building a street rod, so we chose Pete & Jake's ladder bar rear suspension for our '34. The suspension works without binding when the rear wheels encounter bumps individually or when the car is driven across an uneven surface, as the frame ends of the bars are mounted close together, unlike split wishbones attached to the framerails. Other advantages to using ladder bars include the facts that they don't interfere with the car's floor, there are no severe pinion-angle changes throughout the range of suspension travel, only two easily replaceable bushings are used, and they easily handle the forces of acceleration and braking applied to them. Last but not least, they are simple for the homebuilder to assemble.

We also elected to use Pete & Jake's Viper coilovers to absorb the bumps during the Road Tour. The beauty of coilovers is they allow the ride height to be quickly altered, thanks to multiple mounting holes in the brackets, and ride quality can be tuned by changing springs, altering the preload on the springs or adjusting the damping on the shocks.

Here's something often learned the hard way. Install the upper coilover bolts from the front of the crossmember; otherwise, the bolts/coil can't be removed once the gas tank is in place without removing the tank.

Here's something often learned the hard way. Install the upper coilover bolts from the front of the crossmember; otherwise, the bolts/coil can't be removed once the gas tank is in place without removing the tank.

One of the biggest advancements in street rod components has been in the area of brake kits. While there are many options, the most popular combination continues to be discs up front and drums in the rear, and that's what we opted for. Super Bell Super Stoppers with four-piston calipers and Pete & Jake's cool finned aluminum backing plates, vented rotors, and aluminum hubs are used fore; all-new drum assemblies from John's Industries are used aft.

A critical consideration when selecting brake components is the size of the master cylinder; common bore sizes range from 7/8 to 1 1/4 inches. Smaller bore sizes will result in more pressure in the system but may not supply the necessary volume. The master cylinder must be able to supply fluid to all the components with less than two-thirds travel of the available stroke. Of course, the master cylinder required will also depend on the type of brakes used. Typically, a drum brake master cylinder will have a smaller bore than a disc master, and the fluid reservoir chambers will be equal in size. A disc/drum master is designed to push more fluid to the front disc brakes, since they require more volume than drum brakes. Generally speaking, a disc/drum master cylinder will have one fluid reservoir larger than the other. This is because the disc brake pads wear faster than the drum shoes, and the fluid reservoir will drop faster.

Pete & Jake's offers a variety of master cylinders. This is a dual-diaphragm booster and Corvette master cylinder from Classic Performance Products on a Kugel mounting bracket.

Pete & Jake's offers a variety of master cylinders. This is a dual-diaphragm booster and Corvette master cylinder from Classic Performance Products on a Kugel mounting bracket.

A four-wheel disc brake master cylinder is designed to supply more fluid pressure and volume to the rear disc brakes than the disc/drum master does. This is achieved through an internal piston redesign. The piston that feeds the rear brakes on a disc/drum master will run out of stroke, limiting the amount of fluid pressure and volume that may be supplied to the rear disc brakes. If you attempt to use a disc/drum master on a four-wheel disc system, you will get poor rear brake function and experience a spongy brake pedal with excessive pedal travel.

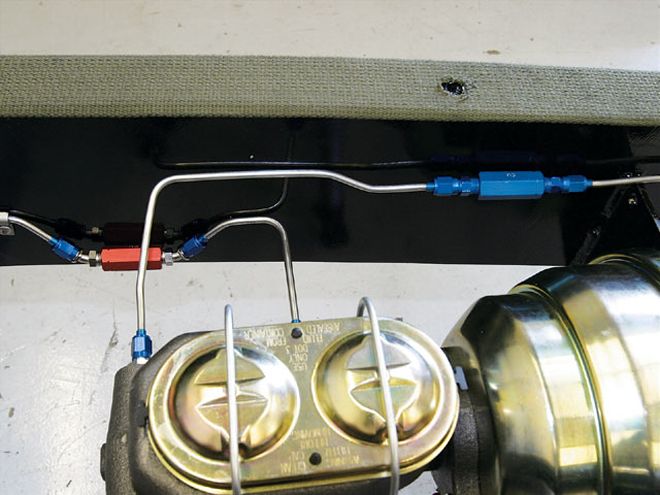

Residual pressure valves are normally built in master cylinders used with drum brakes. Our master cylinder was not equipped, so we installed Wilwood inline valves-10-pound in the rear and 2-pound in the front.

Residual pressure valves are normally built in master cylinders used with drum brakes. Our master cylinder was not equipped, so we installed Wilwood inline valves-10-pound in the rear and 2-pound in the front.

One of the misconceptions about using disc brakes is that a booster is necessary, but that isn't the case with the proper master cylinder. Pete and Jake's offers a 7/8-inch disc/drum master cylinder that works very well; however, boosters are available on request.

We incorporated a proportioning valve and two residual pressure valves as part of the brake system plumbing. Proportioning valves modulate the pressure to the rear brakes; they minimize rear-wheel lockup found in heavy braking and compensate for differences in braking conditions in front-disc/rear-drum systems. Residual valves maintain a small amount of pressure in drum brake systems to keep the wheel cylinder cups expanded. This prevents air from being drawn into the system and allows the brakes to react quicker. A 10-pound valve is common in drum brake systems. Normally, disc brake systems don't have residual pressure valves; however, when the master cylinder is mounted below the floor, and is lower than the calipers, a 2-pound valve is used to prevent the calipers from draining fluid back to the master cylinder.

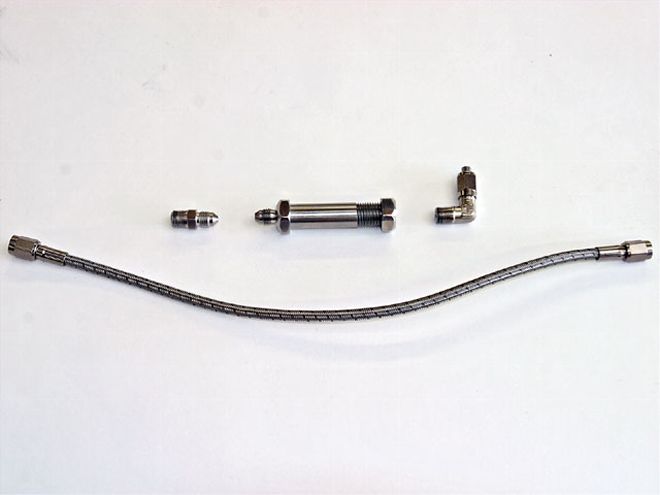

We used through-the-frame fittings to plumb the brake system. They, along with fittings, braided flex hoses, and line clamps, came from Kugel's.

We used through-the-frame fittings to plumb the brake system. They, along with fittings, braided flex hoses, and line clamps, came from Kugel's.

When plumbing a brake system, be aware that the size of the brake lines has no effect on system pressure, and only steel or stainless steel hard lines should be used. Braided lines should only be used between the chassis and wheels. Plumbing an entire chassis with braided line will cause a spongy pedal, because it will swell in use. When routing brake lines, keep them away from heat sources and points of abrasion, and avoid large vertical loops, like over the rear axle that can cause the system to trap air and/or be difficult to bleed.

Our chassis is just about completed, and it's a perfect example of how easy and fun it is to assemble readily available street rod components. And, the great thing about it is anyone can do it.