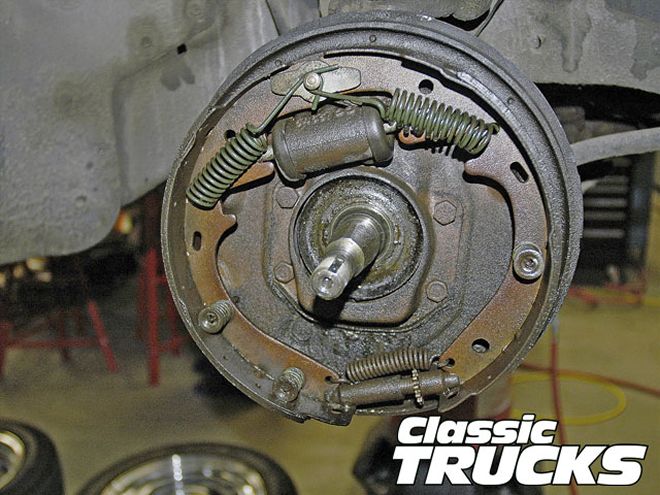

This Bendix drum brake layout became an industry standard. Pre- and post-war trucks use Bendix-, Chrysler-, Lockheed-, Wagner-, or Huck-style brakes. By the end of the '50s, the Bendix design dominated American light trucks. Self-energizing Bendix duo-servo brakes have a dual-piston wheel cylinder, a single (top) anchor pin and an adjuster link between the shoes. Bendix duo-servo brakes with self-adjusting mechanisms are found on disc front/rear drum systems of modern trucks.

This Bendix drum brake layout became an industry standard. Pre- and post-war trucks use Bendix-, Chrysler-, Lockheed-, Wagner-, or Huck-style brakes. By the end of the '50s, the Bendix design dominated American light trucks. Self-energizing Bendix duo-servo brakes have a dual-piston wheel cylinder, a single (top) anchor pin and an adjuster link between the shoes. Bendix duo-servo brakes with self-adjusting mechanisms are found on disc front/rear drum systems of modern trucks.

Note: Steering and brakes rank high on our safety list. Whether your truck is a stock restoration project or a modern street truck build, performance means more than a hot crate motor. In this month's lesson, we'll explore brake system basics.

Hydraulic drum brakes became an industry standard by the late '30s. Designs from Bendix, Wagner, Chrysler, Lockheed, and Huck were popular. In 1939, Bendix introduced a duo-servo design that proved both efficient and easy to service. That single anchor pin, duo-servo system survives to this day.

Duo-servo Bendix-style brakes are easy to identify. They have a single, fixed anchor pin at the top of the backing plate with a dual-piston wheel cylinder mounted below the anchor. A threaded, star wheel adjuster links the lower ends of the shoes. Earlier applications required periodic, manual adjustment of the shoe-to-drum clearance. By the '60s, self-adjuster mechanisms became popular on cars and light trucks.

How Do Bendix Duo-Servo Brakes Work?

When the driver applies brake pedal pressure at the master cylinder, fluid disperses to each wheel cylinder. The curved top ends of each shoe fit against the round anchor pin. As the pistons move outward in the wheel cylinder, the shoe lining contacts the drum. The linked shoes attempt to rotate with the drum. With the vehicle traveling forward, the rear shoe stops against the anchor pin. Backing up, the front shoe stops against the anchor pin.

The obstructed rotational force now redirects, pressing the shoes outward against the drum. This additional force, referred to as "self-energizing", is beyond driver input and hydraulic pressure. When self-energizing force can apply in either direction of rotation, the system is called duo-servo.

Airborne asbestos is a known carcinogen and cause of lung disease. Once wetted, asbestos is no longer airborne. Here, the nozzle of a brake parts washer has flowed aqueous solution between the brake drum and backing plate before removal of the drum. If you work on an older truck chassis with its original brake shoes, beware of the safety risk. Respirators must be rated for asbestos dust protection.

Airborne asbestos is a known carcinogen and cause of lung disease. Once wetted, asbestos is no longer airborne. Here, the nozzle of a brake parts washer has flowed aqueous solution between the brake drum and backing plate before removal of the drum. If you work on an older truck chassis with its original brake shoes, beware of the safety risk. Respirators must be rated for asbestos dust protection.

As the vehicle moves forward, the self-energizing force is greater at the rear shoe. To keep lining wear even, the rear shoe's lining is longer and sometimes of different composition than the forward shoe. With a shorter lining on the primary or forward-facing shoe, self-energizing force is slightly less when the vehicle moves backward. Since the vehicle does not back up at high speeds, braking is sufficient in either direction.

The Bendix duo-servo design provides uncomplicated service with good parts availability. Familiar to repair technicians, these brakes also serve well at the rear of a front disc with rear drum system. For four-wheel drum brake applications, the front brake drums and lining area are often larger than the rear. This compensates for weight transfer and bias toward the front during hard braking. On a light truck without a load, weight bias is to the front. Decreasing the available braking force at the rear helps prevent rear wheel lockup under heavy braking.

Major Components

The drum brake system features a master cylinder, wheel cylinders, lined shoes, and brake drums. Master cylinders mount below the floorboard on GM trucks built to 1959 and Ford models through 1956. Other truck makes also used through-the-floor pedals. By the '60s, suspended pedals and a firewall-mounted master cylinder had become the industry standard.

Safety concerns led to the '67 mandate for a dual master cylinder. The dual master cylinder essentially splits the brake hydraulics into a front and rear system. If a leak occurs at the front wheel hydraulic circuit, the brake system still functions at the rear of the truck. Similarly, a rear leak will not cause the front brakes to fail.

Dual braking may be the most significant safety improvement in hydraulic brakes. Prior to '67 models, a simple leak at a hose, wheel cylinder, or pipe could lead to complete failure of the four-wheel braking system! While disc brakes clearly improve brake performance, the dual master cylinder dramatically enhances vehicle safety.

The only fix for severe rust and scale is glass bead blasting. This also removes any remaining zinc plating. You can re-plate these parts with a zinc plating kit from Eastwood or sublet parts to a plating shop. Paint for backing plates should be heat resistant and rust inhibitive. Do not paint wheel or master cylinder castings, pins, or pushrods. If you're working with an older brake system, many parts are obsolete. Original pieces may require reconditioning.

The only fix for severe rust and scale is glass bead blasting. This also removes any remaining zinc plating. You can re-plate these parts with a zinc plating kit from Eastwood or sublet parts to a plating shop. Paint for backing plates should be heat resistant and rust inhibitive. Do not paint wheel or master cylinder castings, pins, or pushrods. If you're working with an older brake system, many parts are obsolete. Original pieces may require reconditioning.

Lining can be riveted or bonded to steel brake shoes. Arguments in favor of riveted lining note the security of having a mechanical bond between the shoe and lining. Bonded lining, on the other hand, allows more shoe wear without interfering with countersunk brass rivet heads. Riveted lining dates to the earliest brake shoes, when it was popular to reline brakes at a local service garage.

Years ago, bonding methods and materials were less effective. At extreme heat, bonded lining could separate from a shoe. With modern materials and manufacturing techniques, lining separation is not a significant concern. Especially for street use, quality brakes can be either bonded or riveted type.

Brake shoes are secured with hold-down hardware and return springs. These springs and hardware have precise sizing and tension for each application. Use of the wrong hardware can lead to dragging shoes, poor brake response and incorrect shoe-to-backing plate alignment. Old springs and pins are likely fatigued and out of shape. Always install new hardware with a brake job. Hardware kits are available for popular trucks.

This is the most basic of brake layouts. Without self-adjusters, Bendix systems go together quickly. This wheel cylinder is new. Use care and prevent contaminants from entering the hydraulic system. Springs, shoe hold-down hardware, and return springs are available for popular applications. View is the left (driver side) front wheel. Note that the forward or primary shoe has shorter lining than the rear shoe.

This is the most basic of brake layouts. Without self-adjusters, Bendix systems go together quickly. This wheel cylinder is new. Use care and prevent contaminants from entering the hydraulic system. Springs, shoe hold-down hardware, and return springs are available for popular applications. View is the left (driver side) front wheel. Note that the forward or primary shoe has shorter lining than the rear shoe.

Hoses should be the right length and thread size, and they must meet or exceed DOT safety ratings. Factory hose is generally rubber jacketed. Aftermarket performance hoses often use stainless braid wrap. Whether stock replacement hose or aftermarket braided type, any brake hose must withstand maximum operating pressures and fit properly.

Brake pipe can be preformed, double-flared tubing with a DOT brake rating. Such pipe is available through brake parts sources with flare nuts in place and each end double-flared. (Stainless tubing and custom stainless braid hoses can be purchased through CLASSIC TRUCKS' advertisers.) If you must cut a brake pipe to size, double flare the tubing end after installing the flare nut. Follow factory guidelines for tube flaring and use professional grade tools. The easier approach is to purchase correct lengths of brake tubing, already fitted with flare nuts and double-flared at each end.

Hydraulic brake fittings are much higher grade than fittings used commonly for fuel or oil pressure. Always use SAE-rated brake tubing and fittings. This includes any master cylinder, proportioning valve, axle banjo, or frame-junction fitting. A hydraulic brake system is no safer than its weakest point.

Rear brake assembly with parking brake lever and cable is busier than the front brake layout. Brake shoes with modern, non-asbestos lining have been cam-arc surfaced. This matches the radius of the shoes to the resurfaced brake drum's contour. Cam-arc was virtually banned from the '80s- through the '90s due to asbestos dust hazards. Availability of non-asbestos lining has revived interest in this brake "tuning" procedure. The process provides quicker seating of the lining and better brake response after a brake job.

Rear brake assembly with parking brake lever and cable is busier than the front brake layout. Brake shoes with modern, non-asbestos lining have been cam-arc surfaced. This matches the radius of the shoes to the resurfaced brake drum's contour. Cam-arc was virtually banned from the '80s- through the '90s due to asbestos dust hazards. Availability of non-asbestos lining has revived interest in this brake "tuning" procedure. The process provides quicker seating of the lining and better brake response after a brake job.

Service Pointers

Years ago, rebuilding a master or wheel cylinder was common practice. If the bore was not too worn, a cylinder could be honed to break the glaze and eliminate slight surface irregularities. Honing was OK as long as the bore stayed round and within diameter tolerance. By the '70s, factory bore finishing changed. Diamond tool boring, followed by rolling the surface under heavy pressure, created a harder, more polished surface. (GM called this process "bearingized".) If honed during service work, the hard surface goes away, leaving a softer, coarser cast material that could wear prematurely.

Rebuilding or replacing just one wheel cylinder is also unwise. Invariably, the remaining cylinders that do not leak now will soon develop leaks. The master cylinder must be in top condition, too. When in doubt, rebuild or replace it. For best results, service all wheel cylinders and the master cylinder at the same time.

Everyone knows the challenges of brake bleeding. Applying pressure at the master cylinder end of the system is time consuming. It also pushes contaminants into the wheel cylinders. These contaminants can remain trapped within a cylinder, unable to exit through the bleeder valve.

Ball bearing components are vintage GM. Some purists keep ball bearings for authenticity. Limited application has driven parts costs up in recent years. Unless you have a numbers-matching restoration project or a penchant for ball bearings, consider a cost-effective, fully functional tapered roller bearing conversion kit. The brass device is a static ground to help prevent radio interference. Static suppressors fit inside the dust caps and ride against the recessed end of the spindles.

Ball bearing components are vintage GM. Some purists keep ball bearings for authenticity. Limited application has driven parts costs up in recent years. Unless you have a numbers-matching restoration project or a penchant for ball bearings, consider a cost-effective, fully functional tapered roller bearing conversion kit. The brass device is a static ground to help prevent radio interference. Static suppressors fit inside the dust caps and ride against the recessed end of the spindles.

There are other bleeding methods. Vacuum bleeding has gained popularity, and for good reason. Vacuum applied at each wheel cylinder's bleeder valve will draw old fluid, air and contaminants from the confines of the cylinder. Instead of pressurizing the master cylinder, vacuum bleeding pulls air bubbles and contaminated fluid from within each wheel cylinder. By adding enough clean brake fluid at the master cylinder, vacuum bleeding can flush the entire system.

Brake fluid for drum brakes is DOT 3 rated. Use high-temperature-rated DOT 4 for drum/disc systems. You can also use DOT 4 in a four-wheel drum brake system. DOT 3 and DOT 4 brake fluids are compatible.

Silicone DOT 5 brake fluid does not draw moisture. Some use this fluid in a vehicles parked for long periods. When changing to DOT 5 silicone fluid, you must completely flush and dry the brake hydraulic system. New rubber must be installed at the master and wheel cylinders. DOT 5 is not compatible with DOT 3 or 4. Never mix DOT 3 or DOT 4 with DOT 5.

It is very easy to hand-pack ball bearings. Kneed grease between the balls and around the cage until there is no possibility of air gaps. The grease used here is Texaco Starplex II. Suitable for ball or tapered roller-type bearings, this product has exceptional ability to cling when hot (high viscosity) and migrates toward heat. There are much improved modern greases rated for high-temperature ball or roller bearing service. Clean away all old grease and dry the bearings thoroughly before packing. Never mix grease types.

It is very easy to hand-pack ball bearings. Kneed grease between the balls and around the cage until there is no possibility of air gaps. The grease used here is Texaco Starplex II. Suitable for ball or tapered roller-type bearings, this product has exceptional ability to cling when hot (high viscosity) and migrates toward heat. There are much improved modern greases rated for high-temperature ball or roller bearing service. Clean away all old grease and dry the bearings thoroughly before packing. Never mix grease types.

When performing brake work, use a factory workshop manual to determine the layout of parts, the sequence of fit-up, and acceptable tolerances. Keep parts separated per wheel to ensure correct reassembly. An older truck will have a history of brake work, and parts could be out of position or even missing. Compare what you have to factory guidelines and parts illustrations. Use factory service methods for the safest results.

Note: By the '70s, factory service manuals no longer recommend cylinder honing. Light stain removal remains acceptable, using crocus cloth only, followed by careful cleaning and renewal of all rubber parts. Signs of corrosion, pitting, or score lines call for a new cylinder.

What Did You Learn This Month?

Night School would not be complete without a quiz! Don't worry about your test-taking skills or grades. This is an open-magazine, true or false test. Clues can be found within the Night School text, photos and captions. Have a good month!

This modern replacement seal goes squarely in place after fitting the inner wheel bearing. Swab grease in the middle cavity of a spotlessly clean, thoroughly dry wheel hub. Build a dam of grease at the inside and outside edges of each bearing. Grease dams serve as reservoirs, ready to flow grease into the bearings at higher heat. Avoid overfilling the hub, which could damage or dislodge the grease seal. The spindle also needs a coat of grease. The backing plate's shoe contact points require a thin coating of special high-temp brake lube. Keep grease, oil, and brake fluid away from brake lining!

This modern replacement seal goes squarely in place after fitting the inner wheel bearing. Swab grease in the middle cavity of a spotlessly clean, thoroughly dry wheel hub. Build a dam of grease at the inside and outside edges of each bearing. Grease dams serve as reservoirs, ready to flow grease into the bearings at higher heat. Avoid overfilling the hub, which could damage or dislodge the grease seal. The spindle also needs a coat of grease. The backing plate's shoe contact points require a thin coating of special high-temp brake lube. Keep grease, oil, and brake fluid away from brake lining!

True or False Questions:

1. Bendix duo-servo brakes date back to 1939 and are still in use today. Earlier applications require manual adjustment. In the '60s, self-adjusters became popular.

2. On Bendix duo-servo brakes, the front (primary) brake shoe has shorter lining than the rear shoe. Reversing the shoes will decrease braking efficiency.

3. If a 50-year-old wheel cylinder leaks from worn-out rubber and corrosion, it is OK to replace the leaky cylinder and leave the other old wheel cylinders alone. After all, they're not leaking now.

4. The vacuum brake bleeding method pulls old fluid out through the bleeder valve. Vacuum is very effective at removing contaminants.

5. Breathing asbestos dust is very harmful. Older brake shoes with asbestos lining must be handled safely. Asbestos-free replacement lining is better for your health.

6. Before 1962, Chevrolet and GMC light trucks used ball-type front wheel bearings. Adjustment specifications for ball and roller bearings are not the same.

7. It is perfectly OK to mix wheel bearing grease types. If you're in a hurry, just pack fresh grease over the top of old grease.

8. Mineral oil and solvents are highly damaging to rubber brake parts. Gasoline, petroleum distillates, solvents, kerosene, lacquer thinner, and motor or gear oil should never be used around rubber brake parts. Wash hands with soap and water before handling rubber parts.

9. Use isopropyl or denatured alcohol for cleaning hydraulic brake cylinders. Use rubber gloves to keep toxic alcohol from entering your bloodstream through nicks and cuts.

10. A dual master cylinder with a bellows seal cap is far safer than a vintage single master cylinder mounted beneath the floorboard. Single master cylinders vent to atmosphere and draw moisture and contaminants into the braking system.

Answers:

true true false true true true false true true true