There's a need in this industry for service centers that can measure and make changes to a race car for improved geometry-and now one has emerged. CCI Solutions is a company that designs and manufactures machinery that enhances manufacturer's processes. The company also races. So it was only natural that it would develop a process and the machinery that could be used to measure a race car's geometry.

CCI's new Dynamic Chassis Measuring System can help improve your race program.

CCI's new Dynamic Chassis Measuring System can help improve your race program.

Brother and sister, Sonny and Denise Ingram co-own CCI and were looking for a way to service the racing industry both in their local area of North Carolina as well as in other parts of the country. The company is located in Liberty, NC, which is central to many East Coast race teams. Together they came up with the concept and design of a system that would help the race teams improve their performance.

DCMS Explained The Dynamic Chassis Measuring System was designed to be able to quickly measure various functions of the race car's geometry and then offer solutions to make the race car system better. CCI has had lots of success with the teams that have already been through the process. One recent "graduate" team went from running an average of fifth to winning the very first race after going through the DCMS process.

Denise Ingram of CCI Solutions wrote the software that calculates all of the frontend geometry based on the data that the DCMS records. Special care is taken to make sure the data is both correct and accurate.

Denise Ingram of CCI Solutions wrote the software that calculates all of the frontend geometry based on the data that the DCMS records. Special care is taken to make sure the data is both correct and accurate.

The DCMS will measure alignment front and rear, camber in both static and dynamic modes, toe (front and rear), bumpsteer, Ackermann, moment center location in both static and dynamic modes, and rear steer. Once the measurements are taken, the car can be changed to correct any problems and then be remeasured while still on the fixture.

Overall Concept The concept of being able to visit a service center like this one is very new. The attraction is, first of all, convenience. Most race teams don't want to dedicate the time and effort it takes to perform these tasks no matter how much importance they place on the settings. We continually preach to racers that they need to know the geometry settings for their car and we hope that they will put forth the effort to check their race cars, but in many cases they don't.

Granted, it's not easy to measure for the front moment center location. We need special tools to check bumpsteer, toe, and Ackermann. In some cases, a team might not feel up to understanding the technical complexities of the process, and that's OK. We aren't all engineers here; some of us do need help.

We arrived at the CCI facility and set the car at ride heights to get a few measurements so that we could get the car on the DCMS. These measurements are crucial because our first data points recorded on the DCMS will be at ride height.

We arrived at the CCI facility and set the car at ride heights to get a few measurements so that we could get the car on the DCMS. These measurements are crucial because our first data points recorded on the DCMS will be at ride height.

The DCMS process and fixture is a step in the right direction by providing a service racers can use to perfect their race cars. And, the system can be duplicated and service centers can be established around the country. This way, a team could travel a short distance to a service center and have its car analyzed for geometry issues. The process takes only a few hours and the results will last a long time.

What The DCMS Does The race car is placed inside a fixture that contains a series of electronic measuring devices that are used to record precise measurements of the data points needed. This data is then processed and the results are presented in figures and graphs to the race team. Once the data is known, the team can make changes as per the recommendations from the CCI team and then the car is remeasured to record the results of the changes.

The most important functions of the process are: A. Finding the moment center location, both while the car is stationary at ride height and while it is in the mid-turn configuration. This tells us where the MC starts out and where it ends up, which is the most important thing to know.

B. Measuring the bumpsteer characteristics. The BS can be measured at ride height and mid-turn attitude and any excess steer can be adjusted out or to the desired amount for each front wheel.

C. Measuring toe and Ackermann. The fixture measures toe at both the front and rear and also toe change due to chassis dive and roll. This is called Ackermann and can be a very negative effect.

D.Rear steer. Another very detrimental effect of chassis dive and roll is rear steer. We can usually tolerate small amounts of rear steer, but larger amounts will cause unstable handling that can't be corrected with normal setup changes such as spring rates, weight distribution, and moment center changes. Rear alignment is very important.

Now we have to square the car up on the DCMS. Once the car is square and at ride heights we can start taking measurements.

Now we have to square the car up on the DCMS. Once the car is square and at ride heights we can start taking measurements.

E.Camber change. The fixture can measure static and dynamic cambers and provides a view of the change in increments. It's widely accepted that there should be minimal camber change in order to provide the most stable grip characteristics. Modern soft spring setups yield high amounts of camber change and we need to know where the cambers end up at mid-turn.

F.Caster split. The caster for each front wheel can be measured and tracked through dive and roll to where it ends up at mid-turn. With teams using Anti and Pro dive in the frontends, each will cause caster changes and we need to know where each side is going in order to end up with the caster split needed to suit the tracks we are running.

How It All Started The DCMS took 18 months of engineering and creative thinking to dream up. The idea originated with Sonny. "I first had the thought to do it, but I was just over matched mechanically," he says.

He then turned to the company's systems design engineer Paul Dionne. Paul used his mechanical engineering background to design the machine. They use 18 linear variable differential transducers (LVDT or potentiometers) to measure the various points that make up the frontend geometry. These transducers measure accurately to 10 microns. To give you an idea to how accurate that is, this dot (.) is approximately 1/64-inch wide and equals 615 microns. Now think how accurate your caster, camber, Ackermann, bumpsteer, and moment center could be if you knew the technology you were using was accurate to 10 microns.

The DCMS takes data from a multitude of different locations. You have the plate mounted on the outside of the wheel hub that is used to measure camber and bumpsteer. The DCMS is also recording data to define where the upper and lower ball joint locations are.

The DCMS takes data from a multitude of different locations. You have the plate mounted on the outside of the wheel hub that is used to measure camber and bumpsteer. The DCMS is also recording data to define where the upper and lower ball joint locations are.

From there, the other owner of CCI, Sonny's sister Denise, wrote the software that uses the points that the LVDTs produce and converts the data into the readouts for all of the aspects of frontend geometry.

The DCMS accomplishes this by measuring and recording the location of the upper and lower ball joints and the chassis connections for the control arms. The process starts with measuring the points when the car is at ride height. Then the program moves the front suspension from ride height down through a range of motions to full compression. This will allow you to be able to see exactly how your front geometry changes throughout your travel.

One of the most valuable pieces of information is defining where your moment center is located. The moment center's location is crucial to how well your car handles. It does all of this without having to remove the engine from the car. This makes the time you can spend on the DCMS extremely valuable. Don't confuse this process with the normal pull-down rig. A pull-down rig will bring the chassis down and show you how the car is traveling. This process will move the chassis using hydraulic actuators. This allows them to stop at precise positions to retake the measurements.

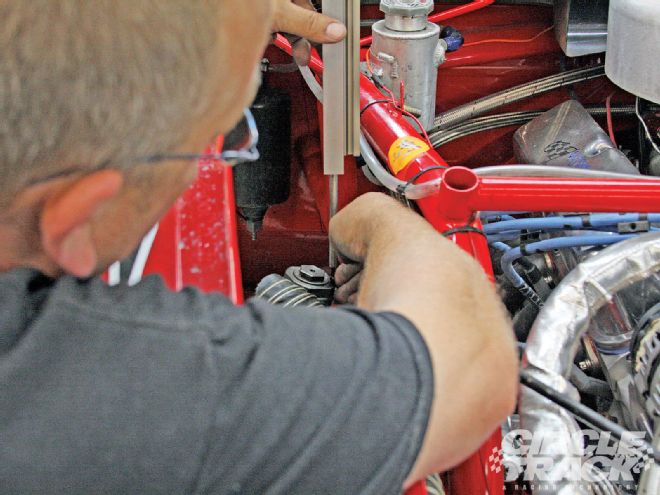

Gathering data for the right front upper ball joint involves taking three measurement points to define the plane of the ball-joint housing and then the center of rotation of the ball joint.

Gathering data for the right front upper ball joint involves taking three measurement points to define the plane of the ball-joint housing and then the center of rotation of the ball joint.

The DCMS will also show you what your camber curves are. You can see from our final run on the DCMS, that our camber curve on the right front actually gains a ton of camber when it reaches full compression. We always knew that we were gaining a few degrees but we never knew we were getting close to 10 degrees of camber at full compression.

The idea is to show up at the racetrack with a car that is as close to perfect as it could be, since normal Saturday night races give less than an hour of practice. Races are not won during race day, they are won with the preparations leading up to the race. The better you can show up at the racetrack, the less you will have to tune on the car to make it handle. You should be fine-tuning your setup at the racetrack, not making wholesale changes.

Recently, we were able to put our USARacing Pro Cup Project Car on the rig to be able to diagnose the frontend geometry problems we were having. We suspected that our moment center might be too far to the right. As you can see in the charts, we documented the trip, a very valuable trip. We spent eight hours there on a Friday and learned more about our car during that short time period than we could ever have done spending eight hours on the racetrack.

To relocate the moment center, we will have to change the upper control arm chassis slugs. Our moment center, according to the data, was too far to the right, so we will have to lower the left-side dive slugs and/or raise the right-side dive slugs to be able to get the moment center back to the left side of the car.

To relocate the moment center, we will have to change the upper control arm chassis slugs. Our moment center, according to the data, was too far to the right, so we will have to lower the left-side dive slugs and/or raise the right-side dive slugs to be able to get the moment center back to the left side of the car.

Information You Can Take With You All of the measurements taken by the DCMS are reduced to data sheets that the team can take home to analyze and evaluate. While at the facility, you can try different configurations with the geometry and then try each at the racetrack to find the most suitable combination for your driver and your racetrack. The personnel at CCI will help you with your decisions.

If you sell your car at the end of the season before building or buying a new one, you can provide the new owner with the data that shows that the car is indeed checked out and in good geometrical condition. It's like having a fresh dyno sheet on the motor. That could help not only sell the car, but may bring a higher price.