Here's Appleton's brand-new, double-ended cylinder rack. It features a 1 inch piston diameter with a high flow open port servo valve and improved cylinder lugs with 3/8 inch mounting bolts.

Here's Appleton's brand-new, double-ended cylinder rack. It features a 1 inch piston diameter with a high flow open port servo valve and improved cylinder lugs with 3/8 inch mounting bolts.

Our final race for Project Dirt Late Model and the United Dirt Late Model Challenge Series last season was at East Bay Raceway Park in Tampa, Florida. I've been around that track more times than I can remember in a number of different types of cars. So naturally, I felt good about our chances to produce that first win. Everything was clicking--the problem with the motor running hot had been solved with a new Edelbrock water pump, Bob Bolles' setup solved the persistent loose problem I had since I got the car, and we made it to the track with plenty of time to spare. It seemed like all the I's were dotted and the T's crossed.

Naturally, that wasn't going to last. I guess that Murphy must have been hiding in the back of the trailer or in the 'cage in the shop watching us. When I went out for hot laps, I headed down the backstretch and everything was good. But halfway through Turn 3, the steering got super stiff. Now anybody who has ever driven a Dirt Late Model knows that they don't turn real well without power steering. In fact, they really don't turn much at all.

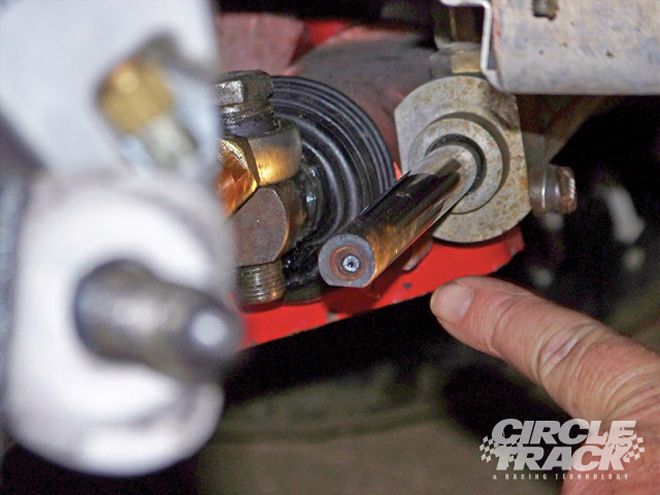

Right in the middle of hot laps in the last race of the '08 season, the bolt that attaches to the shaft that goes through the center of the rack broke. We tried to use an "easy-out" to pull out the broken bolt but it was seized up in there and wouldn't budge.

Right in the middle of hot laps in the last race of the '08 season, the bolt that attaches to the shaft that goes through the center of the rack broke. We tried to use an "easy-out" to pull out the broken bolt but it was seized up in there and wouldn't budge.

Anyway, when I got back around to the pits we quickly found the problem. The bolt that attaches to the shaft that goes through the center of the rack broke. We tried to use an "easy-out" to pull out the broken bolt but it was seized up in there and wouldn't budge. So with time ticking rapidly away until qualifying, we took a stab at trying to backyard engineer a fix by welding another bolt to the slave cylinder shaft. We even put wet rags all around the rack to help keep it cool from the intense welding heat.

Our fix worked--for all of one lap. Here's a note for everybody out there, wet rags will not help protect anything from the heat of a welder. All of the seals around the slave cylinder melted and after that one lap. Power steering fluid was leaking out and showed no signs of stopping.

We still qualified for the race and finished Fourth in the B-Main, too bad only the top two transfer. Unfortunately, our '08 racing season ended with a mechanical failure.

Since there's no sense in crying over spilled power steering fluid, we put in a call to Fred Appleton at Appleton Power Rack & Pinion. We had heard that Appleton had a brand-new rack for Dirt Late Models and we wanted to see if we could get a first-hand look.

A little backyard engineering to fix the seized bolt involved a welder. It worked--for one lap.

A little backyard engineering to fix the seized bolt involved a welder. It worked--for one lap.

Nice Rack!

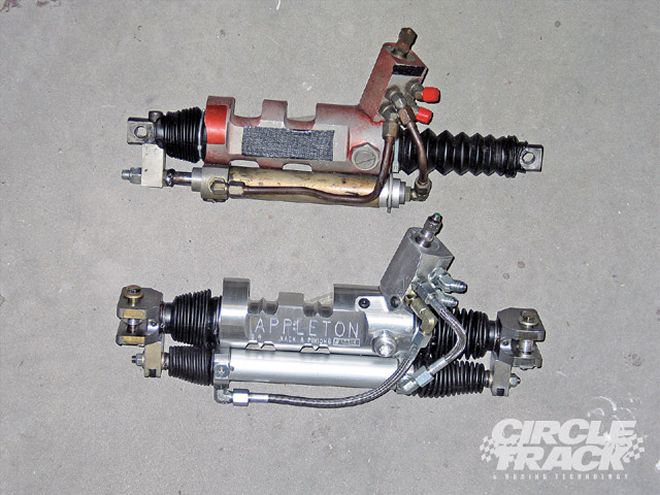

Appleton's new double-ended cylinder rack features a 1 inch piston diameter with a high-flow open-port servo valve and improved cylinder lugs with 3/8 inch mounting bolts. Available in a variety of ratios from 3.4 up to 4.4, it would fit our needs perfectly. In addition, its adjustable ends are inch smaller than the standard adjustable end and give more clearance. It has 1.3 inches of travel where the old style had 2 inches of travel. The cool thing is that these new adjustable ends mount the same way as the old ones, so there's no need to buy a new rack shaft or any other parts to convert.

So, with the rack we wanted identified, it was time get down to the numbers. In talking with Fred, we learned that the rack that had been in Project DLM was actually the wrong size for our chassis. We bought this car used 4 years ago and the busted rack is the one that came with it. The rack worked, so we never thought about replacing it. Sound familiar? We were convinced that we were not the first racer to make this mistake and Fred backed us up. "Not ordering the proper ratio or servo feel for the application is the most common mistake racers make when buying a new rack," he says.

Not surprisingly, ratio and servo feel are two of the Top 5 features a racer should consider when purchasing a rack-and-pinion. The others are whether you want manual or power steering, the type of rack housing, and the length of the rack shaft.

Choosing Wisely So how do you ensure that you get the right one? Chart A lays out Appleton's recommendations for those five most critical items when selecting a new rack.

I can hear you saying, That's all great, but how do you know what rack shaft length you really need? "The rack shaft length should be the same length as the pivot points of the lower control arms," says Fred. "This is to keep the bumpsteer to a minimum." And, in fact, if you refer to Chart B, Fred provided us a list of the most popular chassis and their accompanying shaft lengths.

Taking out the old rack proved to be almost as easy as putting the new one in.

Taking out the old rack proved to be almost as easy as putting the new one in.

Chart A had given some ranges of recommendations and knowing that my old rack had been the wrong one all along, I got concerned about finding the right ratio for my driving style. Fred gave me an education. In general, ratio and "servo feel" is really more up to driver preference. Even so, there are some good rules of thumb to remember. Regardless of whether you're on dirt or asphalt, the ratio most depends on the length of the racetrack. On a small -mile track, a higher ratio would be needed. For example, if that little track was dirt, ratios would range from 3.9 to 4.4 while an asphalt one of the same size would be a 3.0 ratio. Incidentally, Appleton's 4.4 is the fastest ratio rack on the market. So, if you're running those quick little quarters a 4.4 could be perfect for you. Now, a long mile or sweeping track would require a lower ratio. A good dirt example would range between 3.4-3.7, while asphalt would require a range between 2.0-2.5.

But be careful, too fast of ratio on asphalt will cause an inexperienced driver to over steer the car or drive in an erratic darting motion. One other note, on dirt if you're one of those drivers who like to "back it in" you'll want a higher ratio in those ranges mentioned above.

The ratio, if you were wondering, is the distance that the rack shaft travels (in inches) with one turn of the steering wheel. The lighter (smaller diameter) the torsion bar, the more power assist you receive and the less effort to turn the steering wheel. Chart C below shows how the torsion bar weight/size relates to the steering feel.

Here we can see the difference between the two racks, note the adjustability of the new Appleton on the bottom.

Here we can see the difference between the two racks, note the adjustability of the new Appleton on the bottom.

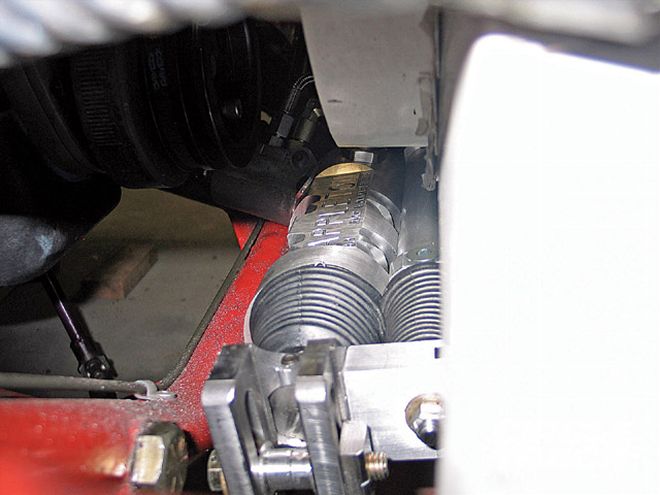

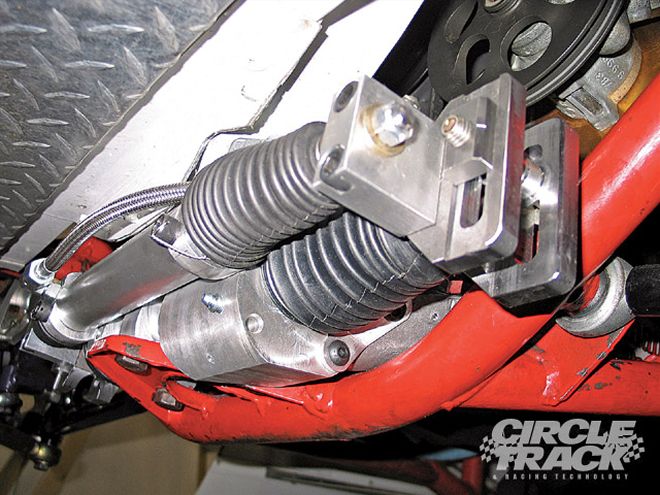

Install Time The installation of the rack-and-pinion is actually one of the easier things to do on a race car. In fact, we installed the rack in less than an hour and that included taking the old one out. With the old rack out of the way, we slid the new one into place, taking advantage of the adjustability to help clear the bottom of the radiator shroud. Three tightened bolts later and the next step was to hook up the hoses to the fittings. Appleton marks the two fittings with a "P" and "T" on the servo housing. The P represents the hose that goes to the pump, and the T is for the hose that goes to the tank. If for some reason you can't see the markings, the 45-degree fitting next to the rack boot goes to the pump and the 45-degree fitting closest to the U-joint goes to the tank.

Once the hoses are all hooked up, all you have to do is double check the fluid level and then turn the wheel back and forth several times, since the system is self-bleeding. You should have between 1,000 and 1,100 psi for the pump to run the rack correctly.

Troubleshooting The problem with our rack was pretty obvious, but sometimes potential problems are not so easy to diagnose. Here are some of the more popular questions that Fred gets asked from racers all across the country.

Q: If my servo valve is leaking can I buy a servo seal kit and fix it myself?A: No, if your servo is leaking out the valve, it has to be sent back to the manufacturer to be fixed because it has to be drilled and centered on the dyno machine. If it's not centered, it will turn one way or the other by itself.

Q: What would cause burnt power steering fluid in my steering unit?A: It could be either a bad pump or line causing burnt power steering fluid. Also, check the pulley setup on your pump. If the pump is a 6 inch, the crank should be 2 1/2 to 3 inches.

Q: What if my rack-and-pinion steers easy one way and hard the other way?A: This could mean that your pump does not have enough pressure, or you could have rubber debris in your servo valve, or possibly damage to your cylinder.

Here you can see that clearance is not an issue with the adjustability of the Appleton. Check out the gap between the rack and the radiator shroud.

Here you can see that clearance is not an issue with the adjustability of the Appleton. Check out the gap between the rack and the radiator shroud.

Q: What should I do if my rack-and-pinion feels like it's darting?A: Check the set screw on top of the rack housing to make sure it isn't too loose. Also, check the 9/16 nut on the end of the slave cylinder to make sure it's not too loose. If both of these are OK, it could be a loose drive pin. In that case, you'll need to send your rack back to the manufacturer. To solve that problem, the rack has to be drilled and centered on the dyno machine.

Q: What if my rack turns by itself?A: You'll have to send your rack back to be looked at because your valve holes could be twisted or you could also have debris in your servo valve.

Upkeep Now that we have our new Appleton rack installed, there are three key maintenance procedures we must follow in order to ensure that the rack performs at the highest level.

With the three bolts tightened and all the hoses hooked up, we're ready to head to the track.

With the three bolts tightened and all the hoses hooked up, we're ready to head to the track.

1. Do not use ATF fluid. Period. We'll use good power steering fluid, preferably a clear one because clear power steering fluid will help you diagnosis steering problems. When it gets dirty you can really see foreign matter in it, plus if it's running hot, clear power steering fluid will get dark.

2. Grease the rack-and-pinion every 8-10 races.

3. Inspect the dust boots after every race and make sure that they are not torn, cracked, or hard. Any of those will let debris into the rack and cause unnecessary or premature wear.

Finally, Appleton recommends servicing the rack-and-pinion at least once a year. A normal rebuild is just seal and bushing replacement. If the car is involved in a severe wreck the rack-and-pinion should be sent in for inspection. Most of the time, a rack-and-pinion that has been damaged in a wreck can be repaired for less than a new unit.

CHART A DIRT ASPHALT ROAD RACING Manual or Power Power Power/Manual Power Rack Housing Cast/Billet Cast Cast Shaft Length 18.25-19.75 16.25-18.25 20 and up Ratio 3.4-4.4 2.0-3.0 1.8-3.0 Servo feel XL-Med Light-Heavy XL-Med CHART B MANUAFACTURER SHAFT LENGTH MANUAFACTURER SHAFT LENGTH Lefthander 18.25 GRT 19.25 Rander 18.25 Rocket 18.25/19.75 {{{Pathfinder}}} 18.25 Larry Shaw 18.25 Port City Racing 18.25 Masterbilt 18.25 Hamke 18.25 Rayburn 18.25 Howe 17.25 Swartz 18.50 Goddard/Warrior 18.25 Victory Circle 18.25

CHART B MANUAFACTURER SHAFT LENGTH MANUAFACTURER SHAFT LENGTH Lefthander 18.25 GRT 19.25 Rander 18.25 Rocket 18.25/19.75 {{{Pathfinder}}} 18.25 Larry Shaw 18.25 Port City Racing 18.25 Masterbilt 18.25 Hamke 18.25 Rayburn 18.25 Howe 17.25 Swartz 18.50 Goddard/Warrior 18.25 Victory Circle 18.25

CHART C TORSION BAR DIAMETER ASSIST Extra Light 0.{{{200}}} Most Assist Medium Light 0.225 More Assist Light 0.250 Medium Assist Medium 0.275 Less Assist Heavy 0.{{{300}}} Least Assist

CHART C TORSION BAR DIAMETER ASSIST Extra Light 0.{{{200}}} Most Assist Medium Light 0.225 More Assist Light 0.250 Medium Assist Medium 0.275 Less Assist Heavy 0.{{{300}}} Least Assist