Sprint Car setup technology has become more or less standardized. Even so, there is still much to learn about the finer points of adjusting our cars for optimum performance. Bob Armbruster

Sprint Car setup technology has become more or less standardized. Even so, there is still much to learn about the finer points of adjusting our cars for optimum performance. Bob Armbruster

Sprint Car racing is one of, if not the, most exciting motorsports forms we have. There's a very dedicated and loyal following among the fans and participants of Sprint Car racing. One of our former owners owned and published Open Wheel magazine until it was decided, wisely or not, that it was no longer economically feasible to continue to offer that title. We would like to continue where OW left off and provide tech content in Circle Track. This article is the beginning of many Sprint Car related offerings in the years to come.

Technology for Sprint Cars has not evolved very much over the years. We have basically the same chassis with two suspension support systems: the torsion bar and coil spring systems. The straight axle front suspension is standard, as is the steering. Designs become "standardized" through trial and error and Sprint Car design is what it is because of the need for simplicity and durability. Is this the only system that will work? We don't know, but it would be fun to experiment. And we might do that in the coming issues. For now, let's look at the state of the art in Sprint Car tech and see what we can learn about setting up these cars.

Dirt Sprint Cars have large and wide right rear tires and the resulting large amount of stagger helps make the car turn and provides more bite when exiting the corners. Stagger changes are used to tune the car for changing track conditions. Bob Bolles

Dirt Sprint Cars have large and wide right rear tires and the resulting large amount of stagger helps make the car turn and provides more bite when exiting the corners. Stagger changes are used to tune the car for changing track conditions. Bob Bolles

Sprint Cars are all constructed in a similar fashion. The suspension has a straight axle for both the front and rear, the driver sits in the center of the car, the rear axle is supported inside birdcages, the rear tires are much larger and wider than the fronts, especially the right rear, and the cars are sprung with either a coilover spring/shock combination, torsion bars, or a combination of both.

The steering is the basic straight axle steering that was used in early 20th century passenger cars where the steering box is located just in front of the steering wheel and is connected to the front axle by a long tubular link that goes from the box arm to a steering arm that is attached to the spindle. A tie rod then connects both front spindles. The cars may have wings or not, depending on the particular rules. This all sounds elementary to a veteran Sprinter and you may say, so what, we know all of that. We are pointing out these various design features so we can evaluate them individually later on.

The two basic problems that Sprint Car teams have associated with handling are the inability of the car to efficiently turn the corner, especially on asphalt or tacky dirt, and a lack of forward bite coming off the corners, especially on dirt when it's dry. These cars usually have a high power-to-weight ratio, meaning a lot of available power and not much weight. The wide RR tire helps provide much of the forward bite but can also make the car tight on entry and in the middle of the turn. If we loosen the car to make it turn, we lose forward bite.

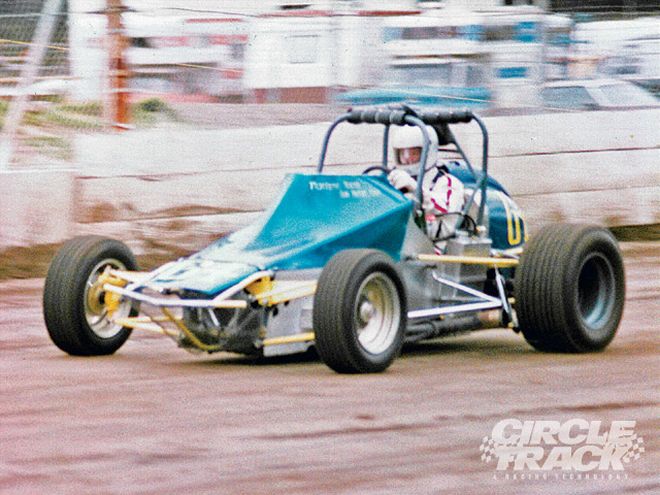

This unique Sprint Car defied tradition. It was custom built by Bill Montagne in 1978 with an independent suspension at the front and rear with torsion bar springs. Do we need for someone to come along now and redefine the Sprint Car, or is the design maxed out? Photo courtesy Bill Montagne

This unique Sprint Car defied tradition. It was custom built by Bill Montagne in 1978 with an independent suspension at the front and rear with torsion bar springs. Do we need for someone to come along now and redefine the Sprint Car, or is the design maxed out? Photo courtesy Bill Montagne

If we use the standard manufacturer's suggested settings for setup, we might not find the true potential for our cars. That is because car builders must publish information that would fit a wide range of tracks and track conditions. If your team runs one particular track every weekend, then you should try to tailor your setup to work for your racetrack.

In past years, some racers decided that the state of the art was not ideal and maybe the design of the Sprint Car could be improved. We never learn anything if we don't try, so in and around 1978, Bill Montagne of California, designed and built his own unique double A-arm front and rear Sprint Car. It had several interesting features.

Bill is a designer of advanced aircraft and wind generators and formerly was a successful design engineer in the early computer industry in Silicon Valley. He had never raced on four wheels before designing and running this car. Here is a summary of the project:

* The car was built to USAC specifications of that era.

Note the inboard push rods linked to the torsion bar arms. This was similar to the IndyCar designs of its day. The real problem would be in repairs after the inevitable hard contact that usually results from close competition. Photo courtesy Bill Montagne

Note the inboard push rods linked to the torsion bar arms. This was similar to the IndyCar designs of its day. The real problem would be in repairs after the inevitable hard contact that usually results from close competition. Photo courtesy Bill Montagne

* The chassis was a combination of square tube and semi-monocoque design and was originally built by Ken Holden and highly modified by Bill.

* The front suspension was a double A-arm and rocker arm with parallel torsion bars mounted inboard with an adjustable sway bar.

* It had a Porsche center-mounted rack-and-pinion steering and the steering shaft went between the fuel injection stacks.

* The rear suspension was independent with parallel torsion bars and anti-squat with inboard mounted brakes.

* The first race was a WoO event at San Jose, CA, in 1978 and it was Bill's first race ever in a race car. The car was also raced at Calistoga, CA.

* When the conditions were right, the car would pull both front wheels off the ground when coming off the corner.

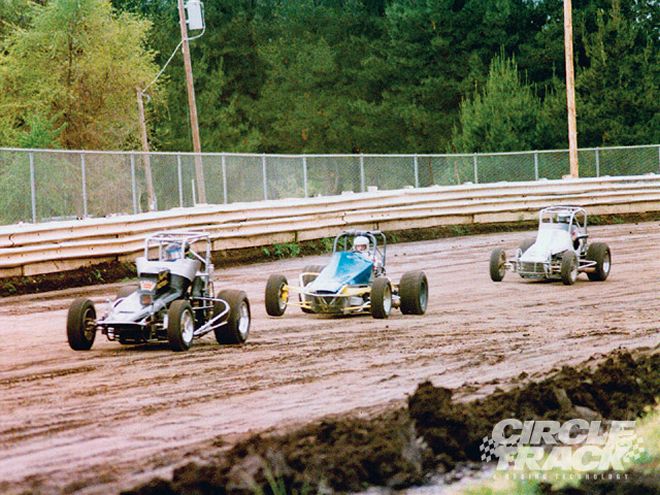

Here we see Bill (blue car) racing and being very competitive with the standard-design Sprint Cars of that era. The car was very compliant and had lots of bite off the corners. He said he could lift both front tires off the track when the conditions were just right. Photo courtesy Bill Montagne

Here we see Bill (blue car) racing and being very competitive with the standard-design Sprint Cars of that era. The car was very compliant and had lots of bite off the corners. He said he could lift both front tires off the track when the conditions were just right. Photo courtesy Bill Montagne

There's a big problem with the steering system on a typical Sprint Car. As the car dives and rolls in the turns, the steering connecting rod pushes or pulls on the steering arm at the spindle causing the wheels to steer when there is no steering input by the driver.

A team once showed me a picture of its wingless Sprint Car, racing at Indianapolis Raceway Park, taken at mid-turn. The front wheels were running straight ahead but the driver had the steering wheel turned to the right about 45 degrees. This may be an extreme example, but maybe not.

This is a hard problem to solve with the current design. Someone needs to put a lot of thought into redesigning the system. If we had our way, the ideal system would not steer at all during body roll. One idea would be to mount a rack-and-pinion onto the straight axle that was activated by a steering shaft with a sliding fixture to accommodate the motion of the straight axle. Any system that would eliminate bump- and roll steer would be a plus.

The wishbone, or parallel trailing arms, on some Sprint Cars are somewhat short. That, combined with a relatively narrow track width, means there could be some significant amount of rear steer as the chassis rolls and moves vertically. The Z-link design with birdcages don't suffer from rear steer as much.

The steering system for Sprint Cars use a steering box located just in front of the steering wheel, and a connecting link that runs from the box's steering arm up to the front spindle steering arm. As the car rolls, the vertical movement of the rear of the connecting link causes the front wheels to steer. Bob Bolles

The steering system for Sprint Cars use a steering box located just in front of the steering wheel, and a connecting link that runs from the box's steering arm up to the front spindle steering arm. As the car rolls, the vertical movement of the rear of the connecting link causes the front wheels to steer. Bob Bolles

If parallel forward mounted arms are used, there will be an arc created when the axle moves. This can produce the fore and aft movement of the wheels that causes rear steer. Ride height changes would seriously affect the rear alignment, too.

On some torsion bar systems, the torsions bar arm is bolted to the birdcage and acts like a trailing link to form a Z-link. These arms are indeed very short and considerable movement of the birdcage occurs as the car rolls and bumps or dives, but the rear axle doesn't move fore and aft to create rear steer.

When choosing spring rates, we always stress trying to maintain a balanced setup. The Sprint Car has a different set of suspension systems than a stock car. Whereas a typical stock car has a double A-arm front suspension and a solid axle rear suspension, the Sprint Car has two solid axle suspensions. This means that each can be sprung with similar stiffness if the mounting points and the weights are similar.

The rear axle is located fore and aft by both a forward link and also a connection to the torsion bar arm at the birdcage. This Z-link arrangement, if properly designed, can help keep the rear from rear-steering during bump and roll. Larrie Ervin

The rear axle is located fore and aft by both a forward link and also a connection to the torsion bar arm at the birdcage. This Z-link arrangement, if properly designed, can help keep the rear from rear-steering during bump and roll. Larrie Ervin

In reality, there are small differences in the spring mounting points as well as the heights of the panhard bars or other lateral location devices. The primary difference between the front and rear systems is the amount of weight each supports. This is important in planning out how we should spring our cars.

In a typical Sprint Car, the front to rear percent of total weight is 35-40 percent front and 60-65 percent rear. With more weight supported by the rear suspension, we would imagine the spring stiffness would be greater at the rear. Traditionally, all Sprint Car teams install either similar rate or stiffer springs at the front than the rear. Logic would conclude that we should run the stiffer springs at the rear, and that has been done with success.

This reverse "theory," as such, has been evaluated and some Sprint Cars have been setup whereas the rear springs were stiffer than the front springs. The cars setup this way had very good results.

Here, we can see the connection of the end of the torsion bar arm to the bottom of the birdcage at the end of the axle tube. The torsion bar provides both spring rate and fore/aft location control of the axle. Bob Bolles

Here, we can see the connection of the end of the torsion bar arm to the bottom of the birdcage at the end of the axle tube. The torsion bar provides both spring rate and fore/aft location control of the axle. Bob Bolles

Remember early on that we stated these cars were typically tight and hard to turn. If the rear is sprung too lightly for the load it carries, then excess load transfer will occur at the front and the left front tire will have much less loading on it at mid-turn. In a worse case scenario, the car will carry the LF off the track surface. A three wheel car will not turn as well as a four wheel car.

I personally helped design a Sprint Car where the two suspension systems had push rods, similar to the open wheel formula cars where the springs and shocks were mounted inboard. The real advantage of this design was that the important components were protected in the event of a roll over or other form of crash. The push rods were simple and easy to make and could be replaced in minutes if need be.

This car was sprung stiffer in the rear. It won its very first and only race it ran. It was banned from competition from then on. The point here is that different designs can work. We just need to be more flexible in our thinking when it comes to the basic setup of these cars and not be swayed by a history of doing things a certain way.

The front straight axle is located fore and aft by parallel radius rods. This helps to maintain caster in the axle while the car is rolling and moving vertically. Note that the torsion bar arm is resting on top of the axle tube. The shocks limit the amount the axle can rebound. Bob Bolles

The front straight axle is located fore and aft by parallel radius rods. This helps to maintain caster in the axle while the car is rolling and moving vertically. Note that the torsion bar arm is resting on top of the axle tube. The shocks limit the amount the axle can rebound. Bob Bolles

Most Sprint Car teams don't scale their cars. Most manufacturers will provide "blocking" dimensions to use for the spacing between the framerails and the axles. These are set distances to be used with suggested spring rates so that the wheel weights will be "right" for the intended use. But this setup system leaves a lot to be desired.

Some teams will scale the car to use as a baseline, especially when the car runs well. Then they will try to repeat those wheel weights in the future. No matter which way you set up the weighing of your car, certain processes must be used to ensure consistency and accuracy.

The car should be blocked back at the shop on a flat concrete surface. Ideally, you would find four spots that are the same elevation to roll the four tires onto. As per the manufacturer's instructions, set the car on jackstands and block under the axles with predetermined height blocks. Set the adjusting bolts so that the torsion arms are neutral. This is a baseline you can use at the track to re-establish your weights, but that's not all you need to do.

This Mini Sprint Car uses a coilover front suspension. This system is not as popular with the full-sized Sprint Cars. Space may be a factor in the choice. Bob Bolles

This Mini Sprint Car uses a coilover front suspension. This system is not as popular with the full-sized Sprint Cars. Space may be a factor in the choice. Bob Bolles

Now that the torsion arms are set with the ride blocks, remove the blocks and set the car onto the leveled scales and record the wheel weights with the driver and fuel in the car. Record the tire sizes that result in those weights. If different tires are used later on, the wheel weights will change.

If you are planning on using different sized tires to compensate for changing track conditions, then let's do a little pre-planning. Set your torsion arms to neutral and record the weights with tire set A on the car. Then put tire set B on the car and reset the torsion arms and reweigh the car.

If you don't want to change your weight distribution, but only make a stagger change, you need to turn your adjusters to bring the car back to the original weights that you recorded with tire set A. Also, record the number of turns you made to the adjusters so you can recreate the adjustments at the track when you change tire sizes.

This Mini Sprinter uses torsion bars for the springs. Each system, coil and torsion, can be adjusted to provide a dynamic balance between the front and rear suspensions. Bob Bolles

This Mini Sprinter uses torsion bars for the springs. Each system, coil and torsion, can be adjusted to provide a dynamic balance between the front and rear suspensions. Bob Bolles

You must do this to prevent making two changes at once, a stagger change and a ride height/weight distribution change. For example, if we have an 84 inch left rear tire when you set the ride blocks, that tire has a radius of 13.37 inches. If we change to a 94 inch LR tire that has a radius of 14.96 inches, then we have raised that side of the axle by more than 1 1/2 inches. That would increase the RF to LR weight percentage considerably.

If a dual change is desired, then OK. But we need to realize just how much of a change is being made. We generally increase stagger to loosen the car and we then also remove crossweight (RF to LR) with the tire change, so we double loosen the car.

The handling balance for a Sprint Car needs to be a dynamic balance just as in a stock car. All four tires need to be in contact with the racing surface and have the most load ending up on them as possible. If we have a truly balanced setup, the LF tire will carry a decent load and the car will turn better.

This adjuster for ride height on a torsion bar system is located at the opposite end of the bar from the arm. Here, we see the adjuster for the left rear chassis height. Changes to the ride height also are changes to the weight distribution. Bob Bolles

This adjuster for ride height on a torsion bar system is located at the opposite end of the bar from the arm. Here, we see the adjuster for the left rear chassis height. Changes to the ride height also are changes to the weight distribution. Bob Bolles

For a winged Sprint Car, it would make sense that our spring rates, side to side, would be the same. Spring split on a solid axle suspension has a dramatic affect on roll tendencies. Since the cars roll first to the right on entry and then left at mid-turn due to the aero forces on the wing, we need to have the same roll stiffness in both directions. If a stiffer RR spring (over the LR spring) promotes roll stiffness in a roll to the right, then the reverse would be true for a roll to the left.

Our handling can be much different from corner entry to mid-turn if we run different rate springs on each side for winged Sprint Cars. The Panhard bar height, or Watt's link moment center height, must also be tuned to the spring stiffness as well as the spring base. The idea is to develop a setup for your Sprint Car that has the same roll characteristics for the front and rear of the chassis so that the handling balance is equal all of the way through the turns. Again, this has been tried and proven to work.

The setups for the winged Sprint Cars vs. wingless Sprint Cars is necessarily much different due to the high amount of downforce produced by the wings. The spring stiffness must be more for the winged cars, especially on asphalt. The speeds are much greater when Sprint Cars are racing on asphalt with wings attached.

Large wings with large rectangular side panels help produce a lot of downforce as well as lateral force for the winged Sprint Cars. These dirt Sprint Cars have two wings, one smaller at the front and the big one over the driver with its added load more centered on the wheel base. At the '08 Winter Nationals at Volusia Raceway Park, the 410 sprinters qualified at more than 130 mph average speeds. Bob Armbruster

Large wings with large rectangular side panels help produce a lot of downforce as well as lateral force for the winged Sprint Cars. These dirt Sprint Cars have two wings, one smaller at the front and the big one over the driver with its added load more centered on the wheel base. At the '08 Winter Nationals at Volusia Raceway Park, the 410 sprinters qualified at more than 130 mph average speeds. Bob Armbruster

More loading means more traction and the lateral g forces go up considerably with the increased speed through the turns. This necessitates a higher overall spring stiffness and in some cases, a spring split with the right side springs being more rate than the left sides.

Here too, we see a definite need for chassis setup balance. We really want all four tires to carry maximum load. At the LF, we need for that tire to carry load to help the car to turn. Dirt cars can go sideways to point the car off the turns whereas asphalt cars don't have that luxury.

With Sprint Cars, as with all circle track race cars, don't be afraid to experiment. Use the manufacturer's baseline to start with and then branch out and try different setup parameters. When something works, keep it. When something doesn't work, note it and don't try it again. Racing technology has evolved since the early days and we don't want to stop that process now.

Everything that will make you faster has not been discovered. That's one of the things that make racing so much fun. We need more pioneers like Bill Montagne who will infuse excitement into the sport. I see no reason why we can't experiment with the car's designs so long as it's safe to do