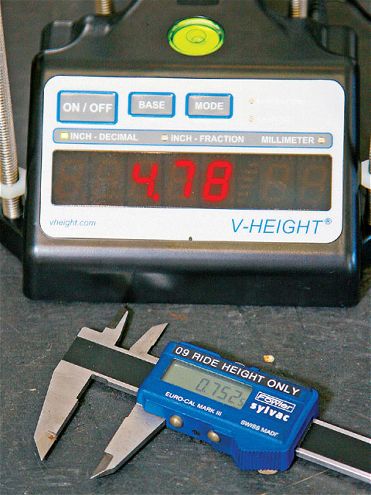

The V-Height device is an easy and accurate way to measure ride height, offering a digital readout similar to a digital caliper.

The V-Height device is an easy and accurate way to measure ride height, offering a digital readout similar to a digital caliper.

The V-Height device was designed for one purpose-accurately and visibly measuring vertical distances underneath hard-to-reach places such as automobile chassis, machine fixtures, molded parts, or any other overhanging features. With a range from 0.75 inch to10 inches, this device provides the stroke needed to reach a wide range of measured surfaces. The numeric output can be toggled between units of inch decimal, inch fraction (1/16 incremental) and millimeter. The display is tilted upward at a 55 degree angle so it may be easily read by a viewer standing upright. In addition, the display is brightly lit for easy viewing in bright or dim areas.

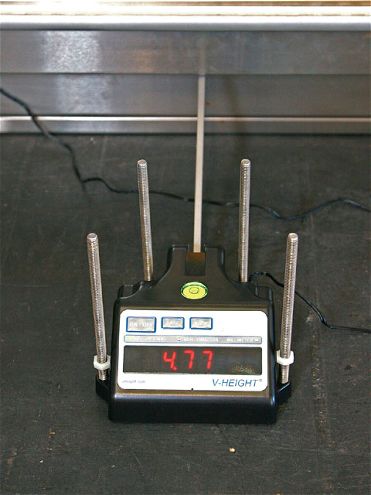

V-Height devices are provided with four stilts. These are used in instances where the measured object is raised above ground. A prime example is a racecar on four scales. With each tire on a 3-inch-thick scale for example, measurements from the chassis to ground level are offset by 3 inches. By setting the V-Height flat on a scale surface and adjusting the stilts to touch the ground, the measurement output will be just as if the car was on the ground. This allows the user to simultaneously weigh each wheel of the car and measure the frame stance. Stilts can translate the measurement ground plane up to 6 inches above the original ground plane.

It is common in auto racing to attain measurements under the chassis, and in the case of cars like those competing in NASCAR events, at each corner of the chassis. Frame rail corner heights are important because they are controlled by rules and also affect the handling of the car. Using under-tire scales to read corner weights, the chassis is raised or lowered at each corner to strike the correct balance of both height and weight.

Most commonly, the height measurements are made with a measuring tape. Using this method, the user may experience awkward body positioning, eye strain from reading tape marks in dimly-lit areas, and the prospect of circling all four corners of the car several times until the proper height is reached on all four corners of the chassis. In addition to this, time is also wasted by factoring fractional tape measure marks to the least common fractional denominator.

Measurements made using the V-Height eliminate error caused by tape mark interpretation and factoring. In addition, measurements are more repeatable and can be made more comfortably. Racecar chassis setup is merely one use for this device. There are many other uses for this concept outside of the realm of the automobile. This apparatus is useful for any application that requires finding the normal distance between a plane and a point.

We tested a V-Height device at the race shop. First you must lower the measuring arm and set the base measurement of 0.75-inch. Then release the arm and let it touch the bottom of the frame or part to be measured. We used the bench top, probably more level than your garage floor, and it gave us measurements of plus or minus 0.05-inch. In reality, this unit would be most accurate when used on a surface plate, but in most situations using a nominally level surface, you can get results with an accuracy error of less than 1/16-inch. Try getting that close with a bent tape measure.

Here we take a measurement up to the bottom of a tool box drawer in the shop. The four stilts shown sticking up are used to space the unit up to a height that might represent the height of your scales or other offsets from the floor. This provides compensation so that you can read the heights as if the tires were on the ground.