The idea for changing the rear suspension on a muscle Mopar came to mind while walking the Manufacturers' Midway at the '07 Mopar Nationals. There we noticed a triangulated four-link rear suspension system-originally designed to fit an A-Body Mopar-at RMS Suspension's booth that really caught our eye. After talking to RMS Suspension's Bill Reilly about the system, we decided we needed to take a closer look at this cool setup.

We came back from the Mopar Nationals very excited about the idea of doing something cool and different. We were also curious to see how well the A-Body system would fit.

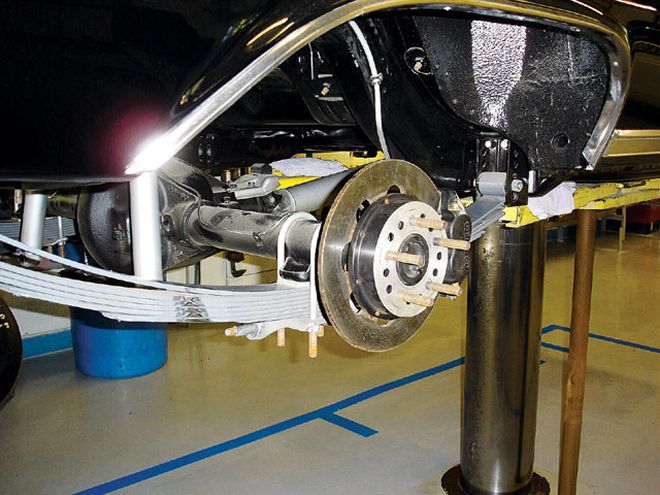

Here is the fully assembled factory style rear suspension with SS springs and MP 50-50 four-speed drag shocks. While it works at the track and on the street, there is something better.

Here is the fully assembled factory style rear suspension with SS springs and MP 50-50 four-speed drag shocks. While it works at the track and on the street, there is something better.

The problem we did encounter at the time of planning was that there was no system offered for the B-Body we planned to work on. In our discussion with Bill, he agreed to send us an entire A-Body system to see if we could make it work in our '67 B-Body-with minimal altering of the components.

After Bill sent the A-Body kit, we dug into it to see if it would actually work on our '67 B-Body in its unaltered form. Surprise, no go. We contacted Bill and showed him pictures of how it wasn't going to work. At this point, he thanked us and told us to keep the hardware for our time and effort put forth.

Now, since we had some hardware to play with, we were destined to design our own triangulated system for this B-Body. We started off by finding exactly where we wanted the rear axle to be located in the car. We chose a location that set the rear axle back about 3/4 inch and slightly higher in order to lower the car. We did this to make room for taller tires and to give the car a more aggressive stance. Now with the rear axle in the desired ride height position, we used the adjustable lower bars from Bill's kit and made adjustable brackets that attached the lower link bar to the body of the car where the original leaf-spring hangers would have mounted.

To get started, we removed the rear wheels. This isn't your typical restored Mopar, and we'll be able to test the link system thoroughly.

To get started, we removed the rear wheels. This isn't your typical restored Mopar, and we'll be able to test the link system thoroughly.

The next step was to create a structure that would attach to the framerails. We wanted this structure to be strong, and we also wanted to be able to mount everything to it except the lower four-link bars, which would mount to the chassis and to the axle. So with the help of coworker, Ron Linton, we came up with the required brackets and mounting points needed.

We started by cutting out the car's original crossmember. With that gone and everything ground smooth, we now had the desired space needed to make the structure. We wanted the structure to have secure mounting locations where it would attach to the framerails of the car. There are actually two crossmembers in this structure: a front and a rear. These two crossmembers are connected by two chrome-moly bars that are welded between them. This new boxed structure with two crossmembers is what gives us the four mounting points. This is necessary for high-horsepower applications. Since the upper link bars attach to the chassis of the car at the structure, a great torsional twist is applied to it due to the force from pinion rise during launch and under acceleration through those upper four-link bars. Because of this torsional force, it was necessary to spread that energy over a greater area of the chassis-the reason for the four mounting points.

Designing the structure this way also allows us to use the rear crossmember to mount the rear coilovers to the chassis. This is a very strong point for the weight of the car to be supported. We now have a one-piece weld-in structure that the suspension mounts to. The beauty of this system is there is minimal altering to the car. The factory sheetmetal crossmember needs to be cut out, a little paint needs to be ground off for welding, and the four mounting points need to be welded on the inside of the framerails-that is the extent of the alterations to the car.

We wanted the car to work well on the dragstrip and have great road manners, and it does. The car seems to be smooth under launching and acceleration. There is no snap or wind up of the suspension during launch. It has a firm positive feel on the road. In addition to the many benefits this system has over the stock leaf-spring suspension, the entire system is also 50 pounds lighter than the stock-style suspension using super-stock leaf springs.