The complete M2 package is shown at the 2005 PRI show in Orlando, Florida. The M2 shock offers a substantial number of unique design features and uses virtually no parts common to its predecessor, the M1.

The complete M2 package is shown at the 2005 PRI show in Orlando, Florida. The M2 shock offers a substantial number of unique design features and uses virtually no parts common to its predecessor, the M1.

We decided to quiz some top shock makers about their new products for 2006. We were surprised to learn that none of them were sitting on their past successes and have been busy designing and producing new and exciting products for this racing season.

With all the advancements teams have been making with setups over the past few years, shocks are the next area of increased performance. Not only are the selections getting larger, but also refinements to the products are making shocks more tuneable for more of the market. Let's take a look at what is available as we let the companies speak for themselves.

AFCO's latest and greatest shock is a gas pressure monotube shock dubbed the "M2." The M2 is the company's second offering of a monotube gas pressure design. However, when compared to the previous M1, the new M2 is a revolution more than it is an evolution. The engineers started with a clean slate on this shock.

The M2 provides the advantages of a gas pressure design while at the same time offering many capabilities of a twin-tube shock. The central components AFCO has incorporated to achieve this goal are a gas pressure bladder and a base valve.

The AFCO bladder design, as opposed to a floating piston design, gives the damping authority back to the shock piston, where it belongs. At extremely low gas pressures, this shock continues to work without cavitation and operates very much like a twin-tube shock with no added rod pressure.

The 360-degree rotating high-flow fitting on the M2 allows for infinite mounting angles and placement.

The 360-degree rotating high-flow fitting on the M2 allows for infinite mounting angles and placement.

The use of a bladder in the AFCO M2 shock reduces the amount of moving parts and friction. As the shaft and piston move, the M2 bladder can instantly react by simply flexing and changing shape. This allows the M2 shock to be hypersensitive to high-frequency movements.

AFCO uses low-friction seals and bearings that are designed to work together. Attention was also paid to improving fluid dynamics in components such as the piston orifices and the connection to the canister. These efforts resulted in a piston design with unique port configurations and custom manufactured high-flow fittings, which also feature 360-degree rotation for easy mounting.

The piston also features an energized O-ring seal that uses the fluid pressure in the shock to continually adjust the sealing force of the piston against the shock bore wall. This lets the shaft move freely, especially at low speeds, and still provides a tight seal when pressures increase at high shaft speeds.

The M2 has a double adjustable design, which means there are adjusters for compression and rebound control. The M2 has 40 clicks of rebound adjustment and 24 clicks of compression adjustment. The spring-loaded adjuster knobs are 100 percent sealed from the elements.

Bilstein's new ABS Series shock.

Bilstein's new ABS Series shock.

The M2 uses an internal valve to isolate the compression and rebound adjustments, so changing one side does not affect the other. The adjustments provide increased levels of control in the critical low-speed and transitional areas of the damping curve, or the nose end of the equation.

For 2006, Bilstein is introducing a new ultra-lightweight shock for the Sprint Car and Midget market, as well as new high-tech products for dirt and asphalt Late Models.

The new aluminum ASB Series shock weighs only 2 pounds. The gas fill valve has been recessed to keep it out of harm's way and a threaded rod guide was built for rapid repair and revalves. The biggest advantage provided to the Sprint or Midget racer is Bilstein's famous non-fade performance and proven reliability in an ultra-lightweight shock.

The linear or digressive valve stack possibilities with this shock are nearly infinite, and due to the small-diameter piston rod and low-seal drag, rod pressure can be run as low as 12 pounds. The ASB is available in a take-apart threaded version in 6-, 7-, and 8-inch strokes. A sealed, smooth, 7-inch stroke body version will be available later this spring for torsion-front Sprint Cars. Valve kits, nitrogen gauges, and coilover kits are also available.

The large-body BG shock may become very popular in the modified and dirt Late Model series.

The large-body BG shock may become very popular in the modified and dirt Late Model series.

The new BG Series for asphalt Late Models features an aluminum 46mm threaded body topped by a whopping 60mm gas chamber. Reduced seal friction, along with the huge nitrogen compartment and a base valve, results in rod pressures as low as 6 pounds while the oil maintains perfect stability.

That means maximum traction with no shock fade from the first lap to the last. The BG will initially be available only in a 7-inch stroke version. However, when the new BG shock was displayed at the PRI Trade Show in December, there was a lot of interest from the big-block modified and dirt Late Model markets as well. So plans are in the works for an 8-inch and 9-inch stroke model.

Bilstein is really excited about its new adjustable components for the existing SN and ASN Series take-apart shocks. The company will introduce its rebound adjustable shaft and compression adjustable canister in the late spring. When designing the new components, Bilstein gave the racer adjustments between clicks that really matter.

The LMJ Series has been popular in the dirt Late Model series.

The LMJ Series has been popular in the dirt Late Model series.

Compression side adjustments are handled through the canister. Additional advantages to the canister include an increase in the size of the gas chamber as well as the room provided for a base valve. Both features result in consistent non-fade performance while lowering rod pressures to the 10-12 pound range. Bilstein will offer shocks that are rebound adjustable only or double adjustable, and will retro-fit the customer's SN or ASN Series shocks with either or both of the new components.

Ohlins Racing Shocks announces a new affordably priced shock absorber. When rules dictate a $200 or less retail price for shock absorbers, hlins USA has the answer-the new CCJ shock absorber.

The all-new CCJ shock utilizes the same 46mm main piston diameter as the Nextel Cup winning WCJ. The CCJ overall design is based on proven performance.

hlins' new CCJ shock designed for the short-track market.

hlins' new CCJ shock designed for the short-track market.

The CCJ also uses a 14mm shaft diameter versus the more common 16mm shaft that is found in most Ohlins shock absorbers. This provides better balance between shaft displacement and gas reservoir volume available in the main body tube. The CCJ is delivered as a complete-emulsion, steel-bodied shock absorber with no external adjustments.

Racers can add their own shim stack selection, oil, or optional gas-separating piston to suit their applications. By adding the optional gas-separating piston, the CCJ becomes a full DeCarbon principle monotube shock. Coilover spring mounting hardware is also easily added to the threaded body for coilover applications. All optional pistons in the hlins 46mm range will work with the CCJ, providing a wide range of tuning options.

QA1's new line of high misalignment rod ends are now available, allowing even more misalignment than traditional spacers. Available exclusively by QA1, these rod ends offer up to 65 degrees of misalignment and feature a black-oxide, heat-treated chrome-moly steel body, a high misalignment 52100 bearing steel ball, and a self-lubricating Teflon liner.

QA1's new line of high misalignment rod ends are now available, allowing even more misalignment than traditional spacers. Available exclusively by QA1, these rod ends offer up to 65 degrees of misalignment and feature a black-oxide, heat-treated chrome-moly steel body, a high misalignment 52100 bearing steel ball, and a self-lubricating Teflon liner.

The LMJ Series remains virtually unchanged for 2006, with the exception of a jam nut under the spring collar to allow for more positive locking of the spring collar. The LMJ remains the only top-level shock absorber available off-the-shelf that is prevalved for dirt Late Model applications.

The LMJ Series shocks are two-way adjustable, with a remote reservoir giving the racer the ability to adjust the rebound and compression strokes without removing the shock from the car. Approximately 20 clicks are available for compression-damping adjustment, and 35 clicks are available for rebound-damping adjustment.

LMJ Series shocks also use the same piston and shaft diameter as its Nextel Cup brother, the WCJ Series, which means there is a vast array of optional pistons, shaft jets, adjustment needles, and jets available for the advanced shock tuner. Look for an optional two-way compression adjuster kit, additional piston recommendations, and more optional tuning parts in the summer of 2006.

Other Ohlins shocks for oval track racing include the WCJ Series for non-coilover application, the MCJ for non-remote reservoir coilover applications, and the more economical STJ Series, which is available in adjustable and non-adjustable versions. All Ohlins shock absorbers are owner-rebuilt and tuneable with shim kits and tools available from any Ohlins dealer.

QA1 introduces its enhanced premium line of large-body twin-tube shocks. Available in aluminum smooth-body (60 and 65 Series), aluminum threaded-body (62 and 67 Series), and steel smooth-body (50 and 57 Series) configurations, each of these shocks is racer revalveable and rebuildable. Deflective disc valving is incorporated into each shock, along with CNC precision-machined aluminum pistons and base valves.

The premium piston incorporates dual bleed circuits for standard or custom valvings, including extreme-split valvings. Tunable to standard or custom valvings, the premium aluminum base valve also adds to the superiority of these shocks.

The 65, 67, and 57 Series maintain the legendary Carrera Racing Shocks curves, providing softer low-speed valving for faster weight transfer and increased traction. The 60, 62, and 50 Series provide stiffer low-speed valving for greater suspension control over rough or very fast track surfaces. These shocks provide consistent, fade-free performance with no valving overlap and are made in the U.S.A., individually dyno tested, and serialized.

QA1 provides rod ends to motorsports, with over 5,000 part numbers in stock and ready to ship. Also available from QA1 are spherical bearings, springs, coilover kits, and other suspension components.

QA1 Motorsports is proud to introduce its new patent-pending steel gas-pressurized monotube shock absorbers. These shocks feature a 46mm piston and are available in non-adjustable (21 Series) and rebound adjustable (24 Series) styles. Both series have deflective disc valving and are racer revalveable and rebuildable.

Advanced ring shim technology allows preload adjustments of the valve stack to be made easily and precisely, resulting in a huge selection of valve curves. The unique two-piece body design allows for quick and inexpensive repair of damaged bodies and bent piston rods. The 21 and 24 Series shocks are available with the option of a base valve to significantly reduce rod force.

The 24 Series has infinite rebound adjustment, affecting the weight transfer characteristics of the car going into and coming out of corners but not affecting the ability of the tire to follow the track at high speeds. The adjustment primarily affects low-speed rebound, and this effect decreases as the piston speed increases.

For IMCA drivers, QA1 offers the 21A Series steel monotube shocks. These shocks feature the same technology as the 21 Series of non-adjustable steel monotube shocks; however, to comply with IMCA rules, they are revalveable and rebuildable only by QA1 Authorized Service Centers.

QA1 monotube gas shocks are made in the U.S.A., individually dyno tested, and serialized.

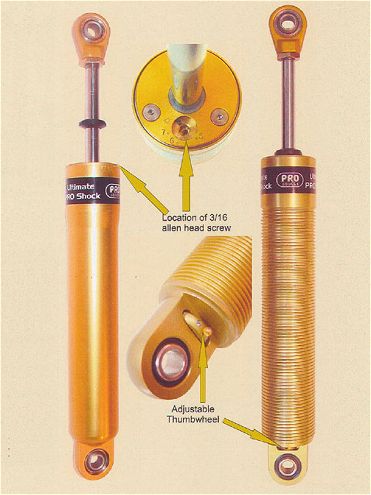

The Double Adjustable A and AC shock uses the patented rebound system of the Rebound Adjustable Pro Shock. Compression is adjusted by turning the thumb wheel. From the "3" valve position to the "7" valve position, you can stop at any degree of adjustment between numbers. The adjustment is infinite. This patented valving system produces the same quality acceleration curves as the proven regular Pro Shock valvings.

The Double Adjustable A and AC shock uses the patented rebound system of the Rebound Adjustable Pro Shock. Compression is adjusted by turning the thumb wheel. From the "3" valve position to the "7" valve position, you can stop at any degree of adjustment between numbers. The adjustment is infinite. This patented valving system produces the same quality acceleration curves as the proven regular Pro Shock valvings.

Pro offers its Patented Adjustable Pro Shock, which is adjustable in four different stages: a) low-speed bleed, b) the rate of seat pressure to blow-off valve, c) rate of spring operating valve, and d) high-speed jet.

The Pro Shock adjustable shock easily adjusts all four stages to create an acceleration curve to match all normal valvings. Pro Shock Adjustables are infinitely adjustable. You can adjust and stop at any desired amount of damping. Put the shock on the dyno and set the exact poundage you are looking for while you dyno. It's just that easy.

The Rebound Adjustable A and AC come in 5-, 6-, 7-, 8-, and 9-inch stroke lengths in large-body shocks. You decide the compression dampening you need to use and then change the rebound dampening by turning an Allen screw. This screw is infinitely adjustable, so you can stop the index pin at any point between the numbers on the plate.

The all-new 46mm Pro Gas high-pressure steel monotube gas shock is available for 2006. This new shock is available in two stroke lengths (7-inch and 9-inch) and 7 popular valvings (3, 4, 5, 6, 3/5, 4/6, and 5/3). The Pro Gas uses a high floating piston to avoid dumping and cavitation and separates the gas and fluid.

The Pro Gas variable pressure Canister shock is unique in that it is the only shock that can be run with high gas pressure as well as any amount of low pressure (down to zero gas pressure). The Pro Gas Canister shock continues to function at 100 percent dampening.