It is said that the leaf-spring suspension is the oldest suspension used for automobiles. The leaf-spring system was used more recently in '70s production cars, some of which are still in service today as race cars. Many racers even prefer to utilize the leaf-spring rear suspension design in their fabricated Late Model Stock and Modified race cars.

Like all other racing components, there is a science and methodology to the use of leaf springs in stock cars, for both dirt and asphalt. The construction of the car may depend on the type of leaf spring to be used and where it will be raced.

A leaf-sprung car can be made to perform much like the three- orfour-bar cars if properly constructed and set up. Note that the rear endis driving straight ahead.

A leaf-sprung car can be made to perform much like the three- orfour-bar cars if properly constructed and set up. Note that the rear endis driving straight ahead.

There are four basic designs of leaf springs that are used in stock car racing:

1. The monoleaf spring is a low-rate, thinner spring that serves to locate the rear end laterally, like a Panhard bar, but offers little spring rate to hold the car up nor much stiffness to bending to help control axle wrap-up. The design of the car must include additional springs to support the car and a system for controlling accelerating and decelerating forces that will try to rotate the rear end.

2. Multileaf springs are just as described, made up of multiple leafs of diminishing length. These tend to be increasing rate springs and are useful for supporting the car as well as controlling axle wrap-up.

3. Parabolic leaf springs can be a single-leaf or multileaf design whereas the leaves are thicker near the axle and have a tapered thickness design out to the eyes. These, too, support the weight of the car without the need for extra springs and do a fair job of controlling axle rotation under acceleration and braking. They can provide a much smoother ride due to the fact that the leaves do not develop the friction associated with standard multileaf designs.

4. Composites are fairly new in racing and have been further refined recently. These leaves come in various rates and, with the lower rates, will need additional springs to support the weight of the car.

The monoleaf spring has just one leaf and can be either a singlelow-rate spring or a parabolic leaf design, where the spring is thickerand higher rated.

The monoleaf spring has just one leaf and can be either a singlelow-rate spring or a parabolic leaf design, where the spring is thickerand higher rated.

The multileaf spring has several springs of different lengths andthicknesses. The multileaf spring is rated higher than the monoleaf andis the most common leaf spring used for stock car racing.

The multileaf spring has several springs of different lengths andthicknesses. The multileaf spring is rated higher than the monoleaf andis the most common leaf spring used for stock car racing.

Advantages to Using Leaf Springs

From the information we have gathered from several excellent sources, leaf-spring suspensions are very forgiving on tacky and rough dirt surfaces. The leaf cars seem to be a lot more consistent under those conditions.

The leaf performs several functions that other suspension systems might need additional hardware to serve. The leaf does the following:

1. Supports the chassis weight

2. Controls chassis roll more efficiently--high rear moment center and wide spring base.

3. Controls rear end wrap-up

4. Controls axle damping

5. Controls lateral forces much the same way a Panhard bar does.

6. Controls braking forces

7. Regulates wheelbase lengths (rear steer) under acceleration and braking.

As the car rolls, the leaf spring bends and the two ends get fartherapart. Because the front eye is bolted to the frame and the rear eye isattached to a free moving shackle, the rear axle will move rearwardunder bump. This is attractive on tight dirt racetracks. As the moisturein the track dries up and the track slows down, there is less g-forcerolling the car with less movement of the spring, so there is less rearsteer.

As the car rolls, the leaf spring bends and the two ends get fartherapart. Because the front eye is bolted to the frame and the rear eye isattached to a free moving shackle, the rear axle will move rearwardunder bump. This is attractive on tight dirt racetracks. As the moisturein the track dries up and the track slows down, there is less g-forcerolling the car with less movement of the spring, so there is less rearsteer.

The proper way to determine the moment center height for a leaf-springsystem is to measure the height of the two eyes from the ground, addthem, and divide by 2. This method has been proven to be true andaccurate through the use of dynamic simulation software.

The proper way to determine the moment center height for a leaf-springsystem is to measure the height of the two eyes from the ground, addthem, and divide by 2. This method has been proven to be true andaccurate through the use of dynamic simulation software.

The reason the leaf-spring design is so good for higher g-force conditions is the design has a very wide spring base. The wider apart the springs are mounted, the fewer roll tendencies there are. Also, the moment center height can be fairly high with a leaf-spring design. This shortens the moment arm in the rear, producing less roll.

There is much less rear steer when going over heavy bumps or holes in the track, so the rough conditions that upset a bar car is welcomed byte leaf-spring car.

The overall cost of a race car is less when using leaf springs mostly because you don't need many of the mounts, linkages, and other hardware that must be used with three- or four-link rear suspensions.

Also, a leaf spring can be used in conjunction with a coil or coilover spring to enhance the spring rate adjustability function for chassis setup balance. Teams will often put a high-rate leaf spring on the left rear and a low-rate monoleaf spring on the right rear along with a coilover spring and shock. They can change the spring fairly easily on the right rear to adjust for changing track conditions. The left-rear spring also controls most of the axle wrap-up and is about half as stiff in that regard, as two stiff leaf springs would be.

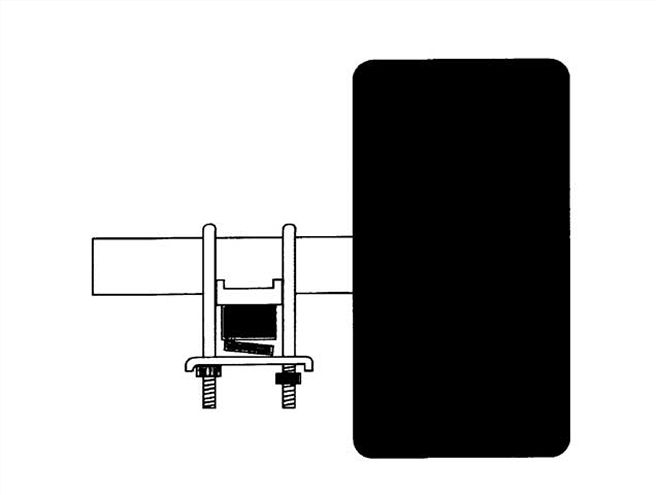

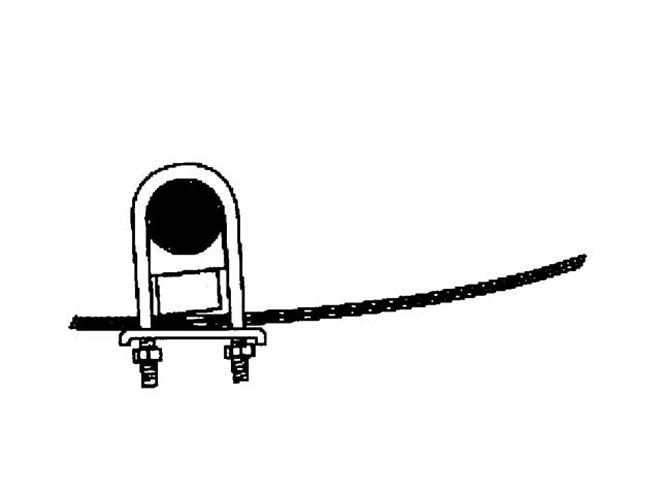

The installation of the leaf spring must be done with care to avoidbinding of the springs. Note the angle of the spring pad to the springfrom a side view before tightening both sides...

The installation of the leaf spring must be done with care to avoidbinding of the springs. Note the angle of the spring pad to the springfrom a side view before tightening both sides...

Disadvantages of the Leaf Spring

The leaf-spring system has some definite disadvantages when compared toe three- or four-link system. Although the typical bar-link type of system does not handle tight, tacky, and rough dirt conditions, the money race is usually run once the track has become slick. So at the end of the night, more times than not, the suspension that favors a slick track will win out.

The steel leaf springs tend to lose shape, and that means the car loses ride height. If the "sag" is uneven between the two springs, it can alter the amount of bite, wedge, or cross weight in the car, changing the handling. Some teams go through three or more sets of springs preseason. Spring sag also changes the rear-steer characteristics of the car.

There is very little, if any, adjustment for rear-steer characteristics with a leaf-spring system. Some builders will put several mounting holes at the front bracket and some only put one hole, keeping with the theory that less adjustment means less rope with which to hang yourself, stepwise.

With the bar cars, the teams have a choice of adding lift bars, pullbars, pushrods, front- or rear-spring mounting options, a wide range of rear-steer adjustability, and variable moment center height adjustments. For the leaf-spring cars, there is a monoleaf floater that can be clamped or open. This allows for a lift arm or pull bar to be added tithe leaf system.

The rear moment center height is not easily adjustable on leaf-spring systems, and the right-rear bite effect of angling the Panhard bar toward the right-rear tire contact patch cannot be done with the leaf-spring system.

Leaf springs are not easy to properly install. The pinion angle is not easily adjustable. The mounting pad on the rear axle tube must either be repositioned to adjust for pinion angle, or wedge-shaped blocks must bemused between the spring and the housing pad. There is no adjustment forth amount of axle wrap-up damping, either. You get what the spring gives you.

The use of rubber or other compliant material as bushings in the spring eyes will help cushion acceleration and braking forces, but overall, compared to the pull-bar and lift-bar systems used with the three-link and four-link system, there isn't much in the way of damping or adjustment for what is there.

...Also observe therelationship from a front or rear view and make adjustments to thespring chassis mounts accordingly.

...Also observe therelationship from a front or rear view and make adjustments to thespring chassis mounts accordingly.

Proper Installation

We must be careful to make sure the leaf spring is not inadvertently bent or bound up when we bolt it into the car. Longitudinal twisting(looking forward or rearward) can add spring rate to the leaf.

If the spring pads on the rearend axle tubes are not parallel from aside view, then when we bolt them up, the springs on each side will be bound in opposite directions. It is best to bolt up one side and then check the other side to see if the pad is flat to the spring. If not, angled spacers must be used to relieve any bending tendencies.

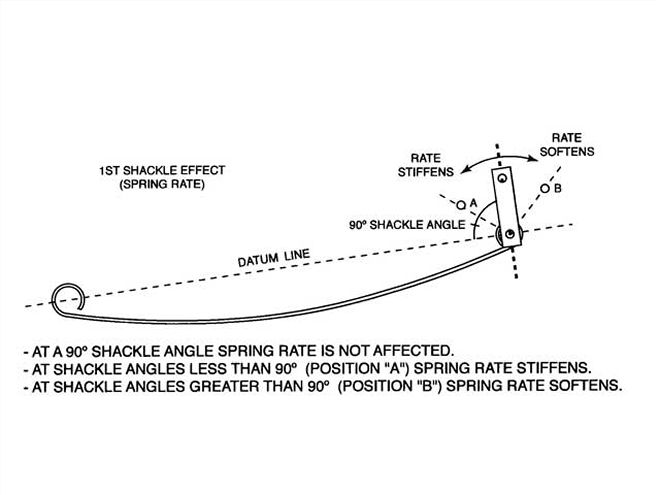

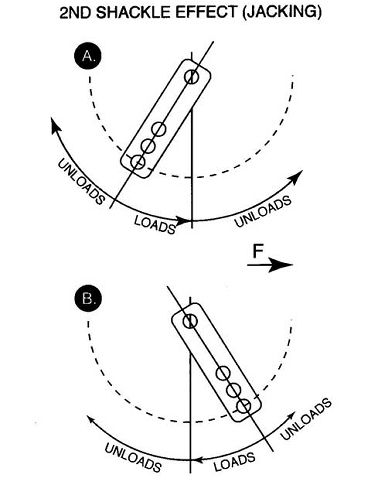

The angle of the spring shackles to the leaf is important. We need the shackle to be at 90 degrees to the rear portion of the leaf when the cares at ride height. That way there will be less influence in the spring rate due to mechanical binding that would take place if the shackle were angled more or less than 90 degrees.

The pinion angle is to be taken into consideration during installation. If the pinion angle needs to change, wedge-shaped blocks must be inserted between the axle pad and the spring. Always check the pinion-to-driveshaft angle with all of the weight on the springs.

The overall spring height, as measured from the ground, and the relationship of the front eye center to the point where the spring attaches to the rear end is important considerations when designing a leaf-spring car.

The spring's eye height determines the rear moment center height. Lowering the spring in relation to the chassis means lowering the rearmament center height and causing more rollover at the rear. This serves to tighten the car all the way around the corners.

Changing the front eye height will affect the rear-steer characteristics and alter the handling of the car in the middle and off the turns. Many chassis builders will only place one hole in the front mount and position it where it will do the most good under most racing conditions.

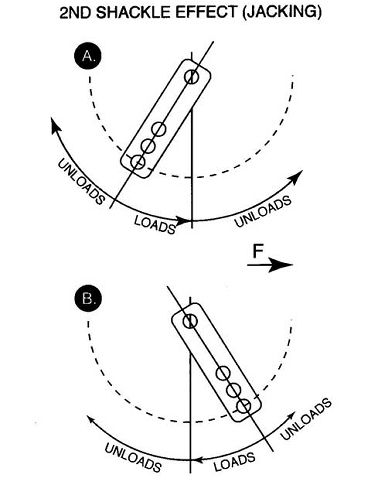

The angle of the leaf spring to the shackle should be nearly 90 degreeswhen the car is at ride height with all of the weight in it. This helpseliminate several effects that alter the spring rate.

The angle of the leaf spring to the shackle should be nearly 90 degreeswhen the car is at ride height with all of the weight in it. This helpseliminate several effects that alter the spring rate.

As the angle of the spring shackle changes from 90 degrees, a series ofevents that will load and unload that corner of the car takes place. Weneed to understand these tendencies so that we can properly design ourcars.

As the angle of the spring shackle changes from 90 degrees, a series ofevents that will load and unload that corner of the car takes place. Weneed to understand these tendencies so that we can properly design ourcars.

Steel vs. Composite

The newest innovation in racing leaf-spring technology is the composite design, or what some would call a fiberglass leaf, although there are other materials involved in the construction of these products. Composite leaf springs are not a new concept. The Chevrolet Corvette has been using this design of spring for quite some time now.

The primary advantages of using a composite leaf spring are a 60-70 percent weight savings over steel springs and the tendency of the composite spring to maintain its shape (according to the advertisements and feedback we got from users, it doesn't sag). The composite leaf springs, just like the steel, come in various rates from 35 to 250 pounds. They can be used as a "single" leaf in low rates or as a "stack “leaf, still a mono-design but thicker (like a stacked steel spring).

It is the characteristic of maintaining a constant arc and shape that most appeals to current users of composite leaf springs, not necessarily the weight savings. The minus we discovered was that the composite must be protected from heat and contact with anything that would chip it, starting a process that might lead to failure. Failure with a composite leaf means breakage whereas a steel leaf will definitely bend, but seldom break.

Is it the Right Choice? Lovers of leaf-spring cars swear by their consistency, and that is what makes them so attractive. For the hobbyist racer who does not have the time nor patience to decipher all of the complexities of the three- or four-bar systems, much less afford all of that "mess," the leaf car offers a good system for a reasonable price that can and does win races.