“Football afforded me the opportunity to have the car you only dream about,” says St. Louis Rams offensive lineman Chris Williams. For this true fan of American muscle, that turned out to be a badass, heavily modified 2008 Dodge Challenger SRT8. Williams traded a 1969 Camaro with an LS2 for the already completed car, buying it sight unseen over the phone from a buddy in Bowling Green, Kentucky, who got it in a trade. Chris puts it, “When I heard the car start, I knew I had to buy it.”

Hailing originally from Glynn, Louisiana, NFL lineman Chris Williams and his wife Marissa love cruising in hard-core American muscle cars. Pic: Chris Williams

Hailing originally from Glynn, Louisiana, NFL lineman Chris Williams and his wife Marissa love cruising in hard-core American muscle cars. Pic: Chris Williams

The raspy sound was more than just the notes generated by the Challenger’s SLP Loud Mouth exhaust system; this car was not a poser. Florida’s Nelson Competition had fully rebuilt the original 6.1L late Hemi stocker into a 426ci stroker beefed with parts designed to complement and withstand Kenne-Bell’s Mammoth liquid-cooled, 3.6L, twin-screw supercharger. The engine output is channeled through a performance torque converter into a fully built Paramount Transmission automatic that transfers the torque via a Driveshaft Shop driveshaft back to the Chrysler/Mercedes IRS beefed with a Quaife differential and BMR Fabrication half-shafts with upgraded 35-spline hubs. If that’s not enough, there’s a custom nitrous-oxide system with a remote bottle opener—call it “War Emergency Power”—in reserve.

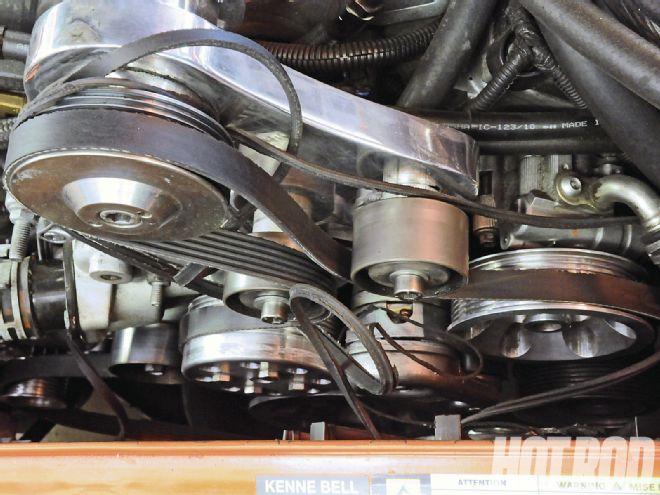

At 1 bar of boost, the 1,000hp 426 New Hemi put out so much drive torque that its eight-rib belt couldn’t survive.

At 1 bar of boost, the 1,000hp 426 New Hemi put out so much drive torque that its eight-rib belt couldn’t survive.

“I think the first owner built the car for his wife, originally. It had probably never been driven hard before I got it.”

— Chris Williams

“When I got the car back to Chicago, of course, I had to see what it could do,” continues Williams. “With my buddy in the passenger seat, I just stomped on it. I put the pedal on the floor. When I got up to 120 mph, I backed off. The belt just flew off. I found whenever I bounce off the rev limiter doing burnouts, the drivebelt would also jump big-time.”

Westech Automotive owner, fixer, and all-around master maintenance tech Norm Brandes contemplates another bad belt day.

Westech Automotive owner, fixer, and all-around master maintenance tech Norm Brandes contemplates another bad belt day.

Chicago? Mysterious belt-retention problems? That sounds like one for the region’s go-to fix-it guy, Westech Automotive’s Norm Brandes in southern Wisconsin.

The original Kenne-Bell serpentine drive used a six-rib Micro-V (serpentine) belt with corresponding pulleys similar to the stock Dodge setup. To get the boost up to 1 bar (about 14.5 psi), the original car builder installed an overdrive blower pulley plus an eight-rib serpentine-drive system. A single belt drove the supercharger plus all the accessories: the alternator, the water pump, the power steering (P/S), the air conditioning (A/C), and the harmonic balancer. In an attempt to keep the belt properly aligned, the kit used four smooth, steel idler pulleys and a Ford Mustang–style belt tensioner in place of the stock Dodge tensioner.

Belt filet, anyone? Uugghh, that’s gotta hurt! Despite its wide eight-rib pulleys and four idler gears, the blown Challenger’s serpentine drive just wasn’t up to the challenge of a boosted 1,000hp engine.

Belt filet, anyone? Uugghh, that’s gotta hurt! Despite its wide eight-rib pulleys and four idler gears, the blown Challenger’s serpentine drive just wasn’t up to the challenge of a boosted 1,000hp engine.

At first, it seemed like a simple pulley-misalignment problem. Brandes corrected the spacing and alignment, slightly milling the alternator bracket where it bolted to the head. The Dodge’s stock P/S pump, made by Toyoda (presently a subsidiary of JTEKT, not to be confused with the car manufacturer Toyota), had a press-on pulley that permitted some leeway in its installation depth, allowing Brandes to slightly alter its press-depth so it properly lined up with the other pulleys.

Seemingly fixed, Williams took the then-orange car to Estrada Customs, a nearby custom paint-and-body shop, where it was sprayed with its present color—a base charcoal with a hint of very-dark-green metallic. No sooner was it out of the shop than Williams leaned on the car again—and off came the belt, again. This time it also damaged the P/S pump pulley. As a rueful Brandes put it, “Not even half a tank of gas later, and it was back.”

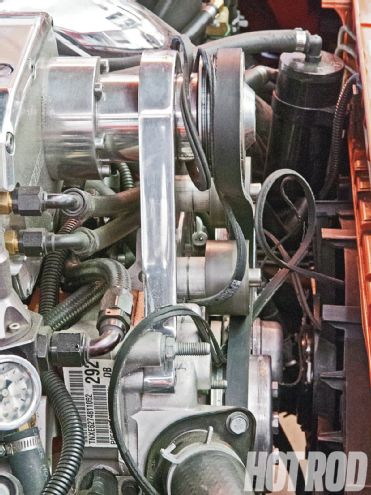

Custom Thump RRR aluminum idlers and an improved belt tensioner fixed the belt. A stronger Turn One P/S pump was needed, too.

Custom Thump RRR aluminum idlers and an improved belt tensioner fixed the belt. A stronger Turn One P/S pump was needed, too.

Analysis determined the existing tensioner and idler pulleys couldn’t contain the sudden change in belt speed, resulting in a failure. Brandes explains, “The smooth backside of the belt is supposed to ride against the idler pulleys, with any slack taken up by the tensioner. When Williams hit the fuel/ignition shutoff or quickly backed off the throttle under high boost, the belt gets loose for a second because of the shock and momentary overdrive. The supercharger is still spinning fast, but the rest of the engine is already slowing down. The belt is trying to drive at two different speeds. The supercharger has gone from a consumer to being the output device.”

But what to do about it? “When the car came back,” relates Brandes, “we talked to the beltdrive specialists at Gates. We discussed how excessive pulley inertial mass plus a long belt running a bunch of accessories can stretch the belt beyond its intended, designed strength. The travel of the Ford tensioner was limited, so it couldn’t take up all the slack when the sudden load reversal stretched the belt. Although relatively small, the idler pulleys were still made from solid steel, making them relatively heavy. The added mass and inertia put into the system further contributed to the belt jumping out of the drive-pulley grooves.”

Brandes looked around to see who had a better tensioning system. The pulley specialists at Thump RRR Racing came to the rescue, axing the kit’s problematic tensioner and idlers for an upgraded, long-travel, Chrysler-style tensioner plus three lightweight aluminum idler pulleys with double bearings. The original fourth steel idler, a small-diameter unit located on the passenger side near the alternator, was already a double-bearing design and was not changed. Brandes also replaced the damaged P/S pump pulley and again put the car back on the road.

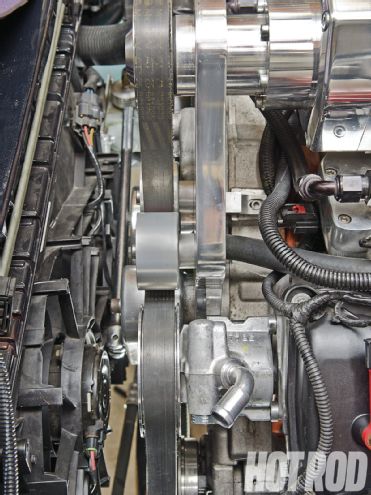

At first, it seemed like a basic pulley-alignment problem, easily corrected by shimming the original eight-rib drive kit’s spacers or slightly changing the pulley-press depth on the power-steering pump. No joy: Correcting the misalignment shown here failed to solve the problem.

At first, it seemed like a basic pulley-alignment problem, easily corrected by shimming the original eight-rib drive kit’s spacers or slightly changing the pulley-press depth on the power-steering pump. No joy: Correcting the misalignment shown here failed to solve the problem.

On-road testing revealed the need for additional refinement. The added tensioner travel, while good because it reduced belt slack and movement, caused the tensioner to contact the water-pump pulley when its internal tensioning spring was in the fully relaxed (low-tension) position at WOT/high-rpm. This cracked the water pump’s belt-tensioner mounting boss (serious), and slightly marred the outside pulley surface (not fatal). The aftermarket eight-rib kit uses a one-off water pump with a bolt-on pulley, compared with the stock Dodge pump with its press-on pulley. Replacement pumps are pricey and only available from the original kit maker.

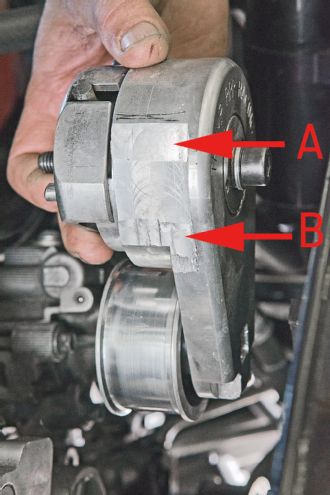

Instead of special-ordering the rare pump, Brandes repaired the tensioner-mounting boss using his high-end TIG welder, initially retaining its tensioner-indexing dowel hole in the stock location. He also machined a flat on the tensioner to increase clearance in the critical contact area. The small, 56mm aluminum pulley initially provided by Thump that mounts at the bottom of the tensioner near the crank was swapped out for a larger, 70mm pulley with added belt-guide lips on its edges.

This solved the initial water-pump contact problem, but then, when the tensioner rotated to the point that its internal spring developed maximum pressure under sudden load reversal, the lower portion of the tensioner “head” now experienced slight interference. The solution was moving the water-pump tensioner mounting boss’s indexing dowel-pin hole slightly counterclockwise from the original, stock position to gain the necessary clearance. Based on Brandes’ experience, Thump plans to modify its tensioners for more clearance and revise its index pin location so the end user won’t have to perform these field fixes in the future if running large eight-rib pulleys.

The re-engineered drive system solved the belt-retention problem, allowing the engine and supercharger to finally reach their true potential. No more belt failures! Game, set, match? Not so fast: Several thousand miles later, the P/S pump itself packed up.

With the belt no longer the system’s weak link, it transferred all the torque generated by the high-boost blower drive to the other pulleys and accessories. Ultimately, this proved to be too much for the stock P/S pump pulley-shaft bushing, which went away. Debris from the disintegrating bushing contaminated the entire steering system, damaging the steering rack. The first clue that Williams was getting a bum steer: a slightly wobbly P/S pump pulley, followed by pump leakage, and ultimately an internal grinding noise. Externally, tugging on the now-shady shaft revealed excessive endplay; think of it as an engine crankshaft thrust bearing starting to fail.

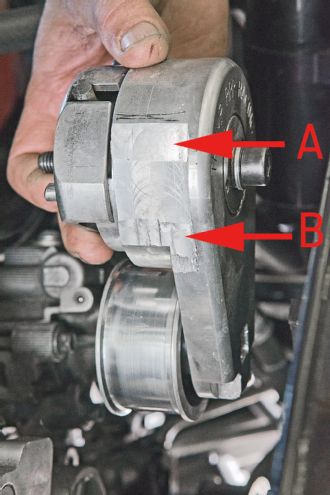

Visible on the tensioner is Westech’s added clearance flat (A), and slight remaining water pump-contact scouring (B) that ultimately required additional mods.

Visible on the tensioner is Westech’s added clearance flat (A), and slight remaining water pump-contact scouring (B) that ultimately required additional mods.

Turn One, builders of modified Saginaw P/S pumps and steering systems for high-end venues like NASCAR Cup racing, had solved a similar issue experienced by Lingenfelter Performance after it seriously turned up the boost on the high-end Caddy CTS-V’s blown LSA engine. Turn One owner and former Saginaw Steering engineer Jeff Roethlisberger came up with a similar fix for the Dodge: a custom unit based on a variation of the Saginaw Type 2 P/S pump that came stock with a shaft-support ball bearing instead of the typical bushing. Roethlisberger cautions that “there are Type 2 Chinese knockoff copies of both the bushing and bearing versions. They’re nowhere near as durable!”

Thump supplied three lightweight aluminum replacement idler pulleys. For the final belt-fix, one—the idler that fits on the bottom of the tensioner near the crank pulley, a location that sees the greatest amount of belt flex—additionally has special flange “lips” on its edges that help further contain a distressed belt.

Thump supplied three lightweight aluminum replacement idler pulleys. For the final belt-fix, one—the idler that fits on the bottom of the tensioner near the crank pulley, a location that sees the greatest amount of belt flex—additionally has special flange “lips” on its edges that help further contain a distressed belt.

Stout as the Real McCoy bearing pump is, it still needs enhancements to withstand the supercharger’s high drive-torque belt loads. Roethlisberger explains, “We knew from our Lingenfelter work that the bearing itself wasn’t enough. Although stronger than a bushing, the bearing is still pressed onto the driveshaft. Excessive belt load can pull the driveshaft through the bearing. We add an additional radial snap ring to prevent this.

“For Williams’ Dodge, we also matched the pressure-valve orifice size to the Toyoda pump to maintain the factory feel, but we can change the orifice size and pump pressure output to provide a different feel and compensate for different tire loads or heavier wheels—whatever the customer wants.

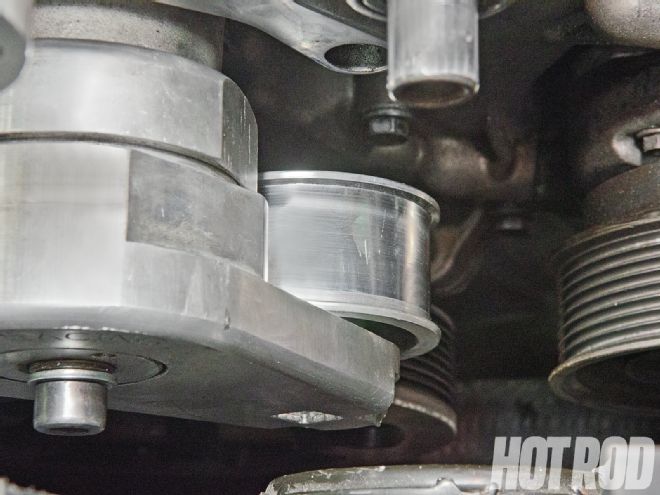

Whoops! As explained in the text, under certain conditions the new, long-travel tensioner hit the water-pump pulley. The nonstock eight-rib pump included in the original drive kit has a hub to accept the wider bolt-on eight-rib pulley. The wider pulley caused the contact problem and may be why the original kit’s makers used the shorter-travel Ford tensioner.

Whoops! As explained in the text, under certain conditions the new, long-travel tensioner hit the water-pump pulley. The nonstock eight-rib pump included in the original drive kit has a hub to accept the wider bolt-on eight-rib pulley. The wider pulley caused the contact problem and may be why the original kit’s makers used the shorter-travel Ford tensioner.

“Internally stock Saginaw pumps consume way more energy than they need to, especially at high rpm, which wastes horsepower. At 5,000 pump rpm, a basic Type 2 pump puts out about 15 gpm [gallons/minute], but a typical steering rack likes about 2–2.5 gpm—the rest is just recirculated through an internal bypass valve. Our pumps put out only 10 gpm at that rpm. Of course, there’s a trade-off: At lower rpm, the pump volume is lower, but unless you have a really heavy vehicle or a rock-crawler, in most instances this isn’t an issue.”

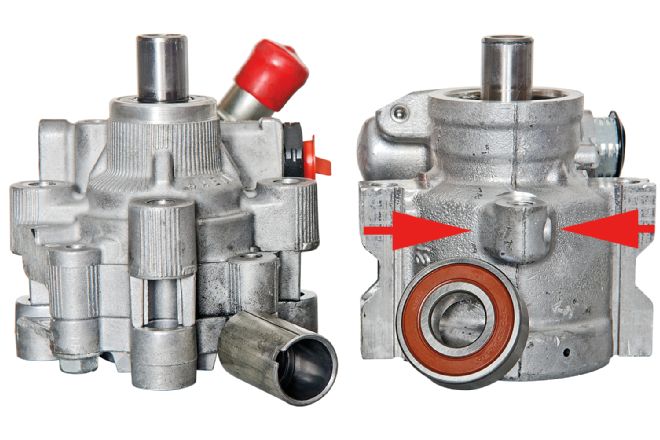

But fix the belt, and the resultant high drive loads failed the stock Toyoda P/S pump (left). Like most P/S pumps, only a plain bushing supports its drive shaft. The fix was a Turn One beefed custom Saginaw Type 2 P/S variant with a stronger ball bearing (right). It has the same mounting-bolt pattern, except one of the bolt bosses is not full length (arrows).

But fix the belt, and the resultant high drive loads failed the stock Toyoda P/S pump (left). Like most P/S pumps, only a plain bushing supports its drive shaft. The fix was a Turn One beefed custom Saginaw Type 2 P/S variant with a stronger ball bearing (right). It has the same mounting-bolt pattern, except one of the bolt bosses is not full length (arrows).

The three-bolt P/S pump mounting bolt-pattern and pulley-shaft diameter is the same for both the Toyoda and Saginaw Type 2 pumps. It’s become sort of an industry standard as GM—once a dominant worldwide supplier of steering products for many different automakers including Chrysler—today itself sources pumps from many sources. (Next Gear, formerly Saginaw Steering Division, in no longer owned by GM.) However, the Challenger’s original Toyoda pump has three full-length, unthreaded, 8mm bolt bosses, compared with the Saginaw pump’s two full-length unthreaded 8mm bolt-bosses, plus one very short, thin, threaded 8mm boss. Brandes felt that reaming the Saginaw pump’s threaded short boss to a full 8 mm and then running a long 8mm bolt through the boss and a long spacer into the cylinder head was insufficiently rigid; eventually, the stressed boss would crack or even break off entirely. He therefore attached the pump using only the two full-length bosses. This is perfectly acceptable: Turn One’s trick NASCAR pumps also use just two out of the three available holes.

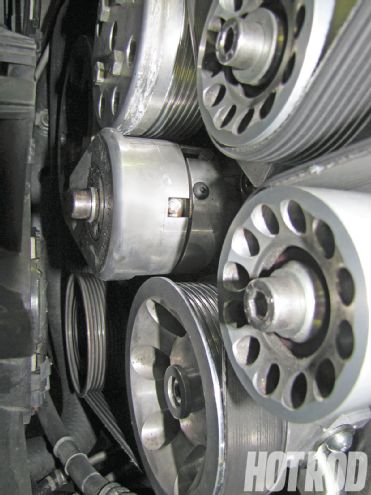

The perfected rescue: All pulleys aligned, Thump tensioner scienced out, and beefed-up

The perfected rescue: All pulleys aligned, Thump tensioner scienced out, and beefed-up

One P/S pump mounting bolthole in the Dodge’s cylinder head had stripped threads. The eight-rib kit used spacers behind the pump for proper pulley alignment but didn’t supply correspondingly longer bolts. The result was insufficient engagement depth in the relatively soft aluminum material, leading to thread failure. The damaged threads were repaired using a special, extra-long helical-coil insert. Two longer and stronger metric socket-head capscrews replaced the original short stock bolts.

A remanufactured steering rack was obtained from Precision Remanufacturing, a leading industry replacement steering component remanufacturer. The original P/S hoses were blown out, cleaned, and reused.

There are no more belt-retention issues. The new Turn One P/S pump has performed flawlessly. Williams can now use his full 1,000 hp—and he does, constantly, though as of this writing, he still hasn’t pressed the nitrous button. But with 1,000-plus horsepower now constantly flowing through the drivetrain, could there be another layer of the onion just waiting to be peeled away?

If you’re considering purchasing a completed project car from a third party, check its reliability by actually test-driving it—at its full potential. As Brandes puts it, “Don’t drive the car in the 25-mph zone.” And as is often the case, curing one problem may allow another, previously unrevealed issue to rear its ugly head.

Belts contained, P/S pump beefed! The Challenger can finally be driven as it was meant to be driven: pedal to the metal.

Belts contained, P/S pump beefed! The Challenger can finally be driven as it was meant to be driven: pedal to the metal.

Includes the final major parts required to fix the problem. Does not include labor, shipping, miscellaneous small shop parts, or sales taxes. Priced 04/12/13 and subject to change. Brand Part Description Part No. AMT. Price Source Price Heli-Coil Insert, Helical-Thread w/tang, 18-8 corrosion-resistant steel, M8×1.25×24, bulk 1084-8CN 240 2 Guardian $3.22 Mandrel, threaded, M8×1.25 helical-thread insert (installation tool) 3747-8 1 JB Tool Sales $10.46 Tap, M8×1.25, helical-thread insert 570-8 1 JB Tool Sales $10.64 McMaster-Carr Capscrew, socket-head, alloy-steel, M8×1.25×110 PC 12.9 (5-pack, 2 required) 91290A470 1 McMaster-Carr $4.45 Mr. Norm’s Pulley, power-steering pump drive, eight-rib, polished PSP-8-Rib 1 Westech $182.03 NAPA Belt, accessory drive, eight-rib Micro-V, 2,642mm/104.025-inch outside circumference NBH 25081035 1 NAPA Online $49.99 OTC Tools Tool Kit, power-steering pump pulley remove and install 4530 1 Summit $38.95 Precision Steering Rack, ’08 Dodge Challenger SRT8 w/ power steering, remanufactured 2027 1 Westech $284.70 Thump RRR Racing Pulley, idler, billet-aluminum, smooth w/edge flanges, double bearing, 64mm od PM-2064-DF 1 Westech $136.25 Pulley, idler, billet-aluminum, smooth, double bearing, 70mm od PM-2070-D 2 Thump RRR $138.00 Tensioner, eight-rib belt, Chrysler-style w/heavy-duty spring and more travel (prototype) PM-1008-64F 1 Westech $493.75 Turn One Pump, power steering, Saginaw Type 2 w/bearing, universal, no pulley, custom build Custom 1 Turn One $350.00 Valvoline Fluid, power steering, 1-quart bottle 602241 2 NAPA $13.26 Vermont Drill Bit, 21⁄64-inch–od HSS, jobber length (for helical-thread insert hole-size) 10221 1 Amazon.com $6.63 Westech Spacer-Plate, power-steering pump, 6061-T6 aluminum, 0.119-inch thick Custom 1 Westech $20.00 Total $1,742.33

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at pitstop@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.

Get More!

Search “HOT ROD to the Rescue” at HOTROD.com.

Product or Service Provided by:

JB Tool Sales Inc.; Livonia, MI; 734.637.8059

Precision Remanufacturing Inc.; Chicago, IL; 773.489.7225