Racing improves the breed. It's a line that's both hopelessly cliché and devastatingly true. Let's examine the facts. Anytime a sanctioning body attempts to crack down on technological innovations, racers and engineers transcend these restrictions by refining an inherently rudimentary design beyond what anyone thought possible. For instance, when NASCAR banned overhead cams and roller valvetrains, teams responded with space-age cam lobe profiles, and incredibly lightweight yet durable valvetrain hardware that can now sustain 9,700-plus rpm with ease. For pushrod engines running flat-tappet lifters, it's a feat that's nothing short of astounding. Likewise, in the world of Outlaw 10.5 drag racing, limiting the maximum turbo compressor wheel diameter to 88mm has catapulted the power capacity of these huffers from 1,300 to nearly 1,700 hp in just a few short years. As a company that literally evolved with ultracompetitive late-model Mustang drag racing classes, Trick Flow knows all about working around rules restrictions. Its High-Port 240cc small-block Ford cylinder heads represent decades worth of refinements, culminating in intake ports that flow a stunning 343 cfm. Airflow figures like that beg the obvious question: Is it possible to crack the 700hp barrier in a pump-gas street motor with out-of-the-box cylinder heads? The answer is "hell yes" with another 31 bonus horsepower on top.

Background

This month's dyno finale marks the third installment of PHR's "Revenge of the Windsor" series. To recap, the first two stories covered the assembly of our stout yet lightweight 454ci short-block. With a horsepower target of 700, a stock 351 Windsor block just wouldn't cut it. Furthermore, taking full advantage of the Trick Flow cylinder heads while maintaining a street-friendly rpm range required maximizing displacement as much as possible. Since this engine is destined to party in a street-driven '67 Mustang that moonlights as a road racer, Ford Racing's new all-aluminum Z351 block served as the perfect foundation for our engine build. Checking in at just 110 pounds—which is nearly 100 pounds lighter than an iron block of similar strength—the Z351 block can accommodate maximum bore and stroke dimensions of 4.125 and 4.250 inches, respectively. Maxing out those generous cylinder dimensions is exactly what we did, netting a big-block–like displacement tally of 454 ci.

Accompanying the Z351 block is a 4.250-inch forged crankshaft and 6.300-inch H-beam rods from Eagle, and custom 11.0:1 JE pistons. Since feeding a hungry 454ci short-block through 240cc intake ports can prove challenging at high rpm, we had Judson Massingill at the School of Automotive Machinists spec out a custom COMP solid-roller camshaft for our Windsor. Although the 268/280-at-.050 duration and .768/.748-inch lift figures of our custom camshaft may cause the limp-wristed to faint, big-block–sized displacement calls for a big-block–sized cam. At the risk of spoiling our test results prematurely, our Windsor's horsepower peak checked in at a grandma-approved 6,700 rpm on the dyno.

1. Last month, we covered the short-block assembly of our 454ci small-block Windsor at Outlaw Motorsports (www.OutlawMS.com). Now it’s ready for a healthy set of Trick Flow lungs to feed it. Although the Ford Racing Z351 aluminum block checks in at just 110 pounds, with beefy reinforcement ribs spanning the width of the lifter valley, it’s one seriously stout unit.

1. Last month, we covered the short-block assembly of our 454ci small-block Windsor at Outlaw Motorsports (www.OutlawMS.com). Now it’s ready for a healthy set of Trick Flow lungs to feed it. Although the Ford Racing Z351 aluminum block checks in at just 110 pounds, with beefy reinforcement ribs spanning the width of the lifter valley, it’s one seriously stout unit.

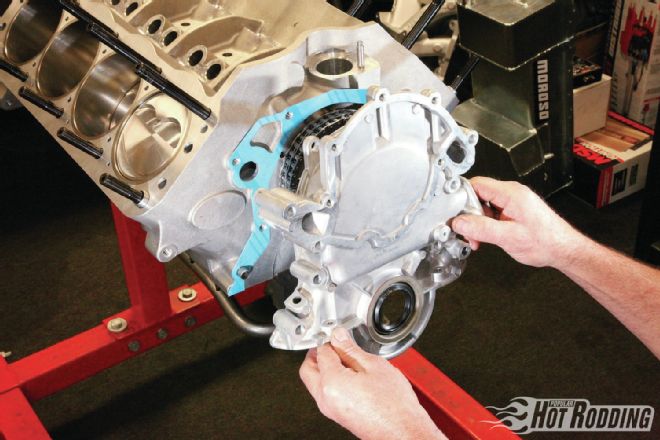

2. Manning the wrenches once again is Ron Aschtgen of Outlaw Motorsports. Before bolting up the top end, Aschtgen had to perform some finishing touches on the short-block. After cleaning the mating surface of the block, Aschtgen bolted down the EngineQuest stock replacement timing cover (PN TC351A) using ARP fasteners. The cover has an integrated dipstick provision as well as a fuel pump mount for mechanical pump applications.

2. Manning the wrenches once again is Ron Aschtgen of Outlaw Motorsports. Before bolting up the top end, Aschtgen had to perform some finishing touches on the short-block. After cleaning the mating surface of the block, Aschtgen bolted down the EngineQuest stock replacement timing cover (PN TC351A) using ARP fasteners. The cover has an integrated dipstick provision as well as a fuel pump mount for mechanical pump applications.

3. After mounting the ATI timing pointer (PN 918948) onto the timing cover, Aschtgen bolted an ATI Super Damper (PN 918924) onto the crank snout. Widely regarded as one of the best dampers on the market, the ATI unit exceeds SFI 18.1 specifications, and is fully rebuildable. To account for varying manufacturing tolerances, the slotted ATI timing pointer can be adjusted clockwise or counterclockwise around the timing marks on the balancer. With the No. 1 cylinder at TDC, Aschtgen zeroed out the pointer.

3. After mounting the ATI timing pointer (PN 918948) onto the timing cover, Aschtgen bolted an ATI Super Damper (PN 918924) onto the crank snout. Widely regarded as one of the best dampers on the market, the ATI unit exceeds SFI 18.1 specifications, and is fully rebuildable. To account for varying manufacturing tolerances, the slotted ATI timing pointer can be adjusted clockwise or counterclockwise around the timing marks on the balancer. With the No. 1 cylinder at TDC, Aschtgen zeroed out the pointer.

4. Since the 454 Windsor will see time on the road course, we ordered one of Moroso’s trick dual kick-out, road-race oil pans (PN 20534). It features a baffled sump with four trap doors to prevent pickup starvation, billet ends for sealing stability, and plenty of clearance for four-bolt main caps. Moroso also supplied the pump pickup, dipstick, gasket, and stud kit.

4. Since the 454 Windsor will see time on the road course, we ordered one of Moroso’s trick dual kick-out, road-race oil pans (PN 20534). It features a baffled sump with four trap doors to prevent pickup starvation, billet ends for sealing stability, and plenty of clearance for four-bolt main caps. Moroso also supplied the pump pickup, dipstick, gasket, and stud kit.

5. The small-block Ford’s 4.380-inch bore spacing, combined with the large 4.125-inch bores of our 454 Windsor, doesn’t leave much meat between the cylinders. Fortunately, when the cylinder walls get too thin for comfort, multilayer steel head gaskets provide the perfect sealing solution. We opted for .042-inch-thick multilayer steel (MLS) Fel-Pro gaskets (PN Q1134SD4) to help tighten up the quench clearance.

5. The small-block Ford’s 4.380-inch bore spacing, combined with the large 4.125-inch bores of our 454 Windsor, doesn’t leave much meat between the cylinders. Fortunately, when the cylinder walls get too thin for comfort, multilayer steel head gaskets provide the perfect sealing solution. We opted for .042-inch-thick multilayer steel (MLS) Fel-Pro gaskets (PN Q1134SD4) to help tighten up the quench clearance.

6. Among the most distinguishable features of the Trick Flow High-Port 240cc cylinder heads (PN 5171T018-C02) are its raised exhaust ports and extra-thick deck. The exhaust ports flow an impressive 257 cfm at .700 lift, and the superior cylinder seal provided by the thick decks have proven immensely appealing to the forced-induction crowd. The heads also have valve cover rails raised .400-inch over stock for additional valvetrain clearance.

6. Among the most distinguishable features of the Trick Flow High-Port 240cc cylinder heads (PN 5171T018-C02) are its raised exhaust ports and extra-thick deck. The exhaust ports flow an impressive 257 cfm at .700 lift, and the superior cylinder seal provided by the thick decks have proven immensely appealing to the forced-induction crowd. The heads also have valve cover rails raised .400-inch over stock for additional valvetrain clearance.

7. Available with either 67 or 76cc combustion chambers, the High-Port 240cc heads come fully assembled with 2.10/1.60-inch valves, 1.55-inch dual valvesprings, and titanium retainers. The large 2.10-inch intake valve requires a minimum bore diameter of 4.125 inches. At $2,996 per pair, the High-Port castings are an exceptional value. To hit our target 11.0:1 compression ratio, we went with the larger 76cc chambers.

7. Available with either 67 or 76cc combustion chambers, the High-Port 240cc heads come fully assembled with 2.10/1.60-inch valves, 1.55-inch dual valvesprings, and titanium retainers. The large 2.10-inch intake valve requires a minimum bore diameter of 4.125 inches. At $2,996 per pair, the High-Port castings are an exceptional value. To hit our target 11.0:1 compression ratio, we went with the larger 76cc chambers.

8. The key to our 454’s output of over 700 hp are CNC-machined intake ports that flow an impressive 343 cfm at .700-inch lift despite retaining that stock 20-degree inline valve configuration. Just as importantly, by .300-inch lift they’re already flowing 222 cfm. Although 240cc intake ports may seem a tad small for a max-effort 454ci motor, with port dimensions measuring 1.310 by 2.300 inches, the cross-sectional area of the High-Port 240 heads is actually larger than the port on Trick Flow’s 250cc 18-degree small-block Chevy castings (1.350 x 2.200). Simply put, the High-Port castings flow more air than their port volume suggests.

8. The key to our 454’s output of over 700 hp are CNC-machined intake ports that flow an impressive 343 cfm at .700-inch lift despite retaining that stock 20-degree inline valve configuration. Just as importantly, by .300-inch lift they’re already flowing 222 cfm. Although 240cc intake ports may seem a tad small for a max-effort 454ci motor, with port dimensions measuring 1.310 by 2.300 inches, the cross-sectional area of the High-Port 240 heads is actually larger than the port on Trick Flow’s 250cc 18-degree small-block Chevy castings (1.350 x 2.200). Simply put, the High-Port castings flow more air than their port volume suggests.

9. To prevent incoming air from stacking up between the “header side” of the combustion chamber and the intake valve, the chambers of the High-Port heads have been laid back to form a distinct teardrop shape. Trick Flow’s Twisted Wedge heads take things one step further by rotating the chambers clockwise within the cylinder bore, thereby creating additional space between the intake valve and the “header side” of the cylinder walls. Since maintaining an inline valvetrain prevents this luxury, the combustion chamber design of the High-Port heads is a clever workaround.

9. To prevent incoming air from stacking up between the “header side” of the combustion chamber and the intake valve, the chambers of the High-Port heads have been laid back to form a distinct teardrop shape. Trick Flow’s Twisted Wedge heads take things one step further by rotating the chambers clockwise within the cylinder bore, thereby creating additional space between the intake valve and the “header side” of the cylinder walls. Since maintaining an inline valvetrain prevents this luxury, the combustion chamber design of the High-Port heads is a clever workaround.

10. With the heads positioned on the block, Aschtgen torqued the ARP studs down to 90 lb-ft in a three-stage process. He started by tightening the studs to 30 lb-ft, then to 60 lb-ft, and finally 90 lb-ft. Applying ARP moly lube to the nuts and washers ensured consistent torque readings.

10. With the heads positioned on the block, Aschtgen torqued the ARP studs down to 90 lb-ft in a three-stage process. He started by tightening the studs to 30 lb-ft, then to 60 lb-ft, and finally 90 lb-ft. Applying ARP moly lube to the nuts and washers ensured consistent torque readings.

High-Port Evolution

With the pivotal role cylinder heads play in the overall power production of an engine, racing classes often regulate the orientation of the valves very closely. In addition to banning modified valve angles, many sanctioning bodies mandate inline valvetrains to eliminate the airflow advantage that canted-valve cylinder heads provide. For small-block Ford racers, that means the popular Cleveland head swap is out of the question. Considering that Trick Flow is a company that literally evolved with the late-model Mustang market, it is all too familiar with working around these restrictions. As Mustang drag racing classes grew in popularity in the 1980s and 1990s, they demanded a set of class-legal inline cylinder heads for their Windsor small-blocks. Trick Flow responded with its original 192cc High-Port castings in 1989, which offered tremendous out-of-the-box performance from an as-cast port. Compared to a stock Windsor head, the Trick Flow High-Ports were based on fortified castings featuring a revised intake port entrance, thicker port walls and decks, modified valve spacing, and exhaust runners raised .750 inch.

The High-Ports proved their mettle on the track time and time again, but as racers pushed the limits of their engine combos more and more each season, Trick Flow continually revised their head castings to stay ahead of the curve. "When we originally introduced the High-Port heads, racers weren't running nearly as much boost as they are today. These days, guys are running 7.30s in the quarter-mile with these heads in drag radial classes," says Mike Downs of Trick Flow. "All that extra boost pushed the original castings beyond what they were designed for, so we have stiffened them up for extra rigidity over the years by thickening the decks as well as the area around the head boltholes."

Since racers are always looking for every last cfm of airflow, strengthening the head casting itself was merely part of the equation. "We eventually added CNC-machined combustion chambers to the High-Port 192 heads. As boost and displacement continued to increase, we developed new CNC-machined ports in 225 and 240cc configurations," Mike explains. For street/strip combos that aren't bound to a rulebook, Trick Flow offers a broad variety of its famous Twisted Wedge castings with intake ports ranging from 170 to 225 cc. Although the Twisted Wedge 225cc castings come within a few cfm of matching the larger High-Port 240cc heads in intake airflow department, the 343 cfm served up by the High-Ports is arguably more impressive considering their less-advantageous inline valve layout. Granted that our 454 won't see any time in a spec racing class, airflow is airflow, and it will reap the rewards of cylinder heads originally developed for spec racing for many years to come. Like a wise man once said, racing improves the breed.

BY THE NUMBERS 454ci Ford Windsor Bore: 4.125 inches Stroke: 4.250 inches Displacement 454 ci Compression ratio: 11.0:1 Camshaft: custom COMP solid roller Valve lift: .768/.748 inch Duration: 268/280 degrees at .050 Lobe separation angle: 112 degrees Cam installed centerline: 108 degrees Rocker and ratio: COMP 1.7:1 Timing set: COMP billet adjustable (PN 8138) Lifters: COMP Race Elite .904 inch (PN 98835-16) Pushrods: COMP 8.600-inch chrome-moly (PN 7906-16) Piston rings: JE, .043, .043, 3mm Piston ring gap: .24-inch top, .26-inch second Piston: custom JE forged Block: Ford Racing Z351 (PN M-6010-Z351) Crankshaft: Eagle forged steel Rods: Eagle 6.300 inches Main journal diameter: 2.750 inches Rod journal diameter: 2.100 inches Bearings: Clevite H-series Cylinder head: TFS 240cc High-Port (PN 5171T018-C02) Intake port flow: 343 cfm at .700-inch lift Exhaust port flow: 257 cfm at .700-inch lift Chamber volume: 76 cc Intake valve diameter: 2.100 inches Exhaust valve diameter: 1.600 inches Valve angle: 20 degrees Valvesprings: TFS 1.55 inches Spring retainers: TFS titanium Head gasket: Fel-Pro MLS (PN Q1134SD4) Intake manifold: Edelbrock Super Victor (PN 2924) Carburetor: Quick Fuel 950 cfm (PN BDQ-950) Header: Outlaw Motorsports custom 2-inch long-tube Ignition: MSD Damper: ATI Water pump: Edelbrock (PN 8846) Oil pan: Moroso road race (PN 20522) Oil pump: Melling high-volume (PN M-83HV) Fuel: 91-octane pump gas Timing advance: 34 degrees total BTDC

On The Dyno 454ci Windsor RPM: TQ: HP: 4,000 532 406 4,100 540 421 4,200 555 444 4,300 581 476 4,400 588 493 4,500 598 512 4,600 614 538 4,700 620 554 4,800 628 574 4,900 632 590 5,000 631 600 5,100 632 614 5,200 628 622 5,300 627 633 5,400 624 642 5,500 624 653 5,600 617 658 5,700 616 669 5,800 607 671 5,900 601 675 6,000 598 683 6,100 597 693 6,200 589 695 6,300 586 703 6,400 585 712 6,500 581 720 6,600 579 728 6,700 573 731 6,800 557 722 6,900 543 714 7,000 538 717

11. After soaking them in a bucket of oil, Aschtgen slid the COMP Elite Race solid roller lifters (PN 98835-16) into the block, matching them up with COMP 8.600-inch pushrods. These robust lifters use 8620 steel bodies, micro-polished 9310 steel wheels, oversized and dual-pinned .400-inch axles, and revised oiling passages. Despite their strength, each lifter weighs less than 100 grams.

11. After soaking them in a bucket of oil, Aschtgen slid the COMP Elite Race solid roller lifters (PN 98835-16) into the block, matching them up with COMP 8.600-inch pushrods. These robust lifters use 8620 steel bodies, micro-polished 9310 steel wheels, oversized and dual-pinned .400-inch axles, and revised oiling passages. Despite their strength, each lifter weighs less than 100 grams.

12. Kicking open the valves are COMP Cams Ultra Pro Magnum 1.7:1 roller rocker arms (PN 630-16). With the cold valve lash set at .022 inch on the intake side and .024 inch on the exhaust side, Aschtgen installed a Trick Flow girdle kit (PN 517000701) onto the rocker studs to assist in stabilizing the valvetrain. (Note that we used .100-inch-tall Manley lash caps so the rockers would clear our retainers at almost .800-inch lift.) The two-piece girdles simply fit around the studs, then bolt together using Allen head bolts. The 7,000 rpm our 454 will turn is modest by today’s standards, but at $190, the stud girdles still provide some cheap insurance.

12. Kicking open the valves are COMP Cams Ultra Pro Magnum 1.7:1 roller rocker arms (PN 630-16). With the cold valve lash set at .022 inch on the intake side and .024 inch on the exhaust side, Aschtgen installed a Trick Flow girdle kit (PN 517000701) onto the rocker studs to assist in stabilizing the valvetrain. (Note that we used .100-inch-tall Manley lash caps so the rockers would clear our retainers at almost .800-inch lift.) The two-piece girdles simply fit around the studs, then bolt together using Allen head bolts. The 7,000 rpm our 454 will turn is modest by today’s standards, but at $190, the stud girdles still provide some cheap insurance.

13. One of the biggest challenges of building a deep breathing, big-inch small-block is finding an intake manifold that can keep pace with the cylinder heads. Getting the job done on our 454 is an Edelbrock Super Victor single-plane manifold (PN 2924). After laying down a bead of RTV on the mating surfaces of the block, Aschtgen torqued the manifold down using ARP bolts.

13. One of the biggest challenges of building a deep breathing, big-inch small-block is finding an intake manifold that can keep pace with the cylinder heads. Getting the job done on our 454 is an Edelbrock Super Victor single-plane manifold (PN 2924). After laying down a bead of RTV on the mating surfaces of the block, Aschtgen torqued the manifold down using ARP bolts.

14. With the intake manifold in place, the port-matching job that Aschtgen performed on the intake runner entrances is clearly visible from inside the plenum. This required slightly enlarging the intake runner openings, then blending them into the runners. The plenum and runner dividers were left untouched.

14. With the intake manifold in place, the port-matching job that Aschtgen performed on the intake runner entrances is clearly visible from inside the plenum. This required slightly enlarging the intake runner openings, then blending them into the runners. The plenum and runner dividers were left untouched.

15. Rounding out the induction package is a Quick Fuel Technology BDQ 950-cfm carburetor. This 4150-style carb boasts a remarkably flat fuel curve, and a slick Black Diamond coating that resists corrosion and reduces heat soak. Just in case you missed it, check out the full write-up on the BDQ-950 in our Jan. ’14 issue.

15. Rounding out the induction package is a Quick Fuel Technology BDQ 950-cfm carburetor. This 4150-style carb boasts a remarkably flat fuel curve, and a slick Black Diamond coating that resists corrosion and reduces heat soak. Just in case you missed it, check out the full write-up on the BDQ-950 in our Jan. ’14 issue.

16. Keeping 731 hp and 454 cubes cool on the street is no small feat, so we ordered an aluminum Victor water pump (PN 8846) from Edelbrock. Highlights include heavy-duty roller bearings, a billet hub, and oversized CNC-machined impellers for increased flow.

16. Keeping 731 hp and 454 cubes cool on the street is no small feat, so we ordered an aluminum Victor water pump (PN 8846) from Edelbrock. Highlights include heavy-duty roller bearings, a billet hub, and oversized CNC-machined impellers for increased flow.

17. Designed specifically for small-block 351 Windsors to clear Edelbrock’s Victor intake manifolds, an MSD Pro Billet distributor was the obvious choice for our 454 Windsor’s ignition system. The MSD unit features a T6-6061 billet shaft that rides on an upper-sealed ball bearing for high-rpm stability. Since our epic COMP solid roller cam won’t produce much vacuum at idle, we opted for a mechanical advance distributor.

17. Designed specifically for small-block 351 Windsors to clear Edelbrock’s Victor intake manifolds, an MSD Pro Billet distributor was the obvious choice for our 454 Windsor’s ignition system. The MSD unit features a T6-6061 billet shaft that rides on an upper-sealed ball bearing for high-rpm stability. Since our epic COMP solid roller cam won’t produce much vacuum at idle, we opted for a mechanical advance distributor.

18. Exhaling through a set of custom Outlaw Motorsports 2-inch headers, the 454 Windsor strained the SuperFlow 901 dyno at Bob Earleywine Performance (Winchester, California) with 731 hp at a very street-friendly 6,700 rpm. Torque checked in at a pavement-ripping 632 lb-ft at 4,900 rpm. That’s not too shabby for a combo that burns 91-octane pump gas. The motor responded best to 34 degrees of total timing, and thanks to the camshaft’s wide 112-degree LSA, it idled at a modest 1,000 rpm.

18. Exhaling through a set of custom Outlaw Motorsports 2-inch headers, the 454 Windsor strained the SuperFlow 901 dyno at Bob Earleywine Performance (Winchester, California) with 731 hp at a very street-friendly 6,700 rpm. Torque checked in at a pavement-ripping 632 lb-ft at 4,900 rpm. That’s not too shabby for a combo that burns 91-octane pump gas. The motor responded best to 34 degrees of total timing, and thanks to the camshaft’s wide 112-degree LSA, it idled at a modest 1,000 rpm.