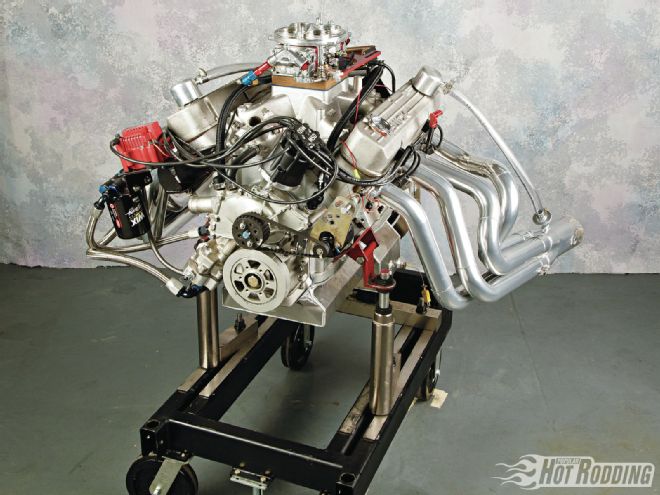

Big-block Buick engines are known as capable powerplants that produce generous torque at modest rpm. It was a formula that was right on target for smoothly and effortlessly powering the stately, large, and luxurious vehicles from this upscale division of General Motors. The same high-torque approach made for surprising performance when these engines were applied to Buick's notable intermediate GS A-body variants, delivering muscle car performance with a refinement that was a cut above the more raucous competition. Now imagine the potential when any pretense of civility is abandoned, and the quest turns to all-out horsepower. That's just what Mike Philips of Automotive Machine & Performance in Philpot, Kentucky, did when creating the production Buick 455-derived beast featured here.

Phillips certainly proved the point of Buick power, and given his engine’s performance has plenty of reason to be proud of his accomplishment.

Phillips certainly proved the point of Buick power, and given his engine’s performance has plenty of reason to be proud of his accomplishment.

The engine was built to compete in the Xtreme Street division of our annual AMSOIL Engine Masters Challenge, an engine competition that demands 8,000-rpm dyno pulls and is the realm of exotic all-out competition engines from the ranks of NASCAR and professional drag racing. A production Buick may seem like an unlikely choice for this competitive venue, but Philips had a purpose: “I wanted to show what these Buicks are capable of.”

Adding Beef

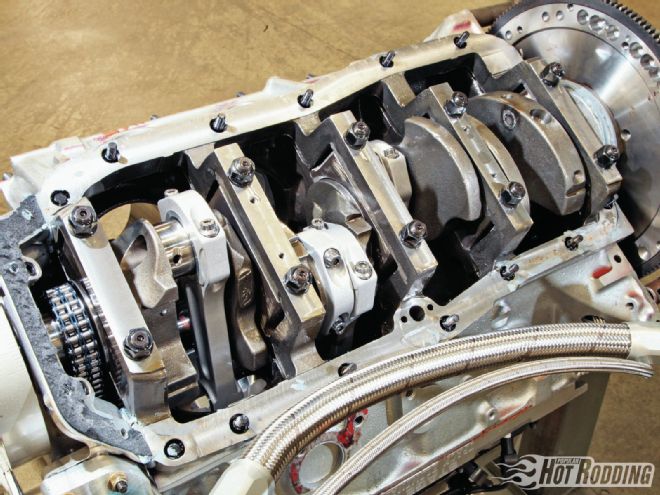

The build started with a 1974 production 455 Buick block, a foundation not known for its strength. As Philips tells us: "The Buick block has weaknesses that have to be addressed to make it live in an application like this, and it is neither easy nor cheap to do. By the time we get done with a block like this, the costs are up in the range of some entry-level Chevy or Ford aftermarket blocks." The block beefing starts at the bottom, with the massive main girdle from T/A Performance that ties the mains to the pan rails. The girdle sandwiches the OEM main caps, which are machined to mate with the girdle structure, and tied into the assembly with studs.

When looking to build massive high-rpm horsepower from a Buick, it is important to understand and address the strength limitations of a production block. Mike Phillips from Automotive Machine & Performance specializes in these powerplants. The casting numbers indicate a 455 block, with the numbers 1241735 denoting a ’72-75 production casting.

When looking to build massive high-rpm horsepower from a Buick, it is important to understand and address the strength limitations of a production block. Mike Phillips from Automotive Machine & Performance specializes in these powerplants. The casting numbers indicate a 455 block, with the numbers 1241735 denoting a ’72-75 production casting.

Moving upward, the lifter valley area is another vulnerability in the Buick block. Philips explains: “The lifter bores will not accept heavy loading and will break, especially if something goes wrong. We tie this area in with a steel reinforcement and then laminate it with multiple layers of epoxy from the top and bottom.” As a further step toward block longevity in this extreme application, the block received a full fill in the water jackets. Philips tells us: “The cylinder walls are thin, especially between the cylinders. This block was actually found to be cracked, so a full fill was needed.”

As with the block, the crankshaft is also an OEM production unit, and a cast piece at that. While this may seem an unlikely part for a high-rpm race engine, Philips explains, "These stock cranks do not often break, unless they're offset ground to maximum stroke. I did cut the crank to a 2.00-inch pin, but kept the stroke at 3.900 inches. The small journals allowed me to use a set of aluminum rods, and that removed enough weight to let me internally balance the engine. The cast crank is a lot more likely to break with weights bolted on at each end for external balance." The 6.800-inch Manley rods are linked to JE domed pistons with a conventional 1/16-, 1/16-, 3/16-inch ring package, delivering a compression ratio of 14.1:1.

The bottom end and main structure of the Buick production block is a weak area. Holding together a production 455 block at high power levels required adding reinforcement, beginning with a heavy-duty bedplate-girdle for the mains from T/A Performance.

The bottom end and main structure of the Buick production block is a weak area. Holding together a production 455 block at high power levels required adding reinforcement, beginning with a heavy-duty bedplate-girdle for the mains from T/A Performance.

The lubrication system also received extensive modifications to help the engine cope with the intended rpm range. The key player here is a scavenging pump with an external pickup developed by Automotive Machine & Performance. The pump arrangement simplifies the oil path, significantly reducing restriction, and ensuring an ample supply of oil. Internally, the block’s oil galleries were modified by enlarging the drillings, and cutting a blended radius at key intersections. As Philips points out, the dyno information reveals nearly constant oil pressure right up to 8,000 rpm.

Power Parts

When discussing the cam and valvetrain, Philips went into detail about the Buick's limitations in an all-out application. "Because of what we have to deal with on the Buick in terms of installed height, valve length, and the spring, you are lucky to get much over 1.850-inch installed height, and the spring diameter is also restricted. On the cam, you have to work around the valvespring limitations, and start there. The spring setup I came up with gave me 210 pounds on the seat and 600 pounds open, and I was limited to .650-inch lift. I specifically selected a cam grind that will work within these spring restrictions, with less aggressive, subtle lobes that wouldn't upset the valvetrain." The cam works in conjunction with T/A Performance solid roller lifters, COMP 3/8-inch pushrods, and 1.6:1 ratio T/A Performance replacement-style shaft-mounted roller rocker arms.

Beneath the T/A Performance solid-roller lifters is a COMP Cams roller cam grind selected by Philips to work within the inherent spring limitations of a replacement-style Buick cylinder head. The cam uses less aggressive lobe profiles to ensure stability.

Beneath the T/A Performance solid-roller lifters is a COMP Cams roller cam grind selected by Philips to work within the inherent spring limitations of a replacement-style Buick cylinder head. The cam uses less aggressive lobe profiles to ensure stability.

Topping the engine is a set of T/A Performance Track Eliminator heads. These heads feature intake runners that are raised a quarter inch from the stock position, and are fitted with 2.250-/1.750-inch valves. The heads were fully ported by Philips, with epoxy added to help match the port runners to his intake manifold configuration. The heads flowed about 365 cfm on the intake side. Philips went to a steeper-than-standard valve angle when cutting the valve job, looking for more than a flow advantage. “I went to a 50-degree valve seat. With the 50-degree seat you change the way the force acts on the valve when it closes, making it less likely to bounce the valve.”

Bridging the gap between the intake ports is a single-plane intake manifold from T/A Performance, though Philips prefers the SPX intake designed for standard port location heads. He says: "We've run the other intake on the dyno, and I find more power with this one. We get these from T/A performance without the CNC work, and match them up to the ports on the heads." As with the cylinder heads, the manifold was treated to full porting, and then topped with a 1,250-cfm Quick Fuel Technology carburetor. Philips was impressed with the capabilities of the large carb: "We put that carb on the engine and within one jet change and three changes to the high-speed bleeds, it was right on. It is a fabulous piece."

At the 2012 AMSOIL Engine Masters Challenge, Philips’ Buick definitely stood out amongst the field of purpose-built racing engines. Unlike most of those specialty pieces, the Buick relied upon OEM production architecture throughout. It is no exaggeration to claim that the unusual combination garnered a tremendous amount of attention from the engine builders and spectators at the event. Most claimed to have never even seen a Buick engine achieve the 8,000-plus rpm required at the competition. Confidently, Philips put the Buick through its paces with a minimum of tuning and fuss, and the house was alight with the buzz of seeing the engine handily achieving the required rpm, and more astonishingly, posting output topping the 800hp mark. If Philips set out to showcase the performance potential of the Buick engine, and the capabilities of Automotive Machine & Performance in getting the most out of them, there is little doubt that he walked out of the dyno cell a winner.

A major constraint is the available space for the valvesprings, with the diameter limited by the proximity to the rocker assembly and the height limited by the valve length. These springs from PSI deliver 210 pounds of seat load, and 600 pounds open.

By The Numbers466ci Buick

Bore:

4.360 inches

Stroke:

3.900 inches

Displacement:

466 ci

Compression ratio:

14.1:1

Camshaft:

T/A Performance solid roller

Camshaft duration:

272/280 degrees at .050-inch tappet rise

Valve lift:

.673/.672 inch

Rocker ratio:

T/A Performance 1.6:1 ratio

Piston rings:

JE 1/16, 1/16 & 3/16 inch

Piston:

JE forged

Block:

OEM Buick production

Crankshaft:

OEM Buick production

Rods:

Manley 6.800 inches

Cylinder head:

T/A Performance

Intake valve diameter:

2.250 inches

Exhaust valve diameter:

1.750 inches

Intake manifold

T/A Performance

Carburetor:

Quick Fuel, 1,250 cfm

Header:

Montgomery 2.125-inch primary

Ignition:

MSD

Damper:

T/A Performance

Oil:

AMSOIL 10W40

Fuel:

VP Q16

On The Dyno 466ci Buick

RPM:

TQ:

HP:

4,000

553

421

4,200

567

454

4,400

581

487

4,600

603

528

4,800

615

562

5,000

642

612

5,200

659

652

5,400

661

680

5,600

661

705

5,800

659

728

6,000

661

755

6,200

654

772

6,400

647

788

6,600

634

797

6,800

619

802

6,900

610

802

7,000

601

801

7,200

583

799

7,400

561

791

7,600

539

780

7,800

524

779

8,000

508

774

A major constraint is the available space for the valvesprings, with the diameter limited by the proximity to the rocker assembly and the height limited by the valve length. These springs from PSI deliver 210 pounds of seat load, and 600 pounds open.

By The Numbers466ci Buick

Bore:

4.360 inches

Stroke:

3.900 inches

Displacement:

466 ci

Compression ratio:

14.1:1

Camshaft:

T/A Performance solid roller

Camshaft duration:

272/280 degrees at .050-inch tappet rise

Valve lift:

.673/.672 inch

Rocker ratio:

T/A Performance 1.6:1 ratio

Piston rings:

JE 1/16, 1/16 & 3/16 inch

Piston:

JE forged

Block:

OEM Buick production

Crankshaft:

OEM Buick production

Rods:

Manley 6.800 inches

Cylinder head:

T/A Performance

Intake valve diameter:

2.250 inches

Exhaust valve diameter:

1.750 inches

Intake manifold

T/A Performance

Carburetor:

Quick Fuel, 1,250 cfm

Header:

Montgomery 2.125-inch primary

Ignition:

MSD

Damper:

T/A Performance

Oil:

AMSOIL 10W40

Fuel:

VP Q16

On The Dyno 466ci Buick

RPM:

TQ:

HP:

4,000

553

421

4,200

567

454

4,400

581

487

4,600

603

528

4,800

615

562

5,000

642

612

5,200

659

652

5,400

661

680

5,600

661

705

5,800

659

728

6,000

661

755

6,200

654

772

6,400

647

788

6,600

634

797

6,800

619

802

6,900

610

802

7,000

601

801

7,200

583

799

7,400

561

791

7,600

539

780

7,800

524

779

8,000

508

774