With their spectacular win in the Xtreme Street Division of the 2012 AMSOIL Engine Masters Challenge, the SAM team had plenty reason to smile. From left to right, Chris Bennett, instructor; Preston Mosher, student; Shawn Hooper, instructor; Judson Massingill, owner/director of education, and Linda Massingill, owner/executive director.

With their spectacular win in the Xtreme Street Division of the 2012 AMSOIL Engine Masters Challenge, the SAM team had plenty reason to smile. From left to right, Chris Bennett, instructor; Preston Mosher, student; Shawn Hooper, instructor; Judson Massingill, owner/director of education, and Linda Massingill, owner/executive director.

Outright victory in the Xtreme Division of the AMSOIL Engine Masters Challenge doesn't come by chance-every factor has to be executed to perfection. Start with the engine combo. Here, the choices are wide open, but the 2012- winning School of Automotive Machinists team selected an entry based upon the small-block Chevrolet SB 2.2 NASCAR components. Success in the Xtreme division demanded starting with a successful engine combination. As SAM instructor Chris Bennett tells us, "The SB2 was one of the best NASCAR engines. From my standpoint the valvetrain is very nice, it has long-pivot rockers, there is a lot of room for the pushrods, it has a great pushrod angle, and great looking geometry. The ports are really small for what they flow, so it's a very efficient port." These Chevy engines are designed to race, so what better platform for an all-out engine competition on the dyno.

Building It

The best engine architecture in the world will not produce a winning engine without the know-how to make it work and go the distance. Here the resources at SAM play a key role, from the extensive in-house machining facilities and necessary engine-building equipment, to the deep pool of talent from the instructors and students alike. From the outset, this Engine Masters competition engine would be a group effort involving the many skilled individuals from the student body as well as the experienced instructor staff.

With the rpm range in competition stretched to 8,000 rpm for the 2012 EMC, the bottom end of the engine had to be bulletproof. SAM started with a 4.00-inch main bearing, standard-cam-height Chevrolet Performance Bow Tie block, finish honed to a final bore dimension of 4.128 inches. This bore size was teamed with a 3.75-inch stroke Lunati crankshaft to produce a final displacement of 402 ci. Interestingly, the bore and stroke combination is very close to that of a production Chevy 400 combination, but the 6.125-inch Lunati connecting rods are significantly longer and infinitely stronger than stock.

With the compression ratio unlimited in the class, a custom set of Diamond pistons was cut specifically for this application. The team settled on a compression ratio of 15:1, after experimenting with even higher ratios. The ring package is a combination that SAM has had considerable experience with; it's been designed for minimal drag and provides the durability needed to go the distance. Bennett explains: "I use that same ring pack on all my drag race stuff, using a really hard steel top and a Napier second, with a 7- to 10-pound, 2mm oil ring. I have a hone job that works really well with that. I use Sunnen diamond abrasives and have great results with that. This engine sealed exceptionally well."

Of course the camshaft selection was to play a vital role in the engines success. The competition is scored on the basis of the horsepower and torque over the entire designated rpm range from 4,000 to 8,000 rpm, so there is no room for holes anywhere in the power curve. The cam combination needs to make as much torque as possible at every rpm point, but the possible specifications are limited by the engine configuration. Here, the SAM team went with a custom COMP solid roller. Bennett expanded on the selection of cam specs: "Every year I learn more about the cam selection for Engine Masters. Last year I had the cam ground with the smallest duration and tightest lobe separation they could grind on the cam core we were working with. This year I went for as much lift as I could get in the engine, based upon piston-to-valve clearance and that kind of thing. Last year I had .800-inch lift, and I was close to .900 with this cam. Everything on the engine this year was as tight as it possibly could be-the deck height, the piston-to-valve clearance on both the intake and exhaust. Everything was dusting the carbon off the piston; I maxed it out for what the purpose was this year."

The cam works in conjunction with Jesel keyway-indexed .937-inch lifters, a setup that Bennett says is his standby arrangement in a serious race-style engine. Custom Smith Brothers pushrods transfer the lifters' motion to the titanium Del West valves via T&D rockers with a very high (2.1/2.0:1) ratio combination. This delivers .892/.850-inch lift, ensuring that the high-lift flow capability of the SB2.2 cylinder heads is well exploited.

With the port layout, the canted valve, and raised runner, you have such a well-designed setup compared to other choices in cylinder heads. -SAM Instructor Shawn Hooper

Those Chevy cylinder heads happen to be well-pedigreed units, having been developed by Joe Gibbs Racing for NASCAR competition. Instructor Shawn Hooper, who led the team's airflow development effort expanded: "The heads were really close to how they were originally set up by Gibbs for NASCAR Nationwide. They were close to the size and shape we were looking for in our application. We were just running a bigger engine at a lower rpm. With the port layout, the canted valve, and raised runner, you have such a well-designed setup compared to other choices in cylinder heads. It is pretty much optimal. There are some other very good aftermarket heads now, but the parts availability is very good for the SB2."

Teamed up with the Chevy SB2.2 heads is an Edelbrock Victor 2862 single-plane single four-barrel intake manifold. This intake turned out to be well sized for the intended application, requiring subtle rather than major modifications. As Hooper details: "The walls are very straight in it; we didn't open the runners up very much or the plenum, we just made all the transitions as nice as possible. We kept it small." Though the manifold did not require major surgery, we were told that the man-hours in the intake easily doubled that of a typical race engine application. Hooper tells us the single four-barrel proved to be the best configuration: "The cast single-plane manifold worked so well because those heads are designed for that configuration. All of the ports are pointed toward the center of the manifold, and it all works as a system with the single carb. We did try a tunnel-ram with dual carbs but it wasn't as good as the single-plane and four-barrel."

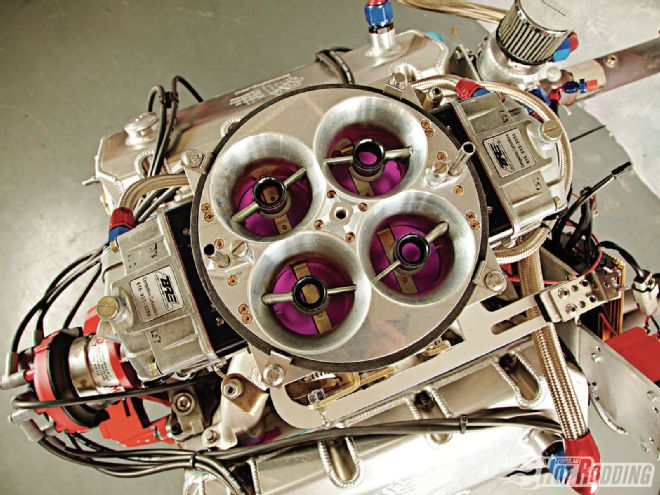

The carburetor itself was an important contributor to the success of the combination. SAM deployed a giant 2.400-inch throttle bore carb from BRE (Book). As Bennett detailed: "I tested two carburetors this year. I started with a 2.00-inch, and the other was a 2.40-inch throttle bore, which is very large for a 400-cube engine. I was worried about a few things. I was worried about it loading down at 3,500 rpm, and I worried about it pulling fuel at such a low rpm. It turned out to move enough fuel and it actually made more power everywhere in the operating test range than the smaller carb."

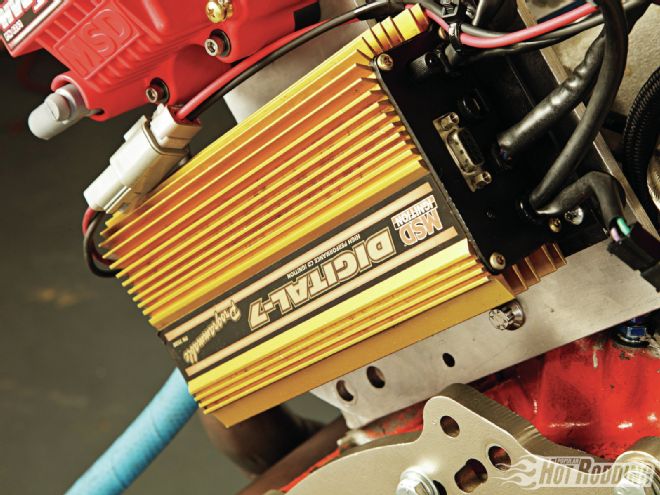

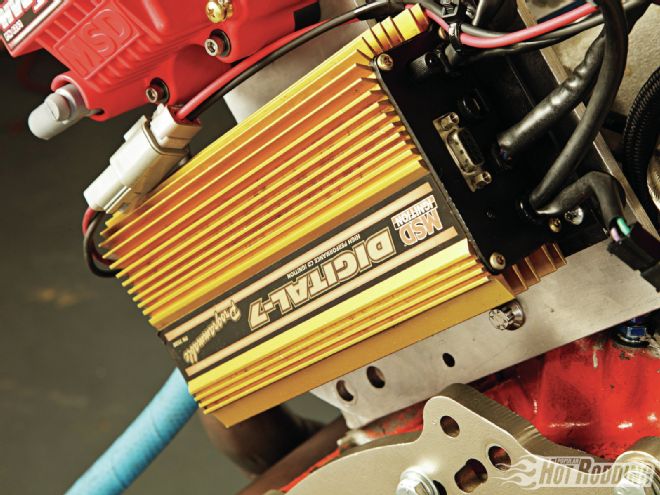

Rounding out the engine combination, the headers from Specialty Metal Craft that SAM had developed for last year's competition were retained. As Bennett tells us this 2- to 2-inch NASCAR-style header remains the best set tested: "The header is the first header we started with on last year's engine, and we tried some other configurations but couldn't beat them." Likewise, previous success led to an all-MSD ignition system featuring the Digital 7 programmable ignition box. "I use MSD on everything, and like to use the Digital 7 box. We had a little bit of a timing curve in it, giving it some ramp up to 29 degrees total."

At the 2012 AMSOIL Engine Masters competition, the SAM team was clearly confident in the ability of their radical SB2.2 Chevy bullet. With stiff competition in the Xtreme Street Division, the 402-cube small-block belted out the kind of fat torque curve over the full test rpm range needed for massive score, while making an incredible 853 peak horsepower in the process. That's 2.12 hp per cubic inch of displacement-a stratospheric level for any normally aspirated engine. With mega power on display, SAM had the field comfortably covered in the competition's qualifying eliminations, going on to perform even better for a convincing victory in Final Eliminations. This little Chevy from SAM clearly took the competition to school.

Starting with a solid Chevy Performance Bow Tie block, the School of Automotive Machinists (SAM) Chevrolet features a bottom end built for strength to go the distance. The beefy block features four-bolt mains on all five bulkheads, with splayed bolts at the center three caps. The Lunati forged crank delivers 3.75-inch stroke for a displacement of 402 cubes with the 4.128-inch bore.

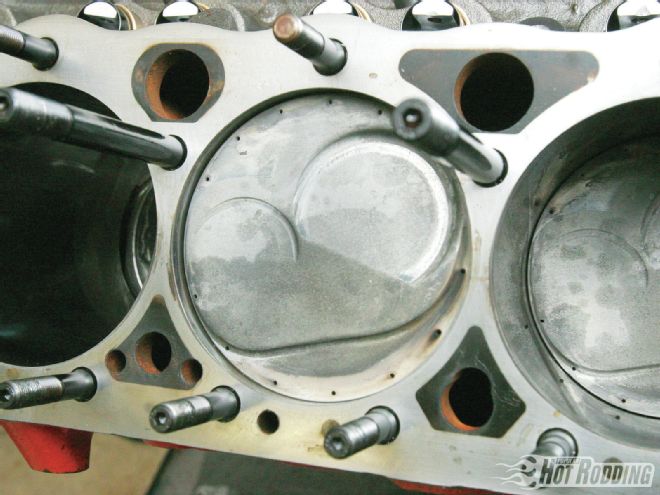

Filling the bores are custom Diamond pistons hanging from Lunati 6.125-inch connecting rods. The pistons are cut for a ring pack consisting of Total Seal .043/.0325 compression rings and a 2mm oil ring, a combination that provides a great seal with minimal drag.

The Diamond pistons feature vertical gas ports for maximum seal of the combustion gases. Note the dome profile and valve notches that are perfectly matched to the SB 2.2 combustion chambers. The clearances here are very tight in this 15:1 compression combination.

Providing the valve action for this high-output Chevy is a custom COMP solid-roller cam working through a set of Jesel 0.937-inch keyway rockers and very high ratio (2.1/2.0:1) T&D shaft-mounted rockers to deliver .892/.850-inch lift. Custom Smith Brothers pushrods complete the stout combination.

Note the lifter bore bushings to accommodate the large diameter keyway-guided Jesel lifters. The lifter position was relocated slightly by the SAM crew to optimize geometry. Visible are the oil drain-back standpipes and plugs to direct oil flow away from the crank and control windage.

The Chevrolet Performance SB2.2 heads are purpose-built race cylinder heads for the small-block Chevy, most famous for their NASCAR success. These are filled with 2.18/1.60-inch titanium valves from Del West, along with Manley springs delivering 250/600 pounds of spring load.

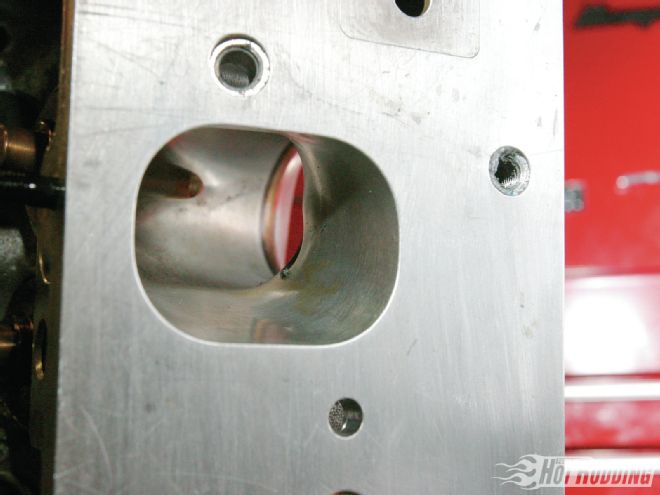

These cylinder heads were actually developed for NASCAR competition, but the final touches for the AMSOIL Engine Masters Challenge were handled by SAM. The intake ports as pictured deliver an incredible 400 cfm at .900-inch lift from a relatively conservative port size.

The high-rise Edelbrock 2862 intake manifold is purpose built for the SB2.2 heads. The manifold is topped with a high-volume adapter spacer to mate with the large pattern Books carburetor. SAM found the single four-barrel arrangement superior to a dual-quad with the SB2.2 heads.

Inside the manifold we can see that every inch of it was touched by a grinder, however the SAM team relates that radical alteration of its form was not necessary. Porting mods strived to give the runners the smoothest possible transition into the head.

The gigantic carburetor from BRE (Books) features 2.40-inch throttle bores, with custom skirted boosters. While there was some concern that this unit would be too big to meter effectively at low rpm, testing showed it made more power than a conventionally sized carb throughout the engine's operating range.

The header is a NASCAR-style piece from Specialty Metal Craft, featuring 2- to 2-inch primary tubes. SAM had time to test other header configurations, but found this arrangement to make optimal power.

SAM team members had good things to say about MSD's programmable Digital 7 ignition. The timing curve was programmed into the unit, ramping up to a maximum of 29 degrees total timing.

Up front an MSD crank trigger initiates the spark event, while the beltdriven distributor handles the secondary voltage and sends it to the appropriate cylinder. A Meziere electric water pump handles the cooling needs without the parasitic drag of a mechanical pump.

On the dyno, the 402-inch Chevy turned some incredible numbers, topping 850 hp for well over 2 hp per cubic inch. Torque came in at an equally impressive 664 lb-ft at 6,200 rpm.