Though not on par with the popularity of Chevy’s Rat, the big-block Ford has a lot going for it, including low cost, availability, and impressive displacement potential. Given the combination, it is a wonder that enthusiasts and the aftermarket didn’t embrace it with open arms. One of the major stumbling blocks of the big-block Ford has always been the cylinder heads, a situation the aftermarket has recently embraced, including Air Flow Research, but let’s take a look at the 460 before we get into our test of the latest headgear available from AFR.

From the factory, the 460 Ford was tops among the Big Three in terms of displacement. When Ford upped the displacement of the 429 to a full 460 inches, the Blue Oval boys easily eclipsed the 440 Dodge, the 454 Chevy, the 455 Buick, and the Pontiac offerings. Only the rarely used, mammoth 472- and 500-inch Cadillacs offered more displacement.

Displacement for the 460 Ford came courtesy of a 4.36-inch bore and 3.85-inch stroke. Enthusiasts should immediately recognize that big-bore combination suggested a candidate for high-rpm use (even more so for the smaller 429 with the 3.59 stroke). Unfortunately, Ford saw fit to use the 460 primarily for low-rpm towing and heavy hauling applications. As big as the 460 is in stock configuration, one of the most popular routes to increased performance is through additional displacement. One of the great things bout the Ford was not only did it offer Chevy- and Dodge-topping displacement in stock trim, but the wide crankcase, tall (10.320 inches) deck height, and 4.90-inch bore spacing allowed the Ford to swallow massive stroker cranks (up to 4.50 inches) and also accept massive overboring (up to 4.440 inches.) Once poked and stroked, it is possible to add nearly 100 ci to the Ford, pushing the stock displacement to 557 ci.

What are the benefits of extra displacement, you ask? One of the tried and true methods of power improvement is displacement. Simply speaking, bigger motors make more power. A little math here goes a long way toward explaining the benefit of the extra inches. Suppose we choose a power output for our racey 460 of 800 hp. Producing 800 hp from a 460 equates to a specific output of 1.739 hp per cubic inch, about the equivalent of a 525hp 302. Reaching this specific output with the 460 would be difficult but not impossible. It would, however, require a whole slew of expensive components designed to allow the race motor to rev to the moon to achieve the elevated specific output. The downside of an elevated specific output is that the combination of compression, cam timing, and head flow would certainly decrease drivability (an 800hp 460 would definitely be considered a race-only motor). In technical terms, the smaller the motor is, the wilder the combination required to reach a given power output.

One way around the drivability (or race-only) issue is through increased displacement. Increasing the displacement reduces the specific output required to reach a given power output. If we retain our goal of 800 hp but increase the displacement of our motor to 557 ci, we see that we have reduced the specific output to just 1.436 hp per cubic inch (the equivalent of a 433hp 302). It is not only much easier to produce 800 hp using a 557 than a 460, but the resulting combination will offer improved torque production, drivability, and engine life due to the decrease in operating speed. An 800hp 460 will likely make peak power near 8,000 rpm, while the same power output from a 557 will easily come 1,000 rpm sooner. Regardless of the method or displacement you choose, one critical element in building power and the Achilles heel of the 460 Ford is head flow.

For years, Ford enthusiasts had to choose one of two paths when building a high-performance 460. For street or street/strip applications, there were stock castings (or their aftermarket equivalent, like Cobra Jet). The canted valves promised much, but unfortunately real-world flow and performance were limited by intake valve placement (too close to cylinder wall) and port design. Despite a massive cross-section, airflow from the stock and Cobra Jet ports never materialized. This was especially true of the exhaust, as flow was greatly diminished thanks to the need to negotiate a treacherous 120-degree dogleg turn. The Cleveland (and Boss) small-block heads suffered from the same problem. Ford engineers seemed to be enamored of massive port entries (and exits), but bigger is always better if the choke point is volume related. Dedicated (Pro Stock) race heads filled the other end of the spectrum, but these were expensive and every bit as ill suited to street/strip motors as the stockers. What the Ford world needed was a set of serious bolt-on heads that were on par with the Chevy offerings. Enter Air Flow Research.

Given that TFS and Kaase already offer big-block Ford heads, it might at first seem that the new AFR heads are the last one to the Blue Oval party, but there is a benefit to being fashionably late. The previous offerings can serve as performance targets, and that is exactly what AFR did when it came time to develop the new Ford heads. Though our test covered a comparison between the AFR and Super Cobra Jet heads, eagle-eyed readers should recognize that the pistons in the 500-inch test motor had more than a few piston notches to accept the different cylinder heads. AFR wouldn’t let us divulge the results, but know that it doesn’t make any sense to produce a head that isn’t a strong marketplace competitor. That AFR also tested the larger 285- and 300-cc versions of the new head shows that AFR is serious about offering a complete performance lineup for big-block Ford fans.

Looking at the stock (and aftermarket) cylinder head offerings, AFR made the changes necessary to dramatically improve performance. The “clean sheet of paper” design offered by AFR changed all the major elements of the stock architecture. In fact, the number of changes made it all the more impressive that this head still employed the standard valvetrain components, header flange, and valve covers. Included in the list of changes are valve angle and relocation, port volume and entry size, and port and combustion chamber shape. Just about everything was change to make the new Ford head a success. If this test is any indication, the new AFR BBF heads might be every bit as popular as the company’s SBF heads. According to AFR, moving the valve away from the chamber wall toward the centerline of the port offered a number of benefits, including increased airflow (thanks to unshrouding), the ability to increase valve size, and improved quench areas in the chamber design (which improve atomization and decrease detonation).

In addition to revised valve locations, the new AFR heads also received extensive work on port shape and volume. The first thing BBF enthusiasts will notice are the size and shape of the intake port. Gone are the massive egg-shaped intake ports, replaced by a much smaller, “roval” (rectangular oval) design. The bigger-is-better crowd might be initially concerned, but know that this new port flows a ton more air through a significantly smaller port. This mean that not only will the new AFR head support more power but it also offers a hefty chunk of cylinder filling along the way to improve torque production through the entire rev range. Where a stock 429/460 head might flow around 290 cfm or a Cobra Jet as much as 320 cfm, this 270cc AFR head checked in closer to 400 cfm-at 0.700 lift no less! Not only is this intake flow good for a BBF, but the AFR BBF head is now more than a match for the Chevy offerings. According to AFR, despite the revised port design, the new AFR heads will not require a dedicated intake. AFR assures us that the stock and aftermarket intakes, like the Edelbrock PN2965, will bolt up. Naturally AFR also offers a manifold designed specifically to work with AFR’s new Ford heads. The intake is available with either 4150 or 4500 carb flanges and is said to offer power gains over existing products.

Although the oversized intake on the Ford heads has always underperformed, the downfall of the big Ford head is actually the exhaust. Much like the small-block Cleveland head, the exhaust flow is forced to take a torturous path that includes a 120-degree turn. Air does not like to turn, especially in tight places. The results are exhaust flow numbers that small-block guys would laugh at (near 135 cfm for stock 460 and 160 cfm for Cobra jet). By combining a revised port design with changes in valve location and filling the floor of the exhaust port (exit), AFR has managed to push exhaust flow of the standard port location up near 275 cfm. AFR also offers 1/4- and 5/8-inch raised exhaust port configurations that may push the exhaust flow up as high as 300 cfm (nearly doubling the exhaust flow of a stock BBF head). On paper all the new design changes looked promising, but there was only one way to find out just how much extra power the heads offered. Off to the dyno!

1. AFR presents a new line of head gear for big-block Ford owners.

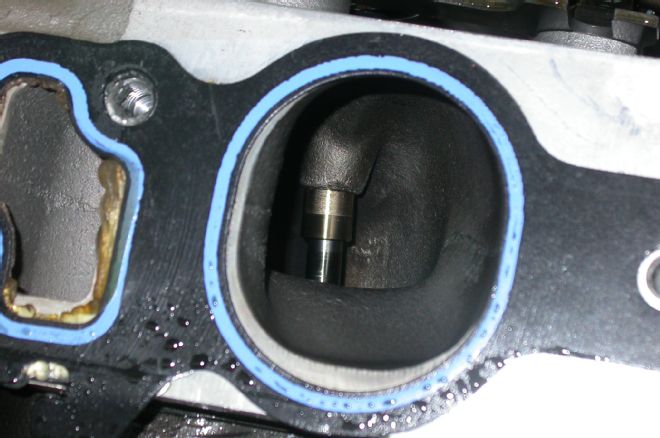

2. The first trick AFR employed with the new design was to relocate the valve closer to the center of the port. This helped unshroud the valves, improve flow, and allow for increased valve sizes. Note also the dual quench pads designed to improve atomization and decrease detonation. AFR offers the new BBF heads with either 75cc or 88cc combustion chambers.

3. BBF fans will immediately recognize the change in size and shape of the intake port on the AFR heads. Though smaller, the new port designed increased flow more than 100 cfm over a stock 460 head.

4. Despite revised valve locations and angles, the AFR BBF heads still accepted standard Ford valvetrain components.

5. There is no mistaking the massive size and shape of the intake port on the Super Cobra Jet heads. Though a significant step up from the stock 429/460 heads, bigger here doesn’t necessarily mean better.

6. To allow the AFR heads to strut their stuff, the 521 crate motor from Ford Racing was treated to a cam upgrade. Out came the mild cam and in went a healthy solid roller from Comp Cams that offered a 0.780 lift, a 275/284-degree duration split, and a 110-degree lsa.

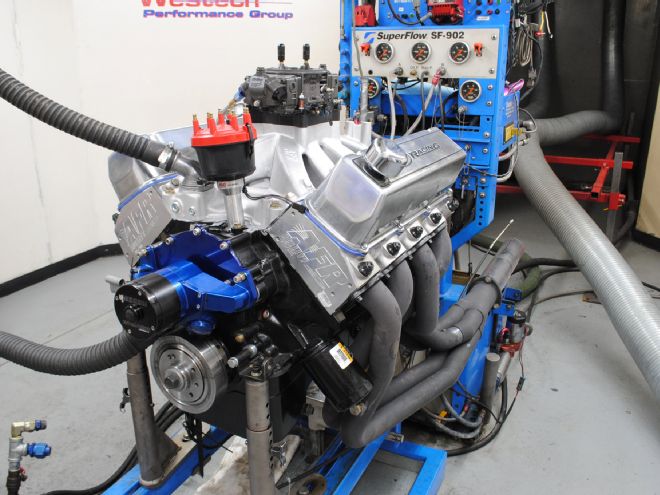

In order to test the new AFR heads, we needed a suitable test motor. Fortunately, AFR had secured just such a test motor in the form of a 521-inch Crate motor from the Ford Racing catalog. The 10.0:1 M-6007-521FT crate motor featured a stroker crank, forged pistons and rods, and a solid roller cam. Looking to illustrate the flow and power potential of the new AFR heads, the cam in the crate motor was upgraded to a healthier grind sporting a 0.780 lift (intake and exhaust), a 275/284-degree duration split, and a 110-degree (+5) lsa. Additional featured of the test motor included a Victor single-plane intake designed to accept a 4500 (Holley Dominator) carb, an MSD distributor, and a front-sump oil pan. For the initial test, the 521 crate motor was equipped with the as-supplied aluminum Super Cobra Jet heads. The Super CJs featured 290-cc intake ports, 72-cc combustion chambers, and a 2.20/1.76 valve combo. These Super Cobra Jet heads already represented a significant step up the performance ladder compared to stock or standard Cobra Jet heads.

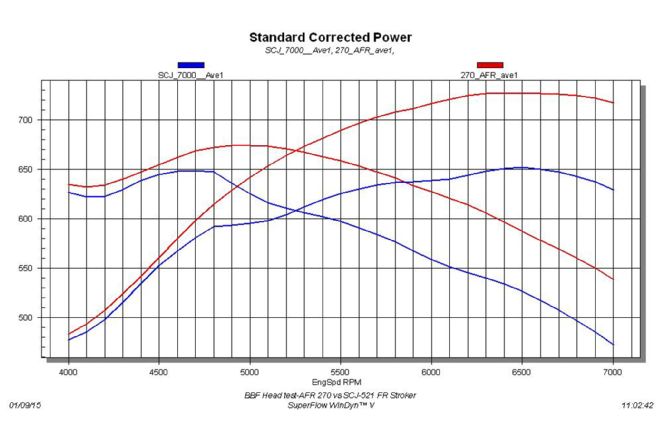

The test procedure was simple: Run the modified 521 first with the Super Cobra Jet heads then again with the new AFR 270s (with 72cc chambers). To ensure adequate airflow, the testing included a 1050 Holley Ultra Dominator carb. Equipped with the Super Cobra Jet heads and Edelbrock intake, the cammed 521 produced 652 hp at 6,500 rpm and 649 lb-ft of torque at 4,700 rpm. After the installation of the new AFR 270 heads, the peak numbers skyrocketed to 727 hp at 6,400 rpm and 674 lb-ft of torque at 5,000 rpm. Note that not only did the extra intake and exhaust flow offer more peak power (as expected) but the efficiency of the new design (bigger flow through a smaller hole) offered power gains through the entire rev range. Extra peak power is good, but more power everywhere is great! Given the flow offered by the AFR 270s, there was even more power to be had with a wilder combination, as the flow numbers suggest even the smallest version of AFR’s new head will support over 800 hp.

The availability of this new AFR head makes us want to go grab any of the thousand 460 truck motors over in the wrecking yard and starting building some Blue Oval power. Chevy owners, beware!

7. The crate motor was also supplied with an MSD billet distributor and wires.

8. The 521ci crate motor came supplied with these Super Cobra Jet heads, but it was necessary to upgrade the spring package for our new cam profile. Equipped with the Super Cobra Jet heads, the 521 produced 652 hp and 649 lb-ft of torque.

9. Though this test involved the Super Cobra Jet and AFR 270 heads, the piston was notched to accept other cylinders heads as well during testing.

10. The Super Cobra Jet heads were removed to make room for the AFR 270s.

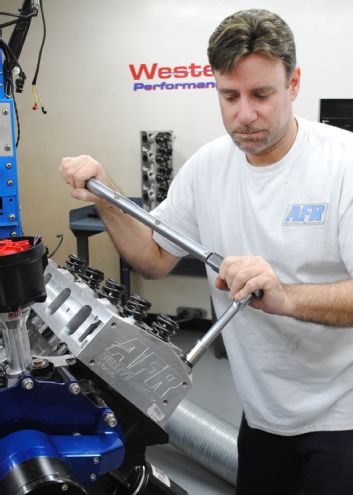

11. Using ARP head studs and Fel Pro head gaskets, the AFR 270 heads were torqued in place.

12. After installation of the dedicated AFR intake, the 521 pumped out 727 hp and 674 lb-ft. The head swap improved the power output of the big-block stroker through the entire rpm range.