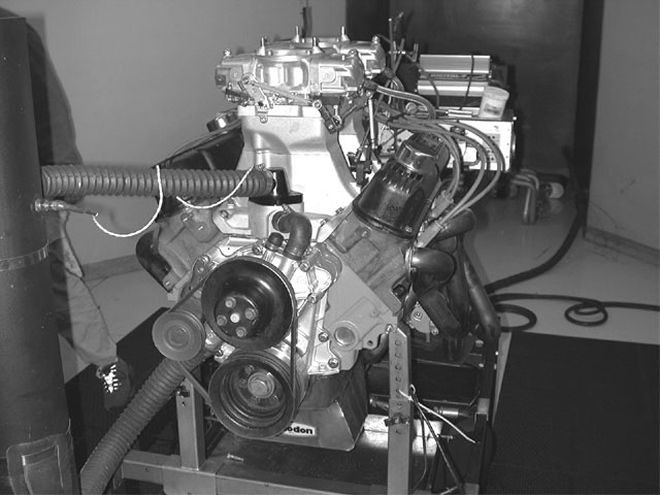

Ready to romp, we headed to Westech and loaded our engine on their dyno to see what 408 cubes of tunnel-rammed, W-2-headed Mopar were worth. Though the Crane roller inside was the smallest listed in their catalog, we'd have no problem opening the valves to create enough power by supplementing it with Crane's 1.6 rockers.

Ready to romp, we headed to Westech and loaded our engine on their dyno to see what 408 cubes of tunnel-rammed, W-2-headed Mopar were worth. Though the Crane roller inside was the smallest listed in their catalog, we'd have no problem opening the valves to create enough power by supplementing it with Crane's 1.6 rockers.

It was with much anticipation that we loaded our 408-stroker small-block for the trip out to the Westech dyno facility. We already knew it had to be a serious combo, even though we changed one specification and dialed the compression back from our original plan of 11.7:1 to a pump-gas friendly 10.4:1 (see sidebar: Compression Quandary). The lower compression specification would certainly lower output, estimated at about 5.5 percent, but we'd have the opportunity to jack it up to race-gas territory later. With the scienced-out heads, plenty of cam on board, and serious induction up top, there was little doubt that our big-inch small-block would deliver.

Finishing It Off

We had a few details to add to our stroker mill before we had a real ready-to-run stroker. A trip to Bob Mazzolini Racing in Riverside, California, netted us a Mopar Performance aluminum bronze-geared distributor drive (#P3690874)-required for compatibility with our steel roller cam. An MSD billet distributor was popped into the hole at the back of the block, and wired to the plugs with MSD wires. The Westech dyno has an MSD Digital 7 ignition, which plugs right into our distributor setup. In an outrageous display of cheapness, we spun the 89-cent Autolite plugs out of our last dyno small-block, and screwed them into our stroker's fresh W-2s.

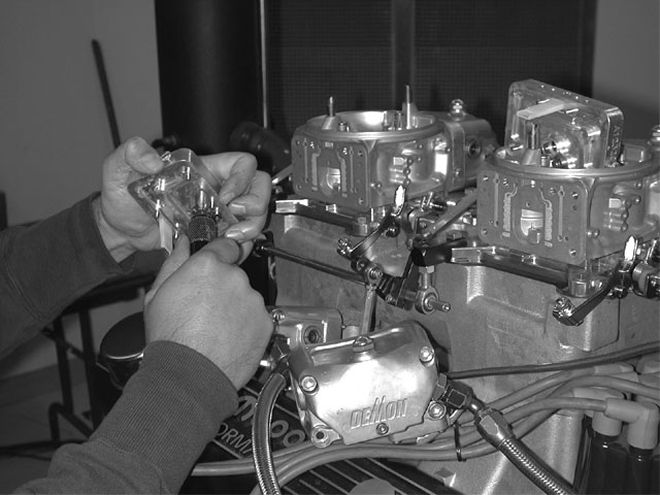

Last month we bolted on a pair of Speed Demon four barrels to set up the Enderlie linkage kit for our MP tunnel ram. We initially had a set of 750 annular race Demons in mind, but found that Demon makes a pair of down-leg booster 750s specifically for tunnel-ram applications. We decided to go with the carbs Demon has already developed for the job, picking up a pair of Race Demon 750TRs. Since these carbs are factory-calibrated for tunnel ram dual-quad applications, we figured they would save us precious dyno time in dialing up a proper fuel curve.

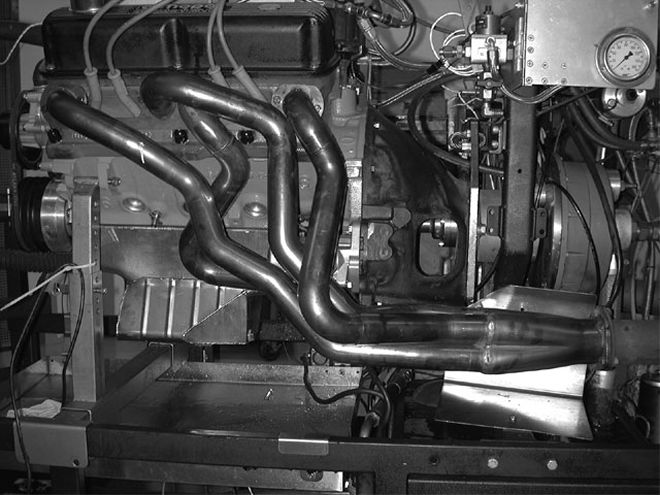

Our last missing components were the headers. We heard that TTI was busy developing 1 7/8-inch headers for both the W-2 and W-5 heads. Good-fitting streetable headers for Mopar Race heads? It sounded too good to be true. Sam Davis and the crew at tti had the jigs complete and just received the bending dies as we were loading our truck for the dyno test. As we mounted the 408 to the SuperFlow dyno, we sent our buddy "The Rooster" to pick up the first set of W-2 headers out of the tti shop. The headers were still hot from welding when he loaded them up.

On the Dyno

With the headers bolted up (they fit like a glove), the 408 was ready for action. True to our pump gas plan, the dyno's fuel system was filled with plain 91 octane Unocal unleaded. We made a few partial pulls to check the jetting, and followed up by fattening the Demons with a jet change to #80s all the way around. We could already see that the 408 was kicking out power, big time. On our partial pull, we had seen 590 hp at 6,000 rpm, and well on its way up. With the jets changed, we were ready to let it rip, so we set the dyno controls up to 6,700 rpm to reap the horsepower. It wasn't going to happen just yet, as a broken rocker adjuster ended our dyno day.

According to Chase Knight, Cam and Valve Train Components Product Manager at Crane Cams, "For years, we never had any problems with our adjusters, but something happened in the late Summer of 2001. Over a 10-day period, we began getting reports of the adjusters snapping off under the lock. We immediately began analyzing three suspected processes involved in producing this part-carburizing, hardening, and annealing. What we discovered was that all processes were within tolerance, but we narrowed the tolerance anyway. Since then, we have had no problems with the adjusters." Should you have rockers that you suspect, call the Crane Cams technical assistance hot line at (386) 258-6174.

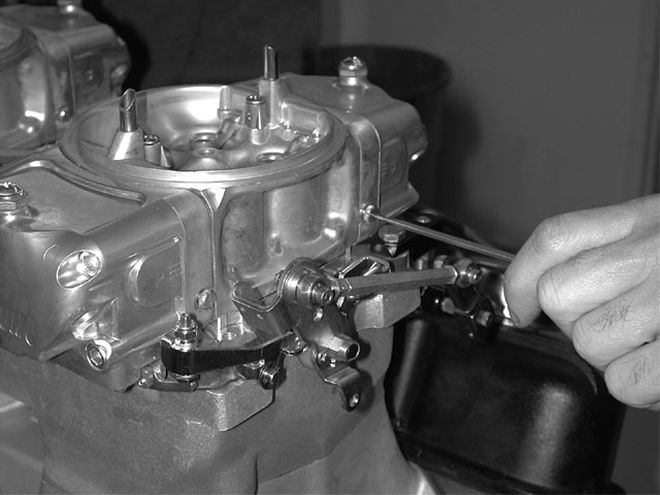

Our fresh stroker was fired, and sounded sweet on a short break-in cycle on the dyno. Some adjustment of the idle mixture screws was all it took to get it to settle into a steady 950 rpm idle, though expectedly with our big cam, idle vacuum was low at about 4.5-5-inch Hg.

Our fresh stroker was fired, and sounded sweet on a short break-in cycle on the dyno. Some adjustment of the idle mixture screws was all it took to get it to settle into a steady 950 rpm idle, though expectedly with our big cam, idle vacuum was low at about 4.5-5-inch Hg.

Despite the set back, the guys at Westech squeezed us in early the following Monday morning, ahead of another scheduled test session, and we arrived at dawn with the parts to replace the rocker. Our first pull of the day showed the 408 breaking up as the rpm cleared over 6,000. We knew exactly where to go for this problem, and pulled the relatively hot Autolite plugs, replacing them with a set of cooler NGK race plugs.

With the minor hang-ups behind us, we were ready to make horsepower. The next pull told the story, ripping a solid 607.5 hp at 6,300 rpm, and an astounding 551.4 ft.-lbs. at 5100 rpm.

"Hey, Brule, you guys test a lot of engines here; how many 600hp 10.5:1 small blocks do you get coming through the door?" we asked the dyno operator.

Without a pause, "None," he replied.

The engine was loaded up on a steady state pull to get a read on the air:fuel ratio, and then jetted according to the numbers that came up. We fattened the carbs to #80s all around.

The engine was loaded up on a steady state pull to get a read on the air:fuel ratio, and then jetted according to the numbers that came up. We fattened the carbs to #80s all around.

Low Profile

Our 408 had shown us some serious output with the MP tunnel ram, Crane's smallest catalog roller grind (run using a 1.6:1 rocker ratio), and dual 750 Demons, but we wondered what it would do with a tamer induction. We had prepped an MP M1 W-2 intake with some plenum work and a port match job, and bolted it on to see what the 408 would turn with a single four-barrel induction. To top the manifold, we pulled out an 850 Speed Demon mechanical secondary carb and a 1-inch Wilson spacer. We weren't expecting this combo to touch the output of the tunnel ram, but for the average street machine, the single four is usually more practical. With the new induction bolted up to our iron-headed 408, the look was strikingly mild when compared to the tunnel ram.

To the average Chevy guy, this thing would appear to be nothing more than a warmed-over iron-head 360 with an intake and headers. A dyno pull later and there was no mistaking the seriousness of the package, registering a solid 583.9 hp at 6,300 rpm, and 533.9 ft.-lbs. at 5,300 rpm. We felt there was even more to be had with the single four-barrel system, as it was clear from the manifold vacuum readings that a bigger carb would have been an advantage. In all fairness to the 850, we only had time for a single jet change since we were on borrowed time, and there were a few more ponies to be dialed up with sharper jetting. Even so, 580-plus horsepower for a single four-barrel pump-gas small-block is a mega dose of Mopar muscle.

Compression Quandry

"Pump gas?"

That was Stunkard's question for me when the last installment of the stroker project hit his desk. We were talking about running the stroker at a compression ratio of 11.7:1, admittedly rather steep even with the fairly sizable cam.

"Well, I'd run it on race gas for the test, and if we have the time, dial back the fuel toward the end of the day and see where the detonation limits are," I responded. At 11.7:1, under controlled dyno conditions, pump gas was certainly a possibility, but in the real world of a reader's ride, that can be another matter entirely. We discussed the theories of compression versus octane, and what we could do to hedge the situation. There are plenty of moves that can make an engine much less prone to detonation, and we agreed that this subject would be worthy of a story of its own. In the meantime, we just jacked up the chamber volume by 9ccs with a head gasket change, dropping the ratio to 10.4:1. At that ratio, it's a pump-gas engine in anyone's book. We'd run it this way as a base, and later change the combo for more exotic thermal and pressure management.

Dyno Results

Superflow 901 engine dyno

Tested at westech performance group