The Combo

Trevor, Wisconsin’s Pat Ryan owns a ’95 Ford Mustang Cobra. Two years ago, Ryan replaced its stock 5.0L EFI engine with a 347ci stroker built by a Texas shop recommended by a friend. The new engine came equipped with Pro Comp aluminum heads, an Edelbrock Victor 5.0 intake manifold, exhaust headers, and an off-brand hydraulic roller cam with associated valvetrain parts sourced from a variety of “Brand-X” vendors. The engine is shifted by a Tremec TKO five-speed manual trans that transfers the torque back to a 3.73:1-geared, 8.8-inch, Ford rearend.

The Problem

Ryan hadn’t put 1,000 miles on the new engine before a pushrod cracked; “1,000 more miles or so, and another one went,” Ryan says. “One of those times I may have missed a shift.” At this point, the original pushrods were replaced with high-quality, thick-wall ones. For a while, everything seemed OK. Then, one morning, Ryan fired up the car and had no oil pressure. “I thought my pump had lost prime for some reason,” Ryan says. “I drove the car down the block at low speed to try to get the oil pressure back up, but it stayed flat. I didn’t hear any weird noises.” It was time to get an expert opinion, so Ryan trailered the car over to our favorite metro-Chicago general-purpose auto repair shop, Westech Automotive in Silver Lake, Wisconsin. It initially appeared to be a slam-dunk fix: just a simple oil-pump replacement.

Zero oil pressure indicates either a defective gauge, a bad sending unit, or an oil pump problem. In this case, a piece of wire jammed in-between the oil pump gears and housing. The wire was so hard it was still round! The wire locked-up the pump, which sheared a 220,000-psi ARP heavy-duty oil pump driveshaft (foreground) right in two.

Zero oil pressure indicates either a defective gauge, a bad sending unit, or an oil pump problem. In this case, a piece of wire jammed in-between the oil pump gears and housing. The wire was so hard it was still round! The wire locked-up the pump, which sheared a 220,000-psi ARP heavy-duty oil pump driveshaft (foreground) right in two.

The Initial Diagnosis

Westech verified the zero-oil-pressure condition with its own known, reliable mechanical pressure gauge. Some lifter clatter was heard, but, as Brandes relates, “If there was an oil-pump failure, the lifters would clatter anyway. We popped the distributor cap, cranked the engine, and saw the rotor wasn’t turning. We pulled the distributor out of the engine, and found the oil-pump driveshaft twisted off, with the top half still stuck in the distributor. We proceeded to drop the oil pan. Upon inspection, we found the other half of the driveshaft lying in the bottom of the pan. This confirmed the oil-pump failure.”

The Fix: Oil Pump and Driveshaft

The oil pump was pulled and disassembled for inspection. Westech found a wire was jammed between the gears. That had seized up the pump, in turn shearing the driveshaft. Westech next inspected the main and rod Bearings for possible oil-starvation damage. They hadn’t yet spun, but as a precaution, Westech replaced them with new Speed-Pro/Federal Mogul Bearings: a ¾-groove Super Duty-alloy small-block Ford Set for the mains, and because the 347 stroker crank is machined for Chevy-sized rod journals, a ’79–’84 Chevy 200–229ci V6-90 Set on the rods. The V6 Bearings have a 2.100-inch small-block Chevy diameter but are narrower than their Chevy V8 counterparts, which helps them clear the stroker crank’s large, tapered journals.

Westech installed a new ARP driveshaft with a new Melling high-volume oil pump. The pan was bolted back on, the distributor installed, and the engine fired. Uh oh! On the cold engine there was only 20 psi of oil pressure at 1,500 rpm. “There should have been 40 psi or more on a cold motor,” Brandes says. “It was also missing and clattering.”

The Final Diagnosis

Was the new oil pump acting up? Was an engine oil passage plugged? Or was it some other mechanical failure? Westech pulled the distributor and used an electric drill motor to drive just the pump through the distributor hole without rotating the engine itself. At about a 4,000-rpm equivalent engine speed, this generated 50-psi gauge pressure at a pressure port above the oil filter.

Obviously, there was a problem somewhere else. Brandes’ crew immediately pulled the valve covers. Brandes explains, “We found the rockers weren’t moving on the front cylinder on the passenger-side” (the No. 1 cylinder as Ford reckons it). A broken No. 1 pushrod was clearly visible. “We knew the customer had broken OE-quality pushrods before, but this piece was a stout chrome-moly, 0.080-inch-wall part.” Clearly, just like “something else” caused the oil pump to break, “something else” was most likely causing the broken pushrods.

The pushrod’s other half was somewhere in the lifter valley, so the intake was pulled. Whoops! Not only was the pushrod broken, but so was its corresponding lifter (that’s where the wire in the pump came from). The failed lifter also opened up a leak path in the lifter bore, resulting in low oil pressure when the engine was operating.

By now this daisy chain of failures had Brandes questioning the entire valvetrain. “We examined the roller rockers. Some had brinelling on the Bearing and shaft. However, a mocked-up valvetrain showed reasonable valvetrain geometry throughout the lifting and closing cycle.”

Evidence was piling up: Something was binding, there was a quality-control issue, and/or there was bad valvetrain harmonics. For years, major cam companies have told us the entire valvetrain—from camshaft through pushrods, plus everything in between—should be single sourced to avoid “bad vibes” at discrete critical rpm points. A lot of people consider this just hype to sell more parts, but engineers will tell you that the individual parts comprising an assembly vibrate at different frequencies and can work at cross purposes if not tested and qualified as a team, eventually leading to fatigue and failure. In the outside world, this has caused engines and wings to fall off of airplanes; in the hot rod world, it can cause random (yet catastrophic) valvetrain failures.

The Fix: Cam and Valvetrain

Comp Cams maintains an extensive in-house research, design, and testing capability. It is the real deal. While none of the disparate cam or valvetrain parts were made by Comp Cams, the good folks there were more than willing to help us out, rising to the challenge to come up with a bulletproof valvetrain combo that would also add power.

Full inspection of the distressed valvetrain reveals (from left) the No. 1 intake lifter on the verge of failure, the No. 1 exhaust lifter that has already failed, a thick-wall pushrod snapped in two, and brinelling on an adjacent rocker-arm shaft. “When we see evidence like this,” relates a deadpan Brandes, “it indicates binding from bad valvetrain harmonics.” You think?

Full inspection of the distressed valvetrain reveals (from left) the No. 1 intake lifter on the verge of failure, the No. 1 exhaust lifter that has already failed, a thick-wall pushrod snapped in two, and brinelling on an adjacent rocker-arm shaft. “When we see evidence like this,” relates a deadpan Brandes, “it indicates binding from bad valvetrain harmonics.” You think?

Brandes sent the valvetrain parts to Comp for analysis. Comp determined the Brand-X cam had GM LS-style lobes ground on a Ford cam billet. But Ford has a different lifter-to-lobe intersection angle than the LS; that changes the lifter acceleration rate, in this case resulting in overly aggressive ramp rates. Rather than “crutch someone else’s poor choice of valvetrain components,” as Comp’s Billy Godbold puts it, “We recommended the entire valvetrain—from timing chain to the rocker arms and springs—be replaced with a coordinated valvetrain. That way there won’t be any unforeseen problems a few thousand miles down the road.”

Adds Brandes, “An overly aggressive cam lobe was the base engine problem, aggravated because the rest of the valvetrain parts didn’t match. The harmonics and loads at the critical rpm range were not in coordination.”

In the last few years, hydraulic roller cams have come into their own. Properly designed, top-end valve crash should no longer be a problem. Comp sent us a custom hydraulic roller profile that revs higher on top while still yielding a reasonably smooth, fuel-injection-friendly idle and good throttle response. The new cam’s EHI-series intake and EHX-series exhaust lobe profiles are designed to run as high as 8,000 rpm with up to 1.8:1-ratio rockers, so they were sure to stay stable with the normal small-block Windsor Ford’s 1.6:1 ratio. Increasing the lobe-separation angle (LSA) from 108 to 112 degrees maintains EFI-friendly idle quality while avoiding piston-to-valve clearance issues, even at 0.600-inch lift.

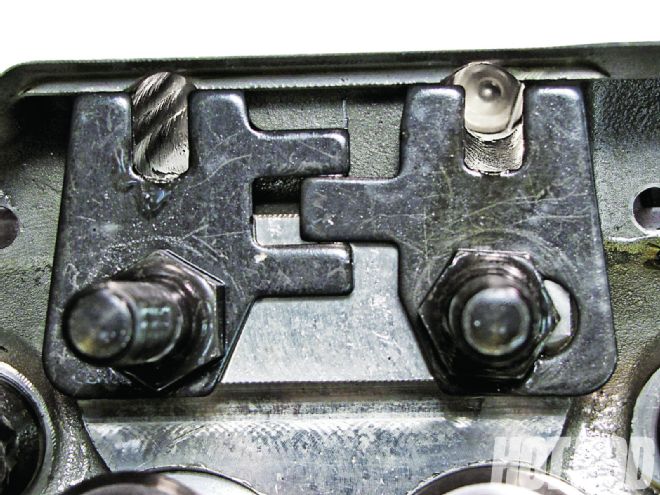

Yet another problem was poorly aligned, two-piece, universal pushrod guideplates. See how the guideplate slots aren’t properly centered over the head’s pushrod slots? Even if right when first installed, minimal tang overlap plus the slotted stud mounting holes make it unlikely to remain so. If you must use a two-piece guideplate, after Setting proper alignment, tack-weld the two halves together.

Yet another problem was poorly aligned, two-piece, universal pushrod guideplates. See how the guideplate slots aren’t properly centered over the head’s pushrod slots? Even if right when first installed, minimal tang overlap plus the slotted stud mounting holes make it unlikely to remain so. If you must use a two-piece guideplate, after Setting proper alignment, tack-weld the two halves together.

Linkbar-style paired lifters were used because they were available for immediate shipment at the time. Since then, lighter, short-travel lifters that fit the stock late-model block’s spiders have become available and should perform even better in a combo with a late-model block like this one.

Since the heads were off anyway, Brandes went ahead and decked them to raise the static compression from 10:1 to just over 10.7:1. Brandes reports that the EFI system’s Mass Airflow Meter was able to compensate for the cam and compression changes with no additional fine-tuning or calibration required.

Results

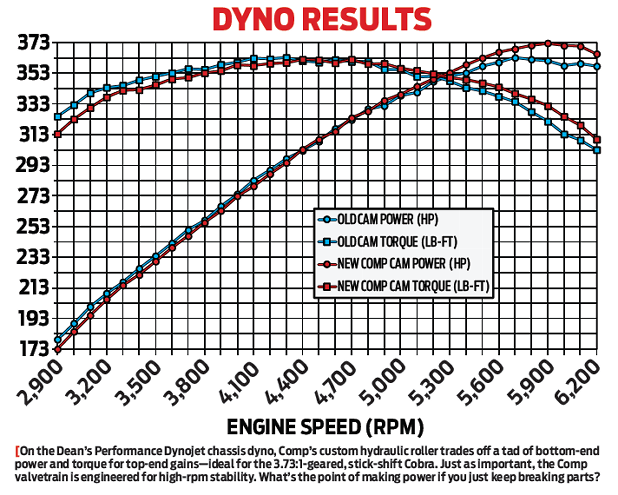

The car was run on the same Dynojet chassis dyno at Dean’s Performance where the original engine was first tested. The combo of higher compression and the new Comp Cams bumpstick installed with complimentary beehive springs, stiffer pushrods, dedicated single-piece guideplates to ensure proper pushrod alignment, and rigid, quality Pro Magnum full roller rocker arms resulted in a 9hp gain (from 363.1 to 372.6 SAE-corrected rear-wheel horsepower). The new peak occurred 200 rpm higher than the previous combo, yet overall average torque and power numbers were virtually unchanged. The new cam’s smoother curve (see graph on page 119) indicates superior top-end valvetrain stability.

Westech decked the Pro Comp heads by 0.026 inch, reducing their 62cc chambers to 59 cc. With a 0.039-inch-thick Fel-Pro performance head gasket, this upped the static compression ratio from 10:1 to 10.74:1. Don’t use a Fel-Pro MLS-type gasket with these heads—it won’t seal against the rectangular machining registers (arrow), leading to minor coolant seepage.

Westech decked the Pro Comp heads by 0.026 inch, reducing their 62cc chambers to 59 cc. With a 0.039-inch-thick Fel-Pro performance head gasket, this upped the static compression ratio from 10:1 to 10.74:1. Don’t use a Fel-Pro MLS-type gasket with these heads—it won’t seal against the rectangular machining registers (arrow), leading to minor coolant seepage.

One thousand miles later, the car still runs strong. Ryan (and family) couldn’t be happier. “It’s making at least as much power as it did before, but the new cam makes it come on much smoother,” Ryan reports.

Lessons Learned

Don’t drive your car when it has no oil pressure; Ryan was lucky he didn’t spin a Bearing and lunch a crank journal. If there is an oil-pump failure, figure out why it failed. Pay attention to little details at assembly; if the oil-pump screen had been positioned slightly higher above the pan floor, the wire may not have been sucked through the screen. A magnetic oil-pan drain plug is also good insurance. Don’t cheap out on the cam and valvetrain; you get what you pay for. Rather than using generic valvetrain parts and an econo no-name cam, consider a matched Set from a quality vendor.

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at pitstop@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.