The Combo

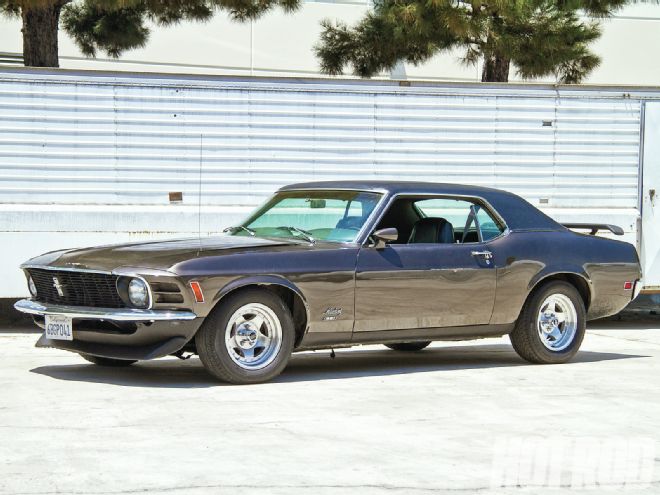

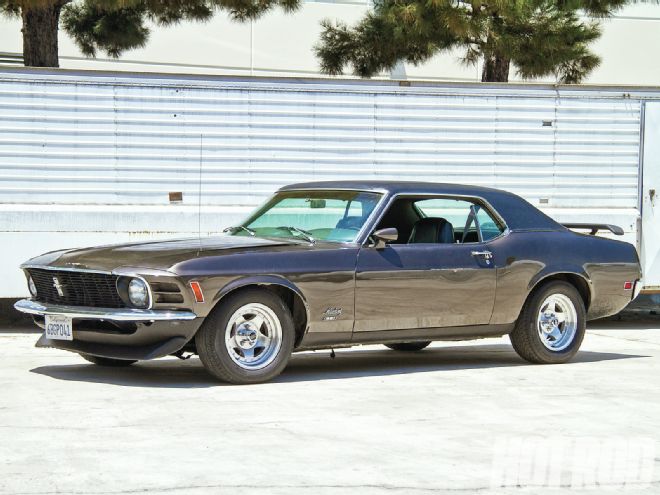

Unlike so many young left coasters, San Diego State University mechanical engineering student Tim Perry's daily driver isn't some Honda weenie but real American muscle: a '70 Mustang with a 351 Cleveland 2V (351C-2V) engine backed by a late-model AOD automatic transmission and a nonlocking, 3.00:1-geared Ford 9-inch rearend. Mildly warmed over, the rebuilt engine sports a stock cam and heads but is upgraded with a 600-cfm Edelbrock Performer carb on an Edelbrock Performer Air-Gap intake, Hooker long-tube headers, and (currently) a large-cap Summit Racing HEI distributor. The Summit unit is basically a GM-style HEI topside with a Ford-compatible bottom half and shaft.

After losing a distributor, college student and car owner Tim Perry had a problem nailing the tune on his warmed-over 351C-2V engine.

After losing a distributor, college student and car owner Tim Perry had a problem nailing the tune on his warmed-over 351C-2V engine.

Perry has owned this classic '70 Mustang Grande for five years, since he turned 16. “It’s my first and only car, and I drive it every day.”

Perry has owned this classic '70 Mustang Grande for five years, since he turned 16. “It’s my first and only car, and I drive it every day.”

The Problem

Perry says things started to go south after the original “Brand X” distributor “blew out on me.” As he tells it, “I knew it was the distributor because I wasn’t getting any spark. I’m now on my second new distributor from a different manufacturer—a Summit HEI—and I still can’t get the stubborn thing to run well. I’ve tried adjusting the initial and final timing, the curve, and the idle mixture, but I’m pretty sure every time I change one thing I mess up two more. Unfortunately, tuning an engine by hand is a lost art, and I have no idea where I can go to have someone help me learn. I figure if anyone can, it’s you guys.”

Well, us and Westech Performance in Mira Loma, California, where ace tech Ernie Mena applied his wizardry to the car on the shop’s SuperFlow chassis dyno. Westech handles everything from routine old-school tune-ups to sorting out complex late-model electronics.

The Fix: Plug Wires

As received by Westech, the 351C was misfiring and stumbling. It was also surging under cruise. Initial inspection revealed several spark-plug wires lying on the headers. On cylinders Nos. 2 and 3 (the second and third cylinders on the passenger side, as Ford reckons it) the wires were burnt clean through. In dim light, arcing was actually visible on No. 3.

As received, the car stumbled and misfired. It turns out the main culprit was poorly routed and burned spark-plug wires.

As received, the car stumbled and misfired. It turns out the main culprit was poorly routed and burned spark-plug wires.

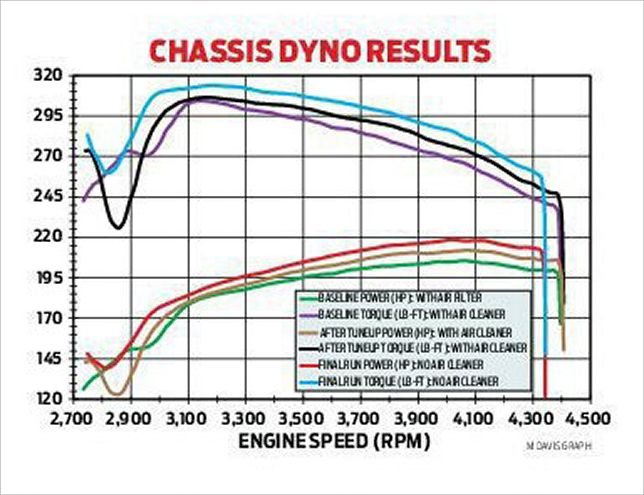

The existing pre-made wire set had 90-degree spark-plug boots and wasn’t really right for the engine installation. Mena custom fabbed a complete new wire set from MSD bulk 8.5mm wire and loose terminals. Replacing the spark-plug wires eliminated the misfires, curing Perry’s main complaint. Now the car was able to make a complete, smooth run on Westech’s SuperFlow chassis dyno, generating, at the rear wheels, 304 lb-ft of torque at 3,150 rpm, and 206 hp at 4,060 rpm. This equates to about 275 flywheel horsepower. At this point, the carb was internally box-stock; still, even after properly adjusting the idle mixture, the carb was lean at part-throttle tip-in, lean at cruise, and fat on top, with an 11.3:1 air/fuel (A/F) ratio. We couldn’t have that.

The Fix: Tune-Up

On Edelbrock Performer carbs, step-up (metering) rods regulate primary-side fuel metering. Because each rod rises out of the primary jet orifice as the throttle blades open further and engine vacuum decreases, thinner (smaller od) rod tips richen the fuel curve. Each rod tip has two steps. Mena replaced the original rods with those with a richer cruise-step but an unchanged (neither richer nor leaner) power step (see table on page 126).

Step-up springs located under the step-up pistons control how fast the step-up rods pull out of the primary-jet orifices. They’re the AFB carb’s equivalent to a Holley power-valve circuit. The step-up springs start to pull the metering rods up off the seat at a discrete vacuum point. Vacuum is high at cruise and drops during the transition to wide-open throttle (WOT). Perry’s carb had blue springs that opened at 3 inches Hg, which caused a lean condition under tip-in throttle and heavy-load conditions like climbing a long hill. To bring in power enrichment earlier, Mena replaced them with silver springs that open at 8 inches Hg.

The carb remained fat at wide-open-throttle (WOT), so the secondary jets were leaned out several steps.

As for the distributor, it turned out the mechanical advance curve was right-on for the engine: 15 degrees initial timing, 35 degrees total. All Mena did was advance the initial timing 2 degrees, for a total of 17 degrees initial and 37 degrees total.

With the carb and distributor pretty much dialed in, the engine picked up about 2 lb-ft and 6 hp at the wheels. WOT A/F ratios improved to 12:1. Still, the gains did not seem commensurate with the effort. Mena felt something was holding the car back. Was it the car’s small 9-inch-od air cleaner?

The Fix: Air Filter

Sure enough, the air cleaner proved a restriction. When Mena removed it, the engine gained about another 8 lb-ft and 7 hp over the best run with the air cleaner installed, with max output climbing to 314 lb-ft at 3,190 rpm and 219 hp at 4,020 rpm. At 12.5:1, the WOT air/fuel ratio was now just about in the ballpark for best power.

Obviously, the Mustang needed a bigger air filter. But what fits? The tight engine bay and rather massive 351C engine installation was hounded by the large-cap HEI distributor in front, intrusive shock-tower braces at the rear, and a low hoodline. After much measuring and head scratching, the biggest air filter that fit turned out to be a unique K&N triangular assembly, turned around backward so the triangle’s base faced toward the distributor. A little outside the box, perhaps, but it does fit, and its airflow capacity more than meets the engine’s airflow needs.

03, 04, 05: Dial-in Edelbrock Carb 01, 02: Custom MSD Spark-Plug Wires <br />

03, 04, 05: Dial-in Edelbrock Carb<br />

06: Relocate Vacuum-Advance Hose <br />

07: Harmonic Damper Delaminating <br />

08: Silence Ticking Lifter <br />

09, 10, 11: Upgrade Undersize Air Filter<br /><br />

Installing new spark-plug wires cured the misfire. But recalibrating the carb and finding a larger air-cleaner assembly that cleared all obstructions were also keys in getting the car to be all it could be. A couple of other things will need future attention. The callout numbers correspond to the detailed photos on the following pages.

01, 02: Custom MSD Spark-Plug Wires <br />

03, 04, 05: Dial-in Edelbrock Carb<br />

06: Relocate Vacuum-Advance Hose <br />

07: Harmonic Damper Delaminating <br />

08: Silence Ticking Lifter <br />

09, 10, 11: Upgrade Undersize Air Filter<br /><br />

Installing new spark-plug wires cured the misfire. But recalibrating the carb and finding a larger air-cleaner assembly that cleared all obstructions were also keys in getting the car to be all it could be. A couple of other things will need future attention. The callout numbers correspond to the detailed photos on the following pages.

Results

From its initial wheezing baseline, the Mustang picked up about 10 lb-ft and 13 hp. Just as good, it was much more driveable both around town and at steady-state cruise. Expending a little extra effort to custom tailor the spark-plug wires for a unique engine configuration should yield future reliability dividends. And as shown in several photos, we also caught some other, presently noncritical things that will need future attention.

Lessons Learned

Before you blindly swap parts, first be sure the parts you have are properly installed. Keeping the spark-plug wires off the headers would have prevented a lot of grief. When there’s a legitimate problem in need of a solution, don’t be afraid to think outside the box—as in the oddball air-cleaner fix.

Need Junk Fixed?

If your car has a gremlin that just won’t quit, you could be chosen for Hot Rod to the Rescue. Email us at pitstop@HotRod.com and put “Rescue” in the subject line. Include a description of your problem, your location, and a daytime phone number.

Perry Edelbrock 1406 carb Calibration Tune Up Step-Up Rods Step-Up Springs Secondary Metering Jets Step-Size OD (Inches) ID Stamped On Part Part No. (ONE Pair) Color Opening Point Spring Kit Part No.* Orifice ID (Inches) ID Stamped On Part Part No. (ONE Pair) BEFORE 0.075 × 0.047 7547 1459 Blue 3 in Hg 1464 0.095 120–395 1426 AFTER 0.073 × 0.047 7347 1456 Silver 8 in Hg 0.089 120–389 1424 *Springs not sold individually; all five available spring pairs are available in Step-Up Spring Kit PN 1464.

01] There are no “correct” pre-made wire sets for a Cleveland Ford with a front-mounted GM HEI-style distributor, so to replace the damaged wires, Mena made a complete new set from MSD bulk wire parts. The flexible, straight spark-plug terminals he used are bendable up to 90 degrees, allowing the end user to achieve the perfect spark-plug intersection angle.

02] For the rest of us, the closest retail equivalent is a black MSD two-in-one 8.5mm universal wire set (PN 31193). It has extra-long, cut-to-length wires with the bendable spark-plug terminals already installed. For the other end, the kit includes loose, old-school distributor-socket and HEI terminals.

03] To access the primary step-up rods and springs and secondary main jets on an Edelbrock or AFB carb, disconnect the linkage, remove the lid retaining bolts, and lift the top of the carb up and away from the main body.

Parts and Prices Includes major parts required to fix the problem. Does not include labor, shipping, sales taxes, small electrical parts and wire, or machining costs. Priced 08/18/12 and subject to change. Company Part Description Part No. Amount Price Source Price Edelbrock Jets, secondary metering, 0.089-inch orifice, 1 pair 120-389 1 Summit $5.69 Rods, primary step-up, 0.073 × 0.047 inch, 1 pair 1456 1 Summit $11.69 Spring Assortment, step-up rods, five different pairs/kit 1464 1¹ Summit $6.95 Hasbro Play-Doh Modeling clay, pack of four 2-ounce cans, classic colors 22114 As required Toys“R”Us $3.99 K&N Air Cleaner Assembly (Complete), 14-inch triangle, chrome 60-1470² 1 Summit $122.95 Marvel Mystery Oil/Lubricant, 16oz (½-quart) bottle MM12R 1 Amazon.com $4.49 MSD Wire-Set, spark plug, 8.5mm-od, black, 2-in-1 V8 universal, multiangle boots 31193 1 Summit $87.95 NOTES: ¹Kit contains five different spring pairs; one pair of silver springs used (opens at 8 in Hg). ²Replacement element only: PN E-3737. TOTAL $243.71

04] On a primary step-up rod, the higher “lean” step is for cruise/high-vacuum conditions; the “rich” or power step at the tip end comes into play when the rod pulls all the way up out of the orifice during the transition to WOT. The existing rods were replaced by those with a richer (thinner) cruise step but the same power step.

05] The secondary side has conventional main jets. Those with a smaller orifice size lean the fuel mixture. To lean out the top end, Mena replaced the carb’s existing 0.095-inch-orifice metering jets with 0.089-inch-orifice jets.

06] We’ve been seeing a lot of misrouted vacuum-advance hoses. Don’t hook your distributor vacuum advance up to full-time (manifold) vacuum. Instead, connect to a spark-ported (timed) vacuum, as shown here on the Edelbrock carb. At this port, vacuum is low at idle and high at cruise, as it should be for best cruise performance and for preventing engine run-on.

07] One thing Perry will need to keep an eye on: Although not yet “condition red,” Mena observed the rubber insulation between the inner and outer harmonic-balancer rings had begun to flake and deteriorate. He checked TDC, and so far the balancer hadn’t spun. But Mena says it will eventually.

08] After the tune up, Perry took a test drive, returning five minutes later with a lifter tick. Oil pressure checked out OK. Maybe some debris in a lifter? Half a quart of Marvel Mystery Oil—a time-tested “secret” lubricant with lots of detergent good for breaking loose sludge and debris—quieted things down. Perry says 500 miles later, the problem has not returned.

09] Perry’s 9-inch-round air filter was a restriction, but there was limited room for a larger unit. We checked hood clearance with columns of Play-Doh clay placed on the front and rear carb flanges. The hood was shut to compress the columns. After opening the hood, the now-compressed columns revealed about a 4¼-inch clearance envelope.

10] A tape measure showed the lateral clearance to be about 10 Inches from the carb’s air-cleaner mounting stud hole to the closest point on the shock-tower braces, and 7½ inches to the distributor.

11, 12] Ultimately, we found the biggest air cleaner that fits and flows enough air for the engine’s needs was a 3.62-inch-high K&N triangular unit (assembly PN 60-1470) mounted backward, with the triangle’s tip facing toward the rear instead of the front. At its rated 495 cfm, the total airflow is roughly equivalent to a round, 14-inch-od x 3-inch-tall filter.

How Much Air Filter Do You Need?

To find the best solution for Perry, K&N sent over a pile of air cleaners. Although the 14-inch, 495-cfm triangular assembly we settled on had the highest flow while still clearing everything, an 11x3 round element fitted with an Xtreme Top (center) that supplies extra filtering area comes in a very close second at 489 cfm.

To find the best solution for Perry, K&N sent over a pile of air cleaners. Although the 14-inch, 495-cfm triangular assembly we settled on had the highest flow while still clearing everything, an 11x3 round element fitted with an Xtreme Top (center) that supplies extra filtering area comes in a very close second at 489 cfm.

Be sure your engine isn’t being choked by an undersize air filter. You can’t go wrong with fitting the largest filter there’s room for, but what if, like Perry, you have a tight engine bay? In that case, you’ll need to find the minimum acceptable filter size based on the engine’s actual air flow in cfm (cubic feet/minute) at maximum engine speed (rpm). In the absence of actual dyno data, estimate a four-stroke engine’s airflow in cfm by factoring its max rpm, displacement (cid), and VE (volumetric efficiency) into the following equation. The filter experts at K&N Engineering recommend using a VE value of 85 percent (0.85) for a normally aspirated (NA) engine.

Perry says he never revs his 351C over 5,000 rpm. Plugging that number into the standard equation, we get:

The equation indicates the need for an air filter that flows 431 cfm. K&N rates its premier washable filter elements at a conservative 11⁄2 inches of water-pressure drop (that’s about equal to 0.1 in Hg). As K&N’s Kevin McClelland puts it, “You want the lowest pressure-drop filter that still gives you the best dirt-stopping efficiencies.” K&N is in the process of flow-testing all its thousands of filter elements, then posting the numbers on its website. So far, only the most popular filters are listed, but in about a year from now, K&N says the project should be fully completed.