There's a place in this world for wretched excess. We're talkin' in-your-face, old-school stuff like a pair of Holley carburetors stuck on top of a monster blower sticking through the hood with a cogged beltdrive that sings like an high-pitch chainsaw. This is classic car crafting, harkening back to the days when you had to look around that huge blower to know when the stoplight turned green. Somehow we've gotten away from that, and there are those who mourn those days. Sitting on the shop floor at the giant Car Craft shop (where Hot Rod has to ask us to use the hoist) was this huge Weiand 6-71 blower just daring us to bolt it on something. It was just like the Siren's song in Greek mythology, and we're one of those ancient mariners who shipwreck onto those giant 6-71 supercharger rocks. Yeah, sail on, brother. Weiand 6-71 Blower whine—give me all you got!

Blown Small Block Chevy 383

So after getting all pumped up on supercharger bench racing, we decided to bolt this big Weiand 6-71 blower on Editor Douglas Glad's much-abused 383ci small block Chevy. Way back in the September '07 issue (“Are Premium Parts Worth the Price?”), we tortured that Lunati rotating assembly 383, with its big Comp Cams grind and Dart aluminum heads, by running a couple of dozen parts across it. The motor never missed a chance to shine and eventually made an impressive 571 hp at 6,900 rpm. Since it's bad karma to let a powerful engine like this just sit around, we ignored common sense and bolted the Weiand 6-71 blower on, hoping that the tight lobe-separation angle and the high compression would kinda cancel each other out. We could have changed the cam (or the compression with different heads), but we didn't. Save your poison emails telling us how wrong we are—we already know. Sometimes you do stuff in spite of the consequences. We just wanted to see what different pulley ratios would do to the power. Most car guys think that more ratio is better. We decided to find out. If you subscribe to the “more is not always better” approach to life and high performance, you might like what happens. But enough rhetoric. If you listen carefully, you can hear the Sirens singing. Crashing is optional.

Blown Small Block Chevy Boost Chart

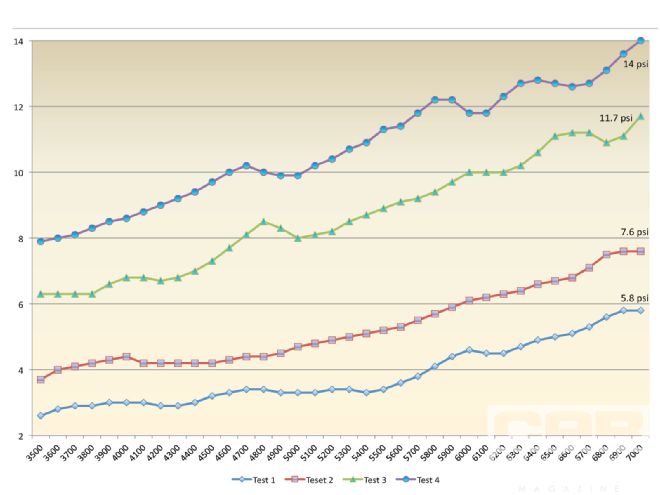

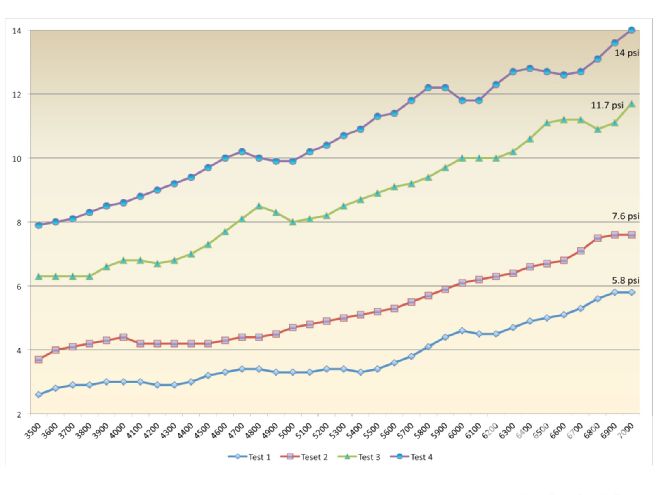

Blower speed is a direct result of the combination of the lower (drive) pulley and the upper (driven) pulley. While this may seem simple, small changes in tooth count can have a drastic effect on power. Below is a simple chart we created based on the four pulleys we had. Unless you have deep pockets (each pulley costs a minimum of roughly $150), three or four pulleys can give you a wide range of boost potential. In the tech service section on Holley's website (www.holley.com), under supercharger instructions, you can find a chart in which Holley lists effective boost combinations based on engine family and displacement. For our blown small block Chevy 383 SBC, for example, the chart says that a 10 percent underdrive should produce 10 psi of boost. Our test showed 7.5 psi, which is relatively close, especially considering our cam has a tight (110-degree) lobe-separation angle, which tends to reduce the boost level compared with a 112- or 114-degree lobe-separation angle. Also, note in test 3 that adding nine teeth to the lower pulley changed the underdrive/overdrive ratio from -11.5 percent to +3.3 percent and caused the boost to increase by 4 psi. The total tooth count is important because there's a range of pulleys that can use the same belt length. Holley lists a complete ratio chart of all its pulleys in the blower instructions.

Test Bottom Pulley Top Pulley Total Teeth Under/Over Percentage Max Boost (psi) 1 51 63 114 -19 3 2 54 61 115 -11.5 7.5 3 63 61 124 +3.2 11.7 4 61 55 116 +10.9 14

Power Curves

First of all, bang the gong and call out the Marines—we made 706 hp with a little 383ci small-block with a venerable 6-71 and only 14 pounds of boost. That's pretty cool. We also made an impressive 603 hp with barely 6 psi of boost. But let's look beyond the “more boost!” peak horsepower curves to see what else our test reveals. Comparing the first two peak horsepower tests, the difference is less than 2 psi of peak boost pressure, increasing from 5.8 to 7.6 psi. Despite this small boost increase, the engine gained 39 hp at a peak of 642 hp. Now let's look at the change in horsepower between test 3, with 11.7 psi (694 hp) and test 4 (706 hp), with 14 psi. This is a similar boost increase of 2.3 psi, yet the power gain was only 12 hp. The explanation for the smaller increase at the higher boost level is the enemy of all superchargers: heat. While we didn't sample the intake-manifold temperature, if we had we would have seen a major increase in heat with the higher boost levels of 11.7 and 14 psi. While we did add boost, and power did increase, you can see in the horsepower graph that the increase in power between tests 3 and 4 isn't nearly as impressive as the gain between tests 1 and 2. At the higher blower speeds and boost levels, the supercharger makes much more heat because it's working harder. Anytime you heat the air, it becomes less dense. So even though the engine sees a higher boost level, the increase in inlet air temperature reduces the density (oxygen content) of this volume of air. Oxygen is the key to making more power, and with less dense air, we have less oxygen. That's why the power improvement from test 3 to 4 isn't very good. This results in less performance for the addition of the same amount of boost. If we had kept going, eventually we would have seen that 16 or 18 psi of manifold pressure would not make as much horsepower as would 14 psi. More boost is not always better.

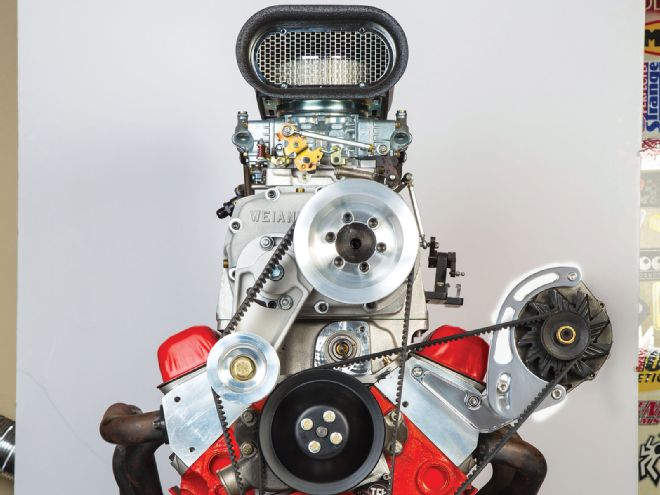

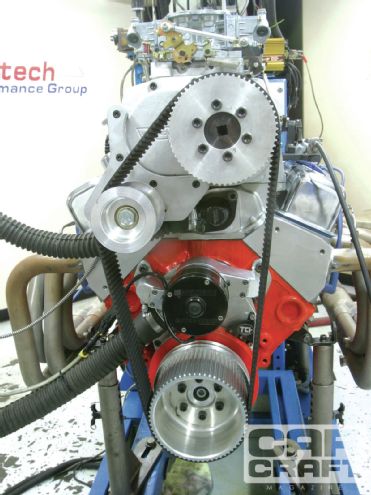

There’s a lot going on in this photo. Let’s start with the pair of Holley boost-referenced blower carburetors. These Holleys use special metering blocks that add power enrichment when referenced to manifold pressure below the blower. There’s more—the Weiand linkage and fuel-line kits. The fuel lines were a breeze to install. The linkage kit took some time to finesse but was not difficult. The key is to open the carburetors evenly with the least amount of linkage travel.

There’s a lot going on in this photo. Let’s start with the pair of Holley boost-referenced blower carburetors. These Holleys use special metering blocks that add power enrichment when referenced to manifold pressure below the blower. There’s more—the Weiand linkage and fuel-line kits. The fuel lines were a breeze to install. The linkage kit took some time to finesse but was not difficult. The key is to open the carburetors evenly with the least amount of linkage travel.

One way to improve this situation is to somehow cool the charge coming out of the supercharger. This can be done with an intercooler, which is unwieldy with a Roots blower. Another way is with water injection, which works very well. A third method is to use E85 fuel. This 85-percent-ethanol fuel enjoys a very high latent heat of vaporization, which means it absorbs a lot of heat, reducing the blower discharge temperature and increasing inlet air density without affecting boost. Plus, E85 has a nominal octane rating of 105, which makes it an outstanding fuel for superchargers. You will need special carburetors, an E85-compatible pump, and fuel lines to move the additional amount of fuel needed when using E85, but it's a great idea that works extremely well.

This straight-on view of the blower gives you a good idea of how pulley ratios work. The larger the crank (drive) pulley and the smaller the upper pulley, the faster it will spin the blower (driven) pulley. For the record, underdrive is the exact opposite with the crank pulley smaller than the blower pulley.

This straight-on view of the blower gives you a good idea of how pulley ratios work. The larger the crank (drive) pulley and the smaller the upper pulley, the faster it will spin the blower (driven) pulley. For the record, underdrive is the exact opposite with the crank pulley smaller than the blower pulley.

Good Gas

Because we were starting with a high static compression ratio of 10.9:1, we needed to use a high-quality, high-octane fuel. Rockett's best fuel is a 118-octane blend that mixes 120 RON with 115 MON fuel to deliver that 118 R+M/2 octane rating. The key is the high MON number when it comes to blower engines. If we'd had access to a set of E85 carburetors, it would have been fun to see how Rockett Racing's race E85 fuel would have performed. We're betting the power would have jumped at least another 20 to 30 hp. With the Rockett race gasoline, we exercised restraint with only 28 degrees of total timing. A lower static compression ratio would have allowed for more timing and perhaps more power.

Parts List

Description

PN

Source

Price

Weiand 6-71 blower kit

7482

Summit Racing

$3,009.95

Weiand blower pulley, 8mm pitch

7109-XX

Summit Racing

149.95 (and up)

Holley 750-cfm blower carbs

0-80576S

Summit Racing

785.95 (2)

Weiand 2x4 linkage kit

7166

Summit Racing

199.95

Weiand fuel line kit

7093

Summit Racing

365.95

MSD Pro Billet distributor

85551

Summit Racing

229.95

MSD spark plug wires

31229

Summit Racing

82.95

Comp mech roller lifters

818-16

Summit Racing

405.95

Comp Hi-tech pushrods

7993-16

Summit Racing

145.95

Comp roller rockers

19002-16

Summit Racing

307.95

ARP head bolts

134-3603

Summit Racing

114.76

Fel-Pro head gasket

1010

Summit Racing

41.95

Fel-Pro intake gasket

1209

Summit Racing

30.99

Autolite race spark plug

AR-3910x

Carshopinc.com

6.95 (x8)

Rockett Race Gas

118

Rockett Brand

See dealer list