Once again HPP was to spend a day on the dyno with Bob and Craig Wise of RaceKrafters. This time Project Pure Poncho (aka The Mule) would be used to do testing on oil instead of swapping parts or making tuning decisions. The protocol was to run a series of oil weights through the engine and see how it responds in horsepower, torque, and oil pressure.

There has been a good deal of buzz about oil the past few years with changes in chemical composition. For this reason, we were looking forward to working with Brad Penn to supply our oil needs for this test. By sticking with one manufacturer, we are able to control the test and provide accurate results. Brad Penn supplied three test weights from its extensive offerings. The Mule would have its 7-quart oil pan filled with 0W-30, 10W-40, and 20W-50 from the company’s partial synthetic line (a blend of mineral and synthetic oil). RaceKrafters uses Brad Penn oil in its high-horsepower street/strip engines. The Mule already had Brad Penn 30-weight break-in oil in it.

Our 467 Mule engine prepared for another round of testing.

Our 467 Mule engine prepared for another round of testing.

The protocol of the test was to baseline the engine with the original break-in oil, and then drain and refill with each product, along with a new ACDelco oil filter. Three to four runs would be made with each grade of oil and the results tabulated. Much care was taken to keep oil temperature for each test as close to identical as possible, while maintaining similar water temperature.

Brad Penn oil is formulated to eliminate the lubrication concerns of Pontiac owners. The oil has all of the necessary phosphorus (1,340 ppm) and zinc (1,500 ppm) that is required for any type of camshaft or valvespring pressure. No further additives are required.

Due to the crude stock Brad Penn uses, the oil has a tenacious ability to cling to the internal engine parts, which we witnessed first hand. In engineering parlance, this is identified as wettability, and it’s important for a Pontiac engine. Even after being idle for long periods of time, many of the parts will not go dry—a key to performance and long life.

For more information about oil, visit www.highperformancepontiac.com/oil1 and www.highperformance pontiac.com/oil2 for an overview of the rating standards used today.

To properly understand our test and how the Brad Penn product applies for Pontiacs, a good foundation of knowledge needs to be established.

This time it’s oil. We tested three different viscosities from Brad Penn to gauge the effect on power.

This time it’s oil. We tested three different viscosities from Brad Penn to gauge the effect on power.

The Meaning of Friction

Friction is the resistance that one surface or object encounters when contacting and sliding over another. If the surfaces are rough, small irregularities will fit together at the contact area to create a mechanical lock or hindrance to motion. If the surfaces are extremely smooth, the force fields around the molecules will attract each other, and the parts will resist motion due to the molecular attraction. Friction on dry surfaces is a result of both molecular attraction and mechanical irregularities.

Friction between sliding surfaces can be reduced by the presence of a lubricant. The function of the lubricant is to displace the two surfaces and reduce both the mechanical interference and molecular attraction. The lubricant should be able to adhere to each surface by molecular attraction and yet be amenable to molecular displacement.

Each layer of lubricant is subjected to a shearing stress, and the force required to overcome the stress is known as the fluid friction.

Fluid or internal friction is a result of the resistance of the lubricant to the shearing stress. A measure of a lubricant’s resistance to shear is called viscosity, or coefficient of viscosity. The viscosity of a lubricant helps to drag the fluid into the separating space between two surfaces, and then retards the escape from the squeezing action that normally occurs as forces try to bring the two surfaces together.

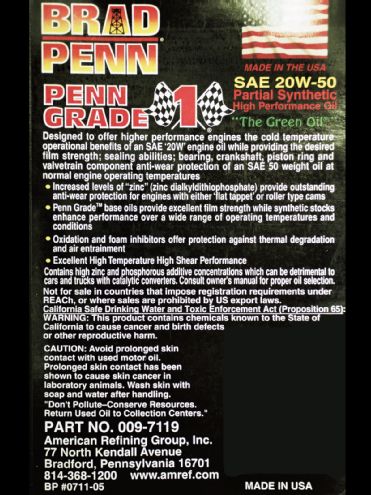

1 The rear label on the oil bottle is very informative and explains the benefit of the high zinc and phosphorous content and also warns about catalytic converter usage.

1 The rear label on the oil bottle is very informative and explains the benefit of the high zinc and phosphorous content and also warns about catalytic converter usage.

The term viscosity index is applied to motor oil as a rating and is defined as a measure of the viscosity/temperature behavior of an oil. It is based on an arbitrary scale of 0 to 100. Zero is representative of very naphthenic oil, which thins down rapidly when heated, and 100 is indicative of paraffinic oil, which thins less rapidly. Because of these effects, a pressure is created in the lubricant, which can be induced and maintained by employing a wedge action within the engine bearing surface.

The Oil Wedge Theory

When an engine is not running, the crankshaft rests on the bearings. When the engine starts and oil pressure is created, the crankshaft moves up on the bearing and pulls some oil under it. As crankshaft rotation continues, the oil is wedged between the shaft and bearing, keeping them separated.

As engine speeds and loads change, the position of the crankshaft with respect to the bearing changes also. Under certain conditions, the mating surfaces may actually break through the oil wedge. There is still enough of an oil film to prevent scoring, but not enough to keep the crankshaft and the bearing completely separated.

Do not confuse the designed oil clearance with the space between the crankshaft and bearing made by the oil wedge. The oil wedge film is approximately 0.0001-inch (1⁄10,000), while the machined clearance for a main or connecting rod bearing is usually between 0.001 to 0.003-inch.

The composition of the engine oil then needs to support the pressure load placed upon it as the flame in the cylinder expands and sends the piston down in the bore. The higher the viscosity (what we define as weight), the greater the load the oil wedge can support, since its escape from the oil clearance is hindered by friction.

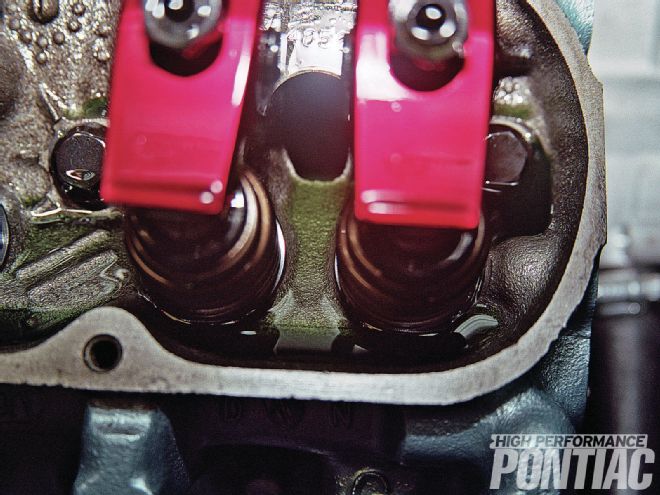

2 We baselined with 30 weight break-in, then tested 0W-30, 10W-40 and finally 20W-50 oil, since we wanted to leave the 20W50 in the engine for future use. The thicker oil heats slower and allows for repeated dyno runs with less cool down time. The Mr. Gasket valve covers were removed for each oil change to aid in filling. It was quicker to remove the cover than pour seven quarts through a small hole.

2 We baselined with 30 weight break-in, then tested 0W-30, 10W-40 and finally 20W-50 oil, since we wanted to leave the 20W50 in the engine for future use. The thicker oil heats slower and allows for repeated dyno runs with less cool down time. The Mr. Gasket valve covers were removed for each oil change to aid in filling. It was quicker to remove the cover than pour seven quarts through a small hole.

Functions of a Lubricant

The main purpose of a lubricant is to prevent wear and reduce friction. These desired properties can have both positive and negative effects. As an example, oil shall prevent wear in the engine but should be made so it does not corrode any of the parts it comes in contact with. As with most things, engine oil is a compromise. A better oil just limits the give-and-take.

The ability of an oil to meet any particular requirement is usually determined by testing. Standards used to test the oil need to be uniform. The American Petroleum Institute (API), along with the Society of Automotive Engineers (SAE), have been responsible for determining both test and grading standards. For example, the viscosity index can be listed as SAE 10W-40. In contrast, the test standard that the oil confirms to is listed with the API prefix, API SG/CC. Some vehicle or engine manufacturers may have created their own standard above the API testing. In this case, their engine requires certain components in the oil that would only be met by a lubricant of that design.

Desired Oil properties

Friction reduction: This reduces the energy requirements to operate the mechanism and reduces local heat generation.

Wear reduction: An obvious need for keeping equipment operating for a longer period and in an efficient manner.

Cooling: In an engine, the lubricant is an initial heat transfer agent between some parts heated by combustion (pistons), and the heat dissipating systems. In other systems of the engine, the lubricant dissipates heat generated by friction or the mechanical work performed.

Anti-corrosion: Either from its own detergent, or by combustion contamination, the oil cannot become acidic and corrode metal. Moist environments and the lack of use can also cause the rusting of ferrous components. The lubricant should counter all of these effects.

Cleaning action: The oil should prevent fouling of mechanical parts from its own degradation or from combustion contamination. Deposits, classified usually by descriptive terms such as solid carbon, varnish, or sludge can interfere with the correct and efficient operation of the engine. In extreme cases, piston rings may become stuck and oil passages blocked if the oil does not prevent these effects.

Sealing: The oil should assist in forming the seals between piston and cylinder.

Undesirable Oil Properties

Too low a viscosity: This will allow metal-to-metal contact and subsequent wear, and can increase oil leakage.

Too high a viscosity: This will waste power and, in the case of some engines, cause starting difficulties and limit the flow of lubrication on initial start-up.

3 The Pennsylvania Grade crude has excellent wetability, as evidenced by it clinging to the tip of the Comp Cams 1.65:1 roller rockers.

3 The Pennsylvania Grade crude has excellent wetability, as evidenced by it clinging to the tip of the Comp Cams 1.65:1 roller rockers.

Too low a viscosity index: This means that it must not thin down too much when hot.

Too volatile: High volatility will appear as a loss of oil (high oil consumption) from the boiling away of the lighter constituents and it has been said to also create deposits.

Foam unduly in service: If an oil foams, this can result in loss of lubricating properties of the oil and the loss of the oil itself from the engine.

Weak to oxidation or chemical attack: Engine oils in particular are subject to high temperatures and contamination by acids and other chemicals. The oil must be resistant to these to preserve its beneficial properties.

Attack emission systems components, coatings, or seals: Catalytic converter performance can be degraded by unsuitable oils or additive treatments, and is the reason for the removal of zinc and phosphorous.

Produce deposits from residues: If an oil decomposes on hot metal components, it produces oxidation products, which polymerize to form a yellow or brown layer known either as varnish or lacquer. This can build up and further carbonize to solid carbon. Either type of deposit can prevent movement of parts.

Modern Motor Oil

The discovery of petroleum in Pennsylvania in 1859 brought about the use of mineral oils that gradually displaced fixed oils for lubricating machine parts. Fixed oils can be animal oils, such as lard or fish oils and vegetable oils like castor oil. The difference between fixed oils and fats is one of temperature only—fats being readily converted into oils when heated. Such fatty oils while good lubricants are not chemically stable and tend to form gums.

The primary division of crude oil by fractional distillation at atmospheric pressure into components of different volatilities is considered part of the refining process. Heavier portions of this process are the reduced crude which contain lubricating oils as well as possible wax and asphalt materials. When we purchase engine oil, what we are getting is a highly refined crude petroleum product that has been blended with additives for the desired performance.

Most engine oils are classified as multi-grade, which indicates that the oil has the characteristics of two different viscosity indexes. Since the temperature of the engine and thus the oil changes from start-up to maximum operating load, a multi-grade oil is required.

When oil is cold, its viscosity changes and it becomes thicker. As it’s heated, the viscosity index number drops and the oil thins.

During initial start-up the oil needs to limit the amount of pumping and rotational friction to allow the starter motor the ability to turn the crankshaft. The oil needs to start to flow quickly to limit the amount of time the engine will run dry, meaning that there is no lubrication. What does become an issue is the oil’s ability to sustain the pressure load placed upon it and still maintain the oil wedge or cushion.

4 These were the 1.5:1-ratio Comp Cams rockers we ran for testing almost one month ago. Look how the oil is still holding on to this part that’s not even in the engine anymore.

4 These were the 1.5:1-ratio Comp Cams rockers we ran for testing almost one month ago. Look how the oil is still holding on to this part that’s not even in the engine anymore.

With the development of multi-grade oils, the lubricant now possesses two distinct personalities. A 10W-40 oil would flow with the characteristics of 10 weight when cold but will maintain the oil cushion properties of 40-weight when heated. Even though this is the accepted definition of a multi-grade, the product is a compromise and does not have the absolute flow characteristics of a single grade oil of either weight. The test temperatures for a 10W-40 viscosity are -22 degrees F and 210 degrees F.

The required weight of the oil is an engine design function that takes many engineering factors into consideration, mainly the bearing clearances. An engine that is manufactured to tighter clearances would require a thinner oil to enter the necessary regions, while a loose engine would require a thicker oil to consume the area and maintain the oil wedge.

For many years, the factory fill was a break-in oil. This was defined as straight oil containing no anti-wear additives. The intent was to accelerate the removal of high spots, which are known as asperities from the rings and cylinder walls. When rebuilding a Pontiac engine, a modern break-in oil with specific additives should be used.

In the ’70s, technology was developed that allowed the car companies to factory fill with fully formulated balanced oils (not break-in) with specially selected anti-wear additives. These were active at the high temperatures generated around asperities and helped remove these chemically without scuffing. After the asperities were removed and the mating surfaces were smooth, high temperatures were no longer created, and the chemical wear ceased.

5 The oil was thoroughly drained between tests. It was a shame to put such good oil in the waste drum after only a few dyno pulls. Brad Penn oil is known for its green color, which is a function of the base crude that is employed.

5 The oil was thoroughly drained between tests. It was a shame to put such good oil in the waste drum after only a few dyno pulls. Brad Penn oil is known for its green color, which is a function of the base crude that is employed.

The Needs of the Pontiac

The use of most street-driven collector Pontiacs can be categorized as severe duty. Numerous cold starts and short trips introduce fuel to the crankcase and are killers of any oil. Gasoline has no lubricity and even the smallest amount in the crankcase will reduce the oil’s ability to reduce friction. Another concern is the long periods of inactivity, which allows moisture to enter the engine and mix with the oil, creating corrosion.

Choosing a viscosity is critical, since the design of the engine and clearances need to be acknowledged. If your engine is completely stock and has not been rebuilt, follow the original Pontiac recommendations for weight.

If your engine has been rebuilt or modified, talk to the engine builder about his preference for the bearing clearances and material used. If you do not know who rebuilt the engine or are in doubt if it is original, start out by using a 10W-40 and adjust the weight accordingly. This can be determined by listening to the engine on initial start-up—if it sounds dry and the valve lifters take a long time to pump up then switch to a 5W-30.

The goal is to have an oil that flows quickly on cold start but is viscous enough to support the oil wedge between the parts. With few exceptions, a good quality 5W-30 oil is a very desirable product for a Pontiac or even a 0W-30. This will allow for very quick oiling of the engine on crank with sufficient viscosity once it gets hot to protect the engine from metal-to-metal contact. A Brad Penn oil of this weight features the additional benefit of wetability and will cling to the engine parts after it is shut down.

The Results

It is important for the readers to understand what our test data reveals. When choosing an oil, do not make a decision based on which made the most horsepower on the dyno at the oil temperature and conditions we exposed it to. Note that the difference was minimal and other factors need to be applied, such as how the Pontiac is driven, the oil temperature under use, and how often it is cold started.

6 The oil filter was replaced with each oil change so that no cross-contamination occurred.

6 The oil filter was replaced with each oil change so that no cross-contamination occurred.

Oil viscosity impacts the lubricant’s ability to absorb heat. A thinner oil will build heat quicker and can be a real attribute for a Pontiac that is not driven long distances or under full load for any amount of time. Getting the oil up to temperature sooner will limit engine wear and improve fuel economy.

In contrast, a thicker oil will take longer to build heat. This can very easily be seen on a dyno. Many engine builders like to run a 20W-50 on the dyno, since they can make more pulls before the oil becomes heat soaked and long periods of cool down are required. Thus, your Pontiac may be dynoed with 20W-50 but the engine builder may recommend 10W-30 for use after it is installed in the car.

Oil pressure is another area of confusion. In theory you want the lowest oil pressure necessary to keep the oil wedge maintained. Anything more and you are wasting horsepower.

Our Mule was built with a Melling M54DS oil pump that Craig set to 25 to 40 psi at hot idle with a maximum high-speed pressure of 80 psi.

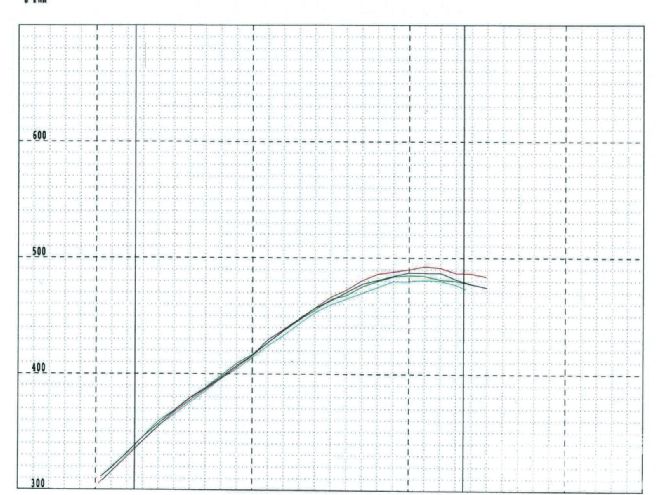

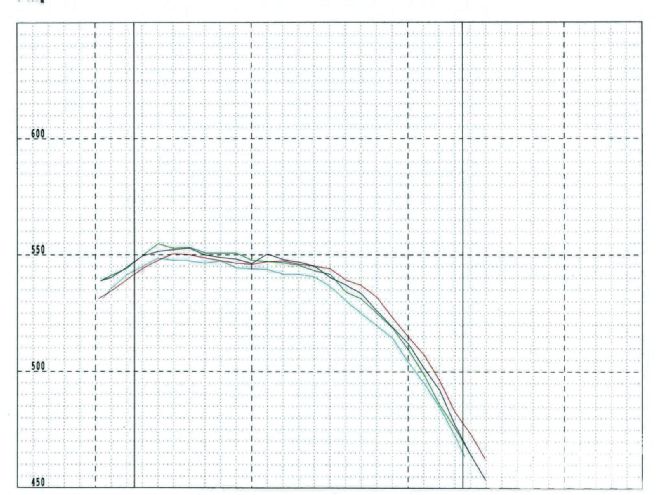

When reviewing the results, it must be noted that the baseline run had the very beat-up Brad Penn 30-weight break-in oil and was run at a slightly lower temperature than the others. We needed to balance the water and oil temperatures to provide accurate results. After all of the dyno runs, the break-in oil was no longer 30-weight and had degraded.

As the oil viscosity changed, the work the engine required to pump it was seen. It is important to reference the average power and torque, since that tells a more accurate story than the peak readings. As viscosity went up the power dropped slightly.

Removing the break-in oil results from the equation, there was less than four horsepower loss on the average between the thinnest and thickest oil. This can easily be read as a defense for using thick oil but that would be incorrect as it removes the need for quick pump-up on cold start and restarting, along with how the oil builds temperature. The use of the Pontiac along with the engine specifications are paramount on choosing a weight.

What does not change is the need for the proper additives along with the wetability and the quality of the product. The Brad Penn oils fit the needs of the street/strip Pontiac owner in every grade offered.

About Brad Penn

Dick Glady, vice president of sales and marketing for Brad Penn, says, “Here the Penn Grade 1 High Performance SAE 10W-30 is shown being tested for ASTM D-5481-10 ‘Standard Test Method for Measuring Apparent Viscosity at High-Temperature and High-Shear Rate by Multi-cell Capillary Viscometer.’ This test measures a lubricant’s viscosity under severe conditions that are similar to those in fired internal combustion engines.”

Dick Glady, vice president of sales and marketing for Brad Penn, says, “Here the Penn Grade 1 High Performance SAE 10W-30 is shown being tested for ASTM D-5481-10 ‘Standard Test Method for Measuring Apparent Viscosity at High-Temperature and High-Shear Rate by Multi-cell Capillary Viscometer.’ This test measures a lubricant’s viscosity under severe conditions that are similar to those in fired internal combustion engines.”

Brad Penn oil is a very unique product since it is truly American made. The crude oil is sourced from an area identified as the Pennsylvania Grade, a region that extends from New York State down to Ohio and West Virginia. The word Grade is the name of the geographic region and not a qualifier of the type of oil. Brad Penn’s refinery was originally built by Kendall. It is the oldest continuously operating refinery in the world. Visit the company website for complete product information.

Corrected Horsepower

7 Red is the baseline with the 30-weight Brad Penn break-in oil, blue is the OW-30 oil, green is the 10W-40, and aqua is the 20W-50.

7 Red is the baseline with the 30-weight Brad Penn break-in oil, blue is the OW-30 oil, green is the 10W-40, and aqua is the 20W-50.

Corrected Torque

7 Red is the baseline with the 30-weight Brad Penn break-in oil, blue is the OW-30 oil, green is the 10W-40, and aqua is the 20W-50.

7 Red is the baseline with the 30-weight Brad Penn break-in oil, blue is the OW-30 oil, green is the 10W-40, and aqua is the 20W-50.

HPP Engine Buildup Worksheet

Engine Displacement: 467 ci

Bore/Stroke: 4.185 / 4.250-in

Bore/Stroke ratio: .98:1

Rod/Stroke ratio: 1.6:1

Bottom End

Block: Stock ’75 455

Preparation: Cooked, magged, line-bored, line-honed, decks squared with BHJ, bored and honed with torque plates

Deck height: 10.205-in

Crank: Butler/Eagle forged

Preparation: Balanced, polished

Balancer: Summit Street/Strip, steel, elastomer, 6.610-in, SFI 18.1

Rods: Eagle forged H-beam, 6.800-in

Preparation: Pin end honed to proper size, balanced, big end checked for proper size

Bearings: Clevite, plain shell, tri-metal

Preparation: Clean, check for proper clearance in rods

Pistons: Butler/Ross forged flat-top with valve reliefs

Preparation: Pin fit, check size, clean

Piston-to-deck height: 0.010-in below

Piston pins: Ross, 0.990-in floating, 0.155-in wall

Method used to retain pins in pistons: Spiro Locks

Rings: Total Seal moly top, ductile second, 3-piece oil, 1⁄16-, 1⁄16-, 3⁄16-in

Preparation: File-fit, clean

Rod bolts and head bolts: ARP

Balancing specs: Internal

Oiling System

Windage tray: Canton in pan

Crank scraper: Canton in pan

Oil pan: Canton Racing Road Race Series 5-quart, wet-sump

Oil pump: Melling M54DS high-volume

Heads

Casting number: 6X

Combustion chamber volume: 96.2 ccs

Maximum flow at 28 inches of pressure

Lift Intake Flow CFM Exhaust Flow CFM

0.100 66 55

0.200 133 106

0.300 191 149

0.400 224 170

0.500 236 182

0.600 250 186

Compression ratio: 9.1:1

Valves: Manley SS 2.11/1.77-in

Angles used in valve job:

Intake 45, 60, 75, and 82-deg, 82 is hand-blended into 75-deg.

Exhaust 45-deg, 12mm radius

Retainers: Comp Cams steel, 10-deg Beehive

Keepers: Comp Cams 10-degee, 11⁄32-in

Valve Guides: K-line bronze liner

Valve Seals: Steel/Viton

Rocker Studs: ARP 7⁄16-in

Rocker Arms: Comp Cams aluminum, full-roller, 1.65:1

Pushrods: Manley 3⁄8x8.900-in

Cam

Brand: Comp Cams Xtreme Energy hydraulic-roller

Duration At 0.050: 224/230-deg

Lift: 0.552/0.561-in

Centerline: 106-deg

Lobe Separation Angle: 110-deg

Installed Position: 106-deg

Lifters: Comp Cams roller

Valvesprings: Comp Cams Beehive

Seat Pressure: 137-lb/in

Open Pressure: 290-lb/in

Timing Chain: Cloyes double-roller

Induction

Carb: Holley 4150 HP 750-cfm, mechanical secondaries

Intake Manifold: Edelbrock Torker II

Ignition

Distributor: MSD Pro-Billet Ready-to-Run

Wires: MSD 8.5mm

Exhaust

Headers: Hooker

Primary Tube Diameter: 1.75-in

Primary Tube Length: 32-in

Collector Size: 3.00-in

Gaskets

Brand: Fel Pro

On the Dyno

Brad Penn Oil

Peak HP

Peak TQ

Avg HP

Avg TQ

Avg Oil PSI

Avg Oil Temp

30 weight break-in

492.6

550.5

436.47

535.28

76.36

121.68

0W-30

487.3

552.7

435.55

534.60

73.81

142.48

10W-40

484.8

554.7

434.84

533.90

79.31

N/A

20W-50

480.7

548.5

431.23

529.46

79.51

137.53

Note the 30-weight break-in oil had nearly 100 pulls on it.