Any engine, even the most power-deficient four-cylinder puttering away in your grandmother's grocery getter sedan is little more than controlled mayhem.

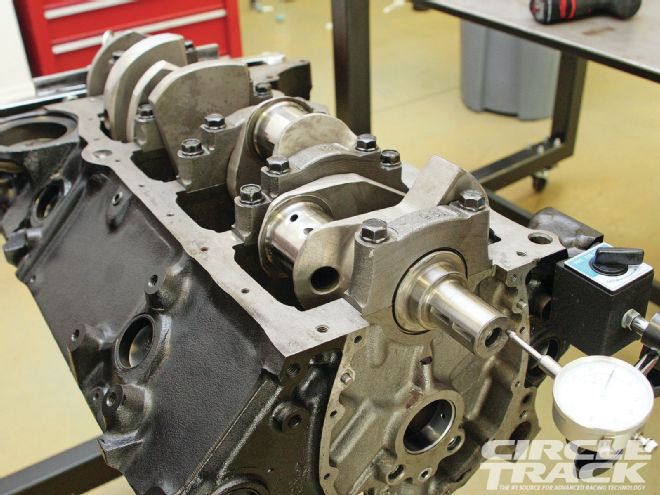

Well, that may be overstating things a bit, but when you think about it, that's not too far off. The point of any gasoline fueled piston engine is to convert the raw energy created from a controlled burn of highly flammable fuel--that's so fast it might as well be called an explosion--into useful work. And things only get worse when you talk about a circle track racing application. Now we're adding compression, increasing the amount of air and fuel crammed into the combustion chambers before the spark is fired and speeding up the rpm, which means more explosions every second. Add the fact that race engines use the lightest components possible to increase efficiency, and you can see how the forces of combustion can create twisting and bending forces that can rob the engine of its power and cause component failures. A race engine turns the energy from combustion into a spinning crankshaft by using a piston, which is pushed down the cylinder bore from the dramatic spike in pressure which comes from rapidly burning the air/fuel mixture in the combustion chamber. Attached to the underside of the piston is the connecting rod, which in turn connects to the crankshaft's rod journal. Because it is offset from the crankshaft's centerline, the rod journal acts as a lever, which rotates the crank.

The problem is that the pressure buildup from combustion isn't exactly gentle--not by a long shot. When the air/fuel mixture in one chamber fires off, the pressure quickly spikes and that pressure is resisted by the inertia of the mass of engine components and even the traction of the tires on the racetrack. Meanwhile, other pistons and connecting rods on other areas of the crank are meeting resistance as they are trying to compress the air/fuel mixture in preparation for firing in other combustion chambers. The result from all these different forces is that the crank--even though it may seem stiff and immovable--actually twists and flexes because of the extreme forces acting along its length. The crank journal can actually twist a bit during the power stroke. Then, when the force is reduced enough for the crank to spring back, it doesn't just return to its original shape right away. Instead, it acts like a spring, twisting back and forth until it settles down. But in a running engine that's continually firing off fresh charges of air and fuel, getting time to settle down simply isn't possible.

In fact, as the engine moves through its rpm range, it can reach a point where the power pulses from ignition of the air/fuel mixture will eventually match the natural frequency of the crankshaft. When this happens the vibrations moving through the crank can build upon each other and gain strength to the point that it has damaging results. Racing an engine without protection from these vibrations can cause damage to the bearings, flexplate or flywheel failure, loosened bolts, a broken timing chain, and erratic timing and valvetrain problems. And over time the crankshaft will weaken and fail, normally at the snout. The solution is to use a harmonic damper to absorb the vibrations, or small shocks, running up and down the length of the crankshaft. Many people also refer to harmonic dampers as balancers, but since almost all race engines are internally balanced that's a bit of a misnomer. A quality race damper has a zero balance so that it won't affect a properly balanced rotating assembly.

Most dampers use a weighted steel ring bonded to the outer shell with rubber rings. The rubber allows the steel ring to move slightly which helps dampen vibrations. But Fluidampr has recently released a new damper designed specifically for oval track racers. The new damper, which Fluidampr calls the CT Gold, is based on the company's signature fluid-filled dampers--but with a twist. "With all of our dampers we use our viscous technology," explains Fluidampr's Ivan Snyder. "The basic construction is we have a housing with an internal inertia ring--some people call it a flywheel. And then between the housing shell and the inertia ring or ‘flywheel ring' is our own viscous silicone which is 45,000 times thicker than 30-weight motor oil. "But with the CT Gold we have a material in there between the housing and the inertia ring in addition to the silicone that causes that internal inertia ring to be centered at all times. So with our conventional damper if the engine sits the internal inertia ring will tend to settle. But with the CT Gold that can't happen."

Snyder declined to explain exactly how the centering system works, saying that it is a patent pending technology that Fluidampr has worked on specifically for its racing dampers, but the idea is certainly worthwhile. If the inertia ring is allowed to settle, the entire engine can become unbalanced during the first few seconds after startup which can, potentially, lead to bearing damage. "With the changes to the CT Gold," Snyder adds, "we also noticed that above 6,000 rpm--which is where most racers are most of the time--that the damper exhibited slight improvements in torsional vibration control. So it is also a little bit better at racing rpm than our standard damper."

In addition, there are a couple other potential advantages to the viscous damper construction. Primarily, elastomeric dampers using a rubber ring should always be tuned to the engine package. Different engines, particularly race engines with different peak power levels, create different harmonics. So engineers must configure the damper to the application. This is one reason a stock damper very rarely works well on a racing engine. Because it is tuned for a much milder engine normally operating not far above idle, a stock damper will struggle at high rpm on a powerful racing engine. Not only does the damper do a poor job of absorbing vibrations and harmonics, but the excessive movement of the inertia ring against the elastomeric rubber it is bound within creates heat that will cause premature failure of the elastomeric component. "When you are racing an elastomeric damper, the builder has to know the details of the engine so that they can choose the right durometer of the elastomer rings in order to tune to the frequency of the harmonics the engine produces," Snyder explains. "Whereas, with the viscous fluid damper it doesn't matter what your engine package is. We only sell one version of the CT Gold because it works equally well with any engine package or power level. "Plus, in a gasoline performance application (Fluidampr also sells a lot to the diesel truck market), these dampers don't wear out. So they don't need to be returned to us and be rebuilt. I've had guys send these dampers back to me after 20 years in drag racing applications, and the silicone inside still looks brand-new. As long as the damper isn't damaged in a wreck--say the housing gets dented or something--the damper doesn't wear out."

Of course, what we really wanted to find out is if Fluidampr's new CT Gold damper will help you win races. So when we were dyno testing a recent Chevy Super Street class racing engine which we finished up in last month's issue of Circle Track, we decided to put the damper to the test. As a baseline, we used a standard Chevrolet damper off the 602 crate engine we were using as the foundation for the Super Street build. We figured we'd see some improvement simply based on the smaller size of the Fluidampr (6.25 inches versus 8 for the Chevy piece) and reduced weight (8.6 pounds versus 14), but the actual difference on the dyno surprised us. For the results, check out the dyno graph included in this article. A harmonic damper is more than just a place to point your timing light. A quality damper installed correctly will protect your expensive racing engine (and make you faster).