The cliché holds there are only two things that you can count on, death and taxes. Actually, there are three. The third is you can rely on car magazines to do small-block Chevy engine stories. It's not because we aren't creative enough to come up with something better. The real reason is that there are just so blasted many little-block engines roaming the earth we can't ignore them. While some guys will always insist on building their own engine, for the rest Chevrolet Performance has done an outstanding job of offering a package that is affordable and can make decent power—with a little bit of help. Mind you, this is not a race engine. Chevy builds those too and that LS-based 770hp LSX454R is just one example of what's going on in that arena. But for the street set, simple crate engines have become the quickest and easiest path to movin' down the highway. But this is STREET RODDER, which means we can't leave it stock. We have a moral obligation to tweak this crate engine to see if we can make it sing. And sing it does.

Basic Crate

But before we get to the fun stuff, let's quickly hit the specs for our Great Crate. This is what Chevrolet Performance calls the 350/290, which stands for 350 ci and 290 hp. The engine employs the classic two-piece rear main seal iron block with iron heads, 8:1 compression ratio, a mild flat-tappet hydraulic camshaft, cast aluminum pistons, and a cast crank. This engine is one step above the basic replacement engine and is designed to run on 87-octane fuel. The iron heads are 76cc combustion chamber units with 1.94/1.50-inch valves and exhaust rotators on the exhaust valves. These rotators help prevent exhaust valve seat erosion under hard use, but also add weight so they're not the best idea for a performance engine. Chevy claims this is an 8.0:1 compression engine and our calculation was pretty close at 8.1:1. The pistons have four valve reliefs and (while we didn't measure it) the dish specs at 10 cc. This dish is a full round dish so there's very little quench, which tends to diminish combustion efficiency slightly, but short of changing pistons (which defeats the main purpose of a crate engine) this is what we'll work with.

Testing, Part I

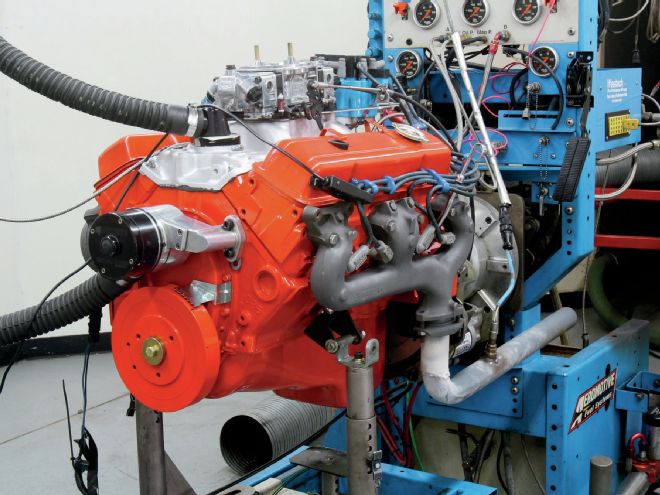

But enough conjecture, we'll find the proof on the dyno so we trundled this small-block out to the Westech Performance Group where Steve Brule and his crew bolted our Great Crate up on the pump in short order had it fired and running. Here's where we need to emphasize how important it is to break the cam in properly. We used AMSOIL's new Break-In Oil that contains ZDDP additive to ensure that the flat-tappet lobes on the cam and lifters have what they need to make happy. Of course, the soft valvesprings in this engine help but this is still an important step. Plus, later we added a second new COMP cam so the heavy additive package was necessary to make sure we had the lube we needed. The break-in procedure included running the engine with a slight load from 2,000 to 2,500 rpm for 20 minutes to ensure that the cam had sufficient lubrication at all times. This is important because the cam and lifter interface is splashed oiled with lube from the crank.

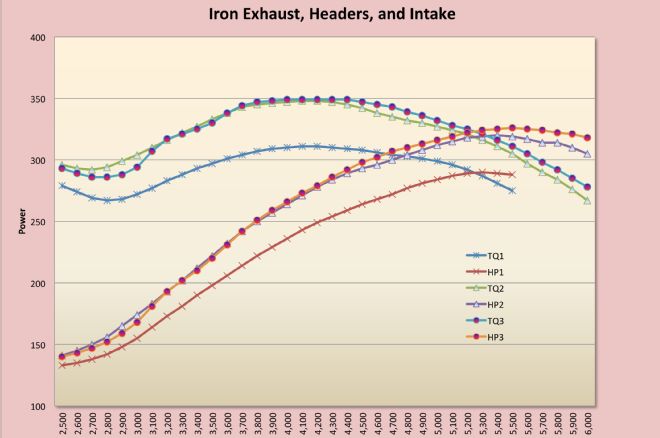

We started testing with stock iron manifolds and the ZZ4 intake. That package without mufflers (all testing would be with open exhaust) made exactly what Chevy claimed at 290 hp. We fell short of the advertised torque, with 311 lb-ft while the book says 326 lb-ft but it was a great start. Right away we kicked the iron manifolds to the curb and went with Westech's dyno headers and the power jumped 30 hp and 37 lb-ft of torque. If you look at the torque curve on the first graph, you'll see that the headers added power everywhere. If you don't do anything else to this engine–do that! The headers are an essential piece of the performance puzzle. You can't make decent power without them. The primary pipe diameter is actually at 1-3/4 inch where on the street we would recommend a 1-5/8-inch primary pipe with long 34-inch primary pipe length with long 18-inch collectors.

This first bash was encouraging so we next swapped the intake for an Edelbrock Performer RPM. This is a great manifold that won't reveal its true potential until we swap heads. Against the ZZ4 intake, the RPM manifold is very close in terms of power and the ZZ4 is less expensive. But you will see why we like this intake in later tests when we really start moving some air through this engine. The peak horsepower jumped to 326 hp but the torque really didn't appreciably change.

Testing, Part II

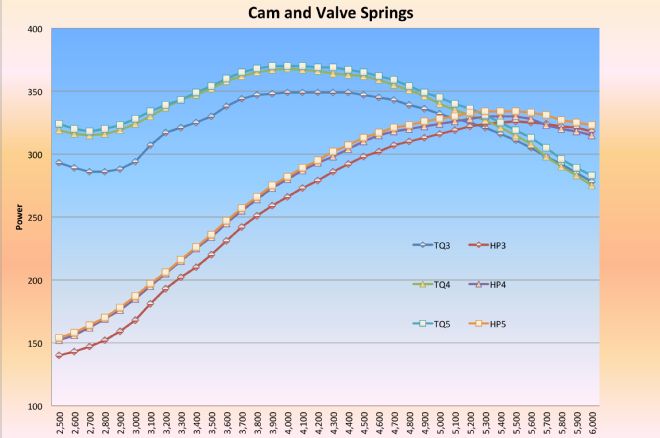

Now we were ready to tear into the engine. Up until now this had been an external bolt-on affair. But now we yanked the intake, harmonic balancer, and front cover then removed the old cam in favor of a COMP Cams Xtreme Energy 268. Cam fans may have already noticed that we didn't really make that much of a change—the 290hp crate engine's intake duration is only 2 degrees less—222 degrees at 0.050 versus 224 degrees for the XE cam. This was for a reason. Sure, we could have bolted in a much longer duration cam and perhaps pumped up the peak horsepower and called ourselves heroes. But long duration cams also move the torque peak to higher engine speeds that this engine package isn't really designed to accommodate. Plus, we wanted a street-friendly idle quality. The COMP cam does add 9 degrees of exhaust duration, which helps the top-end power but perhaps most importantly, the XE cam also moves the lobe separation angle (LSA) tighter from 114 to 110 degrees. If you look at the accompanying second graph that illustrates the power difference from the cam swap, take notice of how the COMP cam added a full 30 lb-ft of torque way down at 2,800 rpm. The additional exhaust duration generally only benefits engine power above peak torque, but the combination of the additional exhaust duration with the increased overlap really improves the low-speed torque.

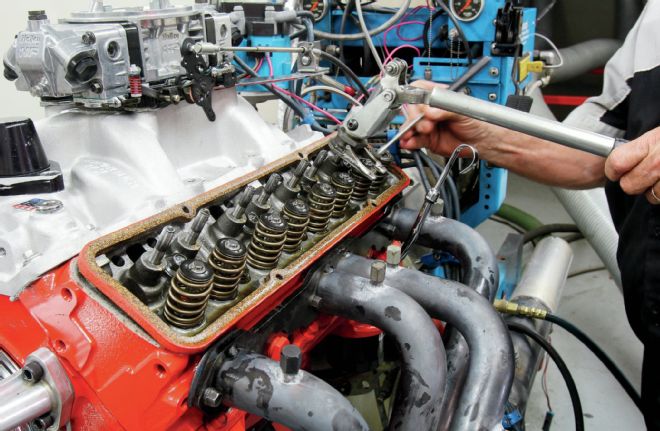

As you continue to look at the curve for Test 4 (see page 52) you'll also notice that the gains generated at lower engine speeds begin to diminish as the rpm increases. By the time we get to 5,300, the improvements are down to barely 10 hp. We anticipated that we might see this because we were still using the stock valvesprings, which included those ugly exhaust rotators. So we then yanked the valve covers and removed the stock springs in favor of a set of COMP Cams beehive springs and new retainers. Running the final test, the springs didn't really improve the power all that much, but at least knew we had good control over the valves. Our final peak horsepower number jumped from the original 290 hp to 334, which is a gain of 44 peak horsepower and a bunch of torque throughout the entire rpm band and all while using the stock iron heads.

In fact, the real reason our peak horsepower gains didn't improve as much as the torque is attributable to the limitations imposed by the stock heads. So you can imagine where our next course of action will likely be aimed. In the second installment of The Great Crate Project, those stock heads will vaporize in favor of a set of Edelbrock Performer RPM aluminum heads and you can bet that the power will jump up as well. But we'll dangle the hook for those numbers and save them for the next story, so stay tuned.

1. The recipe for easy street power is simple–take one 350/290 Chevy crate engine, add a cam, valvesprings, an intake, and headers and all of a sudden this mild-mannered street motor makes 330 hp.

2. Once the 350/290 is unwrapped, this is what you'll find. The big parts it needs to make noise include a balancer and flexplate, intake, carburetor, distributor, and a water pump. We'll get into the accessory drive selection in a later story.

3. As a tip-off, if you try to remove the valve covers, the gaskets are seriously glued on. We bent the covers getting them off and carefully hammered them back into shape. Instead of guideplates, Chevy uses guided rockers to keep the rockers in place over the valve stems. These engines also come with exhaust rotators that we will eventually dump in favor of better springs.

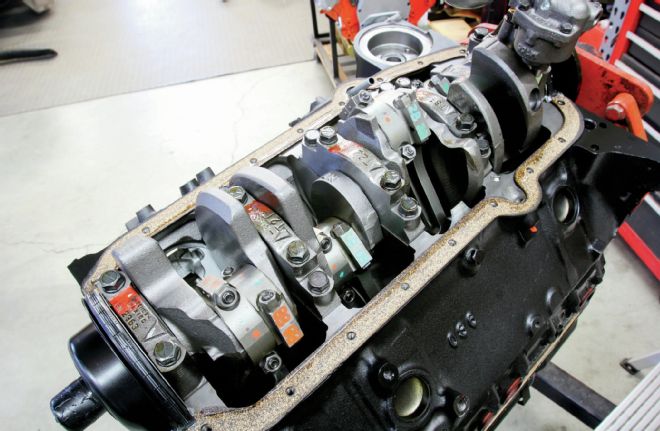

4. We knew we would eventually change the cam, so we yanked the pan ahead of time so we could show you the crank and rod package. Note that this engine does come with four-bolt main caps in the center three. Those are powdered metal rods. There are zero pan baffles and no windage tray so 1 g turns are not recommended.

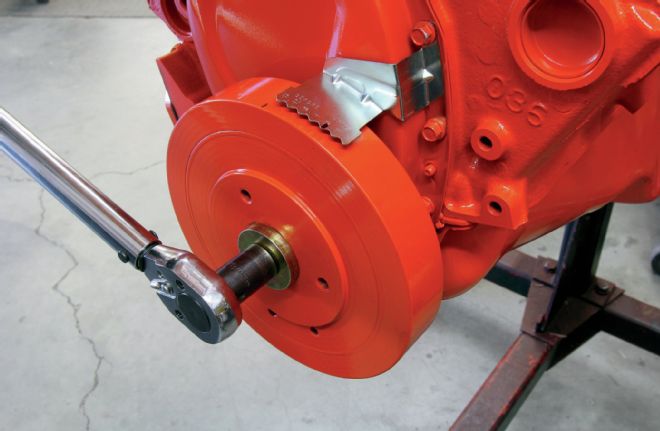

5. No self-respecting small-block Chevy can be painted anything but Chevrolet Orange, so we prepped the engine with Eastwood PRE solvent and then hit it with Eastwood's 2K orange paint. Depress the bottom plunger and mix the paint and apply some really durable catalyzed paint. Always wear the correct mask like this DeVilbiss from Eastwood since this 2K paint is an epoxy that you don't want to breathe.

6. We got a pile of small parts from Summit, including a balancer and bolt, a fuel pump block-off plate, an oil filer adapter, dipstick, Autolite spark plugs, oil and filter, and new Fel-Pro valve cover gaskets to complete the engine and get it ready to fire. When considering a crate engine, it's a good idea to add up all the extra parts it will need to be a complete engine. The little stuff adds up quickly.

7. We filled the engine with AMSOIL's new 30W Break-In Oil and a new AMSOIL filter. We then used a pressure luber adapter driven by a 1/2-inch drill motor. With the valve covers off, we ran the pump for roughly five minutes before oil reached all 16 rocker arms.

8. We finished the prep on the engine by bolting on the Chevrolet Performance ZZ4 intake manifold and a set of cast-iron exhaust manifolds.

9. With the engine on the dyno and the stock cam properly broken in, we had problems with our previously owned 650-cfm Holley so we decided to use a larger 750-cfm Holley because that's all we had. The larger cfm really won't affect our power numbers and this was a known carburetor. In this exact configuration the engine made exactly what Chevy claims with 290 hp. They claim 326 for torque but the best we could twist was 311 lb-ft.

10. The next step was to add headers, which really helped the power, adding as much as 38 lb-ft of torque right where you use it, in the under 4,500-rpm range! Then we added the Edelbrock Performer RPM intake and the power jumped only slightly. This shows that with a stock cam the ZZ4 manifold is pretty good. But we knew the Edelbrock would be worth more once we added a cam.

11. The COMP Cams XE-268 was the next step in our plan. Since the engine was brand new, we reused the Chevy timing chain and gear and bolted everything back together. We did not degree the cam, but it will be within a degree or so of its intended position.

12. We decided to try the COMP cam first with the stock springs and rockers but we threw away those factory adjuster nuts because they rarely hold up under multiple installations. Instead, we substituted these ARP poly locks. Also note how the pushrods are centered in the holes in the head. This is important, as we later discovered.

13. The new cam improved the power, but we thought better springs would also deliver some power, especially with 1.6:1 rockers because the retainer-to-seal clearance is actually pretty close with stock 1.5:1 rockers. We measured the installed height and had to use 0.090-inch worth of shim for each beehive spring to create the proper installed height for both the intake and exhaust valves.

14. This is the new COMP 26981-16 beehive spring that drops right into the stock spring seat. This new spring requires matching retainers that are needed for the beehive configuration.

15. This is a comparison of the position of the pushrod cup in a 1.5:1 roller rocker (left) compared to a 1.6:1 roller rocker (right). Note how much closer the cup is to the rocker arm's fulcrum, which is also the rocker stud centerline. This relocates the pushrod more outboard, which is why the pushrod would bind against the cylinder head.

16. We discovered that attempting to use a 1.6:1 ratio rocker binds the pushrod against the hole in the cylinder head. This occurs because the higher ratio moves the pushrod cup closer to the rocker stud fulcrum. This required returning to a 1.5:1 Magnum rocker to keep the pushrods in their intended location.

17. Here's our finished engine still with stock heads, a mild cam and headers and it makes 334 hp and 370 lb-ft of torque. That's more than enough to spin the tires and thrill the neighbors. Just wait till part II where we will make about 50 more!

Cam Specs Camshaft Adv. Duration Duration @0.050 Lift (inches) Lobe Sep. Angle Stock Intake NA 222 0.450 114 Stock Exhaust NA 222 0.46 --- XE-268 Intake 268 224 0.477 110 XE-268 Exhaust 280 231 0.480 ---

Test Descriptions

Test 1: This is the baseline test with the small-block outfitted with the Chevrolet ZZ intake manifold, 750-cfm Holley carburetor, and cast-iron exhaust manifolds.

Test 2: The first change was to add Westech's dyno headers.

Test 3: This test added the Edelbrock Performer RPM intake manifold.

Test 4: The only change was to add the COMP Cams Xtreme Energy 268 camshaft.

Test 5: The last change was to add better COMP valvesprings and Magnum 1.5:1 roller tipped rocker arms.