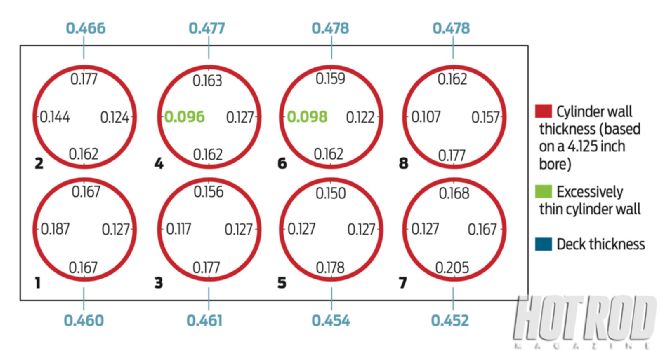

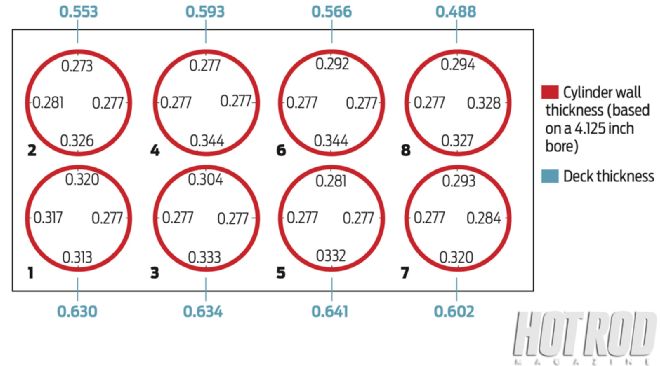

There's a limit to what you can do with old-school GM passenger-car parts, and the breaking point is relatively low when it comes to the Gen I small-block Chevy cylinder block. Sure, you can bore the block to within an inch of its life and fill the water passages with concrete before stuffing a 4.00-inch stroker crank into it and make decent power for a while. The fun won't last long, though, when the block cracks, leaks water, or flexes enough to pinch the main bearings or lose the head-gasket seal. To find the beef of the stock 350 and the aftermarket alternatives, we had Pfaff Engines sonic-test six different blocks with 350-style main journals (some are available with 400 main journals) and standard deck heights to see how far they could be bored and how thick the decks were. We also put them on the scale and called every manufacturer to find out how much work it is to drop a big arm into each one. The results were surprising, but we are savvy small-block Chevy shoppers now.

Dart Machinery SHP

ModelPN 31161211 Block CompositionSAE grade G3000 cast gray iron Bore4.120-inch (unfinished); 4.165-inch max Maximum Stroke Clearance3.750 out of the box using steel rods; 4.000 with some pan-rail clearancing and a small base-circle camshaft (0.900 diameter) Deck Height9.020 inch Deck Thickness at Thinnest Point0.430 inch Maximum Recommended Horsepower600 Weight170 pounds Price$1,578.57 from DartHeads.com

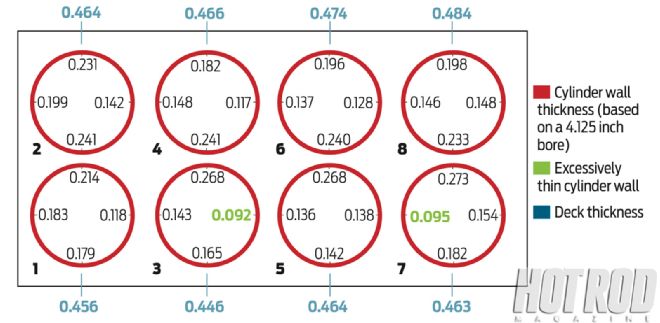

Chevrolet Performance

ModelPN 101051237 late-model, one-piece rear main seal (adapter available for two-piece seal) Block CompositionCast iron Bore4.040 inches (stock bore is 4.000 inch) Maximum Stroke Clearance3.750 inches with steel rods Deck Height9.020 inch Deck Thickness at Thinnest Point0.456 inch Maximum Recommended Horsepower360 Weight157 pounds Price$789.95 at SDPC.com

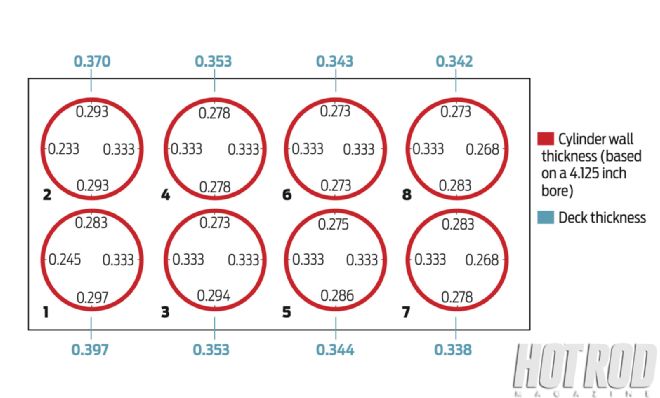

World Products Motown II

ModelPN 084010 nodular iron main caps; PN 084110 billet steel main caps Block CompositionCast iron Bore3.990-inch (unfinished); 4.200-inch max Maximum Stroke Clearance4.000 inches (pan rails are factory-notched for H-beam steel rods) Deck Height9.020 inch Deck Thickness at Thinnest Point0.338 inch Maximum Recommended HorsepowerWorld Products told us four-digit power, but not to quote them on it Weight225 pounds (deduct 9-10 pounds when boring to 4.125 inches) Price$2,151.95 at SummitRacing.com (nodular iron main caps, splayed billet steel caps are optional)

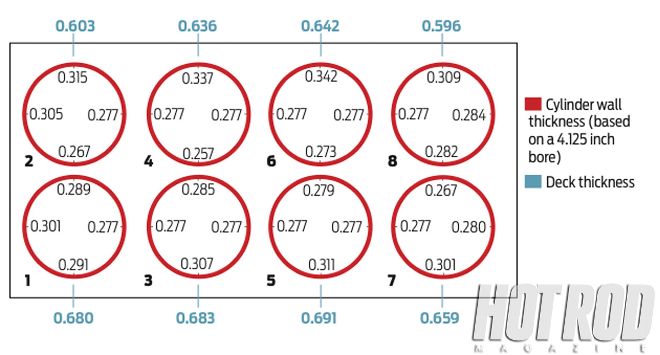

Dart Machinery Iron Eagle

ModelPN 31121212 (0.391-inch raised cam and 0.800-inch spread pan rail versus stock 350 Chevy Block CompositionClass 32B cast iron Bore4.120-inch (unfinished); 4.185-inch max Maximum Stroke Clearance3.875 inches out of the box using steel rods; 4.250 inches with pan rail and bottom of the cylinder clearancing Deck Height9.020 inch Deck Thickness at Thinnest Point0.488 inch Maximum Recommended HorsepowerDart wouldn't give us a number, but assume 1,000-plus Weight195 pounds Price$3,026.46 at DartHeads.com (includes optional 2.125-inch BBC-size cam journal

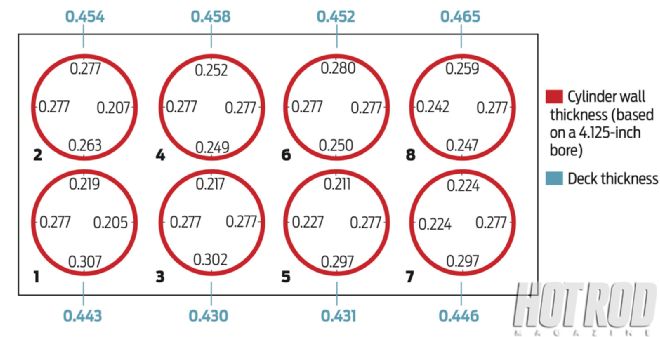

OE '69 Chevrolet

ModelCasting number 3932388 standard two-bolt main Block CompositionCast iron Bore4.000-inch (stock); 4.060-inch max Maximum Stroke Clearance3.800 inches with steel rods Deck Height9.020 inch Deck Thickness at Thinnest Point0.452 inch Maximum Recommended Horsepower360 Weight171 pounds (includes cam bearings) Price$200.00 (used standard-bore block)

Dart Machinery Little M Sportsman

ModelPN 31131211 350 main journals; PN 31132211 400 main journals Block CompositionClass 32B cast iron Bore4.120-inch (unfinished); 4.165-inch max Maximum Stroke Clearance3.800 inches out of the box using steel rods; 4.000 inches with some pan-rail clearancing and a small base-circle camshaft (0.900-inch diameter Deck Height9.020 inch Deck Thickness at Thinnest Point0.488 inch Maximum Recommended HorsepowerDart wouldn't tell us, but we assume 1,000-plus Weight201 pounds Price$2,314.45 at DartHeads.com (includes coated cam bearings, dowels, and freeze plugs)

The Science Behind the Sonic Checker

Sonic checkers, like NDT Systems' CB110, determine the thickness of cylinder walls and decks by transmitting ultrasonic frequencies into metal, recording how long the signal takes to reflect back to the checker, and then converting that data into a measurement. It's similar to the way a naval submarine's sonar system operates to verify the range to a target, except that the frequency is much higher, 2-10 MHz, or two to ten million cycles per second in this instance.

The transmitter's probe sends a short pulse into the metal using a coupling material such as water or oil, and then the checker records the total transit time through the test metal. This is called the sound velocity, which is what is converted into thickness readings used to determine if the cylinder walls or deck of our engine block are thick enough for the foundation of a reliable racing engine.

According to NDT Systems' Greg Smith, designer of the CB110, the sound velocity is different for various types of metal. The pulse travels relatively slowly through cast iron, while it reflects more quickly through steel, and even faster in aluminum. Checking alloys complicates the readings to a degree because the metallurgy of a block fluctuates from one area to another enough to change the speed of the pulse by as much as 18 percent, ultimately affecting the thickness measurement by up to 0.055 inch. Using a test piece of material similar to the block you're testing gives a reference for a "good" reading versus an incorrect one.

Did you know?

15 years ago, General Motors shipped the original tooling for the small-block Chevy from its Flint, Michigan, plant to the Toluca, Mexico, facility, where crate engine block production continues.

Pfaff Engines is staffed by hot rodders with decades of championship-winning experience under their belts and the best equipment money can buy. From crank grinding, head porting, and block machining to EFI tuning and dyno testing, this shop can do it all.

Pfaff Engines is staffed by hot rodders with decades of championship-winning experience under their belts and the best equipment money can buy. From crank grinding, head porting, and block machining to EFI tuning and dyno testing, this shop can do it all.

When to Buy a New Block?

At what point do you sell your stock block and invest in an aftermarket one? Engine design will dictate an upgrade if you plan to increase the stroke of the crankshaft beyond 3.800 inches or bore it more than 0.060 inch. Look closely at the sonic check results and you'll see how thin the cylinder walls of a stock block are when you bore them to 4.125 inch. Cooling the engine also becomes an issue with an overly large bore. GM rates the original small-block cylinder case at no more than 360 hp, but we've seen them stay together at 600 hp or more by stabilizing the bores with a block fill (www.HardBlok.com is a well known supplier) up to the water jackets. Beyond that, we recommend stepping up to an aftermarket block. If you're starting from scratch, consider the cost of sonic-checking, pressure-testing, and machining an old block before you ignore the option of spending more bucks on a new one. Here's a rundown of what it costs to have Pfaff Engines chuck a block up in its five-axis machining center and boring machine:

Say What?

Baffled by the terms in this article? Here's the lowdown on the more confusing ones.

Blind Tapped: This refers to boltholes that are drilled and tapped into the block without protruding into an open space, like the water jacket. Non-blind tapped holes require thread sealent on the bolts or studs and are prone to leaking water.

Siamese Bores: Early GM blocks have water passages between each cylinder bore. Late-model and aftermarket blocks have what are called Siamese or conjoined bores, which means there is no coolant passage between them. The metal-to-metal contact of each cylinder wall makes them more stable and prone to staying round under intense cylinder pressure that forced induction provides.

Splayed Bolts: GM passenger car blocks have main caps with bolts threaded straight down into the main webs. GM Bowtie racing blocks and most aftermarket blocks have splayed outer bolts in Nos. 2, 3 and 4 main caps. These bolts thread into the side of the block at an angle, usually around 10 degrees or greater. The side of the block has more material thickness than the bottom of the web, making it a stronger foundation for the bolts to grip.

Priority-Main Oiling: A factory 350 block's oiling system sends oil from the pump to the filter, then to the lifters and then to the cam bearings. The main and rod bearings are the last to receive oil, which isn't a good thing at high rpm or when you first start the engine. Priority main oiling reverses the path the oil takes, giving the main bearings the liquid of life first.

10 Used Block Retailers

Want the thrill of building an engine from used parts? Here are 10 websites where you'll find deals unloved building blocks.