Crate motors cut costs, but they almost always deliver less power than a purpose-built engine. On the face of it, a purpose-built custom motor should always have the edge, but there's one area where a crate motor has the potential to play catch-up as far as power is concerned. Imagine you're an experienced engine builder, and you have to build a custom but basic street motor for a single customer. You have to get it right the first time around. But what if you knew you were going to sell hundreds? Then you could afford to do some serious development. If crate motors are built in sufficient numbers, there is the opportunity to refine a spec optimally for a given price, because high R&D costs are spread out over many engines.

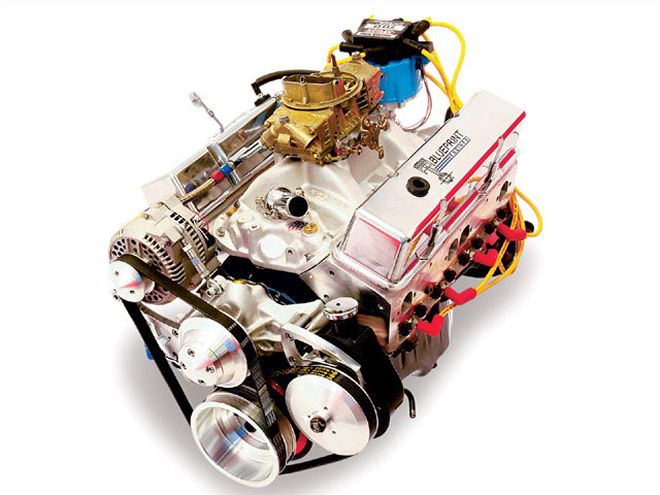

Blueprint Engines (a division of Marshall Engines) is in this position. As one of the largest independent engine builders in the country, Marshall builds a complete line of replacement engines. Under the Blueprint label, Marshall sells performance engines through speed shops, performance outlets like Jegs and Summit, and automotive mass merchandisers like AutoZone. These engines also come with a 30-month, 50,000-mile warranty for street applications.

With a big-time warranty, reliability is a prime issue. Unless you've been living on another planet, you'll have heard that the removal of zinc additives has been causing cam companies and their customers flat-tappet woes. Zinc (in the form of ZDDP) is a high-pressure lube that is a necessity if a typical flat-tappet cam is to survive. Without ZDDP, a cam's chance of survival is way less than 50 percent. If you were selling 1,000 engines a month, how long would you be in business if 500 came back under warranty?

Blueprint starts with a hand-selected, seasoned block that is bored, honed, align-honed on the mains, and decked. After that, a coat of engine enamel is applied.

Blueprint starts with a hand-selected, seasoned block that is bored, honed, align-honed on the mains, and decked. After that, a coat of engine enamel is applied.

Blueprint was quick to appreciate that they had to have a solution in place before the time limit for ZDDP use ran out. Using their considerable in-house technology, plus that of COMP Cams, Blueprint committed themselves to a long and tedious development program that allowed them to offer engines equipped with the meanest flat-tappet street cam profiles available. So since they were tying up dyno time for hundreds of hours, it seemed that it would be a good idea to also test everything else in an effort to refine the engine spec for max horsepower.

Reliability & Power

So was adopting this strategy a good move? It seems so, as Norris Marshall, president of Marshall Engines, showed me dyno sheets that indicate a 55 ft-lb and 65 hp increase on what is essentially their base flat-tappet small-block Chevy performance crate motor. This is what can happen when the dyno time is extensive, allowing tests of a multitude of intakes, cams, and heads. All the dyno testing for power and reliability allows Blueprint to target more hp per dollar combined with an extended life.

At this point, I got to talking with Tony Brown, longtime racer, and now race series promoter. Tony was of a mind that bracket racing still fell short of the needs of budget-constrained racers who wanted true head's-up racing. Operating out of Atlantic Racing (his Charlotte, North Carolina, speed shop), Tony started the PTRA (Pro Tree Racer's Association) in an effort to address that situation. Tony has brought a considerable amount of experience building and racing cars in other series in structuring the rules for the PTRA.

Here is the Scat/KB rotating assembly that Blueprint uses in their 383s. By selecting either dished or flat-top, a compression ratio between 9:1 and 10.25:1 can be had. Our engine used forged flat-tops for the higher 10.25 ratio. The bushed-pin Scat stroker rods feature 7/16-inch ARP bolts, and are good to 800 hp.

Here is the Scat/KB rotating assembly that Blueprint uses in their 383s. By selecting either dished or flat-top, a compression ratio between 9:1 and 10.25:1 can be had. Our engine used forged flat-tops for the higher 10.25 ratio. The bushed-pin Scat stroker rods feature 7/16-inch ARP bolts, and are good to 800 hp.

To make the series work, there had to be a class to fit every budget. At the entry level, Tony devised the Performance Street class, which is designed for American-made cars with the word "budget" strongly infused. (For the rules, go to www.headsupsuperseries.com) Essentially, the rules are structured so that if you have a small-block Chevy making about 480-500 hp in a well-set-up chassis at the mandated minimum 3,100 pounds, you have a real chance of making it to the quarter-finals if you cut a good light.

I took a look at the class rules, and figured it would be a great one in which to run a Blueprint engine. Here was an opportunity to see if claimed dyno numbers actually measured up to real-world performance. That's when Tony told me his dad (who started racing in the mid-'60s) had a nice '79 Camaro with no motor. A look at the car convinced me to call Blueprint Engines' Norris Marshall to ask if he was willing to showcase the capability of his engines. It was, in essence, put your money where your mouth is. I explained that to stand any chance of being competitive, we needed 480-500 hp. Would the base Blueprint flat-tappet motor be up to the job? Then Norris made a point that is worth our consideration. Blueprint Engines uses a relatively conservative DTS dyno. As we know from the Engine Masters Challenge, the DTS dyno tends to read lower than a SuperFlow. Off the top of his head, he told us the engine we were looking at made about 465 hp, and he would be happy to see it square off against engines that claimed 490 hp. The implication is that the BS stops when the green flag drops.

We chose Blueprint's baseline, flat-tappet 383 street motor. To make it eligible for PTRA Performance Street, it actually had to be detuned some. Normally, this engine comes with an air-gap intake and an 800-cfm carb; examples of such on Blueprint's DTS show right around 460 hp and 492 lb-ft. As things stood, it looked as if a 460hp Blueprint crate motor could fare reasonably well against 490 hp from other sources, but there was the rule-mandated intake manifold and carb to deal with. The starting power figures had the advantage of a more performance-orientated intake manifold and carb than allowed by the rules. To qualify for PTRA Performance Street, we needed a non-air-gap manifold, a 750 Holley (Part No. 4779), and exhaust collectors of no more than 21/2 inches in diameter, plus a muffler. We could be giving away as much as 15 hp here. Although it would still be a ton of fun, I began to doubt if we could do better than midfield if we were no more than 450 hp, but the white Camaro looked so lost without an engine that I decided to go ahead anyway.

The crank for our 383 build was from Scat. Shown here is the Scat forged crank upgrade option, which is about $440 more. We elected to use the lower-cost cast crank, as this is good to well over 600 hp.

The crank for our 383 build was from Scat. Shown here is the Scat forged crank upgrade option, which is about $440 more. We elected to use the lower-cost cast crank, as this is good to well over 600 hp.

To make sure the engine was at its best, Blueprint agreed to test all the non-air-gap intakes that were eligible; Norris also had his carb supplier build a blueprinted 750 Holley.

Cost-Conscious Components

The Blueprint 383 short-block is centered around a selected, seasoned block, which goes through all the basic machining procedures that a race block would see. That includes a rust/carbon strip process to get the block down to virgin cast iron. From there, the block is given a pre-machining inspection. If it's OK, it gets bored, honed, align-honed on the mains, and decked to 9 inches flat. After a coat of engine enamel is applied, it's ready to go.

For a rotating assembly, Norris points out that it is important to go with a company that makes stout stuff, because anyone who's good at building power is better than average at breaking parts. With that in mind, Blueprint wanted (even for their base engines) tough, cost-effective parts. Blueprint chose Scat cranks and rods, and based on what they've seen over many years, they saw no point in changing that. If a new crank is in the cards, it may as well be a 383 stroker crank with a set of heavy-duty stroker-clearanced rods. With that many cubes to fill, it's important to get the cylinder heads and valvetrain right on. For pistons, Blueprint offers several depending on the application, but for the most part, it's KB slugs equipped with a Sealed Power moly ring set.

Our flat-top KB pistons were equipped with a Sealed Power moly ring set. Care during piston installation is important so as not to damage the thin rails of the oil-control ring pack.

Our flat-top KB pistons were equipped with a Sealed Power moly ring set. Care during piston installation is important so as not to damage the thin rails of the oil-control ring pack.

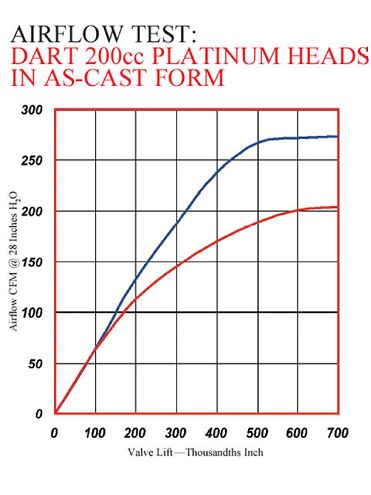

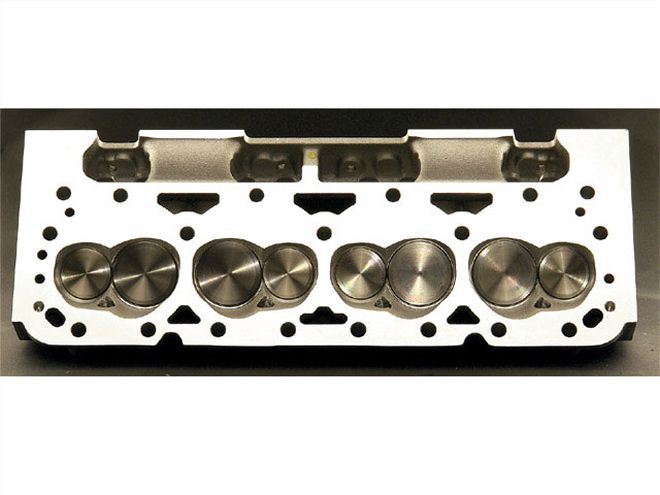

Heads

Based on both cost and performance, Blueprint chose 200cc Dart Platinum Pro 1 heads. For this base engine, these are used in as-cast form. The wet flow of these heads proved to be capable of generating a substantial amount of extra torque and hp over the original Pro 1. With modern fine-casting techniques, as-cast heads are a country mile ahead of heads produced 15 years ago. With forms closely replicating ported heads, they flow substantial amounts of air (see chart). These heads are available in straight or angled plug, and with 72cc or 64cc chambers. We used the 72cc angle plug heads (Part No. 11411111P). This combination of parts and block decking gave our Blueprint engine a 10.25:1 compression ratio.

Cam & Valvetrain

If the heads are ineffectual, nothing else matters if power is the intent. Nevertheless, if good heads are to be used, the responsibility toward making power then falls squarely on the cam and valvetrain. Make any kind of judgmental error, and the prospect of optimal output just flies out of the window. The guys at Blueprint had a good idea of what was needed for their 383 stroker, so they used this round of testing to get the cam spec right for the Dart Platinum Pro 1 heads. Certain characteristics were known to be needed. This included a higher valve lift than for a 350, as well as a tighter LCA. Also, all this had to be tied in with fast opening and closing, so a fairly aggressive profile was needed to allow for ample cylinder filling. The problem is that aggressive cams tend to wear fast, and the absence of ZDDP in the new oils exaggerates this. A major part of the fix is the use of COMP's flat-tappet cam nitride hardening service. For $110 over the cost of the cam, you can have the cam case hardened to produce a low-friction, super wear-resistant surface. Anything that helps reliability in this department is worthwhile. With a compatible quality material lifter, nitriding has shown to deliver long life, even with an aggressive cam.

So how aggressive a cam are we talking? Using catalog profiles, Blueprint chose a custom grind. This cam has a COMP No. 5444 profile on the intake, and a 5445 on the exhaust. These gave seat and 50 thousandths lift durations of 270/226 and 274/230 respectively, and with a 1.65:1 COMP rocker on the intake and a 1.6 on the exhaust, valve lift was .530 and .520. The lobes were ground on a 106-degree lobe centerline angle at four degrees advance. From the short duration figures, it can be appreciated that the cam is more what you would expect in a truck motor than a race motor. This point is being made so that you understand this is no race motor thinly disguised as a street unit; you really could put this engine in your truck, load it up, and drive it.

Our motor's oil pan was a stock pattern unit with a tough plastic enamel finish that resists stone chips better than a painted finish. The pan has a basic oil surge baffle to keep the oil around the pump pick-up during braking.Caption07

Our motor's oil pan was a stock pattern unit with a tough plastic enamel finish that resists stone chips better than a painted finish. The pan has a basic oil surge baffle to keep the oil around the pump pick-up during braking.Caption07

A couple of points to note here regarding the cam duration and lift: First, the intake-to-exhaust-duration split. It is more usual to have the exhaust 6-8 degrees longer than the intake, and though this is good for top end, it does cause a drop in cruise mileage. Note the cam spec has only four degrees more exhaust duration for better street mileage. It's a small but relevant point demonstrating that Blueprint is making a real effort to get mileage as well as performance. Also note the use of a 1.6:1 rocker instead of the more common 1.5:1 on the exhaust. Although not necessarily the case with bigger cams, Blueprint's testing has shown that with the Dart heads and a shorter-than-usual cam, exhaust duration with the 1.6s paid off.

Induction & Ignition

To run in PTRA Performance Street, a non-air-gap intake from any one of four different manufacturers is mandated, as is a totally unmodified 750 Holley. After dyno testing showed a very minimal difference between all the candidates, an Edelbrock Performer (part No. 7101) intake was chosen. As for the carb, Blueprint had their carb supplier build a spec Holley 750 for an additional $55 to the cost of the standard build. For ignition, a custom distributor with vacuum advance was built for Blueprint Engines by Performance Distributors. The relevance of this is that it is a mileage distributor. Many hot rodders are still running non-vacuum advance distributors on the street, and it's costing mileage. With an appropriate vacuum can, the Performance Distributor's unit can be worth as much as 2-3 extra mpg.

Dyno TimeTo fit within the regulations for Performance Street, we had to downgrade this engine's normal spec. It's now time to see how it fares on the dyno in the form that we'll run it in the car. The nearby power curves show the results.

The 490 lb-ft of torque from a 10.25:1 motor looks really impressive, especially with the curve carrying down well to the low end. For what is essentially a street motor with mileage in mind, the 453 hp seen was also very good, but would this be enough to cut the mustard against engines purportedly pumping out 490 hp?

The 200cc port Dart Platinum Pro 1's looked to be ideal for our application. The intake valve lift we used was .530, and just above this point the flow leveled out. If it had gone on climbing, it would be an indication that the port was needlessly oversized. This size match assures good port velocity for a strong torque curve.

The 200cc port Dart Platinum Pro 1's looked to be ideal for our application. The intake valve lift we used was .530, and just above this point the flow leveled out. If it had gone on climbing, it would be an indication that the port was needlessly oversized. This size match assures good port velocity for a strong torque curve.

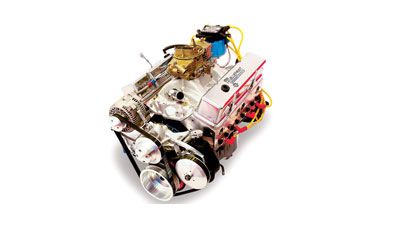

The lead shot of the completed engine shows it as received from Blueprint Engines, but with our March beltdrive system and ancillaries added. We did this so you can see what a good-looker a regular street unit can be; however, the plan here was to run the engine with an electric water pump, and less alternator and power steering.

A few words about the car are called for to set the scene. This chassis had been used as a bracket car, with a high-rpm 350 for power. It had a Powerglide two-speed with a converter that stalled about 4,400, and a rearend ratio of 5.13:1. Our first reaction was that this wouldn't be ideal, but the first race was only days away, so that's what we had to run.

The installation was finished three days before the first race, just in time for a test and tune session at Shadyside Dragway near Shelby, North Carolina. To be competitive, it was estimated we had to run a 7.3 at 92 mph in the eighth-mile. On our eighth-mile to quarter-mile conversion chart, that equals an 11.26 at between 113 and115 mph. Our first test day recorded nearly record high temperatures. In spite of that, we rolled off the trailer with a 7.36 at 91.92 mph. This was even more encouraging than the numbers might suggest. As suspected, the stall speed on the converter was too high, and the gearing too low: Our Blueprint Engine power plant was turning better than 6,600 rpm in the lights, and peak power was only 5,250 rpm. Also, the engine was breathing hot underhood air, and the suspension travel on the front was topping out and tending to unhook the tires, as indicated by a 1.58-second 60-foot time. If we had the suspension just right, even with leaf springs and the series spec tire, this car should crack the 1.5-second mark for the 60 foot.

Because they work well and come in at a very friendly price, Blueprint uses Dart Platinum Pro 1's on many of their small-block offerings. This is what our motor came equipped with.

Because they work well and come in at a very friendly price, Blueprint uses Dart Platinum Pro 1's on many of their small-block offerings. This is what our motor came equipped with.

So on that night, we took the car home knowing we could go faster. Since race day was 36 hours away, we knew that there was insufficient time to install a cold air system to the carb, or to get a more appropriate converter and rearend set, but we could make adjustments to the front suspension, so that is all we did the morning before the race. With the weather a little more normal, we expected to turn times a little better than our test. That proved to be the case. Our suspension adjustment looked like a move in the right direction, as we cut a sub-1.5 second for the 60-foot. As for the rest of the numbers, our Blueprint motor powered our 3,100-pound car to a 7.19 at 93.5 mph. That, my friends, was good enough for us to make it through to the final round, where we lost to a car with a real race engine that cost way more than our crate motor.

The real fun part of the day was when the race announcer informed the crowd that our car had a street-spec Blueprint crate motor with a 30,000-mile warranty! We sure had a bunch of folks check us out in the pits after our runner-up performance. There were also a couple of drivers we put away that had a hard time accepting they'd been beaten by a crate motor. The BS stops when the green flag drops!

So with what is essentially a moderate budget motor, we have already achieved a good measure of success. Where from here? The general consensus is that a 7-oh at 95 mph is within reach. We're now looking to test a 4.86 rearend and a converter with 400 rpm less stall for our torque-laden 383. Add to that a cold-air intake, and we can reasonably expect to see our target numbers, but we'll update you on that down the road. Meanwhile, if you're in the market for a hi-po street motor with better mileage than most, check out Blueprint Engines.