Given the current price for a gallon of gas in Southern California ($4.55 as this goes to print!) and elsewhere in the good ol’ US of A, there’s no better time than now to make that old gas guzzling pickup truck a little more efficient. And let’s face it, given our truck’s size, weight, and overall lack of anything reflecting aerodynamics, we can use all we can get. Enter the world of computer-controlled throttle body fuel injection or TBI.

Here’s the stock 307 motor as it appeared when I originally picked up the truck a few months back. We went over the dress-up story back in the December issue, I just wanted to reiterate the fact that these old, dirty motors shouldn’t be written off simply on appearances alone.

Here’s the stock 307 motor as it appeared when I originally picked up the truck a few months back. We went over the dress-up story back in the December issue, I just wanted to reiterate the fact that these old, dirty motors shouldn’t be written off simply on appearances alone.

While it’s true that TBI setups have been around for over twenty years, the technology that it takes to make a truly plug-and-play system that can be transplanted to any old V-8 is fairly new. Even more recent is the development of electronic control units or ECUs that have a self-learning capability. Just a few years ago, if one wanted to upgrade to a fuel injected system, it meant hooking up a laptop to the ECU in order to program it to fit the particular application. This required either a fairly competent understanding of the fuel system on the part of the end user or their ECU be ‘flashed’ by a third-party. For us carb guys, that was like speaking Greek in a Cajun accent.

Well, remember those videos in your science class where the guys in the white lab coats dithered away in front of trailer-sized computers? Years late, all that tweaking resulted in computer systems that can figure out the program needed by taking parameters from a given set of sensors on an engine, and make changes to the fuel program on the fly. Simply put, the geeks figured out how to tune an engine better than the gearheads! No offense to any self-professed geeks of course.

That’s great news to any of us old die hards who tune a carburetor using instincts and a screwdriver but are sick of the poor gas mileage usually associated with the old fuel dumpers. And I fall into that category to be sure. I’ve always been a stalwart supporter of a mechanical carburetor and the ability to diagnose a problem when it reared its head. Then I got to thinking; My wife’s Toyota is completely computer controlled, as was my Ranger pickup and neither of them had ever left us stranded. They fired right up when it was cold and got pretty good gas mileage to boot. I never had to adjust the floats, change the jets, or the accelerator pump settings either come to think of it. So, why not give that technology a try on our project ’68 C10? I couldn’t think of a good reason not to.

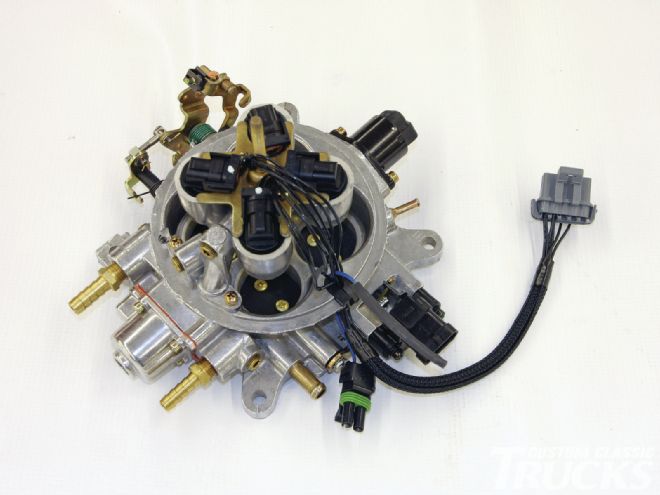

This is the 700-cfm TBI Avenger assembly with 65 lb/hr injectors. Those two black plastic protuberances are the idle air control (IAC motor) on the upper righthand side and the throttle position sensor (TPS) on the lower right side. The barb fittings on the lower left side of the TBI are the 3/8-inch inlet (upper left) and 5/16-inch return (lower left). The IAC motor is flanked by a pair of vacuum ports with an additional port (full vacuum) visible at the lower right corner. The two pigtail connectors are for the air temperature sensor (blue and black wires on the left) and the main fuel injector harness (gray connector).

This is the 700-cfm TBI Avenger assembly with 65 lb/hr injectors. Those two black plastic protuberances are the idle air control (IAC motor) on the upper righthand side and the throttle position sensor (TPS) on the lower right side. The barb fittings on the lower left side of the TBI are the 3/8-inch inlet (upper left) and 5/16-inch return (lower left). The IAC motor is flanked by a pair of vacuum ports with an additional port (full vacuum) visible at the lower right corner. The two pigtail connectors are for the air temperature sensor (blue and black wires on the left) and the main fuel injector harness (gray connector).

And so, with that optimism on my mind, I tore into the induction system with furious abandon, swapping out the 650-cfm carb with Holley’s Avenger EFI system.

The installation of a throttle body injection system on an engine that’s already equipped with a four barrel carb is pretty straight forward since the TBI simply takes the place of the carb. There are, however, a few things necessary for an EFI setup that isn’t for a standard carb system. For one, a return line must be used with Holley’s Avenger EFI kit. This is pretty straight forward however and the ease of this addition really comes down to each particular application. If you’re building a truck from the ground up, it’s easy to order a tank with a bung already built into it for such a purpose. For those of us who are retrofitting an old tank however, it’s a little more involved. I found that a later model sending unit could be easily manipulated to take a return line and in a matter of an hour or so, had the tank up and ready to accept a return line without having to remove it from the cab.

The brains of the whole EFI operation is Holley’s Avenger EFI ECU and hand held controller. This is what provides the initial programming to get the system up and running.

The brains of the whole EFI operation is Holley’s Avenger EFI ECU and hand held controller. This is what provides the initial programming to get the system up and running.

The other issue that could come to bear is the addition of added electrical draws from a switched key source. Back in the day, our trucks had extra fuse panel outlets for a heater and maybe a radio, but that was about it. Start adding the necessary components for a fuel injection system and you might find yourself without a proper source to draw power, so that is something definitely worth consideration.

Once these two items are sorted out however, it’s fairly straight forward to install the necessary components to get that antiquated carburetor out of the way in favor of a modern fuel injection system.

And speaking of easy, remember the geeks I mentioned earlier? Well, they’ve taken the guess work out of programming a modern EFI system by inventing an ECU that does the guess work for you. Using a handheld programmer, all you have to do is enter a few parameters regarding your particular engine setup and then simply hop in your truck and drive away. Yes, it’s that simple. The ECU takes over from there and learns the necessary driving parameters based on the inputs of the various sensors installed. Using information gathered from the vacuum signal, O2 readings, TPS location, and engine speed, the ECU determines the changes necessary to maintain roughly a 14:1 air/fuel ratio throughout the engine’s load and power band. Pretty neat stuff ain’t it!? So instead of a roughly idling, hard starting, fuel guzzling carburetor, you’re left with a finely tuned Swiss watch of an induction system.

Oh, and I almost forgot one of the most important aspects of adding an EFI system—the fuel mileage. When I first got the ’68 up and running in its latest incarnation, I was pretty excited at what the five-speed transmission and 3.73 rear ratio would yield when it came to highway gas mileage. Once I crunched the numbers, however, I was left wanting a bit more. Based on my initial calculations, the stock 307 with a 650 carb was good for about 13 mpg on the highway, cruising at about 65 mph. Not too bad for a big, heavy, longbed truck, but not exactly an ideal daily driver status. With the new Holley Avenger EFI setup, however, I’ve bumped that number up to a much more economical, wait for it…18 mpg! Ok, so that doesn’t seem like much, but a quick calculation says that for every twenty gallons of gas, I’m getting an additional hundred miles of out it. And at nearly five bucks a gallon, that’s pretty darn good! CCT