Does your stock or mildly modified Pontiac engine idle higher than it should because each time you try to dial it down, it runs rough? If so, this article is for you. We’ll tell you why it’s happening and how to fix it.

No Pontiac mill was ever designed to leave the factory with an excessive idle speed. Rather to the contrary, it was meant to idle very slowly. The hallmark of a refined and well-tuned engine is a low idle speed. The information supplied will be just as effective with a stock Pontiac as a modified one.

What is Slow?

It’s easy to state that the engine should idle slowly, but a value needs to be attached. The component that has the most impact on the potential idle speed is the camshaft profile. The carburetor is the second determining factor.

Our subject engine was a '79 Trans Am with a 400 and four-speed manual tranmission.

Our subject engine was a '79 Trans Am with a 400 and four-speed manual tranmission.

If your Pontiac is stock or nearly so, then the factory specification for idle speed should be your first target. Once that is achieved, it’s good practice to try and get the engine to idle about five to ten percent slower than that. For example, if the idle specification is 650 rpm, then the goal may be between 590 rpm and 620 rpm. The caveat is that the engine needs to be as smooth at the lower speed and run as well.

You may ask, “Why should we try to have our engine idle slower than the specification listed by Pontiac?” All car manufacturers suggest an idle speed specification that will mask or make up for a poor state of tune as the vehicle experiences a lack of care during its life. Thus, the specification is slightly on the high side to guarantee a smooth idle regardless of the abuse the owner has given the Pontiac or the lack of maintenance.

A modified Pontiac with any style of performance camshaft will traditionally have an increased amount of overlap. This describes keeping both intake and exhaust valves open simultaneously for a longer period of time, measured in rotational degrees. When overlap is increased, there is a reversion of exhaust gas back into the cylinder bore, which dilutes the incoming charge. The effect mandates both a richer air/fuel mixture (due to the dilution) and a higher idle speed. The propagation of the flame in the bore is not as smooth due to the reversion (the inert exhaust gas disturbs the burn rate). Thus, a Pontiac engine with a modified cam profile may require more fuel at idle but still should be able to run at a slow speed. In these applications it becomes more of a balancing act of finding the proper mixture strength and then decreasing the idle speed. An aside to increased overlap and other factors that are part of a performance camshaft, is that engine vacuum will be lower at idle and light load.

An all-out race engine with a very aggressive cam profile and large ports in the cylinder heads and intake manifold runners will want a higher idle speed (maybe 100 to 150 rpm more) but the goal should still be the same. The mindset needs to be, “How slow can I get this combination to idle?”

A modern EFI Pontiac, like the LS2 GTO shown here, has no mixture or traditional idle speed adjustment. But if the engine and fuel injectors are carbon laden, the idle speed will be unstable and slightly higher than it should be.

A modern EFI Pontiac, like the LS2 GTO shown here, has no mixture or traditional idle speed adjustment. But if the engine and fuel injectors are carbon laden, the idle speed will be unstable and slightly higher than it should be.

A street/strip Pontiac engine should be able to idle at a speed no more than about 100 rpm above its stock specification. As always this is a guideline and will be application specific. But if your engine needs to run at 850 to 900 rpm when the stock specification is 650 rpm, you are out of the ballpark.

Under analysis the required idle speed of the engine is impacted by many factors. The throttle plate needs to be opened sufficiently to produce the required power to overcome all internal engine friction. This is a design area and is one of the three loses in any engine when converting chemical to mechanical energy. Approximately 25 percent of the potential energy in the gasoline (Btu) is used to turn the flywheel. The other 75 percent is assigned to three areas of loss with each taking almost the same amount of energy. These losses are pumping, thermal, and frictional.

Pumping losses are the work that is required to move the air/fuel mixture into the cylinder bore and then evacuate the spent gases on the exhaust stroke. Thermal losses are the heat energy that is sent to the engine coolant, engine block, and out the exhaust pipe. Internal friction is the last loss and that is the fuel used for the engine to turn the crankshaft, camshaft, valvetrain, and water and oil pumps. For this reason, an engine needs a certain amount of idle speed just to keep going but anything beyond that is unnecessary and wasteful.

A propane enrichment tool is excellent to find minor air leaks. With the tune-up tachometer installed, go around any possible area of leakage with propane while watching the instrument. If the idle speed picks up or smoothes out you found a minor leak.

A propane enrichment tool is excellent to find minor air leaks. With the tune-up tachometer installed, go around any possible area of leakage with propane while watching the instrument. If the idle speed picks up or smoothes out you found a minor leak.

The mixture strength or amount of fuel and air required to run the engine is based on the fuel’s stoichiometric rating. This is the recipe of fuel and air required for the most efficient chemical conversion of the gasoline. For street gasoline without any ethanol added, the value is 14.7:1. That is 14.7 parts of air to one part of fuel. When the gasoline has 10 percent ethanol, the stoichiometric value drops to about 14.3:1. If you are interested in learning more about gasoline and its interaction with a Pontiac engine, reference the Sept. ’11 issue of HPP, which includes a primer and fuel test.

Causes of Idle Instability

The main cause for a high idle speed is to mask instability—either a roughness or swing in engine speed. The main culprit for idle instability is uneven fuel distribution in the intake manifold. If each cylinder is receiving a different air/fuel ratio, then the amount of power produced during each expansion stroke (the proper name for the power stroke) will be altered. Distribution problems are usually rooted not in the intake manifold design, though some amount of variation can be found there. The real issue lies with the mixture delivered by the carburetor or fuel injector and then the variation in the created versus delivered mixture strength.

Chevron Techron is an excellent tool to remove deposits from the fuel injectors and intake valves. It is just as effective on a carburetor equipped Pontiac and should be part of your service routine.

Chevron Techron is an excellent tool to remove deposits from the fuel injectors and intake valves. It is just as effective on a carburetor equipped Pontiac and should be part of your service routine.

Created mixture is the one that exits at the carburetor throttle plates and is found just as the charge enters the plenum of the intake manifold. Charge describes the homogenized fuel and air. Delivered mixture is what ends up in the cylinder bore and is ignited.

Many things can alter and can be responsible for this difference. The carburetor serves three purposes: throttle the engine, atomize the fuel, and emulsify the fuel. Throttling describes controlling the amount of airflow entering the engine. Atomization is breaking the liquid fuel into very small particles. Emulsification is mixing the fuel with air. That is why a carburetor has emulsion tubes or orifices in it. But the fuel is still not ready to burn in the cylinder.

A phase change called vaporization needs to occur. That is when the fuel changes from a liquid (in very small particles) to a rarefied or gaseous state. The vaporized fuel is what combusts. Vaporization occurs in the intake manifold with a carburetor and in the cylinder head intake runner in a port EFI system. It requires heat for the phase change to happen. It is identified as the latent heat of vaporization.

An EGR valve that is not closing all the way will dilute the charge with exhaust gas and impact the idle quality.

An EGR valve that is not closing all the way will dilute the charge with exhaust gas and impact the idle quality.

If the carburetor does not do a uniform or good job of atomizing and emulsifying the fuel then the vaporization rate in each cylinder will be different. Heavy fuel particles will stick to the intake manifold runners leaving behind a high level of hydrocarbons. Then as the speed of the charge in the manifold runner increases or more heat is applied, it will pull away some of the wetting from the manifold wall and alter the delivered mixture. Thus, the created versus delivered mixture will be different.

At first, during the wetting process, the delivered mixture will be weaker (leaner) than created. Once the wetted fuel starts to evaporate into the charge it will be richer. The engine will respond with an idle instability, since the amount of fuel being supplied will constantly be varied. In addition, it is possible that the poor atomization is not occurring in each carburetor bore and due to the intake manifold style (single or dual-plane) will impact only a few cylinders. The easiest way to mask this skewing of the mixture is to raise the idle speed, which most enthusiasts and professionals alike do. The proper approach is to fix the disparity in charge delivery to each bore.

GM Top Engine Cleaner is an excellent chemical to remove deposits from the combustion chambers and intake valves. It is now labeled as Upper Engine and Fuel Injector Cleaner and works on both carburetor and EFI Pontiacs.

GM Top Engine Cleaner is an excellent chemical to remove deposits from the combustion chambers and intake valves. It is now labeled as Upper Engine and Fuel Injector Cleaner and works on both carburetor and EFI Pontiacs.

A greater obstacle to uniform delivery of the air/fuel ratio is carbon deposited on the backside of the intake valve, especially with a port EFI engine. Gasoline is a complex chain of hydrocarbons. When it is burned or exposed to heat, carbon will form. There are two regions where the carbon builds in any engine. These are in the combustion chamber and on the intake valve. They are described as CCD for combustion chamber deposits and IVD for intake valve deposits. When it comes to idle speed, IVD is a very large offender.

When carbon forms on the intake valve two things occur. The first being the obvious, a decrease in airflow into the cylinder bore, since the carbon effectively makes the valve smaller in size. The other being the carbon acts like a sponge, wicking in the fuel from the engine until it becomes saturated. Once this occurs, it then releases the hydrocarbons into the charge stream, artificially richening the mixture. During the wicking process, the delivered mixture is leaner than the created air/fuel ratio. When the carbon starts to give up the fuel, the mixture is now richer than the delivered ratio. One of the major problems is the carbon deposits do not build uniformly on each valve. It is very likely that no matter how well tuned the carburetor is, the mixture distribution in the cylinder bores (not the intake manifold) will be skewed and cause a rough and rolling idle.

The spark plugs should be properly gapped and in good shape. If the ignition system is strong, a slightly wider gap will improve idle quality and allow a slower speed since it provides a larger ionization window.

The spark plugs should be properly gapped and in good shape. If the ignition system is strong, a slightly wider gap will improve idle quality and allow a slower speed since it provides a larger ionization window.

Though this impacts all gasoline engines. port EFI systems are more prone to being affected by IVD. The fuel injector is aimed to spray right on the intake valve. This is done to help atomize the fuel and to also have the heat from the valve improve the vaporization rate. For this reason, an EFI Pontiac engine can run leaner during a cold start through warm-up than a carburetor counterpart. Approximately 50 percent of gasoline is vaporized at 60 degree F, but the intake valve with its face in the combustion chamber will build heat very quickly. Thus, the fuel’s rate of vaporization will greatly improve. But if the intake valve is carbon-laden, then the fuel from the injector is wicked into the deposit at a higher rate than it would be with a carburetor, since the spray is directed at the valve.

Ignition timing will also impact the engine’s ability to idle slowly. As with the idle speed specification, the suggested base timing is a good starting point. From there you should advance and then retard the value two to three degrees and then try lowering the idle speed through the carburetor curb idle screw.

The distributor cap, advance weights and vacuum canister all need to be in good condition to help lower the idle speed. An HEI Delco module should have 7-10 degrees dwell at idle and 30-35 degrees at 2,000 rpm.

The distributor cap, advance weights and vacuum canister all need to be in good condition to help lower the idle speed. An HEI Delco module should have 7-10 degrees dwell at idle and 30-35 degrees at 2,000 rpm.

The rate of ignition advance is a function of the flame speed across the bore in relation to the piston speed. The slower the flame burns, the more of a head start (advance) is required. Many factors impact this, such as the combustion chamber shape and design, spark plug location in relation to the bore center, charge motion and cam profile.

A good rule for any engine is that at very minimal throttle opening (idle) the burn rate is slower, so more advance is required. This is due to the lack of turbulent motion in the bore as the piston sweeps toward TDC. It is the result of a minimal amount of volumetric efficiency (cylinder fill percentage) due to the slow piston speed and the throttling effect of a closed throttle plate. As the throttle is opened more, the volumetric efficiency improves along with the burn rate. As with many things in an engine, the spark advance rate is usually an inverted bell curve.

CAT Products offers an excellent tool to administer a carbon removal chemical into the engine while running via a vacuum hose. It is very effective at removing IVD.

CAT Products offers an excellent tool to administer a carbon removal chemical into the engine while running via a vacuum hose. It is very effective at removing IVD.

The problem with altering the base timing at idle for a slow speed means that you are skewing the total spark advance curve. For this reason, it will be necessary to recurve the distributor to achieve the same total timing at a given engine speed and load, while satisfying the requirements of the engine at idle. You cannot just twist the distributor and forget about it.

Achieving the Goal

With the basics established, we will now discuss how to go about lowering the idle speed on your Pontiac.

Many Pontiac engines had an adjustable idle-up solenoid that would evoke when the A/C was engaged to increase the engine speed. This allowed for a slow idle and a means to compensate for the load of the compressor.

Many Pontiac engines had an adjustable idle-up solenoid that would evoke when the A/C was engaged to increase the engine speed. This allowed for a slow idle and a means to compensate for the load of the compressor.

A manual transmission Pontiac will always be able to idle at a slightly lower speed than one with an automatic transmission due to the load the torque converter places on the engine when in a drive gear. A very loose drag race-style converter will slip at idle and not load the engine but will be inefficient and drive poorly on the street. For this reason, our discussion will be focused on the stock or street/strip Pontiac and not a race engine.

The first place to go when attempting to lower the idle speed is the basic tune-up. The Pontiac should not be suffering from a dirty carburetor, fouled spark plugs, a plugged air filter, and a multitude of vacuum leaks. You need to make sure that the engine and its sub-systems are in proper working order.

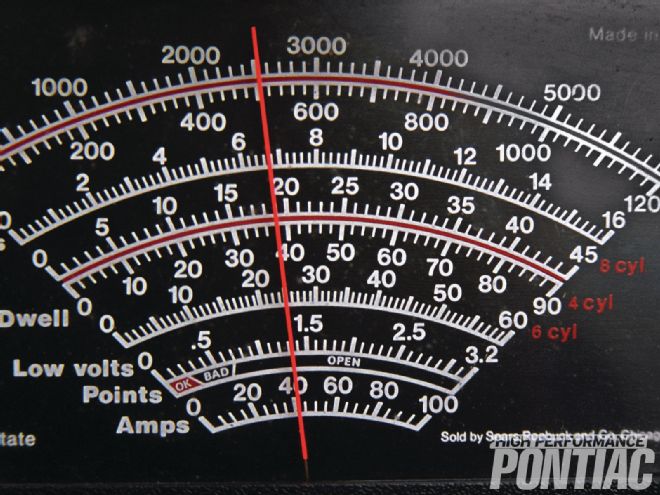

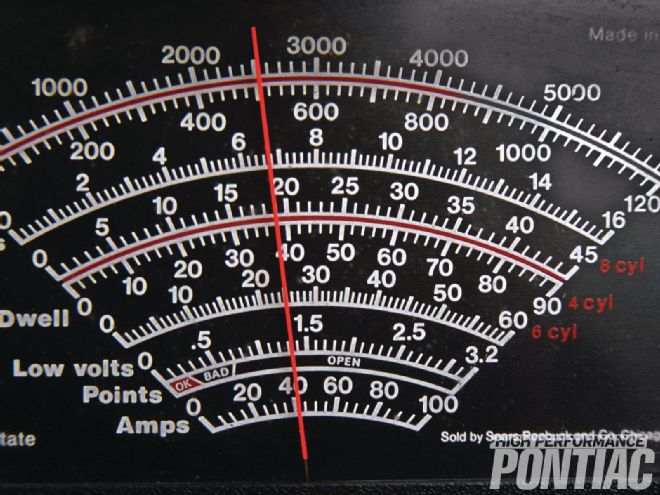

With this accomplished, the next step is to adjust the idle mixture screws for the proper air/fuel ratio. This is very easy but requires patience, along with a tune-up style tachometer for precise resolution.

A Holley carburetor has a booster style in the venturi that was designed more for performance than idle quality and low speed operation. It works well but was not as precise as a Rochester carburetor in these areas.

A Holley carburetor has a booster style in the venturi that was designed more for performance than idle quality and low speed operation. It works well but was not as precise as a Rochester carburetor in these areas.

To properly adjust the mixture screws on any Pontiac, follow these steps:

1. With the engine off, gently seat the mixture screw(s) and then turn them out two complete revolutions.

2. Connect a tune-up tachometer and start the engine and allow it to fully warm-up.

3. With a helper sitting in the driver’s seat and his or her foot on the brake, the wheels chocked, and the parking brake on, place the transmission in drive.

4. Adjust the idle speed screw to the slowest smooth idle that can be achieved.

The Quadrajet has the now famous booster within a booster design. It provides a very strong metering signal and excellent fuel atomization at low engine speeds. Superb engineering.

The Quadrajet has the now famous booster within a booster design. It provides a very strong metering signal and excellent fuel atomization at low engine speeds. Superb engineering.

5. Install the air filter and housing while locating a tool that will allow access to the mixture screws with these parts in place. You want to adjust the carburetor with the pressure drop created by the air cleaner.

6. Slowly turn one mixture screw in (lean) while watching the tune-up tach. Go in 1⁄64 of a turn and then wait for the engine to stabilize. Keep doing this until the engine speed drops. Then stop.

7. Now incrementally turn the mixture screw out (rich) in 1⁄64 increments, waiting for the engine to stabilize while watching the tach. Be patient. Keep doing this until the highest engine speed is obtained. Then repeat the procedure for the other mixture screw.

The mixture screw in a performance carburetor is removed from the discharge point and is housed in the metering block. A design that works well but is not the best for a slow, smooth idle.

The mixture screw in a performance carburetor is removed from the discharge point and is housed in the metering block. A design that works well but is not the best for a slow, smooth idle.

8. When the highest idle speed is obtained via the mixture screws, the air/fuel ratio is perfect. Now the engine idle speed will be too high. If need be, remove the air filter and back out the throttle stop screw to get a slower idle speed. When you have reached the slowest speed that you feel the engine is happy with, reinstall the air filter and try tweaking it with the mixture screws following the same procedure as before. You may find that the engine wants a slightly different mixture screw setting than before, since the throttle plates are closed more now.

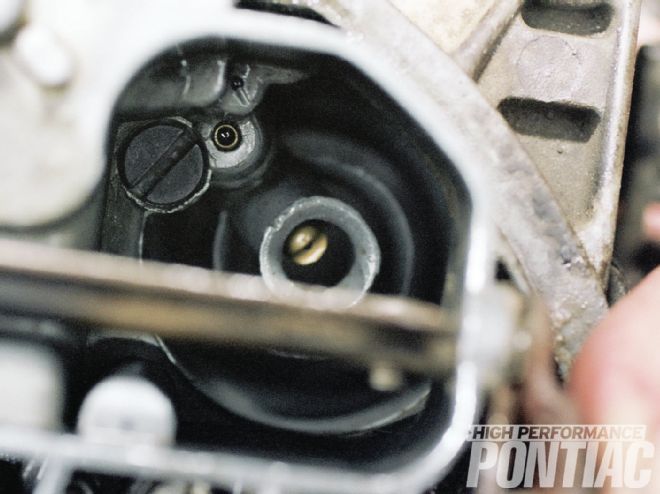

Every carburetor has a transfer slot in each bore with an idle circuit that allows the fuel to be pulled from the main metering circuit. Next to it (the round hole) is the idle discharge port. The trick is to have as little of the transfer slot exposed during idle by closing down the throttle plates. This provides more authority to the idle mixture screws. That is why it is a good idea to try different ignition timing settings so that the transfer slot area can be reduced.

Every carburetor has a transfer slot in each bore with an idle circuit that allows the fuel to be pulled from the main metering circuit. Next to it (the round hole) is the idle discharge port. The trick is to have as little of the transfer slot exposed during idle by closing down the throttle plates. This provides more authority to the idle mixture screws. That is why it is a good idea to try different ignition timing settings so that the transfer slot area can be reduced.

9. If you’re happy with the results and how the engine runs, you don’t need to play with the base ignition timing, but it may not be a bad idea to try.

10. Remove the tune-up tachometer and take the Pontiac for a drive. It should run great.

The mixture screw on a Rochester carburetor has the needle valve at the end of the discharge port, a much better design for fuel control and a smooth, slow idle.

The mixture screw on a Rochester carburetor has the needle valve at the end of the discharge port, a much better design for fuel control and a smooth, slow idle.

If your Pontiac has a performance camshaft then you might want to consider installing a CD ignition, such as an MSD, Crane, and others. These systems have a multi-strike feature that will help mask the fuel distribution issues in the engine if reversion is taking place. If the CD box steadies the idle and allows a lower speed then you know that distribution is an issue.

The process for obtaining bragging rights of a slow and steady idle speed is not difficult but requires a careful touch and listening to what the engine is telling you through the tachometer, feel, and the sound of the exhaust. A mildly cammed Pontiac sounds and runs the best when the idle speed and mixture is adjusted properly. A high idle speed masks a lot of the rumpty-rump we all love to hear.

The Q-jet has a transfer slot too. You can see the tip of the idle mixture screw in the idle discharge port. The Q-jet is an often misunderstood but excellent carburetor.

The Q-jet has a transfer slot too. You can see the tip of the idle mixture screw in the idle discharge port. The Q-jet is an often misunderstood but excellent carburetor.

To create this primer, HPP worked with Classic Restorations in Sloatsburg, New York. There, technician Greg Schwark used a ’79 Trans Am with a 400 for us to photograph the proper steps.

In closing, a slow and stable idle to a Pontiac engine guy is just as impressive as tire smoking performance. If you follow the steps provided here, your Pontiac will be a kitten at idle but a tiger when you stomp on the go pedal. Isn’t that what it is all about?

Usually a few degrees more ignition advance at idle will allow the throttle plate to be closed more and magnify the mixture control through the idle mixture adjustment.

Usually a few degrees more ignition advance at idle will allow the throttle plate to be closed more and magnify the mixture control through the idle mixture adjustment.