Among hot rod engines, the flathead Ford V8 and small-block Chevy V8 are usually considered the most significant milestone powerplants. But there's another mill that ranks right up there with the Big Two: Chrysler's first-generation Hemi of the '50s, Detroit's first serious attempt to build a mass-produced, no-compromise engine using advanced (for the time) hemispherical combustion chamber technology previously reserved for aircraft or exotic sports cars.

Chrysler's early Hemi grew out of experience gained during World War II with developing Hemi-headed aircraft and tank engines for the war effort. After the war, Chrysler needed to remain competitive with the new Caddy and Olds overhead-valve V8s, so it began developing brand-new motors. Early testing of alternative head and valve layouts revealed that the hemispherical combustion chamber was superior to other designs.

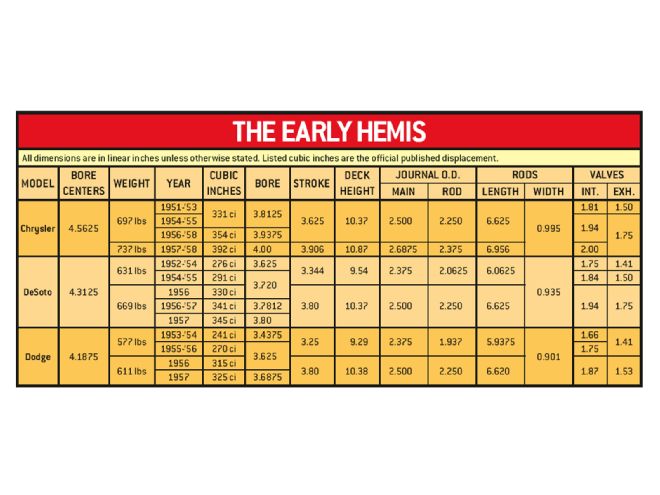

The result was the 1951 debut of the 331 Chrysler Hemi. DeSoto and Dodge Hemis followed in 1952 and 1953, respectively. Each division's Hemi had a unique block, heads, and cylinder-bore spacing. Virtually no internal parts interchange between them. In the Chrysler line, the 331 grew to 354 ci in 1956, and finally--using a raised-deck block--to 392 for '57 to '58. In the process, hard-core racers quickly discovered the engine's potential. The Hemi's efficient combustion chambers responded well to the new high-octane gas and was unsurpassed while running on alcohol and later nitromethane, a legacy maintained by the Hemi's modern-day descendents.

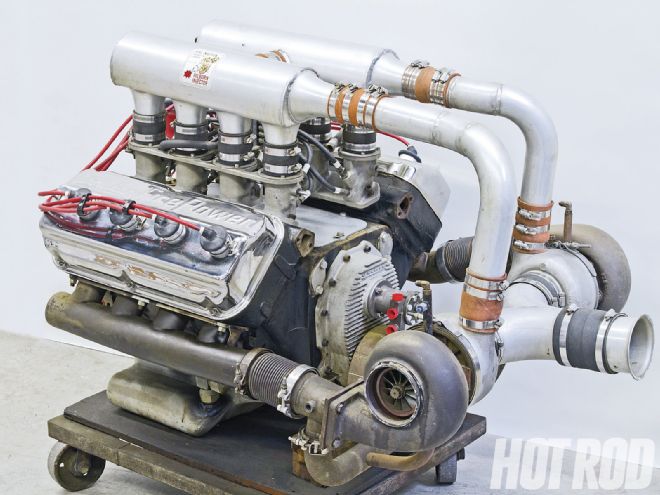

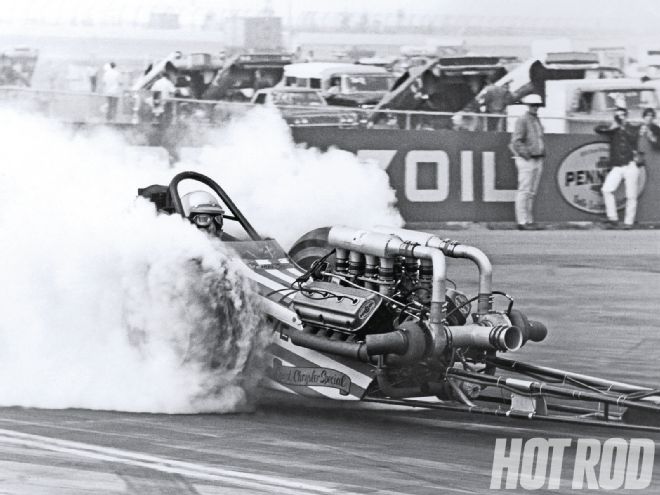

> Dusted off recently at Hilborn, this 0.030-over 392 pulled Don Enriquez’s

AA/Gas front-engine dragster to a 7.45 e.t. at 194 mph in 1975. State of the art for its

era, it had two huge Indy car Air Research turbos, Hilborn mechanical injection, and a

Hays twin-disc clutch. Enriquez, still at Hilborn today, says, “I had to ride the clutch

hard to get the boost up. Going down the track it sounded like a Buick with blown-out

mufflers.” With 20 psi of boost, the 8.5:1 motor made 1,245 hp turbocharged, compared with

850 hp with a Roots 6-71.

> Dusted off recently at Hilborn, this 0.030-over 392 pulled Don Enriquez’s

AA/Gas front-engine dragster to a 7.45 e.t. at 194 mph in 1975. State of the art for its

era, it had two huge Indy car Air Research turbos, Hilborn mechanical injection, and a

Hays twin-disc clutch. Enriquez, still at Hilborn today, says, “I had to ride the clutch

hard to get the boost up. Going down the track it sounded like a Buick with blown-out

mufflers.” With 20 psi of boost, the 8.5:1 motor made 1,245 hp turbocharged, compared with

850 hp with a Roots 6-71.

Alas, the engine was more massive for its displacement than its competitors' products, making it harder to package in increasingly streamlined engine compartments. The heads' fully machined combustion chambers and complicated valve layout made it costly to produce. In 1959, Chrysler turned to the cheaper wedge motors, bringing the first-gen Hemi's short, eight-year run to a close.

Today, first-gen Hemis and their full-race Donovan 417 offspring live on in nostalgia fuel racing. Street rodders tired of cookie-cutter, me-too small-blocks are snapping up old Hemis for use in retro rods. Their unique, in-your-face appearance makes a badass engine swap, even in a classic muscle car. For many years, early Hemi parts were scarce, but renewed interest in them has made it profitable for aftermarket parts vendors to push out improved parts that now make those old Hemis bigger and faster than they ever were. Pickings are still a little slim for the DeSoto and Dodge versions, but the situation is improving even for those oddball offshoots. Nevertheless, this article will concentrate on the more available Chrysler Hemi. As of early 2012, the only major parts lacking for fully resurrecting these engines are new blocks and affordable aftermarket cranks, but we expect this to be remedied by early next year.

For the scoop on first-gen Hemis, we consulted Gene Adams, one of the pioneers of early Hemi development who continues to build and race them to this day; Bob McKray, ace Hemi engine builder and head porter; Gary Patrick of RockerArms.com (formerly Rocker Arm Specialist); and Bob Walker, owner of Hot Heads, your complete one-stop source for early Chrysler, Dodge, and DeSoto Hemi hot rod parts.

Chrysler Vs. DeSoto Vs. Dodge

Early Hemi block lengths from the rear bellhousing face to the front

of an adopted Chevy V8 short water pump pulley mounting flange: Dodge, 27 inches; DeSoto,

27-1/4 inches; Chrysler (without integral bellhousing), 28-3/4 inches.

Blocks

All production blocks are cast iron and have two-bolt main caps. If

it passes a sonic check, Adams says you can overbore a normally aspirated 331 up to 0.125

inch (1/8 over stock). A 354 or 392 can take 0.060 over. For supercharged gas street

engines, you need to maintain at least 0.125-inch wall thickness after overbore on the thin

or thrust side, which usually mandates limiting the max overbore to 0.030 inch.

Unbeefed production blocks have adequate strength for normal usage--about 400 to 500 hp on a 354, 500 to 600 on a 392. Replacing your 50-year-old bolts with ARP main and head studs provides good insurance. As Adams puts it, "Don't use bolts--use studs everywhere you can." Nevertheless, running more than 11.0 to 12.0:1 compression, cramming in 8 psi or more of boost, or packing lots of nitrous or nitro stands a good chance of failing the cylinder walls and main webs. In the '60s, the main solution (pun intended) was to use a support girdle for the two-bolt caps in addition to filling the block with concrete (or half filling them for street use). New four-bolt conversion caps have made girdles obsolete (although TR Waters still sells them).

Race-only aluminum blocks have been developed (as in the Donovan 417), but they lack water jackets and/or won't accept most internal or external production parts. Later this year, Adams, in collaboration with Claude Lavoie, plans to introduce all-new, water-jacketed, iron and aluminum replacement blocks with siamesed cylinder walls that permit up to 4.310-inch bores. The aluminum casting is a dry-sleeve design that prevents water seepage into the oil pan. All production parts fit, including oil pans, bearings, cranks, and front covers; externally, the blocks retain stock engine-mount provisions and accessory bosses. A 392 deck height is standard, but the decks are thick enough to permit milling to the lower 331/354 height. Four-bolt caps on the center three mains plus added metal in the main web area and lower cylinder walls greatly strengthen these blocks over the old production castings. In place of the original (and much maligned) rear main rope seal, the new blocks will use widely available (and reliable) Ford FE big-block main seals.

Block Identification

Year and CI

Casting Numbers

'51-'54 331

1323329

'55-'56 331

1551629, 1619629

'56-'58 354

1619829

'57-'58 392

1673729

Cranks, Bearings, Balancers, and Flywheels

All stock early Hemis had beefy forged cranks and are internally

balanced. According to Adams, "Some Chrysler 300 and industrial engine cranks may be

nitrided." "The old-school Fueler guys used to make 1,200 to 1,500 hp on stock Hemi cranks

back in the day," McKray points out. Although Hot Heads' Walker says he "mags every crank we

use--the only bad ones I find are ex-race-car cranks, and they're almost always cracked."

McKray finds that the "first failure point will probably be a crack through the mains."

The 331 and 354 cranks physically interchange--they have the same stroke and main- and rod-journal diameters. However, the 331 crank has only -1/4-inch oil-feed holes; for racing, you need to open and chamfer them to the 354's larger 5/16-inch size. The 331/354 cranks won't interchange with the 3.906-inch stroke 392 crank, which has larger main and rod journals. Any of these cranks can turned by as much as 0.040 inch undersize. To maintain adequate strength, McKray cautions, "Be sure to put in a good radius when turning them undersize." Bearing availability was once a problem, but now King Bearings has stepped up and offers good trimetal main and rod bearings in standard and up to 0.040 inch under through selected distributors like Egge and Hot Heads.

You can increase a stock crank's stroke by offset grinding, which moves the rod journal centerlines farther away from the main bearing journal centerlines. The new, reduced-diameter offset journal must be the same size as one used by a different (but still commonly available) rod. On early Hemis, the cam-bore location is so high in the block that rod-to-cam interference with stroker cranks is not a problem as it often is on many small-block engines. On the other hand, it can be hard to find a virgin early Hemi crank that hasn't already been straight-ground severely undersize. Assuming you can find a "good" crank, offset-grinding down to the big-block Chevy's 2.20-inch size and using big-block Chevy-style rods and rod bearings is a popular option. On the 331/354 crank's 2.250-inch mains, this yields about a 0.045-inch stroke increase; with the 392's 2.375-inch journals, about a 0.170-inch increase is achieved. (The "missing" 0.005 inch is a safety factor to allow for journal cleanup.) A 6.75- or 6.800-inch center-to-center rod length is usually a good fit with these combos. The slight 0.006-inch difference between the big-block Chevy 0.990-inch piston pin and Chrysler's 0.984 pin is easily accommodated with a slightly thicker rod pin bushing. Alternatively, you can order your custom pistons for the big-block Chevy pin from the get-go. As can be seen in the table (pg. 82), in the early Hemi's case, a 392 attains significant displacement increases using the big-block Chevy journal size.

Still a problem is the lack of affordable aftermarket cranks. Hot Heads is working on a 4.160-inch-stroke 392 billet crank that with a 4.035-inch bore yields 426 ci. At the top of the food chain there are Sonny Bryant and Crower custom-order Top Fuel–level cranks, but they're priced accordingly. A high-end, custom-order, 5/8-inch stroker on a 0.060-over 392 yields 469 ci, or 529 ci with a 4.310-inch bore in Adams' new thick-wall aftermarket block.

Most stock harmonic dampers are long used up. Even in their day they were prone to failure. Using a Mopar 318/340 small-block's neutral-balanced damper is a practical budget approach; Hot Heads sells converted and indexed 340 dampers that are direct early Hemi bolt-ons. Fluidampr and BHJ offer dedicated, SFI-approved early Hemi balancers.

Hot Heads carries lightweight stock- replacement aluminum flywheels; 146-tooth versions fit '51 to '56 engines, and 172-tooth units fit '57 to '59 engines. Steel and aluminum replacement flywheels are also available from Wilcap.

Where it all Began

Chrysler developed its first Hemi--the 2,500hp XIV-2220 V16 inverted

engine--as a potential replacement for Pratt & Whitney's R-2800 radial motor in the World

War II P-47 fighter. By the time the engine was ready in 1945, the war was ending, so it did

not go into production. Chrysler also collaborated with Continental on the air-cooled

AV-17905B V12 hemi-headed engine used in the postwar M47 Patton tank.

Crank Identification

CI

Forging Numbers

331

1323335, 1335001, 1409241, 1419421

354

1409421, 1491421, 1523335, 1619647, 1617184, 1635690

392

1673755

Offset-ground stroker combos using big-block chevy rod journal

Stock CI

Old Stroke

Stroke Increase

New Stroke

New CI

331

3.625

0.045

3.670

346

354

3.625

0.045

3.670

369

392

3.906

0.170

4.076

422

Rods and Pistons

All stock early Hemi rods are forged steel with 3/8-inch bolts and

come bushed for floating pins. The 331/354 rod length and journal sizes differ from the 392.

Properly rebuilt, the rods are OK for most normally aspirated engines. At a minimum, stock

rods should be shot-peened and subjected to magnetic-particle inspection, the big ends

rebuilt, the small ends rebushed, the beams polished, and the assembly fitted with modern

ARP rod bolts (they're the same bolts as those on B/RB Chrysler wedge engines).

Alternatively, you can swap in more modern rods--either production or aftermarket equivalents--with minor mods. Hot Heads will sell you modern rods with the required mods already performed. Remember, alternative rods require rebalancing the engine and in some cases even adding Mallory heavy metal to the crank.

Pontiac 400 rods can be used in a 331/354. Bore the small end to accept the 354 wristpin bushing, drill and chamfer the rod top 1/8 inch for additional pin oiling, and use Pontiac rod bearings.

Some builders create a low-deck 392 by installing the 392 crank in a 354 block. To do this, use 383/400 Chrysler rods and bearings, turn down the 392 crank's main journals to 2.500 inches, resize the thrust surface to the short-deck block's size, and bore the 354 0.062 over.

For a normal, high-deck 392, 440 Chrysler rods work. At 6.76 inches center to center, this 0.200-inch-shorter rod is widely available, inexpensive, and uses a low-cost bearing. The 440 rod has a wider beam, so either the journal must be ground wider or the rod and bearings narrowed about 0.020 inch. Yet another alternative is even stouter 426 Hemi rods with 7/16-inch bolts. Custom pistons with the right compression height and a 1.090-inch pin bore are needed as well.

Then there are aftermarket aluminum billet or forged rods. Bill Miller, GRP, or Venolia can, as Adams puts it, "make an aluminum rod any way you want it." Popular on race cars, street use remains controversial due to aluminum's finite fatigue life. You may have to clearance the oil-pan rails and the bottom of the cylinders to use aluminum rods; be careful not to run into the water passages.

Stock Hemi pistons were cast aluminum. Aftermarket choices run the gamut from stock cast replacement-style (Egge, Hot Heads, Kanter), to Keith Black cast hypereutectic (392 only), to shelf-stock forgings(Arias and Ross), to custom, made-to-order forgings (just about all major piston outfits, but check especially Arias, Hot Heads, JE, Ross, and Venolia).

Walker says early Hemis "really like 10.0:1 compression. They'll run all day on 92-octane gas. With our aluminum heads, you can run more. I'm building an 11.0:1 engine now for the street to prove it." McKray concurs, going as high as 11.0 to 11.5:1 with aluminum heads, "depending on cam timing." For N/A racing on good gas, McKray says, "Go as high as you need it if you can get it on a piston. Sometimes it's hard to run super-high compression due to the Hemi's dome profile." If putting a huffer on it, hold compression down around 8.0 to 8.5:1.

To benefit from the latest and greatest piston-ring technology, it pays to custom-order aftermarket pistons for at least 1/16-1/16-3/16 rings instead of the Hemi's original 5/64-5/64-3/16 ring pack. Ring availability is not a problem for the 392's 4-inch bore (which many other engines share). Even for the oddball 331/354, you can now get high-quality, modern rings from Hot Hemi, Total Seal, and others.

BHJ offers cylinder honing plates. McKray considers them "optional on the street, mandatory for racing." However, Adams says, "The blocks are pretty stiff. The bolts aren't too close to the cylinder wall, and they don't go into water. Plates aren't as critical as they are for some other engines." Preferred honing techniques are pretty much in line with any of today's engines.

The '51 to early-'55 331s used a long, threaded front snout to retain the cam sprocket; '56-and later engines use a short snout with a bolt, a cupped washer, and a thrust plate to retain the cam. All aftermarket cam cores are the late, short-snout style. Short-snout cams and timing sets for '55-and-later low-deck engines can be used to replace earlier long-snout cams.

Rod Identification

CI

Forging Numbers

331 - 354

1324222, 1821345

392

1673758

Cam and Valvetrain

Most early Hemis had hydraulic flat-tappet cams, but some high-perf,

marine, and industrial engines had factory solid grinds. The nonadjustable, hydraulic-cam

valvetrain parts were different from the adjustable (and rare today) mechanical valvetrain.

Special valve covers with bumps were needed to clear the adjustable rockers, making it easy

to identify a solid-lifter–equipped engine. Early engines had long-snout cams and unique

timing sets that are long gone, but Hot Heads and other early Hemi specialists can convert

existing long-snout cams and front ends to use '55-and-later short-snout cams.

All 392 engines take short-snout cams, but because the block's lifter bores are slightly relocated to maintain proper valvetrain geometry on the high-deck block, 392 cams have a slightly different lobe orientation. The 331/354 and 392 cams physically interchange in the block, and the engine will even start up and run, but the timing events won't be right. There's no easy way for the average Joe to tell the difference without degreeing the cam.

High-perf, short-snout cam cores are available, but often the cam itself must be ground to order. Catalog grinds include offerings by Comp (392 hydraulic flat-tappet Thumpr grinds), Crane (early Hemi retrofit hydraulic and mechanical roller cams for both 331/354 and 392 engines), Hot Heads (hydraulic and solid flat-tappet and hydraulic roller cams for all early Hemis), Schneider (solid and hydraulic flat-tappets and solid roller cams), Engle (392 solid roller), and Isky (hydraulic and mechanical flat-tappet cams).

As for specific cam timing, Hemis flow so well on the exhaust side that a dual-pattern cam isn't really needed. For the average performance flat-tappet hydraulic street cam, McKray recommends a grind with about 225 to 230 degrees at 0.050. Add another 10 to 13 degrees on a solid.

An early Hemi hydraulic flat-tappet lifter is similar to the hydraulic lifters specified for the Chrysler LA small-block ('64 to '87 273/318/340/360 non-Magnum) or B/RB big-block wedge ('64 to '78 only). The difference is the early Hemi hydraulic valvetrain pushrod seat has a -1/4-inch ball-seat pushrod tip, but these later lifters have a 5/16-inch ball-seat pushrod tip. Therefore, if early Hemi hydraulic flat-tappet lifters are out of stock (check Hot Heads or Comp Cams), substitute widely available lifters from these specified later engines by changing to custom pushrods with 5/16-inch tips on the lifter ends and (to maintain compatibility with the stock upper valvetrain) -1/4-inch tips at the rocker-arm ends. Likewise, with the right pushrods, solid lifters from specified later engines fit, as will hydraulic or mechanical roller lifter bodies (less the guide links). Crane and Hot Heads sell complete, dedicated early Hemi hydraulic- or mechanical-lifter-paired assemblies complete with the proper links.

For hard-core use, the stock 5/16-inch-od pushrod bodies should be upgraded to 3/8 inch or even larger. This may require opening up the pushrod holes in the heads for clearance. The use of 7/16-inch pushrods with more than 0.850-inch-lift cams for extreme racing may require pushrod sleeves because grinding the necessary clearance excessively thins out the head. Check pushrod-to-head clearance through the entire valve opening/closing cycle, not just statically.

The basic upper valvetrain is OK for street use, but the stock, cast, shaft-mounted rockers will fail under severe use--blowers, max compression ratio, gonzo spring rates, or high-rpm, all-out racing. The exhausts have the most problems and usually fail first. "With more than 0.500 lift, you need to consider an aftermarket exhaust arm," Adams maintains.

Some racers say the nonadjustable hydraulic valvetrain is stronger overall because the mechanical valvetrain's rockers are weaker in the adjuster area. Due to the strength factor and scarcity of stock adjustable-valvetrain parts, for years racers used adjustable pushrods to obtain needed adjustability on the hydraulic valvetrain.

RockerArms.com specializes in rebuilding and refurbishing Hemi shaft-mounted upper valvetrains (as well as for many other old engines). It can bush the stock rockers and hard-chrome the shafts for severe use. Heavy-duty chrome-moly shafts are also available. Other services include correcting geometry problems, compensating for long valves by reradiusing the rocker tips so the scrub radius moves farther outboard, and even altering the effective rocker ratio beyond the stock 1.5:1. The -1/4-inch pushrod cups in the rockers can be machined to 5/16, eliminating the need for hybrid-tip pushrods when using later Chrysler lifters. Hydraulic valvetrains can be made adjustable without using the rare, stock-style mechanical valvetrain parts (although RockerArms.com does stock OE adjusters). Some of these services are available through Hot Heads, too.

For high-end use, adjustable, aluminum roller-rocker shaft-mount valvetrain assemblies are available from Hot Heads, RockerArms.com, and T&D. RockerArms.com will soon offer a fully rebuildable, high-tech 17-4 investment-cast stainless-steel rocker with an adjustable insert tip that allows easy ratio changes or compensation for valve stem–induced wear.

Complexity or Simplicity?

At first glance, the double-shaft Hemi valvetrain appears overly

complicated, but Adams says, "It's the simplest thing you can make. You can pull the heads

without pulling the distributor or the headers. Remove 10 bolts and you can lift off both

the intake and exhaust rocker shafts and rockers together as an assembly."

Oiling

The efficient stock oil system needs few mods. One thing to watch for

is excessive lifter bore wear. All main bearings except the rear receive oil from the

passenger-side lifter gallery. If there is more than 0.0025 inch of lifter-to-bore

clearance, the main bearings can become starved for oil. This can be solved by bushing the

lifter bores. Shoot for a 0.0005- to 0.0010-inch clearance.

Wear-induced, loose clearances between the rocker arms and shaft allow too much oil upstairs. With only 5/16-inch oil return holes in the heads, the oil pan can be starved. The fix is to ream and bush the rocker arms, then turn and hard-chrome the shafts.

The stock oil pump is adequate. Melling has retooled early 392 Hemi pumps, but they won't fit 331/354s. A modern alternative is a modified 318/340 oil pump. Don't use a standard-volume 318/340 pump; it flows about 15.5 percent less than the standard Hemi unit, while Melling's high-volume 318/340 pump flows about 3.5 percent more.

For a modern, spin-on oil filter, ax the stock filter mount for Hot Heads' 30-degree, up-angle mount or vertical mount. Wilcap has a forward-facing spin-on mount.

Air, Fuel, and Spark

The original factory parts are obsolete for anything other than a

straight resto. But thanks to the Hemi's resurgence in popularity, there are plenty of

modern aftermarket options.

Intake Manifolds: There was once a heavy factory 2x4 intake for dual Carter AFBs that's said to be worth 50 hp more than the equivalent factory iron single-carb intake--good luck finding one. Offenhauser once offered a slew of multicarb intakes, but nowadays they're swap-meet-only items. Hot Heads offers modern intakes that far surpass any of this old-school stuff, anyway. And there's always EFI .

Ignition: Bolt-in pointless distributors are available from Mallory (Unilite or magnetic-trigger), MSD (Ready-to-Run), and Performance Distributors (drop-in large-cap DUI). Hot Heads offers adapters for installing Chevy V8 distributors. Chrysler 318/340/360 distributors bolt in using longer Hot Heads intermediate shafts. Joe Hunt and Vertex still sell magnetos; Vertex also has a pointless distributor that resembles its traditional magneto on the outside. Pre-'55, 6-volt electrical systems must be upgraded to 12 volts to use a later distributor.

Exhaust: Reputedly, truck manifolds (identified by their four-bolt exhaust pipe mounting flange) are the best factory units, but that's not saying much. For performance, nothing beats tube headers. Hot Heads stocks shorty, universal-block-hugger, full-length-block-hugger, Gasser, and over-chassis styles. Sanderson Headers sells shorties as well as classic-style, full-length Roadster headers. Any premade header requires a Hot Heads adapter plate to fit early 331, small, round-port heads. For fabricators, Hot Heads also sells welded- and bare-flange header kits. Headers By Ed offers exhaust flanges and prebent tubing sections for early Hemis and just about every other engine as well. McKray likes to see 15?8- or 1-3/4-inch primaries into 3-inch collectors for most streetable applications, but for no-compromise power in a 354 race application, Adams specs 2-inch-od x 30-inch primaries into 3-1/2-inch-od x 8- to 10-inch collectors.

Forced Induction: Roots blower kits are available from all the leading supercharger outfits, including Blower Driver Service, Dyer's Blowers, Littlefield, and Mooneyham. Adams says the best early Hemi supercharger manifolds are exclusively available through Hot Heads.

331/354/392 vs. 426

The easiest way to tell early Hemis from a 426: The early Hemi had a

rear-mount distributor, an internal oil pump, and a separate valley cover. The 426 Hemis

have a front-mount distributor, an external oil pump, and no valley cover with stock intake

manifolds.

Primary Sources

We want to specially thank Al Kirschenbaum and Pat Ganahl, along with

the following companies that contributed to this article.

Bob McKray Performance; Mission Viejo, CA; 949/458-7087; BobMcKrayPerformance@yahoo.com: Early Hemi engine builder and head porter

Gene Adams Performance; Anderson, CA; 530/357-5570: GeneAdams354@live.com. Early Hemi engine builder and racer, new replacement blocks coming soon.

Hilborn Fuel Injection; Aliso Viejo, CA; 949/360-0909; HilbornInjection.com: Individual-stack mechanical and electronic fuel injection systems and intakes

Hot Heads Research & Racing Inc.; Lowgap, NC; 336/352-4866; HotHemiHeads.com: Aluminum heads and your one-stop shop for Chrysler, Dodge, and DeSoto Hemis parts and info

RockerArms.com (Rocker Arm Specialist); Anderson, CA; 530/378-1075; RockerArms.com: Shaft-mount valvetrain refurbishing, modification and upgrading; roller rocker systems

More To Come...

We ain't done yet! Stay with us next month as we delve into early Hemi cylinder heads (including flow numbers), look at modern transmission adopters, scope out front-end drives, and offer up a complete early Hemi supplier source list.