Dale Asks:

I'm a little confused about how and when to install oil restrictors on a Ford 351C block. The last time this was referenced (Pit Stop, May '11), you recommended installing oil restrictors in all five main saddles. Moroso has a Ford Cleveland oil restrictor kit (PN 22050) that comes with five plugs: four small (1/4 inch) and one large (5/16 inch). The kit instructions say not to modify the No. 1 main saddle and put the large plug in the No. 5 saddle. Moroso also says "Do not use this kit with hydraulic cams." Should I buy two kits so I have enough plugs for all the saddles, follow the kit instructions, or not install any plugs at all? I have a hydraulic cam with 0.560-inch lift.

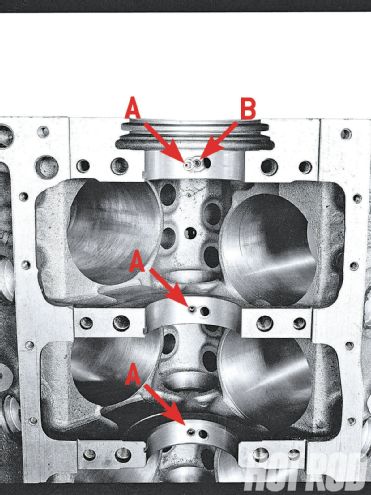

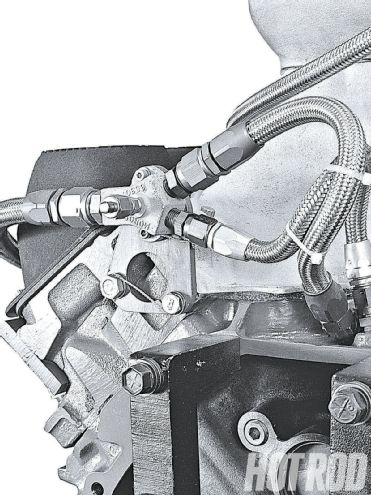

Current practice is to install the small restrictor plugs in the vertical oil passages between the main bearing bores and the cam bearings in the No. 2 through No. 5 main webs (Nos. 3 through 5 shown, A). No plug is installed in the No. 1 web. If used, the large plug goes in the diagonal passage that runs from the No. 5 main bearing bore (B) to the left oil gallery.

Current practice is to install the small restrictor plugs in the vertical oil passages between the main bearing bores and the cam bearings in the No. 2 through No. 5 main webs (Nos. 3 through 5 shown, A). No plug is installed in the No. 1 web. If used, the large plug goes in the diagonal passage that runs from the No. 5 main bearing bore (B) to the left oil gallery.

Dale Johnson, Via email

Marlan answers:

How and when to restrict Ford Cleveland engine oiling is somewhat controversial, with various approaches tried over the years. Your letter prompted me to re-evaluate the issue with longtime Ford racer and engine builder Chris Kaufmann, now a consultant with Aaron Hoekstra (Hoek'd Up Performance). Basically, current thinking about how (or even whether) to restrict oil to the top end on these engines has evolved.

According to Kaufmann, "The Cleveland/385-Series blocks used only two oil galleries." Just the No. 1 (front) main bearing received oil directly from the oil pump. Only after first feeding the lifters and all the upper valvetrain did the remaining oil volume in the galleries flow to the other four main bearings, and through the crank to the rod bearings. There was an additional leak path in this scheme: The cam bearings were also fed oil off the main bearings.

Hank the Crank was among the first to develop elaborate Cleveland oiling mods back in the ’70s to solve problems that arose when Ford NASCAR racers first ran Clevelands. Besides the usual main saddle restrictors, the setup used a fabbed lifter-valley oil manifold to carry oil from a ½-inch external line and distribute it directly to the center three mains through specially drilled and restricted passages.

Hank the Crank was among the first to develop elaborate Cleveland oiling mods back in the ’70s to solve problems that arose when Ford NASCAR racers first ran Clevelands. Besides the usual main saddle restrictors, the setup used a fabbed lifter-valley oil manifold to carry oil from a ½-inch external line and distribute it directly to the center three mains through specially drilled and restricted passages.

The Cleveland's ass-backward oil distribution system "is a true design flaw," Kaufmann maintains. "Since there was no dedicated main/crank oiling, the critical main and rod bearings can get starved for oil under competition conditions." Any rocker arm or pushrod failure that caused a lifter to pop out of its lifter bore would also cause a loss of oil pressure to all the mains. If that failure happened at high rpm, it could result in catastrophic engine failure. Even with no failures, Kaufmann points out that "when all that top-end oil returns to the bottom end, it causes a power loss with so much splash on the crankshaft area and running into the pan. Oil control is a source of great power. These days we bush the lifter bores or use a new Ford Racing block with a revised oiling system that eliminates all these negatives."

Realistically, all this concern is probably overkill for a daily driver. Even if you still have an old production block, Kaufmann says oil restrictors "are not really worth the trouble" if engine rpm doesn't exceed 6,000. A simpler alternative is restricted pushrods (with just 0.040-inch oil holes).

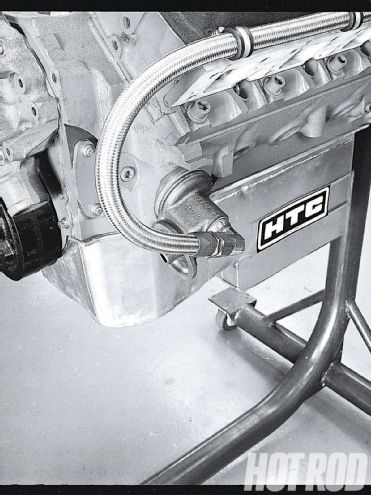

Hank used a Ford Econoline van 90-degree oil filter adapter (modern equivalent: Ford Racing PN M-6880-A50) modified to supply oil directly from the oil pump to a junction block at the rear of the block through a AN-8 (½-inch) oil line.

Hank used a Ford Econoline van 90-degree oil filter adapter (modern equivalent: Ford Racing PN M-6880-A50) modified to supply oil directly from the oil pump to a junction block at the rear of the block through a AN-8 (½-inch) oil line.

On the other extreme are those who routinely run over 8,000 rpm. With today's humongous valvespring pressures, it may be more important to cool the springs and get good valvetrain lubrication. Some hard-core Ford racers like Glidden and Roush ran oil sprayers to the valve covers for this purpose. "We also ran both internal and external oil lines to get oil where we needed it," Kaufmann adds.

If you are in between the two extremes--say 6,100 through 7,900 rpm with a production Cleveland block--you still might consider restricting the oil passages. If using the old-school main-saddle restrictor plug technique, the current recommended practice is not to restrict oil to the No. 1 main saddle, because this passage also supplies splash on the timing chain in addition to lubricating the distributor gear. This is why today's restrictor plug kits (including the referenced Moroso kit) now have only four small restrictors for the main saddles.

The kit's single, large plug that goes in the No. 5 main saddle's big hole should only be installed if running solid flat-tappet or solid-roller cams. It should not be used with any hydraulic flat-tappet or hydraulic-roller lifter. Also, use late-model, high-perf hydraulic lifters with a small oil opening (0.040 inch), or use restricted pushrods as noted above. Whether it's wise to take a hydraulic cam to such high rpm is, of course, another question entirely.

When installing oil restrictors, the engine should ideally be disassembled before tapping the restrictor holes. This permits flushing the iron chips out of the block without contaminating the oil passages. If you must do this on an already assembled engine, at least make sure to use a lot of grease on the tap and clean it often. Don't blow into the tappet area; instead, blow down from the lifter bores so junk goes down, not deeper into the oil gallery.

The Y-block splits oil flow so one AN-6 (3⁄8-inch) outlet supplies oil to the lifter-valley oil manifold and one AN-8 (½-inch) line feeds the rear main bearing and (through the main bearing bore restrictor) the left lifter gallery. Back then, Hank still installed small restrictor plugs to all five main-saddle vertical passages (the front passage fed the right lifter gallery).

The Y-block splits oil flow so one AN-6 (3⁄8-inch) outlet supplies oil to the lifter-valley oil manifold and one AN-8 (½-inch) line feeds the rear main bearing and (through the main bearing bore restrictor) the left lifter gallery. Back then, Hank still installed small restrictor plugs to all five main-saddle vertical passages (the front passage fed the right lifter gallery).

Today, there is a better alternative to the old restrictor plugs. Tim Meyer offers special cam bearings with the oil-restrictor holes built into the bearing (PN F26 fits Cleveland). Check out his website for further info. Ideally, these should be used with the restricted pushrods and/or lifters, keeping the majority of oil downstairs to support the mains and rods. Whether using conventional or Meyer's special cam bearings, Kaufmann says to make sure the front cam bearing isn't pushed in too deep. "I used to set them about 0.005 inch back of flush with the front of the block surface," he says.

Another Kaufmann tip for high-perf Cleveland oiling (with or without restrictors) is to use a high-volume oil pump (such as Melling PN M-84AHV or Speed-Pro PN 224-41166V), along with a Moroso (or similar) 100-psi, high- pressure spring (PN 22850, incorrectly listed last May as the PN for the restrictor kit). That in turn mandates an increased-capacity oil pan if running high rpm. Also, consider fully grooved main bearings (such as Clevite; PN MS-1010VG).

Ultimately--if your name is Daddy Warbucks--there's the dry-sump solution, filled with a high-end synthetic oil such as Red Line.