The Advanced Engineering Technology Conference may sound like a gathering of brainiacs discussing computer code or the best materials for bridge abutments, but don't let the name fool you. The AETC, as it's commonly known, is all about engines, and it gets even better than that. The AETC focuses on the most innovative ways to make big-time horsepower. The only time fuel economy is mentioned is when someone is discussing combustion efficiency in order to burn more fuel and--you guessed it--make more power.

Edelbrock's Dr. Rick Roberts talks about understanding how air and fuel behave inside the induction track of your intake manifold and cylinder heads.

Edelbrock's Dr. Rick Roberts talks about understanding how air and fuel behave inside the induction track of your intake manifold and cylinder heads.

Last year, Circle Track covered the AETC conference because it was concentrating on stock car racing engine technology. But we decided to return this year even though there was no specific category topic, it was general engine technology. However, the quality of information available was second to none and we wanted to pass it along to you.

This year, the 22nd annual AETC featured such speakers as Edelbrock's Dr. Rick Roberts, who provided insights on how he designed some of Edelbrock's best performing intake manifolds; drag racing engine builder Jon Kaase on making big power with big cubic inch engines; Lake Speed Jr. on how to determine the best oil for your racing engine; and Roush Yates Engines' Josh Stewart provided a behind-the-scenes look at how Roush Yates developed new racing engine packages.

Champion Spark Plugs spends more money on R&D every year in order to continue to improve its products than most race teams spend on their entire racing program. Here, Champion's Richard Keller shares some of that information on engine tuning freely and answers attendees' questions afterward.

Champion Spark Plugs spends more money on R&D every year in order to continue to improve its products than most race teams spend on their entire racing program. Here, Champion's Richard Keller shares some of that information on engine tuning freely and answers attendees' questions afterward.

The AETC covers nearly three full days filled with speakers, demonstrations, and group discussions on practically every engine related topic imaginable--as long as it relates to making your racing effort better. Obviously, we can't bring you all of it, but here are a few highlights. If you are interested in attending for yourself next year, the AETC will be held in Orlando, November 26-28. Circle Track magazine will again be sponsoring the conference as we have the last two years. It's a highly technical, highly valuable three-day event. For more information, check out www.aetconline.com.

One of the greatest aspects of the AETC is that it encourages its speakers to discuss a topic honestly without feeling the need to become a pitchman for the companies they work for. Every speaker is very highly qualified in his or her chosen field, so this often leads to some interesting nuggets of information that aren't directly tied to what you think a particular person's area of expertise should be.

For example, Richard Keller is an engineer with Champion Spark Plugs, and his presentation was based on the principles of ignition for high-performance engines, as you might expect. But he also touched on a few things he's learned through his extensive research that don't specifically relate to the ignition system. One area where the spark plugs are often blamed incorrectly is when racers or engine builders experience detonation with an engine. They may say the plug is too hot in the heat range or otherwise creating hot spots in the combustion chamber. Detonation is a serious issue in high-performance racing engines, but have you ever considered the idea that the real source of detonation your engine is suffering from is because of the cooling system?

Bill Hancock speaks at the 2011 AETC conference. Where else can you have the man who helped run Chrysler's NASCAR program and worked alongside Richard Petty in his heyday give you an hour's worth of tips on improving your testing program?

Bill Hancock speaks at the 2011 AETC conference. Where else can you have the man who helped run Chrysler's NASCAR program and worked alongside Richard Petty in his heyday give you an hour's worth of tips on improving your testing program?

Keller points out that high- performance heads often move the intake ports and valve locations and change the shape of the combustion chambers. The head manufacturer's focus is on improving torque and horsepower and as a result, the water jacket volume is often compromised. Now, not only is your engine producing more power--which equals heat--the heads also have less volume of coolant flowing through them.

Of course, few of us are willing to dial back on the power just to get more water moving through the heads, so one solution Keller offered is to look at the amount of turbulence of the air/fuel mixture the cylinder head creates. More turbulence equals better movement of the air/fuel charge inside the chamber. This reduces the chance for any fuel to remain against a hot spot long enough to ignite on its own before the spark plug fires and causes detonation. So, if you can find a pair of heads that produce more swirl and tumble, all things being equal, you're less likely to see engine damaging detonation.

Lake Speed Jr., Joe Gibbs' General Manager of its high-performance oil program pointed out that there are lots of quality motor oils on the market. No longer is it a matter of avoiding bad or poorly performing motor oil formulations and finding the best one. Instead, these days it's more a matter of avoiding the oils that may be great for the type of engines they were designed for but ineffective for your particular engine.

Different parts of an engine are subject to different types of friction. So, for most oils there are different additives that are designed to protect the piston skirts as they slide up and down the cylinder walls, the lifters as they ride over the camshaft tappets and the main and rod bearings. But a flat tappet lifter has very different requirements than a roller lifter. Likewise, a race engine is very different from a street engine.

So don't judge the quality of an oil by its price tag alone. Also, don't assume an oil that works great in a modern sports car will work just as well in your Street Stock. Finding the best oil for your particular application is key.

Keeping the harmonic vibrations of your valvesprings to a minimum is one of the most important things you can do to keep your valvetrain happy and healthy over the long haul. Years ago engine builders in the Cup Series discovered that flooding the valvecovers with oil does a great job at both dampening spring harmonics and keeping the springs cooler. That trick has caught on in a lot of other racing series, but if you're racing a wet-sump engine this trick isn't practical.

PAC Racing Springs is developing this external spring damper that can help improve spring performance and life. There are some issues that must be overcome before they will work in a high-performance application but you could definitely see something like this in racing fairly soon.

PAC Racing Springs is developing this external spring damper that can help improve spring performance and life. There are some issues that must be overcome before they will work in a high-performance application but you could definitely see something like this in racing fairly soon.

Jason Youd of PAC Racing Springs says that the company has been experimenting with an external spring dampener that shows promise. The dampener is a plastic or otherwise non-metallic cup that the valvespring sits inside of. The cup provides a guide that keeps the spring from moving laterally as the valve opens and closes. This dampens any harmonic movement and helps improve valve control.

But one issue is that the cup holds oil near the spring. Oil needs to be constantly moving across the spring to pull away heat. This isn't too big of a deal in OEM engines that spend most of their lives just above idle, but the design still needs some refinement to work in race engine applications. Maybe we will see this on the racetrack someday soon.

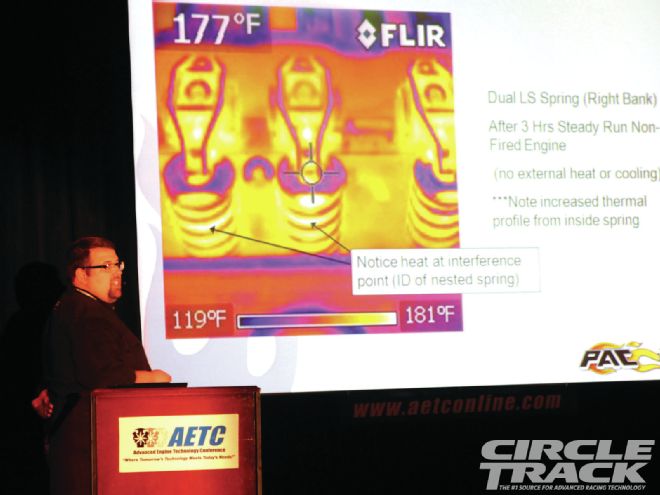

PAC's Jason Youd shared this infra-red photo showing how an inner spring damper can actually cause a buildup of damaging heat front the interior of a valvespring in a racing engine.

PAC's Jason Youd shared this infra-red photo showing how an inner spring damper can actually cause a buildup of damaging heat front the interior of a valvespring in a racing engine.

Bill Hancock worked in Chrysler Corporation's NASCAR racing programs for a decade before leaving to start his own company, Arrow Racing Engines. He offered some very interesting tips for track testing based on his many years of experience.

Jon Kaase of Kaase Racing Engines.

Jon Kaase of Kaase Racing Engines.

Hancock stressed that you must make the very same safety precautions for a test session as you do a race. It can be easy to let your guard down during a day of testing. There is no one else at the track, the pace is slower, and life seems easy. But Keller points out that the race car and that wall has no idea that this isn't a race and can kill you just as quickly at a test as during a race.

It's also a good idea to have someone at every test who's only job is to record the data you collect. While you're busy trying to swap intakes or throw a new set of shocks underneath the car for one last run, it can be easy to forget to write down all the details. But the most important thing you can gain from any track test is good data you can use later on. Don't depend on remembering anything correctly; make it a priority to get the data down where you can go over it again later when it's quiet and you can concentrate.

Many engine builders guard their methods like they were State secrets, but Kaase was open with many great tips. Here, he shows how he uses a mildly abrasive pad to round off the sharp edges on the camshaft's distributor gear. This will help the bronze gear on the distributor live much longer.

Many engine builders guard their methods like they were State secrets, but Kaase was open with many great tips. Here, he shows how he uses a mildly abrasive pad to round off the sharp edges on the camshaft's distributor gear. This will help the bronze gear on the distributor live much longer.

Finally, it's rarely a good idea to make several test runs on the same set of tires. Tire wear can negate any gains you make in later tests. This doesn't mean that you have to throw on a new set of tires every time your race car hits the track, but you do have to have at least two sets you can rotate out to keep tire wear even.

Jon Kaase is a dominant engine builder in the Pro Stock drag racing classes. That's such a specialized engine you might think it would have nothing to do with stock car racing. But Kaase's presentation on engine building tips had so many great tidbits of information we could write a book from it.

For example, Kaase told a story of switching to a ring package with lower tension against the cylinder wall. This is a common tactic in stock car engine building to reduce friction between the rings and cylinder bore to free up a little horsepower. But after making the switch Kaase says he began blowing up engines.

The knee-jerk reaction would simply be to blame the rings for being poor quality. Or some engine builders would simply write off low tension rings saying, "they just won't work in that engine." But Kaase says a little out-of-the-box thinking was required to find the real source of the engine failures.

It turns out that the reduced friction the low tension rings created wasn't helping to slow the piston down at TDC as much as the beefier old rings with more friction. This was putting more stress on the rods and causing failures. So, instead of writing off the rings, Kaase worked with his rod manufacturer to design a beefier rod cap that both eliminated the failures and allowed him to keep the horsepower created from the low tension rings. By finding the real source of the problem Kaase was able to make more horsepower in an engine with improved durability.

These are just five tips from this year's AETC that we learned by attending the conference. While the conference is highly technical in nature it's also exceedingly valuable. If you have the wherewithal to make a trip to Orlando next December we would highly recommend attending the AETC. It takes place just before the PRI show and it's in Florida--so you can get into some sunny and warm weather for a few days, in addition to broadening your engine knowledge.

The roundtable at the conclusion of the conference allowed attendees to have an open discussion with many of the top innovators in the motorsports industry.

The roundtable at the conclusion of the conference allowed attendees to have an open discussion with many of the top innovators in the motorsports industry.