You can’t make horsepower in an internal combustion engine without burning gasoline. And the byproduct, of course, is heat. We all know what to do with the power generated, but the heat is something else.

An efficient cooling system not only keeps your expensive race engine healthy, but it can also offer a competitive advantage. For example, a mechanical fan robs horsepower from the engine, so any time you can run an electric fan like you see here and still keep your engine cool enough, you’re sending a few extra horsepower straight to the rear wheels.

An efficient cooling system not only keeps your expensive race engine healthy, but it can also offer a competitive advantage. For example, a mechanical fan robs horsepower from the engine, so any time you can run an electric fan like you see here and still keep your engine cool enough, you’re sending a few extra horsepower straight to the rear wheels.

If the heat generated by the combustion of gasoline isn’t controlled, you’ll wind up with detonation, the engine oil will break down which will lead to lubrication problems, and other bad (not to mention expensive) things will happen. Plus, the more power you’re making, typically the more fuel you’re burning, so heat control becomes even more of a factor.

Fortunately, proper engine cooling systems are more than capable of handling the heat created by your race motor. The trick is to choose the best radiator that will work for your situation and maintain it properly so that it performs just as well at the end of the season as the day you bought it.

High-performance aluminum radiators have been the standard in racing for years now. They are significantly better than stock-style radiators that were made of copper and soldered together. Aluminum construction creates a radiator that can shed heat better than practically any other material.

But there’s more to it than simply making a radiator out of aluminum. PWR Performance Products has only been a part of stock car racing in the United States for a few years, but the Australian radiator manufacturer is already used by approximately half of the teams in NASCAR’s Sprint Cup Series. The company has been welcomed by many of NASCAR’s top teams because it can custom-build radiators to any size. As a longtime builder for several Formula 1 teams, it has been bringing several new features to the table for stock car racing.

Thanks to that success, PWR has recently begun a brand-new product line of radiators for Saturday night racers. These radiators will be completely made in the USA and designed specifically for the needs of racers competing on the bullrings all across America.

Cooling fins are the thin strips of aluminum that form an almost corrugated construction between the cooling tubes in your radiator core. For most Saturday night tracks less than 5⁄8-mile, a relatively light fin density of 15 fins per inch normally works best. Higher speed tracks can use a radiator with a greater fin density because the greater speed helps push the air through the more congested radiator core.

Cooling fins are the thin strips of aluminum that form an almost corrugated construction between the cooling tubes in your radiator core. For most Saturday night tracks less than 5⁄8-mile, a relatively light fin density of 15 fins per inch normally works best. Higher speed tracks can use a radiator with a greater fin density because the greater speed helps push the air through the more congested radiator core.

These won’t have all the bells and whistles that the radiators the Cup guys are running have, but PWR’s Justin Raybourn and John Dullam—the domestic arm of the company—say that many of the features that work well for the high-speed Cup cars won’t be beneficial to short track racers. For example, Saturday night racers normally see slower speeds and tighter traffic, so their radiators need a lower fin count to allow air to move through the radiator core more easily.

“Cup teams are also running pressurized cooling systems and require a radiator that can handle coolant pressures over 200 psi,” Raybourn adds. “That’s just not necessary on a Saturday night car, and building that kind of capability into a radiator is, honestly, a bit expensive. So by being smart about how our Street and Racer series of radiators are built to the customer’s needs we can provide a very high-quality radiator at a reasonable price.”

A radiator’s thermal efficiency, or how quickly it can pull heat out of the coolant flowing through it and radiate it into the air, can be improved by maximizing the surface area of the tubes the coolant is flowing through. To do this the tubes are wide by very thin vertically. Picture a drinking straw pressed nearly flat. This means that almost all the water flowing through the tube is actually in contact with the tube itself, which improves heat transfer. Then, in order to move the heat from the tube to the fins and the atmosphere beyond it, the wall thickness of the tubing is also minimized as much as possible.

But doing this also makes it difficult to properly seal the radiator from leaks. The old school method was to use epoxy to seal the tubes to the tanks on either side of the radiator. But epoxy works as an insulator, which keeps the radiator from working as efficiently as possible. Today, most high-quality radiators use a brazing method to seal the joints.

According to Raybourn, PWR actually uses an ingenious method to braze its radiators without harming its efficiency when it comes to cooling the engine. The aluminum radiator tubes actually feature two different materials. The inner portion of the tube is made from high-strength aluminum with a high melting point. But the outer 10 percent of the tubing (approximately) is clad with a different aluminum alloy that is also very good at transferring heat but has a lower melting point.

Once the radiator is assembled, it’s heated to a temperature that’s high enough to melt the aluminum cladding on the outside of the tubes but not the main alloy. This brazes the radiator into one functional piece, which eliminates leaks without harming the piece’s ability to remove heat from the cooling system.

Two of the biggest decisions to make when determining what radiator best fits your needs is thickness and fin count. For Saturday night racing, a single- or double-row radiator with a lower fin count seems to work best. Dullam points out that for a radiator to do its job, the most air possible has to flow through the core.

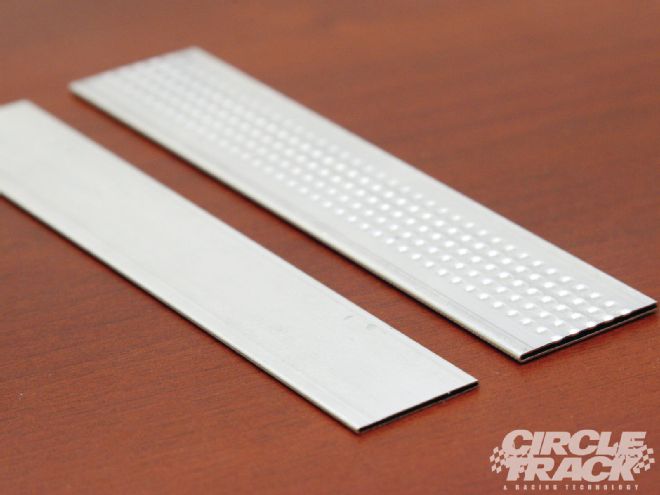

Here’s a shot of the clad aluminum cooling tubes. In the foreground is a typical tube from the Street and Racer Series. In the background is a Cup-style cooling tube that may someday make its way down to the Saturday night levels. Notice the dimples in the tube; they’re designed to help create turbulence in the coolant as it passes by so more of it comes into contact with the walls of the tubing.

Here’s a shot of the clad aluminum cooling tubes. In the foreground is a typical tube from the Street and Racer Series. In the background is a Cup-style cooling tube that may someday make its way down to the Saturday night levels. Notice the dimples in the tube; they’re designed to help create turbulence in the coolant as it passes by so more of it comes into contact with the walls of the tubing.

A radiator that has the coolant tubes and cooling fins packed too tightly will actually block air from moving through it. But more fins offer more surface area, so finding the right balance is critical. Dullam says Cup cars normally use a fin count in the range of 20 per inch because their higher on-track speeds create higher air pressures in front of the radiator to force the air through. But for the tight racetracks that Saturday night racers normally compete on, a lower fin count works better.

Normally, a radiator design with around 15 fins per inch works best. It provides plenty of surface area to move the heat from the radiator to the air moving through the core while still being open enough to allow plenty of air to flow through.

In applications where the height or width of the radiator is limited by the framerails, you may choose to go with a two-row radiator. This style places a second row of cooling tubes right behind the first. This allows for more cooling in a smaller radiator, but the extra thickness a second row creates can also stall the air as it moves through the radiator core. There are even three-row radiators, but you should only consider one of these on very high speed tracks, typically a mile or more.

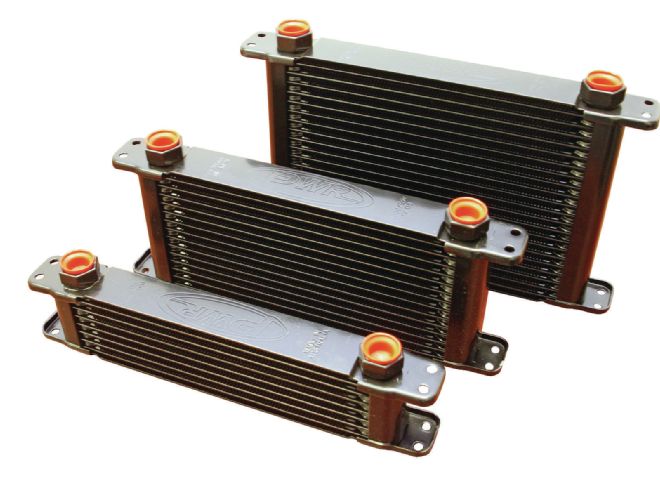

If you’re racing a high-horsepower, dry-sump engine, or you’re doing a lot of shifting and having transmission issues, you may need to consider additional cooling beyond a typical radiator. If you need all the engine cooling you can get, or need to find a way to get the oil temps in your transmission down, a separate oil cooler may be necessary. This requires extra lines, extra space, and extra money.

PWR is also bringing to the U.S. a line of affordable but high-quality gear oil coolers made specifically to handle the higher viscosities of oil.

PWR is also bringing to the U.S. a line of affordable but high-quality gear oil coolers made specifically to handle the higher viscosities of oil.

Another option is an integrated heat exchanger that’s part of your radiator. It functions by routing the oil lines through the radiator manifold. The heat from the engine oil is passed to the water and eventually to the air as the water flows through the cooling tubes.

One caveat with running a heat exchanger is that the oil provides an additional heat source for the coolant. So if you’re running a heat exchanger to cool your transmission oil, be aware that it will reduce the radiator’s ability to control the engine temps. This may require a larger radiator than you used previously.

After tacking it in place, the clamps are removed and the horns are fully welded to the butt plates.

After tacking it in place, the clamps are removed and the horns are fully welded to the butt plates.

A mechanical fan can draw as much as 20 horsepower at 6,500 rpm. That’s power that would otherwise go to the rear wheels, and a reason you may want to consider moving to an electric fan. Modern designs use ultra-efficient fan blades and powerful electric motors and do a better job of moving air through the radiator than older designs that often struggled to keep a race engine in the proper temperature operating range.

And other than the draw on the alternator (if you run one) an electric radiator fan causes no horsepower penalty. If you run short features you may even be able to get by running an electric radiator fan completely off your battery and not running an alternator at all. You may even be able to completely turn it off when racing under green-flag conditions if you’re moving enough air through the radiator to keep it cool on its own.

An old racing myth is that in order to maximize cooling efficiency you have to restrict the speed of coolant flow through the system. The thinking was that if the water travelled more slowly through the engine it would have time to pull away more heat. But that thinking won’t work for a few reasons.

The side mounting plates for the bottom of the radiator are simply plates bent into an “L.” Make sure they are at least ¼-inch higher than the sway bar tube to protect the radiator from hitting the track if the suspension bottoms out. Here, Newling uses a level to make sure they’re in line with the upper radiator support brace.

The side mounting plates for the bottom of the radiator are simply plates bent into an “L.” Make sure they are at least ¼-inch higher than the sway bar tube to protect the radiator from hitting the track if the suspension bottoms out. Here, Newling uses a level to make sure they’re in line with the upper radiator support brace.

First, restricting water flow through the cooling system causes the water pump to work harder than necessary. This not only can be a horsepower drain on your engine, but requiring the water pump to try to push water through a restriction can lead to cavitation. Cavitation hurts the system’s ability to cool the engine because it creates air bubbles in the coolant. And air not only doesn’t move heat as efficiently as water, but it can also get trapped in the water jackets and create steam pockets that lead to detonation.

Second, once the water gets past the restrictor, it moves more slowly through the radiator’s cooling tubes. Slow moving water moves smoothly through the tubes with little tumbling. It’s called “laminar flow” and when you have this condition the water that’s in contact with the cooling tubes is cooled while the water that’s in the center of the tube is insulated and isn’t able to shed its heat into the radiator and eventually the atmosphere.

But engine coolant that rushes quickly through the cooling tubes becomes turbulent. Instead of flowing smoothly, it tumbles through the cooling tubes so that it all comes into contact with the walls of the tubing. Turbulent flow promotes more homogenous cooling which makes for a more efficient radiator.

Once you’ve selected the perfect radiator size and style for your racing application, you’ll also need to maintain it to make sure it’s performing just as efficiently at the end of the season as when you first installed it.

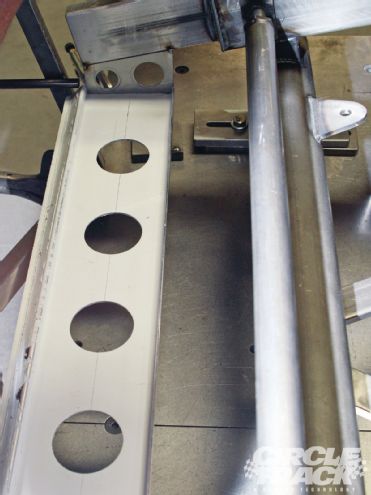

Now the braces are tack welded to the bottom of the horns. The plates could have been slapped to the sides of the horns, but Newling trimmed them and welded them flush with the bottom of the horns to save a few more ounces (along with the lightening holes).

Now the braces are tack welded to the bottom of the horns. The plates could have been slapped to the sides of the horns, but Newling trimmed them and welded them flush with the bottom of the horns to save a few more ounces (along with the lightening holes).

One of the most important things is to make sure you have absolutely no air trapped in the cooling system. Air trapped in the water jackets of either the block or cylinder heads, as we’ve already mentioned, causes high-pressure pockets of heat that the coolant can’t reach and causes all sorts of problems. Also, if air bubbles are pushed through the radiator’s cooling tubes it can cause them to swell or crack. And even if the tubes don’t crack, the expansion from swelling can smash the cooling fins together. This can be a difficult mystery to solve. You have a radiator that doesn’t leak or show signs of damage but isn’t cooling as well as it used to.

To keep this from happening, you should occasionally vent your cooling system. When routing your plumbing, make sure that the water neck on top of the intake is the highest point in the system. With the engine running, and before the coolant gets too hot, you can crack the line joining the water neck to vent the system until only water comes out. This helps eliminate any air that may have gotten into the cooling system.

Another option is to use a surge tank. Instead of filling the cooling system through the radiator cap, you can fill it through a surge tank that connects to the radiator through a length of flexible hose. The surge tank is mounted in the car so that it is the highest point in the entire cooling system, including the radiator, all hoses and cylinder heads. Water or coolant stays in the surge tank and is drawn into the system as necessary, and any air trapped in the system will find its way to the surge tank because the air will always seek out the highest point in the system.

The lower mounting plate is fabricated from aluminum and will be mounted to the side plates with two ¼-20 bolts on each side. Notice the lip and ramp on the front of the mounting plate. This gives the race team a place to secure the sheetmetal for the radiator box, and the ramp pushes the air up so that all of it is directed into the radiator core.

The lower mounting plate is fabricated from aluminum and will be mounted to the side plates with two ¼-20 bolts on each side. Notice the lip and ramp on the front of the mounting plate. This gives the race team a place to secure the sheetmetal for the radiator box, and the ramp pushes the air up so that all of it is directed into the radiator core.

As you race, getting trash built up in the radiator is inevitable. On dirt it’s usually mud, while on asphalt it’s bits of rubber and oil dry, but no matter what it is, debris caught between the fins blocks air from moving through the radiator core and should be removed.

Resist the temptation to blast it out when you’re cleaning the car with a pressure washer. This will normally only serve to push the debris in further, while a high-pressure stream of water can bend and damage the cooling fins on its own.

The best method for cleaning your radiator requires removing it from the car. Cap the openings to make sure no debris can enter either the headers or the tubing and run gently flowing water from a hose through the radiator from the back to the front. The idea is to push the debris back out the way it came. You may also need to periodically soak the entire radiator in soapy water to help loosen the more stubborn pieces of trash and debris.

Resist the urge to use any solvents. It may work the first time to get out pieces of tire rubber, but any solvent residue that remains will attack the next piece of tire rubber that lodges itself in the cooling fins. But instead of helping get it out, the solvent will only cause the rubber to swell and lodge itself even more securely in your radiator.

Many class rulebooks allow only water in the cooling system—because antifreeze leaking on a racetrack is notoriously difficult to clean up—but if your class doesn’t have this rule you may want to consider a chemical additive that can potentially help increase the efficiency of your cooling system.

AMSOIL has long been an innovator in the racing industry when it comes to lubricants. And now it has introduced a new product called Coolant Boost that’s designed to both reduce corrosion (which can clog your radiator) and enhance the heat transfer capabilities of the water in your cooling system.

Coolant Boost contains chemicals that are safe for both your radiator and engine but also reduce the surface tension of the water allowing better contact with the metal surfaces inside the water jacket of the race engine and also the cooling tubes in the radiator. The idea is that the coolant is now better able to both draw heat away from the engine and to move it into the aluminum of the radiator.

While there are several different brands of coolant additives on the market, AMSOIL says it’s Coolant Boost additive is unique because it uses three different substances to reduce the water’s surface tension. The reason is each works best in a different temperature range, so the additive enhanced coolant works best at practically any engine operating temperature.