Pete Aardema marches to the beat of a different drummer. For years his niche has been one-off overhead cam (OHC) conversions on mainstream V8 pushrod engine architectures, starting with the production block and adapting existing OHC cylinder heads—usually from a variety of imports—to them. He firmly believes OHC engine architecture is superior to pushrod-engine technology due to its higher rpm capability, greater valvetrain stability, lighter weight, and suitability for multivalve combustion-chamber configurations that permit more valve envelope area (and hence more airflow) for a given bore size.

You can’t find a big-bore, short-stroke, four-cylinder block—so we built one.

Also for years, Aardema has raced old Ford Model A–based four-cylinder engines in Bonneville’s nostalgia classes. As Pete’s Model A motors evolved, he treated them to ever more radical OHC conversions and later extreme block deck-height modifications that included shortened deck-height blocks with bolt-on deck plates and even four separate “miniheads” sunk into the existing block. Despite rule-makers’ attempts to rein him in, eventually Aardema’s streamliner ran a best of 240 mph. “There have been less than five As that have gone 200-plus,” Aardema proudly points out. But increasingly hamstrung by sanctioning bodies, Pete finally got to the point where he felt “we had reached the limit of the original Model A architecture—or at least what they’d let us get away with and still call it a Model A.” Pete says that’s about 400 hp, normally aspirated, on race gas.

Pete wanted more, so he decided to take things to the next level and move up to “modern” (non-nostalgia) classes for post-1935 engine designs that aren’t restricted to ancient engine technologies. “We were screwing with basically a 100-year-old block with inherently bad geometry. We were stuck with a long stroke, small bore—which limits your valve sizing, breathing ability, and high-rpm capability.”

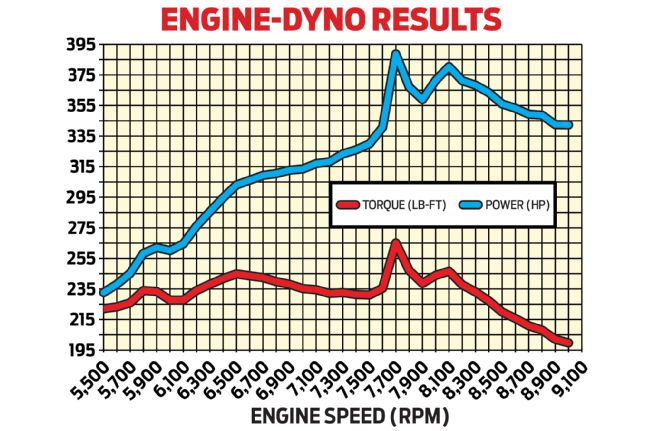

Build Sheet All dimensions in linear inches, except as noted. Type Aardema DOHC 3-valve L4 Displacement 180.4 ci (2.96 L) Max torque 265.1 lb-ft at 7,700 rpm Max power 388.7 hp at 7,700 rpm Power / cubic-inch 2.15 hp / ci Static compression ratio 14.85:1 Bore × Stroke 4.375 × 3.00 Connecting rod center-to-center 5.700 Rod/stroke ratio 1.9:1 Crank centerline-to-block deck 8.5 Piston compression height 1.350 Piston-to-block deck height –0.050 (piston above deck) Head gasket bore 4.425 Head gasket compressed thickness 0.090 Piston volume –7 cc (valve notches) Combustion chamber volume 36 cc Main bearing clearance 0.0027 Rod bearing clearance 0.003 Crankshaft thrust clearance 0.008 Piston-to-cylinder wall clearance 0.006 Piston-ring endgap 0.021 (rings 1, 2), 0.015 (oil ring) Cam rated duration (0.015 lash) 292° intake / 298° exhaust Cam duration at 0.050 lift 255° intake / 263° exhaust Cam lift 0.624 intake / 0.616 exhaust Cam running hot lash 0.010 intake / 0.012 exhaust Cam lobe centerline* 114° intake / 102° exhaust Cam lobe separation angle* 108° Valvespring installed height 1.850 Valvespring seat pressure 110 psi intake / 193 psi exhaust Valvespring open pressure 354 psi intake / 518 psi exhaust Valvespring distance to coil-bind 0.180 intake / 0.090 exhaust *Baseline; on a multicam DOHC engine, both can be adjusted as needed.

After examining a bunch of existing four-cylinder architectures that might be competitive in Bonneville’s F/Gas class for naturally aspirated engines with displacements up to 3.0 L, Pete determined “there were no existing L4s to our liking—so why not built one…from scratch?”

We’re not talking about merely getting an aftermarket block and building it up with a unique rotating assembly, or even a custom head that bolts on an existing block. No, we are far beyond that. This is a ground-up, scratch-built, custom engine—as in, everything, including the block, the heads, and the valvetrain are all one-off parts, custom-built in a home workshop (well, a very well-victualed workshop).

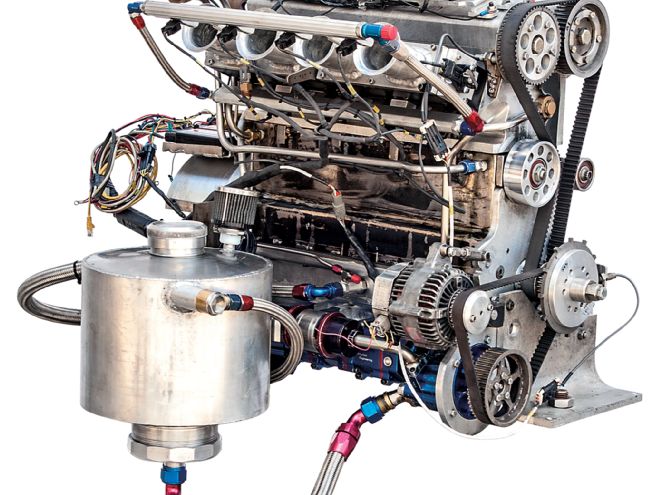

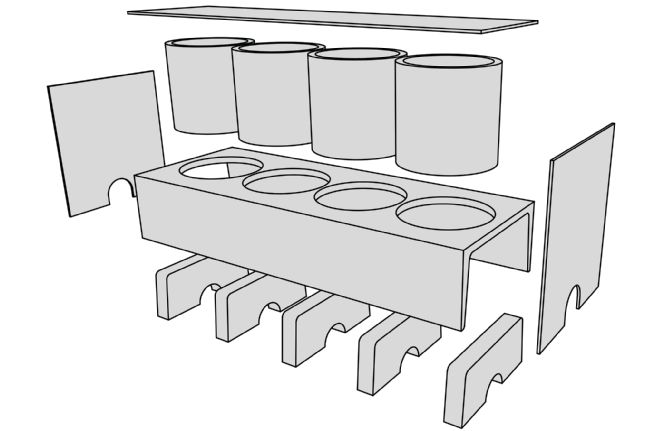

Working with assistants Scott Goetz and Kevin Braun, a scratch-built block was MIG-welded together out of steel plate and tube sections. Then, Pete continues, “We bought a CNC mill and made a billet bolt-on bottom-end girdle. We designed and built our own three-valve, dual-overhead cam [DOHC] head and fuel-injection induction system.”

To make more power, you need better breathing: Aardema’s new engine features 4.840-inch big-block Chevy cylinder-bore spacing, allowing a really large-diameter bore, lots of valve envelope, and a high-rpm-friendly short-stroke. It also lets custom piston-makers start with readily available big-block Chevy piston blanks.

The final result is a real screamer. Still early in its development cycle, peak power is now up to nearly 390 hp at 8,700 rpm from 180 ci on VP C-16 race gas. Pete says continuing cam development and intake and exhaust runner-length tuning should push output to at least 450 hp. Current plans call for debuting the engine in a new Streamliner at Bonneville 2015. Check out the following pages for a detailed look at this one-of-a-kind engine that puts a whole new meaning to that hoary phrase “engineuity in action.”

While Pete’s engine is a one-off he built for himself alone, there are several other new—let’s call them, at least for the moment, “non-mainsteam”—engine architectures out there being toyed with, some of which are available right now to any hot rodder who’s willing to step up and pay the freight. We’ll take a gander at them, too.

The block is fabricated from welded-together mild-steel plate and tubing. Pete says that most of the “machining” was done by high-pressure water-jet equipment. “Everything was cut perfect within 0.010 inch. After it was together, we normalized the assembly by baking it in an oven for six hours at 600 degrees Fahrenheit.”

The block is fabricated from welded-together mild-steel plate and tubing. Pete says that most of the “machining” was done by high-pressure water-jet equipment. “Everything was cut perfect within 0.010 inch. After it was together, we normalized the assembly by baking it in an oven for six hours at 600 degrees Fahrenheit.”

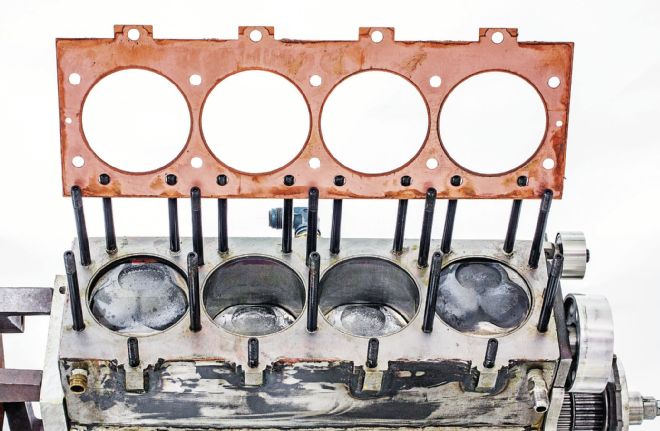

This is the complete, welded-together block assembly. The weld beads are a subtle indicator that this block is fabbed, not cast. The final step was establishing a head-bolt pattern that cleared the ports and maintains maximum gasket integrity. They ended up using 7⁄16-inch bolts, seven per cylinder. They’re ARP, as are the main and rod bolts.

This is the complete, welded-together block assembly. The weld beads are a subtle indicator that this block is fabbed, not cast. The final step was establishing a head-bolt pattern that cleared the ports and maintains maximum gasket integrity. They ended up using 7⁄16-inch bolts, seven per cylinder. They’re ARP, as are the main and rod bolts.

Scott Goetz did the sanitary MIG-welding. Here, the U-channel has been joined to the thick plate sections that form the main webs’ upper halves.

Scott Goetz did the sanitary MIG-welding. Here, the U-channel has been joined to the thick plate sections that form the main webs’ upper halves.

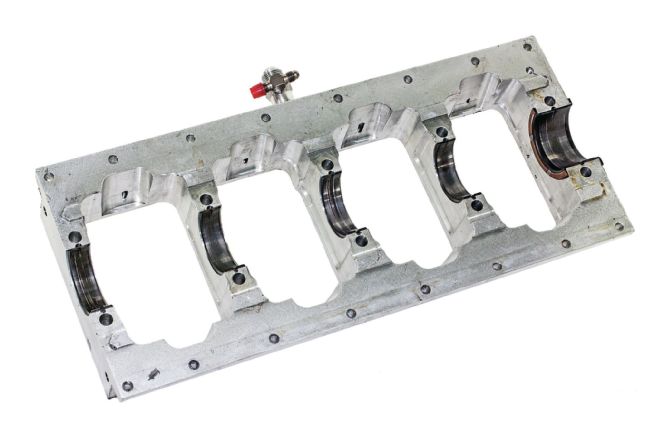

Aardema CNC-machined the bottom half of the main webs as a bolt-on 6061-T6 billet aluminum girdle. It bolts to the bottom of the block and is said to enhance overall structural integrity.

Aardema CNC-machined the bottom half of the main webs as a bolt-on 6061-T6 billet aluminum girdle. It bolts to the bottom of the block and is said to enhance overall structural integrity.

We wanted a big bore for maximum valve area on the intake side.

Aardema had Crower grind a one-off, 3-inch-stroke, internally balanced, 4340 billet-steel crank with 2.30-inch-od small-journal small-block Chevy mains and 1.890-inch Honda rod journals that spin in Clevite performance bearings. No harmonic damper is used; Pete claims, “Four-cylinders don’t need one.”

Aardema had Crower grind a one-off, 3-inch-stroke, internally balanced, 4340 billet-steel crank with 2.30-inch-od small-journal small-block Chevy mains and 1.890-inch Honda rod journals that spin in Clevite performance bearings. No harmonic damper is used; Pete claims, “Four-cylinders don’t need one.”

CP pistons retained on floating small-block Chevy-style 0.927 tool-steel pins by bulletproof round-wire retainers are swung by Crower billet-steel rods. Total Seal provided the lightweight 1mm–1mm–3mm ring pack. The rod/stroke ratio comes out to a desirable 1.9:1, which makes for good piston dwell time, low piston speeds, and—in theory—superior top-end performance.

CP pistons retained on floating small-block Chevy-style 0.927 tool-steel pins by bulletproof round-wire retainers are swung by Crower billet-steel rods. Total Seal provided the lightweight 1mm–1mm–3mm ring pack. The rod/stroke ratio comes out to a desirable 1.9:1, which makes for good piston dwell time, low piston speeds, and—in theory—superior top-end performance.

Crower RBT (Radial Beam Technology) I-beam billet rods combine lightweight performance with extended-rpm reliability. Their 5.7-inch center-to-center length matches a small-block Chevy stocker—but to fit Pete’s high-revvin’, DOHC inline they’re a custom job with a nonoffset beam, Honda rod journals, and 7⁄16-inch ARP-2000 bolts.

Crower RBT (Radial Beam Technology) I-beam billet rods combine lightweight performance with extended-rpm reliability. Their 5.7-inch center-to-center length matches a small-block Chevy stocker—but to fit Pete’s high-revvin’, DOHC inline they’re a custom job with a nonoffset beam, Honda rod journals, and 7⁄16-inch ARP-2000 bolts.

“We sent our head to CP-Carrillo. It profiled the chamber to come up with the proper dome shape that provides plenty of valve clearance.” The piston sticks out of the deck 0.050 at TDC. With an 0.090-inch compressed-thickness Cometic head gasket, static compression comes in at 14.85:1. Pistons for OHC motors typically have fairly thick decks to clear their deep valve reliefs.

“We sent our head to CP-Carrillo. It profiled the chamber to come up with the proper dome shape that provides plenty of valve clearance.” The piston sticks out of the deck 0.050 at TDC. With an 0.090-inch compressed-thickness Cometic head gasket, static compression comes in at 14.85:1. Pistons for OHC motors typically have fairly thick decks to clear their deep valve reliefs.

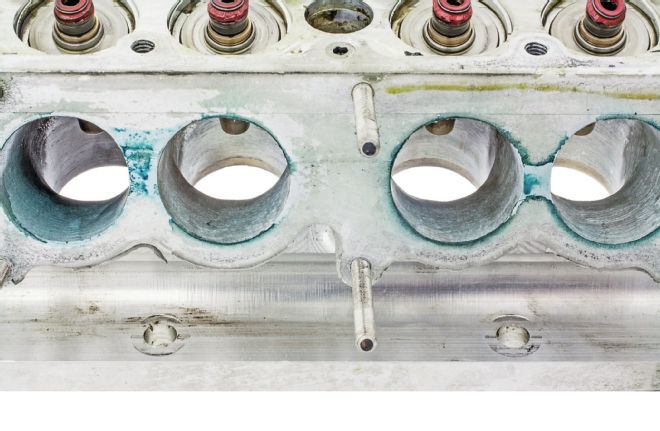

Ports of haul: The benefits of starting with a clean sheet of paper design yield a virtually straight approach to the intake valve seat.

Ports of haul: The benefits of starting with a clean sheet of paper design yield a virtually straight approach to the intake valve seat.

A one-off, made-to-order, Cometic solid-copper head gasket combines with stainless steel O-rings and receiver grooves cut into the head and deck to seal the head to the block. The gasket was deliberately spec’d thicker than usual—0.090-inch compressed—to get the quench right with the engine’s above-the-block piston deck height.

A one-off, made-to-order, Cometic solid-copper head gasket combines with stainless steel O-rings and receiver grooves cut into the head and deck to seal the head to the block. The gasket was deliberately spec’d thicker than usual—0.090-inch compressed—to get the quench right with the engine’s above-the-block piston deck height.

Pete says the exhaust side’s raw flow numbers need only be about 75 percent of the intake—but even with just one valve, the exhaust side does better than expected, flowing within 68–70 percent of the intake side over 0.500-inch lift. Big-block Chevy exhaust-port spacing lets Pete fit Rat-motor headers by cutting off the standard Chevy flange and welding on his custom flange.

Pete says the exhaust side’s raw flow numbers need only be about 75 percent of the intake—but even with just one valve, the exhaust side does better than expected, flowing within 68–70 percent of the intake side over 0.500-inch lift. Big-block Chevy exhaust-port spacing lets Pete fit Rat-motor headers by cutting off the standard Chevy flange and welding on his custom flange.

Yikes! The lobes develop in excess of 0.600-inch lift with over 250 degrees duration at 0.050. Like the old Offy valvetrains it’s based on, Aardema’s engine has direct-action overhead cams with no rockers or followers—meaning no ratio multiplier effect: All lift must be directly developed by the lobes themselves. Pretty impressive in a profile with zero seat bounce.

Yikes! The lobes develop in excess of 0.600-inch lift with over 250 degrees duration at 0.050. Like the old Offy valvetrains it’s based on, Aardema’s engine has direct-action overhead cams with no rockers or followers—meaning no ratio multiplier effect: All lift must be directly developed by the lobes themselves. Pretty impressive in a profile with zero seat bounce.

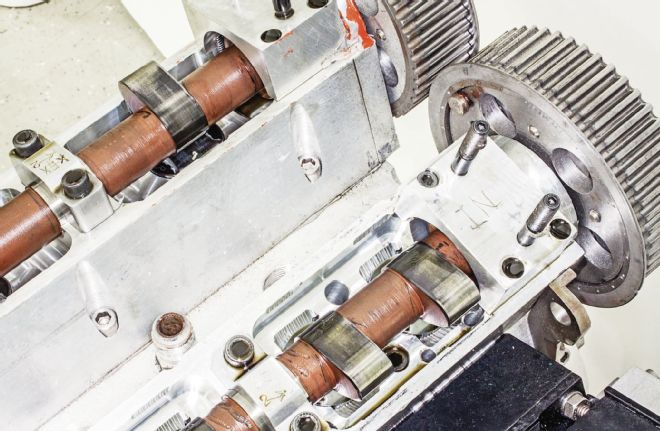

The two-valve/cylinder intake and single-valve exhaust cams bolt into billet-aluminum carriers. The Schneider Racing Cams’ lobe profiles are based on 60-year-old Offenhauser Indy engine tech, a period when the classic, normally aspirated, DOHC Offy motor reached its highest state of development (later Offys were turbocharged and featured extensive redesign).

The two-valve/cylinder intake and single-valve exhaust cams bolt into billet-aluminum carriers. The Schneider Racing Cams’ lobe profiles are based on 60-year-old Offenhauser Indy engine tech, a period when the classic, normally aspirated, DOHC Offy motor reached its highest state of development (later Offys were turbocharged and featured extensive redesign).

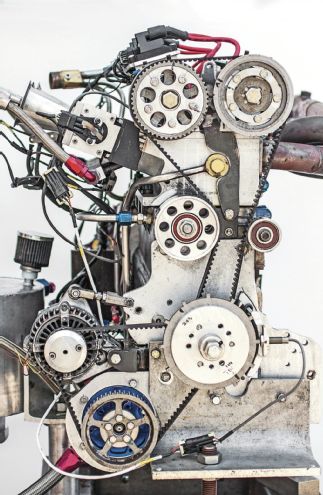

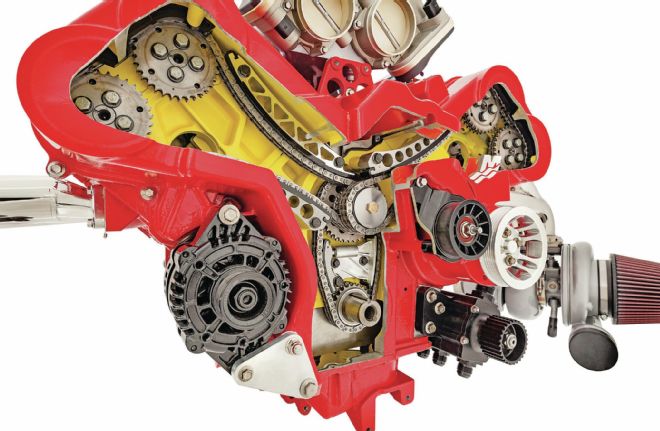

Aardema’s DOHC beltdrive setup is based around Nissan sprockets with a custom-length Gates belt. The tensioner was built in-house. Pete says, “A chain is heavy and needs constant lubrication. We’ve done 100 belt-driven OHC engines, and they’ve proven very reliable.”

Aardema’s DOHC beltdrive setup is based around Nissan sprockets with a custom-length Gates belt. The tensioner was built in-house. Pete says, “A chain is heavy and needs constant lubrication. We’ve done 100 belt-driven OHC engines, and they’ve proven very reliable.”

Ed Pink supplied a set of rare Offy buckets. Instead of being flat, their lobe-contact end has nearly a 3-inch radius that performs like a roller lifter. A keyway keeps them from rotating in the cam-carrier. Lash is fixed—the only way to change it is by grinding the valvestem down. Dual PSI springs are held on the valves by Manley titanium retainers and steel beadlocks.

Ed Pink supplied a set of rare Offy buckets. Instead of being flat, their lobe-contact end has nearly a 3-inch radius that performs like a roller lifter. A keyway keeps them from rotating in the cam-carrier. Lash is fixed—the only way to change it is by grinding the valvestem down. Dual PSI springs are held on the valves by Manley titanium retainers and steel beadlocks.

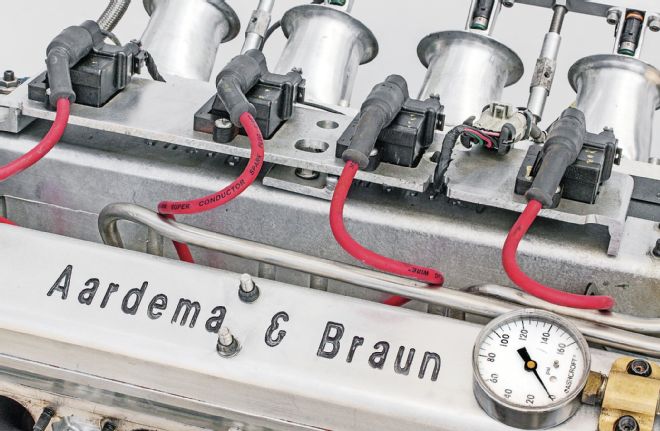

The other injectors have been moved to the top of the stacks. On Pete’s setup, they come in around 4,500 rpm. Top-mounting the 39-lb/hr high-speed injectors gives the fuel more time to cool the air as it travels through the runner, increasing air density.

The other injectors have been moved to the top of the stacks. On Pete’s setup, they come in around 4,500 rpm. Top-mounting the 39-lb/hr high-speed injectors gives the fuel more time to cool the air as it travels through the runner, increasing air density.

Most carburetors, throttle-bodies, and barrel valves use pivoting “butterfly”-style throttle-blades that even wide open still impose some throttle-bore restriction. Aardema fabricated his own slider barrel valve that rotates fully out of the way. It’s shown about two-thirds open here.

Most carburetors, throttle-bodies, and barrel valves use pivoting “butterfly”-style throttle-blades that even wide open still impose some throttle-bore restriction. Aardema fabricated his own slider barrel valve that rotates fully out of the way. It’s shown about two-thirds open here.

Distributors and mags have gone the way of the dinosaurs. The PE-3 ECU has no problem driving four GM LS smart coils. Very reliable with good output, they require only minimal amperage demands through the computer—and you can find ’em anywhere.

Distributors and mags have gone the way of the dinosaurs. The PE-3 ECU has no problem driving four GM LS smart coils. Very reliable with good output, they require only minimal amperage demands through the computer—and you can find ’em anywhere.

This motor screams. Aardema doesn’t even run it under 5,500 rpm. We expect the peak power to move up to 8,700 rpm or higher when the engine is fully developed.

This motor screams. Aardema doesn’t even run it under 5,500 rpm. We expect the peak power to move up to 8,700 rpm or higher when the engine is fully developed.

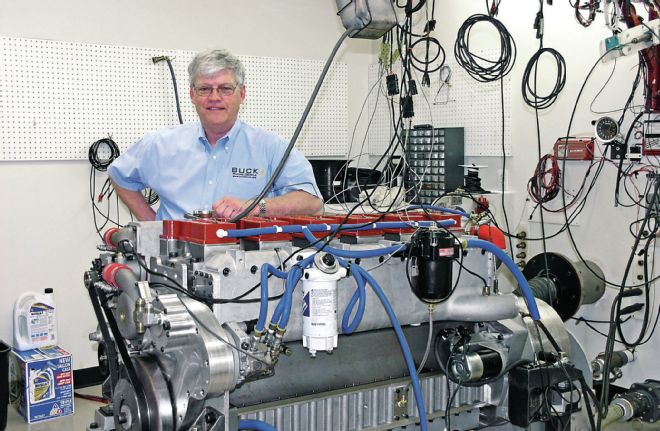

When you’re out in the middle of the ocean on your fishing rig and the engine conks out, wouldn’t it be great to be able to perform an expeditious in-place repair? That’s what happened to Kenneth Michael Buck, and it led him to develop his potentially game-changing Buck engine, a unique new pushrod engine architecture that not only should offer extreme durability in the first instance, but, if something does go south, is super-easy to service and repair. “Everything can be repaired from the top of the engine, even the main bearings,” Buck explains. “You can replace the crank while the block remains on the mounts. Rods and pistons can be swapped without draining the oil or dropping the pan. You can replace an entire single cylinder, including the connecting rod, in 10 minutes or less. The engine never needs to be completely rebuilt or remanufactured as a unit. Most parts are light enough to be shipped by UPS. No other engine can do any of that.”

Early prototype 6.7L inline six-cylinder diesel Buck engines like this one produced 375 hp, but the latest evolved versions should make up to 75 hp/L. The architecture is said to be applicable to any gaseous fuel and could even be built as a spark-ignition engine. The basic design is scalable from 2–200 liters in inline or V configurations with any number of cylinders.

Early prototype 6.7L inline six-cylinder diesel Buck engines like this one produced 375 hp, but the latest evolved versions should make up to 75 hp/L. The architecture is said to be applicable to any gaseous fuel and could even be built as a spark-ignition engine. The basic design is scalable from 2–200 liters in inline or V configurations with any number of cylinders.

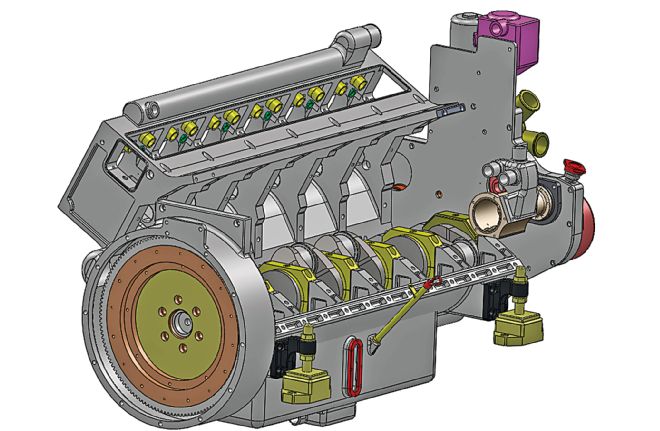

How’s it possible to service the crank and main bearings without major teardown? The entire top of the motor pivots up and away. There are no separate main caps on this innovative design. This type of architecture could be a game changer if it ever goes into production.

How’s it possible to service the crank and main bearings without major teardown? The entire top of the motor pivots up and away. There are no separate main caps on this innovative design. This type of architecture could be a game changer if it ever goes into production.

The engine will monitor individual dynamic cylinder pressures in real time, allowing the brain to vary direct fuel-injector pulse width to maintain the optimum cylinder pressure—which means the same package can run on just about any fuel regardless of its Btu quotient. The same sensor also provides advance warning that service could be needed soon. Compared to conventional engines, Buck says his design reduces parts inventory by at least 60 percent and engine downtime by 80 percent. Although initially targeted toward the Marine diesel market, this “repair-in-place” concept obviously has interesting implications for off-roaders, commercial trucks, and military vehicles. Buck is currently trying to raise capital to put the engine into production. “We’d be producing them within 18 months if we get the funds to tool up for mass production.” Anyone with $150 million, please contact Buck.

For years Ryan Falconer was a leader in high-end small-block Chevy V8 and 90-degree V6 road-race engine development. Some of his old GTP V6 3.0L turbocharged Chevys made more than 1,200 hp. Back in the late 1980s, Falconer teamed with aircraft engine builder and racer Dave Zeuschel to develop an aircraft V12 based on the Chevy small-block architecture. Zeuschel was killed but Falconer pressed forward with its development up to the present day. Falconer explains he “wanted a big cubic-inch engine in a small package. The Chevy’s architecture makes great power in a compact package. I just added four more cylinders!

This Falconer V12 is in Eric Zausner’s steam-punk custom 1933 Ford Vicky (HOT ROD, Dec. 2013 print edition, also posted on HOTROD.com). MoTeC EFI, seven-stage dry-sump oiling systems, and splay-valve heads are standard on Falconer V12 engines. A reverse-rotation option is available for aircraft use. Traditional Chevy V8 engine mounts and bellhousing bolt patterns are used.

This Falconer V12 is in Eric Zausner’s steam-punk custom 1933 Ford Vicky (HOT ROD, Dec. 2013 print edition, also posted on HOTROD.com). MoTeC EFI, seven-stage dry-sump oiling systems, and splay-valve heads are standard on Falconer V12 engines. A reverse-rotation option is available for aircraft use. Traditional Chevy V8 engine mounts and bellhousing bolt patterns are used.

This Falconer V12 has nonstandard wet-sump oiling. Chip Foose currently has this engine at his shop. The engine oil pan, 4L80E trans pan, and the converter cover are three massive slabs of billet aluminum. Engine wiring routes through the oil pan’s sides and is terminated with two Canon plugs. The extra fuel-rail really contains the injector wiring and connectors.

This Falconer V12 has nonstandard wet-sump oiling. Chip Foose currently has this engine at his shop. The engine oil pan, 4L80E trans pan, and the converter cover are three massive slabs of billet aluminum. Engine wiring routes through the oil pan’s sides and is terminated with two Canon plugs. The extra fuel-rail really contains the injector wiring and connectors.

“Originally, the aircraft companies were going to buy 300 engines for ¾-scale P-51 Mustang replicas, but they didn’t live up to their part of the bargain. I kept going anyway. I’ve built about 60 so far for a variety of markets. I make production runs of 20 aluminum block and head castings at a time. The usual wait to get one is around 10–12 weeks. The standard engine has a 41⁄8-inch bore and 3¾-inch stroke, which comes out to 601.4 cubic inches.” Like an OE Chevy 90-degree V6, the blocks are 90-degree with odd-fire cranks. “Basic engines start at $65,000, Options include turbos, superchargers, and different displacements, in either street- or full-race trim. “I did a turbo one at 500 ci that made 1,650 hp.”

John Hartley Jr. was inspired to develop his own engine when a 200-mph Suzuki Hayabusa motorcycle screamed past his Lotus 7. “Why can’t my car sound like that?” he thought. One thing led to another, and he designed a series of ground-up engines based around the Hayabusa’s DOHC cylinder head. Originally, both a four-cylinder (the H2) and a V8 (the H1) were available. The extremely compact, normally aspirated, H1 V8 used two of the Suzuki heads, displaced 3.0L, and went for $45,000. It made 450–470 hp, and weighed in at around 200 pounds—about 70–100 pounds lighter than equivalent automotive-based four-cylinders. “It’s smaller and lighter than a typical Ford Duratec 2.0L L4,” Hartley claims. “The engine can be made so light because it’s based on motorcycle tech—and because the block is machined from 7075 aluminum alloy (about twice as strong as the more common 6061). Normally aspirated H1s run 12.5–13.5:1 static compression on pump gas using DTA or MoTeC engine-management systems. Custom back plates are available to bolt up various bellhousings, but it’s really designed for “specialty track cars” racing in small-displacement classes using low-profile racing boxes or transaxles. For 2015, Hartley is replacing the original “H”-series engines with the new, more robust, “Bolt” series.

The latest evolution is the Hartley Bolt 4. It’s currently in production and weighs only 160 pounds. A turbocharged 1.4L L4 Bolt makes 350–400 hp.

The latest evolution is the Hartley Bolt 4. It’s currently in production and weighs only 160 pounds. A turbocharged 1.4L L4 Bolt makes 350–400 hp.

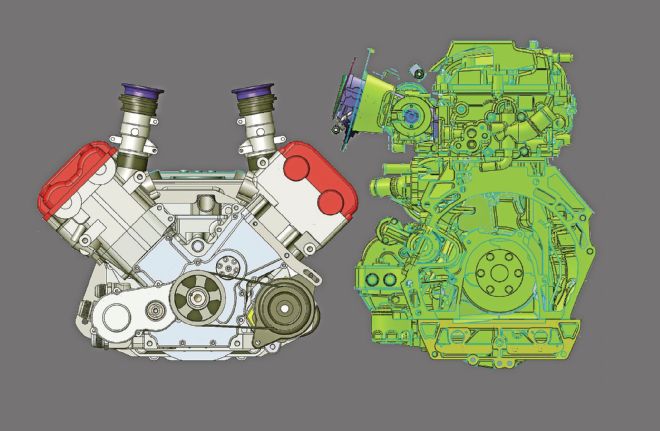

Currently under development by Hartley is the Bolt 8 V8, a new robust design for twin-turbo applications. It will displace 2.8 L and should make at least 650 hp. These engines could be available by early 2015. Note its compact dimensions compared to a 2.0L Ford Duratec L4.

Currently under development by Hartley is the Bolt 8 V8, a new robust design for twin-turbo applications. It will displace 2.8 L and should make at least 650 hp. These engines could be available by early 2015. Note its compact dimensions compared to a 2.0L Ford Duratec L4.

Mercury Marine’s Mercury Racing division has long been known for high-performance outboard boat engines and automotive-based sterndrive propulsion systems for marine applications. Merc’s marinized Chevy-based big-blocks, in particular, have a huge following in the boat world. Merc’s MerCruiser division also assembled the early 1990s Corvette LT5 DOHC engines under a GM contract.

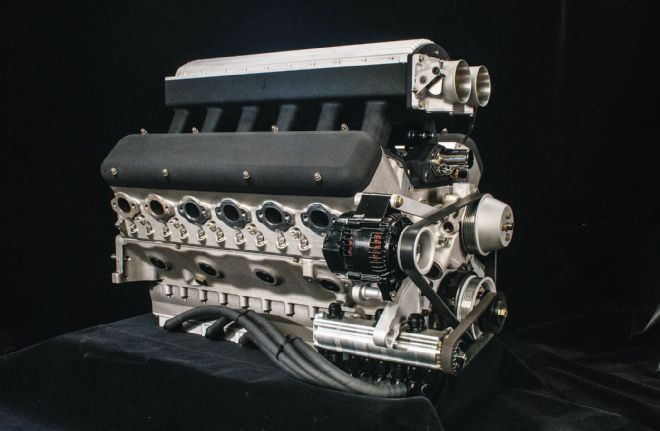

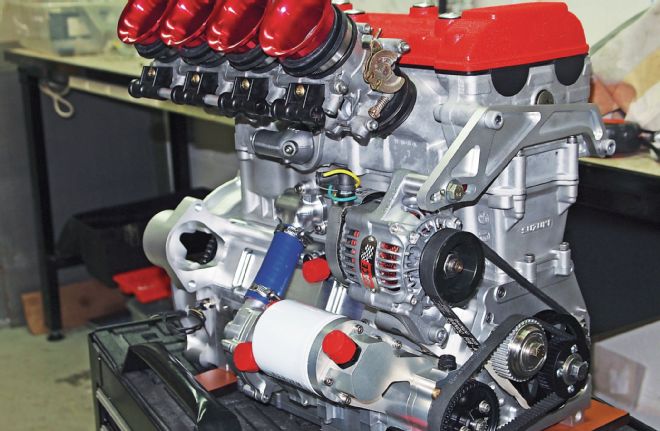

Mercury’s QC4v (Quad Cam 4-valve) is not based on a big-block Chevy or the new LS small-blocks. It’s a brand-new design that shares no parts with any previous engine architecture. The internals are incredibly beefed up to withstand offshore racing for hours on end. This version is the dry-sumped automotive crate motor, complete with drive-by-wire technology and EFI. Twin turbos are a standard option.

Mercury’s QC4v (Quad Cam 4-valve) is not based on a big-block Chevy or the new LS small-blocks. It’s a brand-new design that shares no parts with any previous engine architecture. The internals are incredibly beefed up to withstand offshore racing for hours on end. This version is the dry-sumped automotive crate motor, complete with drive-by-wire technology and EFI. Twin turbos are a standard option.

In the most severe duty cycle, offshore racing and high-performance boats powered by multiple engines spend hours at full throttle, with the boats skipping across the waves at high speed. The props may come out of the water, causing extreme rpm fluctuations if the “throttle man” isn’t careful. Merc’s Rick Mackie compares offshore racing to “dropping a tractor/trailer combo off a third-floor parking-garage ramp over and over and expecting nothing to happen.”

Yet the boats keep getting bigger, their owners demanding ever more performance. Mackie maintains the classic big-block Chevy has reached the end of the line in terms of its development for high-power marine engines. “Our previous line of big-blocks were supercharged and topped out at 1,200 hp. At that level, we were really stretching the envelope. They required a full refresh at 150 hours.”

The chain-driven DOHC setups utilize two cams per cylinder head, with two intake and two exhaust valves per chamber. Rather than direct-acting cam lobes, a Formula 1–style finger-follower valvetrain design multiplies cam lobe lift to reduce cam lobe unit loading.

The chain-driven DOHC setups utilize two cams per cylinder head, with two intake and two exhaust valves per chamber. Rather than direct-acting cam lobes, a Formula 1–style finger-follower valvetrain design multiplies cam lobe lift to reduce cam lobe unit loading.

Merc’s solution: Engineer an all-new architecture. What it calls the “QC4v” is a DOHC 9.0L (552ci) engine based around an aluminum block and heads that, in its “1350 configuration” with twin turbos, makes 1,350 hp reliably for hours on end on 91-octane pump gas. There’s also an 1100 model, an 89-octane variant that makes “only” 1,100 hp, plus the ultimate “1650” that pounds out (you guessed it) 1,650 hp on 112-octane race gas. All have torque curves as flat as a billiard table. Consumer models carry a one-year warranty and should reliably go 300–400 hours before needing a complete teardown.

Although originally configured for the marine market, Mercury recently introduced QC4v-based motors for ground vehicles. A variety of configurations are offered, from long-blocks to complete, ready-to-run models at various power ratings. QC4v blocks have a traditional Chevy V8 bellhousing pattern, but use metric bolts (as does the entire engine). Engine mounts are similar (but not identical) to an old-school Chevy V8—and, of course, the block is much longer to accommodate huge 4.567-inch bores (the stroke is 4.213). A basic long-block with timing cover and dry-sump oil pan weighs 645 pounds. You can order a complete car crate motor today less exhaust for about $68,000.