It’s time for egghead theory and speculation to put up or shut up. Elsewhere in this issue, you’ll find pages upon pages of scintillating tech theory explaining the fundamentals of camshaft dynamics. Even so, how factors like lift, duration, and lobe-separation angle should affect the power curve are often quite different from how they actually impact engine output in real life. Techno babble is fine for message board know-it-alls, but the ultimate truth serum for any camshaft is the liquid that flows through a dyno’s water brake. As engine expert and PHR contributor David Vizard often says: “I don’t have an opinion, I have a dyno.” With the help of the School of Automotive Machinists (www.samracing.com), we tested three of COMP Cams’ most popular small-block Ford hydraulic roller grinds on a street 347 stroker to gauge how different lobe profiles impact engine output and driveability characteristics in the real world.

Test Mule

To maximize the relevance of our quaint dyno thrash, we needed a test engine that represented what a large cross-section of the hot rodding public would build. As such, our test subject is about as mainstream as you can get, a 302-based small-block Ford stroked to 347 ci with a projected output of 450 hp. Living in magazineland for too long would lead you to believe that everyone is building 900hp big-blocks or twin-turbo LS1s, but that simply isn’t the case. Not only is a more pedestrian small-block like our 347 much easier on the budget, it’s also more representative of the kind of motor found in your typical street machine. Furthermore, since engines are merely glorified air pumps, the results gleaned from this cam test could just as well apply to a similarly spec’d 350 small-block Chevy.

The short-block specs on our test mule are rather ordinary, featuring a factory block bored to 4.030 inches, an Eagle 3.400-inch steel crankshaft and rods, and pump-gas–friendly 9.6:1 JE pistons. The 347’s primary breathing apparatus, on the other hand, is quite a bit more impressive. Using this dyno session as a good excuse to test out the newest addition to the Brodix SBF cylinder head catalog, we ordered a set of its new LH-series 17-degree aluminum castings. With ports designed by famed Ford engine builder Keith Craft, the heads flow an advertised 300 cfm at .700-inch lift. Feeding the 195cc ports is an Edelbrock Victor Jr. intake manifold and a Holley 750-cfm carb.

A Tale of Three Cams

As no surprise, a quick call to COMP Cams’ Trent Goodwin confirmed that the most popular grinds in the SBF catalog are relatively mild designs that offer a great balance between sub-6,500 rpm power and low-speed driveability. The challenge was picking three cams that were different enough to show a measurable difference on the dyno, yet similar enough to where variations in horsepower and torque output could be pinpointed to specific differences in their lobe profiles. The smallest of the lot, which we’ll call Cam A for the sake of simplicity, is a 224/232-at-.050 unit with .555/.565-inch lift and a 112-degree lobe-separation angle. Cam B, the largest of the bunch, features 232/240 degrees of duration at .050, and .565/.574-inch lift, also with a 112-degree LSA. The wild card of the bunch is Cam C, which measures in at 227/241 degrees of duration at .050, with .531/.515-inch lift and a 107-degree LSA. As one of COMP’s Thumpr grinds, Cam C was designed with a lopey, aggressive-sounding idle in mind, and as such, it has a tighter LSA and an earlier exhaust valve opening point.

Two of COMP Cams’ most popular SBF camshafts are PN 35-518-8 and PN 35-522-8. Both are Xtreme Energy grinds, the former measuring in at 224/232 degrees of duration at .050, and the latter with 232/240 degrees at .050. The wild card of the bunch was the 227/241-at-.050 Thumpr, which proved to be the best all-around performer in our 347. All three grinds idled well at 900 rpm, with the Thumpr providing a noticeably choppier disposition.

Two of COMP Cams’ most popular SBF camshafts are PN 35-518-8 and PN 35-522-8. Both are Xtreme Energy grinds, the former measuring in at 224/232 degrees of duration at .050, and the latter with 232/240 degrees at .050. The wild card of the bunch was the 227/241-at-.050 Thumpr, which proved to be the best all-around performer in our 347. All three grinds idled well at 900 rpm, with the Thumpr providing a noticeably choppier disposition.

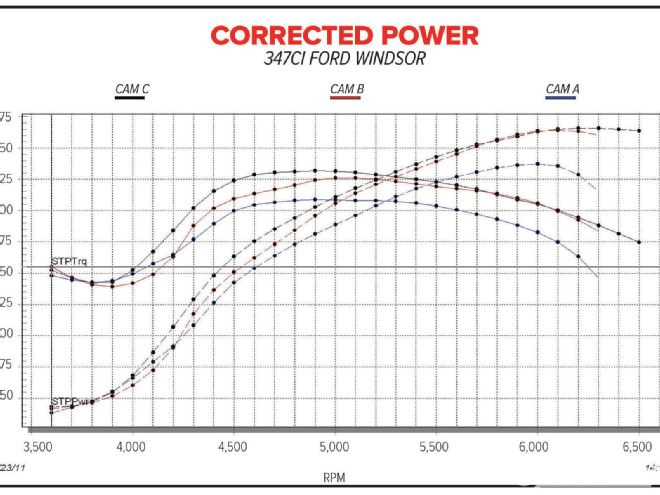

Based on specs alone, Cam B would seem to have the advantage on paper since it packs the most duration and lift, but that’s not how things played out on the dyno. Cam A was good for 437 hp at 6,000 rpm, and 409 lb-ft of torque at 4,900 rpm. As expected, Cam B improved upon those figures dramatically, kicking out 464 hp at 6,200 rpm and 426 lb-ft of torque at 5,100 rpm. Longer-duration cams typically sacrifice low-end torque for top end power, and predictably, Cam A held an advantage of 5 to 10 lb-ft of torque from 3,600 to 4,200 rpm. After that point, Cam B pulls ahead big time, holding a 15-25hp advantage throughout the rest of the power curve.

While the SAM crew slid Cam C into the block, since its duration specs fell in between Cams A and B, we expected horsepower output to fall somewhere in the middle as well. Boy, were we wrong. Cam C proved to be the most potent of them all despite giving up 5 degrees of intake duration to Cam B, and .034- and .059-inch of lift on the intake and exhaust valves, respectively. In fact, the Thumpr produced more torque down low than the smallest cam in the test, in addition to posting the highest peak output of 466 hp at 6,300 rpm. Peak output aside, the Thumpr trounced the 232/240-at-.050 grind by a large margin in the area-under-the-curve department, holding a 10-15 hp advantage throughout the majority of the power curve. The Thumpr proved to be the most rev-happy as well, pulling hard to 6,600 rpm, while Cam B was out of breath by 6,200 rpm.

Post Dyno Analysis

What started out as a simple cam test turned out to be a real head-scratcher, as the results were puzzling for a number of reasons. First off, the biggest cam didn’t make the most power. Secondly, the Thumpr’s specs suggest that it should run out of breath the earliest. Instead, it proved to be the most rev-happy cam of the bunch. The most obvious distinguishing factor between the Thumpr and its test mates is its tight LSA. Whereas Cam A and Cam B both shared 112-degree LSAs, the Thumpr was ground at 107 degrees. Tighter lobe-separation angles generally boost low-end torque at the expense of top end power. Furthermore, compared to Cam B, the Thumpr has an earlier intake valve closing point of 65 degrees after bottom dead center as opposed to 70 degrees ABDC. Intake valve closing is by far the most important of the four valve events in terms of power output, and a later IC generally improves top end power while sacrificing low-end torque. Again, neither of these scenarios held true during our test.

Plucked straight out of a 12-second ’65 Mustang coupe, this 347 stroker perfectly represents the kind of motor found in your typical street machine. The Brodix LH17 heads were mighty impressive, good for 466 hp with a relatively tame cam. Based on how well they performed on our 347, it’s safe to presume that they’d easily support 550 hp in a 408 ci or larger combo with a more aggressive camshaft.

Plucked straight out of a 12-second ’65 Mustang coupe, this 347 stroker perfectly represents the kind of motor found in your typical street machine. The Brodix LH17 heads were mighty impressive, good for 466 hp with a relatively tame cam. Based on how well they performed on our 347, it’s safe to presume that they’d easily support 550 hp in a 408 ci or larger combo with a more aggressive camshaft.

Seeking the expertise of someone much smarter than the typical journalist, we ran the results by SAM’s Head Instructor Judson Massingill for a more educated opinion. As it turns out, it’s all about cylinder pressure. “The intake duration of the Thumpr cam falls right in between Cam A and Cam B, so duration isn’t what’s accounting for the power difference. Plus, the Thumpr has the least amount of lift, so you can throw that out of the equation as well,” he says. “What’s going on in this motor is that the tighter LSA and increased overlap of the Thumpr is helping pull more air through the intake valve. The improvements in intake charge filling and cylinder pressure is what’s bumping up both torque and horsepower. Tight LSA cams usually drop off at high rpm, but the reason that’s not happening in this instance has to do with cylinder pressure. On a relatively low compression motor like this 347, you don’t have much cylinder pressure to begin with, so having a wide LSA really hurts you. With a tighter 107 LSA, the increase in cylinder pressure helps make up for the low compression ratio of the motor. If this 347 had a higher compression ratio, the tighter LSA of the Thumpr would have made less of a difference on the dyno.”

Judson says, what makes this best-of-both-worlds scenario possible, in which low-end torque doesn’t come at the expense of top end power, are cylinder heads that flat-out get the job done. “When you have heads that move a lot of air, you can get by with a short-duration camshaft because tightening up the LSA increases cylinder pressure everywhere. You always want the best heads possible with the least amount of cam as possible,” he says. “In an application like this 347, the only reason to run a wider LSA is to smooth out the idle quality. As long as you can get it to hook, the Thumpr would be at least two-tenths quicker at the track than the other cams in this test. Not only does it produce more midrange power, it also carries that power to a higher rpm.”

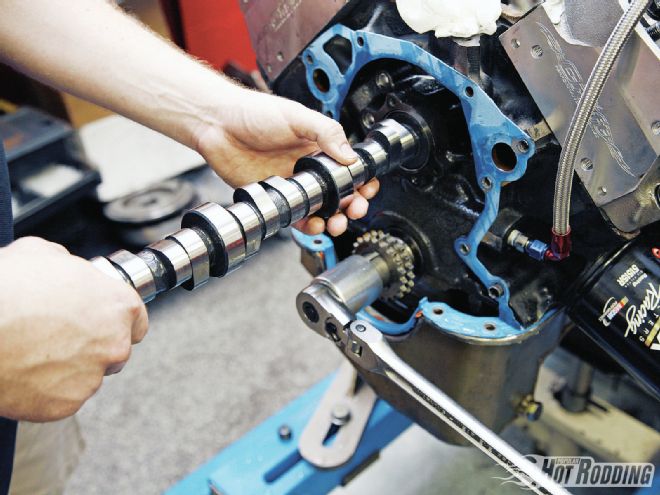

Formerly occupying the cam bores in the 347 was a mild hydraulic flat-tappet grind that fell on its face above 5,500 rpm. The three COMP hydraulic roller cams promised superior top end pull in addition to improved low-end grunt, thanks to their faster ramp acceleration rates.

Formerly occupying the cam bores in the 347 was a mild hydraulic flat-tappet grind that fell on its face above 5,500 rpm. The three COMP hydraulic roller cams promised superior top end pull in addition to improved low-end grunt, thanks to their faster ramp acceleration rates.

Ultimately, no amount of speculating is an adequate substitute for good old-fashioned dyno testing. Since speculation doesn’t always hold up on the dyno, it’s not a bad idea to dyno test multiple cams in your engine combo of choice before deciding on the perfect grind for your application. Compared to what it costs to build a motor, cams are relatively inexpensive, so it’s cheap experimentation.

Cam A and Cam B both produced peak horsepower in the 6,100- to 6,200-rpm range, but the smaller grind falls off a table after peak while the larger cam does not. By 6,300 rpm, Cam A is down to 415 hp, while Cam B is still making 460 hp. That 45 hp difference is far greater than the 27hp gap posted by Cam B at peak power, proving once again that peak power is just part of the equation. The Thumpr (Cam C), on the other hand, clearly destroys the other two cams everywhere in the power and torque curve.

Cam A and Cam B both produced peak horsepower in the 6,100- to 6,200-rpm range, but the smaller grind falls off a table after peak while the larger cam does not. By 6,300 rpm, Cam A is down to 415 hp, while Cam B is still making 460 hp. That 45 hp difference is far greater than the 27hp gap posted by Cam B at peak power, proving once again that peak power is just part of the equation. The Thumpr (Cam C), on the other hand, clearly destroys the other two cams everywhere in the power and torque curve.