When it comes to building power on a budget, the surefire formula for success is to start with the biggest factory engine you can find and use that framework to its maximum potential. In the world of Chevrolet small-blocks, that framework is the factory 400 block. The capacity for power is already built into the 400, with a bore size that dwarfs the other factory small-blocks at 4.125 inches, standard, and a factory stroke of 3.75 inches. When looking to make Chevy power on a budget, the appeal here is that you really do not have to make radical alterations to the factory combination in search of cubes; you can spend your time and money optimizing those cubes for serious horsepower.

When Chris Henderson of Henderson Machine looked to build a top-level street engine, he looked no further than the Chevy 400 small-block. With a big factory bore and ample stroke, the 400 is an excellent foundation for a hot Chevy combination.

When Chris Henderson of Henderson Machine looked to build a top-level street engine, he looked no further than the Chevy 400 small-block. With a big factory bore and ample stroke, the 400 is an excellent foundation for a hot Chevy combination.

That was just the plan Chris Henderson had in building a small-block Chevrolet for the AMSOIL Engine Masters Challenge. The idea wasn't to reinvent the small-block. Rather, Henderson makes the most of the best of what's already there. Henderson's philosophy is to pay attention to the details, and letting all of those small improvements add incrementally to a good basic package.

This engine was based upon a production 400 block, but Chris was looking to improve on the factory's original layout. First thing on the hit list were the short OEM rods. One of the drawbacks of the original 400 Chevy was the short 5.565-inch connecting rod, which increased cylinder wall loading and led to accelerated bore wear when the engines were delivered as OEM. While a common upgrade when building the 400 is to use 5.7-inch connecting rods, Henderson is a believer in the long-rod advantage, leading him to employ a 6.00-inch rod combination. Henderson explains his thinking: "I selected a 6-inch rod so that there will be a longer piston dwell around TDC. This will require a small enough port to keep an accelerated air velocity for good cylinder filling, but with a large enough port to make enough higher-rpm power."

If you are going to build serious horsepower, you'd better pack some beef into the block. This '76 vintage 400 (the last year of 400 factory production) received a partial fill in the water jackets, Eagle billet four-bolt mains, and ARP main studs.

If you are going to build serious horsepower, you'd better pack some beef into the block. This '76 vintage 400 (the last year of 400 factory production) received a partial fill in the water jackets, Eagle billet four-bolt mains, and ARP main studs.

While it seems like this situation would create a difficult balancing act, the port size was largely determined by the intake manifold of choice, Edelbrock's Performer RPM Air-Gap. Henderson tells us, "My rod-to-stroke combo has a 1.6:1 ratio, which responds better to larger port volumes, with larger cfm carbs relative to the displacement. My ports are as big as I can practically make them with the intake."

The Build Starting with the production block, Henderson began with modifications to ensure the block's integrity at the expected high power level. The block was prepped with a partial fill using Moroso block filler in the water jacket, a move that increases the cylinder rigidity and also helps with piston ring seal. Eagle billet four-bolt main caps clamped with ARP studs add even more security to the lower structure. Prepped like this, the factory block can be very reliable at high power levels.

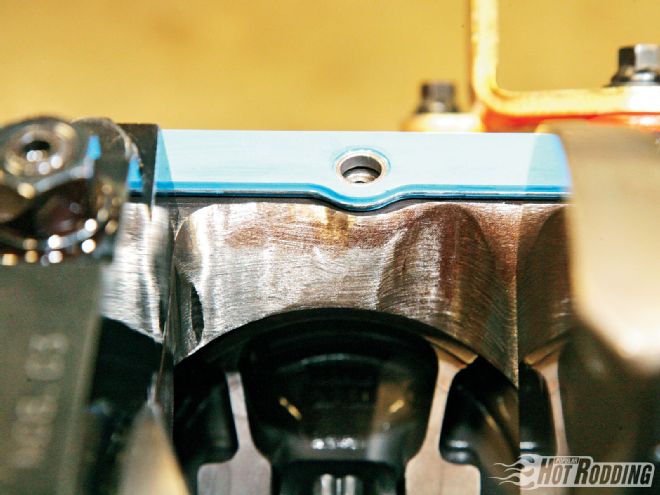

You will not find the factory crankshaft residing within the reinforced block structure, but rather a Scat Aero-wing crankshaft in the factory stroke. The crank is made with 350-sized main journals rather than the larger 400 mains, with COMP bearing spacers taking up the slack. This move reduces bearing speed and drag, and Henderson is always looking for ways to reduce parasitic drag in the engine assembly. Henderson favors this crankshaft for windage reduction, a theme he carried through to his block prep by relieving and polishing the inside of the crankcase for increased clearance to the crank as well as improved drain back.

The crankcase was relieved for reduced windage and improved drain back. The grinding and polishing here is tedious and time consuming, but it is just one of the small details that add up to less parasitic loss-and free horsepower.

The crankcase was relieved for reduced windage and improved drain back. The grinding and polishing here is tedious and time consuming, but it is just one of the small details that add up to less parasitic loss-and free horsepower.

To further reduce the possibility of unnecessary windage-related power losses, the lifter valley was fitted with standpipes, and the oil drain directed to the front and back of the engine. Henderson says, "Up front with the Jesel beltdrive, there isn't anything for the oil to get caught up in; it's all smooth up there." Completing the rotating assembly, Henderson filled the bores with off-the-shelf Mahle domed pistons with a compression height of 1.125 inches, giving a compression ratio of 11.4:1.

A stout bottom end and ample compression ratio will provide the right foundation for a stout street performer, but to get the job done you'll need the right combination of power parts, including the cam, heads, and induction. In keeping with the budget-minded theme, the cylinder heads are Pro Comp's affordable aluminum castings, which were ordered with Pro Comp's CNC porting. That was not the end of the story, however, since Henderson reworked the heads with hand-finishing of the ports and chambers, as well as revising the valvejob.

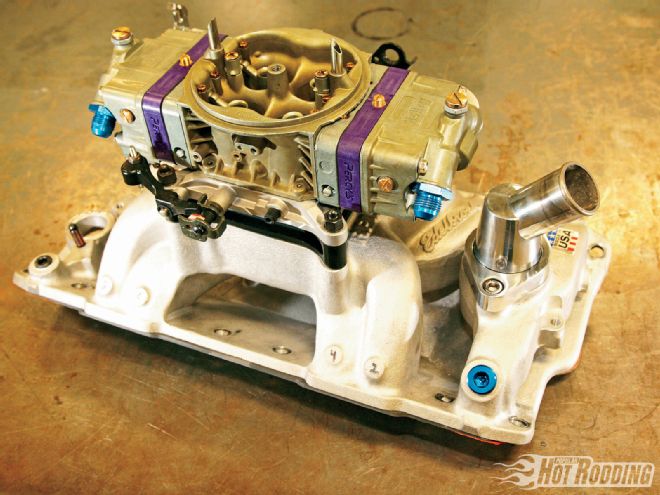

At the top of the engine we find the induction system comprised of an Edelbrock Performer RPM Air-Gap intake manifold and a Holley 830 HP-Series carb. The intake was port matched to flow seamlessly into the head's ports.

At the top of the engine we find the induction system comprised of an Edelbrock Performer RPM Air-Gap intake manifold and a Holley 830 HP-Series carb. The intake was port matched to flow seamlessly into the head's ports.

At the valves, Henderson focuses on the exhaust valve configuration. Henderson favors a tulip profile valve form over the conventional nailhead valve. The theory here is that the tulip shape will help the flow quality out of the chamber, but the same valve will cost some flow. Henderson figures the trade-off is worth it, taking other measures with the camshaft, header, and a larger valve diameter to compensate for any flow loss. Both the intake and exhaust valves are Ferrea hollow-stem stainless units, measuring 2.125 and 1.625 inches, respectively.

Working those valves is a custom hydraulic-roller camshaft from COMP Cams. As noted above, the cam was designed with extended exhaust duration, which Henderson relates is just the right move when using the tulip exhaust valve. The duration specifications are 246 degrees at .050 on the intake, with 258 degrees on the exhaust. The cam was ground on a wide lobe separation angle of 113.5 degrees. Henderson says: "With the 113.5 LSA, I was trying to create a very wide broad powerband, which seemed to work, but I think I could have used even bigger heads. I kind of went to the conservative side." The cam was tested for the optimal installed centerline, with 4 degrees advance producing the best results. Henderson says: "Retarding the cam took away numbers across the board. I think because it was taking away the dynamic compression ratio, because the intake valve is closing a little later. It liked the advance."

You may notice the extra purple blocks sandwiched between the original carb metering blocks and the float bowls. This is Percy's Adjust-A-Jet system, which replaces the main jets with a screw adjustment for regulating the main metering circuit mixture. This arrangement allows very quick mixture adjustments with no disassembly of the carburetor.

You may notice the extra purple blocks sandwiched between the original carb metering blocks and the float bowls. This is Percy's Adjust-A-Jet system, which replaces the main jets with a screw adjustment for regulating the main metering circuit mixture. This arrangement allows very quick mixture adjustments with no disassembly of the carburetor.

Completing the flow system is an Edelbrock Performer RPM Air-Gap two-plane intake manifold topped with a Holley 830 HP carb. The manifold was deep port matched to the heads, while the intake plenum was modified by adding a 45-degree angle to one side of the divider. Henderson says, "The divider seemed to favor one side, so the angle was cut in to direct the flow." To make the carb adjustments easier and far quicker on the dyno, the metering blocks were fitted with Percy's Adjust-A-Jet system. These auxiliary metering blocks allow the main circuit metering to be adjusted with a simple turn of a screw rather than changing jets. On the exhaust side, a Stan's tri-Y header was selected to improve exhaust scavenging.

On the dyno at Koffel's Place, the engine proved to deliver prodigious power. A custom ignition curve was programmed into the MSD Digital-7 ignition, coming in with full timing at 2,500 rpm at 34 degrees. At 4,500 rpm a smooth downward sloping retard of 2 degrees was initiated, taking the timing back to 32 degrees by 6,500 rpm. Peak horsepower was found in abundance, with 577 recorded at 6,100 rpm. In terms of raw twist, the 407-cube Chevy delivered bucket loads of torque, hammering out 430 lb-ft at only 2,500 rpm, and rising to a swollen 538 lb-ft by 4,600 rpm. Power and torque like this doesn't just appear by magic-it's the details that make the difference.

At the Engine Masters Challenge, Henderson fielded the Chevy along with teammates Tim Kransen, Scott White, and John Absi. Mechanical problems during qualifying thwarted the competition effort, but this real-world engine combination would be right at home in a hard-hitting street machine.

At the Engine Masters Challenge, Henderson fielded the Chevy along with teammates Tim Kransen, Scott White, and John Absi. Mechanical problems during qualifying thwarted the competition effort, but this real-world engine combination would be right at home in a hard-hitting street machine.

BY THE NUMBERS HENDERSON MARINE 407CI SMALL-BLOCK CHEVY Bore: 4.155-inch Stroke: 3.750-inch Compression ratio: 11.4:1 Carburetor: Holley 830 cfm Jets Percy's Adjust-A-Jet Intake: Edelbrock Performer RPM Carb spacer: Wilson Manifolds Cylinder heads: Pro Comp Intake valve: 2.125-inch Exhaust valve: 1.625-inch Gaskets: Fel-Pro Block: '76 GM 400 Camshaft specs: COMP Cams Valve lift: .647-inch lift Duration: 246/258 degrees at .050 Rocker arms: COMP stainless steel Pushrods: COMP 3/8 inch Valvesprings K-Motion Crankshaft: Scat Rods: Eagle Rod length 6.00-inch Pistons: Mahle Rings: Total Seal; 1.5/1.5/3mm Coatings: Techline Ignition: MSD Water pump: Edelbrock Damper: Innovators West Oil: AMSOIL 5W20 Headers: Stan's Mufflers: MagnaFlow

DYNO DATA 407CI SMALL-BLOCK CHEVY RPM TQ HP 2,500 429 204 2,600 433 214 2,700 439 226 2,800 446 238 2,900 452 249 3,000 456 260 3,100 459 271 3,200 463 282 3,300 466 293 3,400 473 306 3,500 484 323 3,600 494 339 3,700 505 356 3,800 514 372 3,900 521 387 4,000 526 401 4,100 529 413 4,200 529 423 4,300 531 435 4,400 534 447 4,500 535 459 4,600 538 472 4,700 538 481 4,800 535 489 4,900 533 497 5,000 534 508 5,100 533 518 5,200 532 527 5,300 530 535 5,400 527 542 5,500 520 545 5,600 514 548 5,700 512 556 5,800 511 564 5,900 508 570 6,000 503 575 6,100 497 577 6,200 488 576 6,300 478 574