Cam swaps are all the rage and for good reason. Adding an aftermarket cam to an otherwise stock engine can boost output by 40-60 hp (or more) with no other changes (except possibly a valvespring upgrade). When choosing a cam, power gains shouldn’t be the only consideration. Cam timing plays an important role not only in the power generated but also the overall character of the powerplant. More than any other component, the cam profile determines things like idle quality, mileage, and overall driveability.

Unfortunately, good street manners are often at odds with performance, as wilder cam timing usually decreases idle and (low-speed) driveability. Here are the basics: higher lift values open the valves to increase airflow and longer duration keeps the valves open longer. Higher lift and longer duration profiles add power, but do so at higher engine speeds (especially true of duration). While lift and duration are most often discussed when talk turns to cam timing, there is a third variable that has a decided effect on both power and personality. Enter lobe separation angle.

Before we all start suffering from separation anxiety, we need to understand what lobe separation angle actually is and then how it affects your engine. According to the Comp Cams catalog, “The lobe separation angle (LSA) is equal to 1/2 the angle in crankshaft degrees of rotation between the maximum exhaust valve lift and maximum intake lift.”

If you drew a line that divided the intake lobe in half right at the point of maximum lift, then did the same to the exhaust lobe, then measured the distance in cam degrees between the two, that would be the lobe separation angle. On engines equipped with independent intake and exhaust cams, the LSA is adjustable. But for small-block Chevys (like the LS applications in this story), the LSA is ground into the cam. It is possible to advance and retard the timing events, but the distance between the centerline of the lobes will remain constant.

Now that we have a basic understanding of lobe separation angle, we can put together a test to illustrate just what happens when you make changes to it.

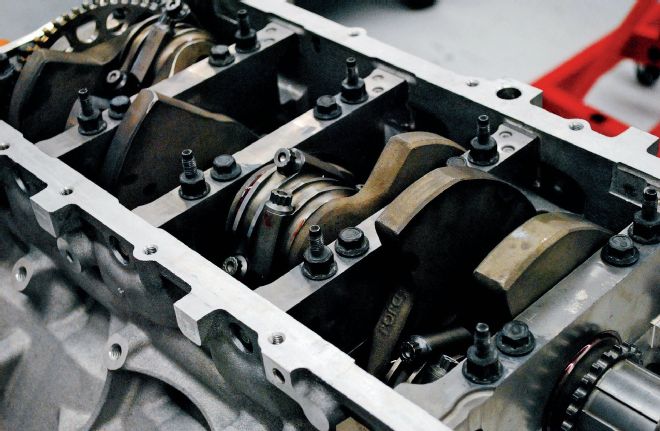

Before getting to the cam profiles, we had to make sure we had a reasonable test engine. The 402-inch LS2/LS3 hybrid stroker started out with an LS2 aluminum block. The standard bore block was then stuffed with a 4340 forged steel 4.0-inch crank and 6.125-inch rods, along with a set of flat-top, forged JE pistons.

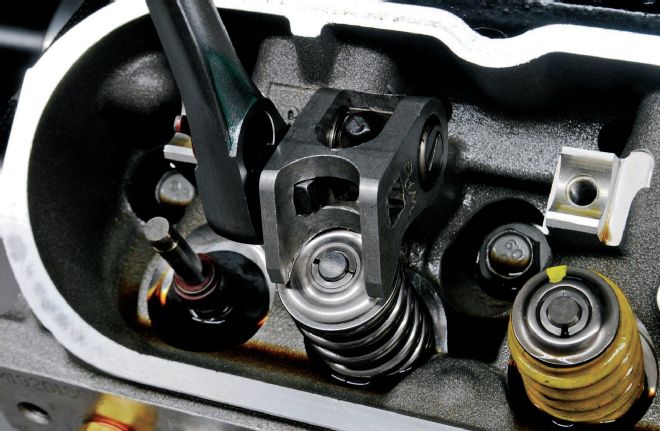

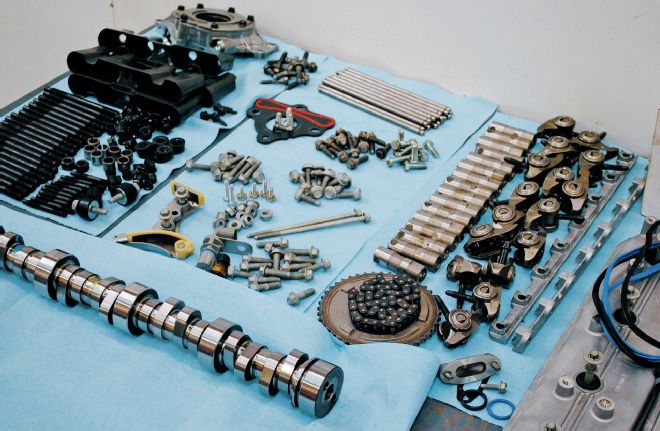

Topping the short-block was a set of Chevrolet Performance CNC LS3 heads from Gandrud Chevrolet. The stock valvesprings supplied with the CNC LS3 heads were swapped out in favor of a set of dual springs from Brian Tooley Racing. The 402 was run with a FAST LSXR LS3 intake and matching 102mm throttle body along with stock LS3 rockers, a Holley HP management system and 7.4-inch hardened pushrods (from Comp Cams). Also present during testing was a set of 1 7/8-inch Kooks headers, Comp hydraulic roller lifters, and F-body oil pan. All testing was performed with an Aeromotive fuel pump feeding a set of 42-lb/hr injectors. Since we were only changing the lobe separation angle, we had to make sure every variable (air/fuel, timing, water, air, and oil temps) was identical during testing.

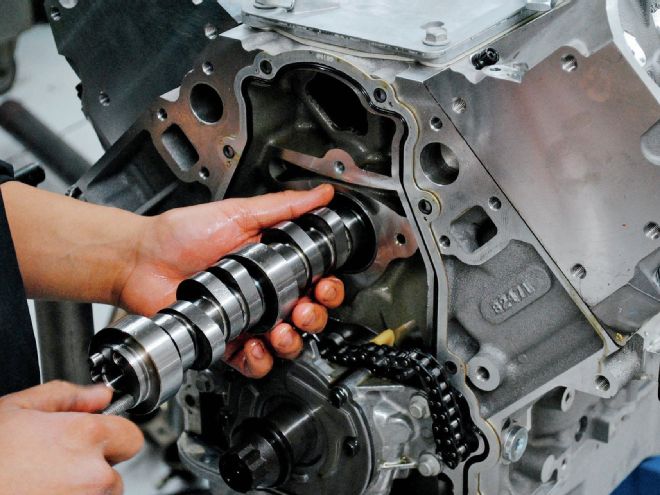

To illustrate the differences offered by changes in the LSA, we had Crane cams grind us three cam profiles that shared the same lift and duration figures, but differed only in the LSA. The custom cams we selected all featured 0.624-inch lift (both intake and exhaust) and a 232/242-degree duration split. The first cam featured a wide 120-degree LSA, while cam number two narrowed the angle to 112 degrees. The final cam was tighter still, with a 108-degree LSA.

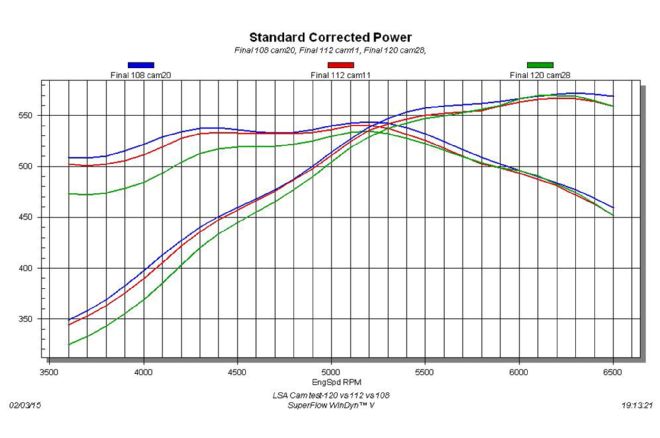

Equipped with the 120-degree (LSA) cam, the hybrid stroker produced 570 hp at 6,200 rpm and 535 lb-ft of torque at 5,200 rpm. Another important measurement was the torque production at 4,000 rpm and this cam checked in with 484 lb-ft of torque. Next up was the 112-degree cam, which actually lost out in peak power slightly to the 120-degree cam, but offered considerably more torque. The 112-degree cam produced peak numbers of 567 hp at 6,200 rpm and 540 lb-ft of torque while pumping out 511 lb-ft of torque at 4,000 rpm. The final, 108-degree cam stepped power up even further, with peaks of 572 hp at 6,300 rpm and 544 lb-ft at 5,200 rpm. This cam also offered the highest torque output at 4,000 rpm with 522 lb-ft.

Based on the peak numbers alone you might be tempted to grab the one with the tightest (108-degree) LSA, but there is more to a cam test than power. True enough, the tight LSA improved power through the entire rev range, from 3,600 to 6,500 rpm, but the extra power came with a penalty in idle quality. The 108 LSA offered the lowest idle vacuum of the three (down 4 inches). Despite no changes in lift or duration, this cam sounded much more aggressive than the other two with wider LSAs. Tuning this cam would be slightly more difficult due to the reduced idle vacuum, but it is hard to argue with all the extra power. The 112-degree cam offered nearly all the low-speed and mid-range torque of the 108 cam but the peak power suffered above 5,200 rpm. The idle quality was better with the 112-degree LSA but not as good as the wider 120-degree cam.The ultra-wide 120-degree LSA lost low-speed power and never recovered, but know that this wide LSA is often beneficial on positive displacement, supercharged applications. Like choosing a cam in general, the key to eliminating separation anxiety is to find the proper balance of driveability and performance.

01 Choosing the right lobe separation angle for your LS cam shouldn’t cause anxiety.

02 The 402-inch stroker short-block combined an aluminum LS2 block with a 4.000-inch crank and 6.125-inch rods.

03 The 4.000-inch crank and 6.125-inch rods were combined with a set of forged asymmetrical pistons from JE.

04 Minor modifications to the factory windage tray were necessary to work with the new stroker assembly.

05 To ensure our stroker combo had sufficient airflow, we installed a set of Chevrolet Performance CNC-ported LS3 heads from Gandrud Chevrolet. The ported heads were capable of supporting over 700 hp, so we knew they would not be restrictive on our stroker.

06 The ported heads featured a 2.165/1.590-inch valve combo. We even treated them to some chamber work before installation.

07 Though the CNC-ported heads offered plenty of flow, it was necessary to upgrade the supplied valvesprings. Lucky for us, Brian Tooley Racing stepped up with a dual spring package that allowed us to safely run our 0.624-lift cam.

08 Additional components used to build the stroker included a set of Comp hydraulic roller lifters, ARP head studs, and a new oil pump.

09 All testing was run through a set of 1 3/4-inch long-tube headers and 3-inch exhaust.

10 Tuning the timing curve and fuel from the 42-lb/hr FAST injectors was handled by this Holley HP management system.

11 Doing LS cam swaps on the engine dyno is a breeze, each taking less than 1 hour. The 120-degree cam minimized torque production through most of the curve, while the 112-degree cam offered more torque but slightly less peak power.

12 In terms of power production, the stroker LS3 performed best with the tightest lobe separation angle. The 108-degree cam offered both the most power and torque, but idle quality suffered compared to the wider LSAs.

13 The three power curves indicate that the wide (120-degree) LSA (green lines) lost considerable torque to the other two cams. The 112-degree cam (red lines) picked up much of the torque, but the big winner was the cam with the tightest lobe separation angle. The 108-degree cam (blue lines) outperformed the other two, but idle quality suffered. Realize what the engine is going in, however, as you may not be able to use the wildest cam out there.