No two race cars are exactly the same. Sure you can purchase a rolling chassis from a builder that turns out 100 (mostly) identical cars a year. And you can use a body kit that uses sheetmetal stampings and bumper cover moldings that are all alike, but every team finishes the construction of their car with their own touches. Changes to the front clip, the way accessories are mounted to the engine, the header design, the way the steering shaft is mounted up, and many other factors can change the way you will need to route your plug wires.

Here are the contents as they arrived in our MSD wire kit (PN 31239). Eight plug wires with 90-degree spark plug boots, one coil wire, two styles of distributor plug boots, two different types of terminals, and a few extras thrown in in case of a screw-up (which we always appreciate).

Here are the contents as they arrived in our MSD wire kit (PN 31239). Eight plug wires with 90-degree spark plug boots, one coil wire, two styles of distributor plug boots, two different types of terminals, and a few extras thrown in in case of a screw-up (which we always appreciate).

So even though the major ignition companies offer a multitude of different plug wire kits designed to fit most engine configurations, there are still times when your particular situation requires a custom set of wires. Of course, the much more common scenario is when a racer suffers the misfortune of one or two wires coming in contact with a set of glowing headers and has them ruined. Instead of throwing away six good wires and starting over, you can purchase a do-it-yourself plug wire kit, build yourself just the wires you need, save some money, and have spares left over in case it happens again.

Typically, a do-it-yourself plug wire kit is boxed with the spark plug terminals and boots already attached to the wires. The wires are already cut to approximate lengths but are left long to allow for different routing options. Also included are loose terminals and boots for the end to be attached to the distributor. Usually, an extra length of wire and boots is included for the coil as well. When ordering your wires, you need to be able to specify whether you need straight or angled spark plug boots and the type of distributor you are working with. The best style of plug boot is usually determined by your cylinder heads and headers. Cylinder heads with straight-cut plug holes—which is what you will normally find in stock-style heads—will almost always require angled plug boots in order to avoid contact with the headers.

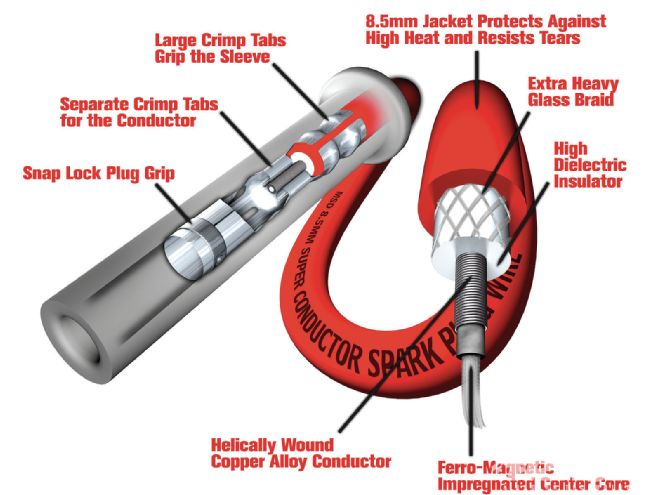

There is more to a quality set of plug wires than a simple conductor and an insulator. We borrowed this graphic from MSD to show how a performance wire has a much more complicated construction in order to eliminate electro magnetic interference while still providing excellent conductivity of the energy that will create a strong, hot spark in the combustion chamber.

There is more to a quality set of plug wires than a simple conductor and an insulator. We borrowed this graphic from MSD to show how a performance wire has a much more complicated construction in order to eliminate electro magnetic interference while still providing excellent conductivity of the energy that will create a strong, hot spark in the combustion chamber.

Which to Choose

Not all plug wires are created the same. Performance plug wires must exhibit both low resistance to make sure the maximum spark power gets to the plugs. They should also have good insulation, in terms of limiting EMI (electro magnetic interference) and protection from heat.

Most performance wires are built generally the same. At the core is a spiral-wound conductive wire. The spiral winding is important because that’s what limits the EMI from screwing up electronics. Some may think this isn’t an issue because EMI is normally associated with radio interference and other electronic glitches that are found on over-the-road automobiles. But EMI can also interfere with your ignition box and harm overall power. The tighter the spiral winding in the core, the greater protection from EMI you will have, but a tighter winding can also increase the electrical resistance of the wire (measured in ohms).

The motor for this project is a Late Model Stock Chevrolet that needed a new set of plug wires while it was at KT Engine Development for a refresh. We did things a little backwards by building the set of plug wires before the engine was torn down and rebuilt—those are the sacrifices you have to make when the magazine deadlines start getting tight.

The motor for this project is a Late Model Stock Chevrolet that needed a new set of plug wires while it was at KT Engine Development for a refresh. We did things a little backwards by building the set of plug wires before the engine was torn down and rebuilt—those are the sacrifices you have to make when the magazine deadlines start getting tight.

"If you have too much resistance, that’s just going to go back into the coil," explains Scott Sowards, the shop foreman for Performance Distributors. "You can think of resistance in the plug wires just like water flowing through a pipe. If the resistance is too high, that’s just like using a pipe that’s too small for the amount of water you are trying to get through there. The water doesn’t just go away; it backs up at the beginning of the pipe. It’s the same way with electricity. If the wire is too restrictive, the electricity that the ignition produces that can’t make its way down the wire to the plug in time doesn’t just go away. Instead, it backs up in the coil.

"As a result, the electricity will back up in the coil and cause trouble. The coil will get excessively hot and reduce the operating life. The cap will also exhibit a lot more corrosion buildup."

As a general rule, Sowards recommends a wire with a rated resistance of 300 ohms or less per foot. If you want to check it yourself, you can hook both ends of your plug wire up to an ohm meter and gather your own readings. Also, because the resistance increases as the length of wire gets longer, it’s always a good practice to keep your plug wires to the minimum useful length. Now, get out those cutters and get to work!