Bolting on a set of headers has long been one of the first moves a hot rodder makes in search of more performance. Traditionally, factory iron log exhaust manifolds are set aside in favor of a pair of tube headers, typically of the four-into-one configuration. Most enthusiasts know that the headers will provide an increase in power, generally attributing the gain to a reduction in backpressure. Sure, reduced backpressure is a factor, but the real secret to a set of headers is the tune, determined by the length and diameter of the primary tubes and collector.

At each combustion event a pulse of high-velocity exhaust gas makes its way down the primary tube, and upon reaching the collector at the end of the primary tube, a low-pressure wave is reflected back up the pipe. Now if that low-pressure wave reaches the exhaust valve while it is open during the overlap period, the pressure differential will actually scavenge the cylinder of exhaust gases. Since the intake valve is also open during overlap, the effect is to actually draw on the induction side. This scavenging effect actually aids in filling the cylinders with a greater charge for higher volumetric efficiency and, of course, more power. The cam plays a vital role here, since the overlap provides the window for the scavenging effect to occur. Obviously, a very short duration cam with virtually no overlap will represent a closed door to the exhaust header scavenging. Fortunately, most hot rodded engines are also equipped with bigger cams, which go hand in hand with headers.

We hit the dyno with a stout 427ci big-block Chevy to put a variety of Hooker header configurations to the test. Our street big-block featured a solid street roller Crane cam and AFR 305cc cylinder heads. With a power capacity approaching 600 hp, the test engine represents a hot street/strip big-block.

We hit the dyno with a stout 427ci big-block Chevy to put a variety of Hooker header configurations to the test. Our street big-block featured a solid street roller Crane cam and AFR 305cc cylinder heads. With a power capacity approaching 600 hp, the test engine represents a hot street/strip big-block.

Since this scavenging effect is dependent upon the low-pressure wave communicating with the cylinder through an open exhaust valve, the arrival of the low pressure wave needs to be correctly timed. To achieve this, the tube length and diameter are the main tuning variables. Luckily, a high-performance engine with a healthy cam represents a pretty big target as far as the tuning window, so the tuned length is not super critical. Even headers compromised for fit with moderately varying tube lengths will provide most of the benefit of the "perfect" tuned length.

Primary tube diameter also affects the tuning of the header, but to a lesser degree than length. The primary tube needs to be of sufficient capacity for the volume of exhaust gases. There are many ways to estimate the required primary tube diameter, from simple formulas to elaborate and complex computer programs. Engine horsepower is an accurate predictor of required primary tube diameter, with the rule of thumb being a higher-powered engine will require a larger primary diameter.

Our first setup was a set of Hooker Block Hugger shorties with 1⅞-inch primary pipes. The shorties were run with open downpipes, and give us mid 550s in horsepower.

Our first setup was a set of Hooker Block Hugger shorties with 1⅞-inch primary pipes. The shorties were run with open downpipes, and give us mid 550s in horsepower.

Often the final header configuration is more a matter of what is available and what will fit the car than a result of number crunching theory. In the real world, cataloged header configurations are what most guys have to choose from, and the usual compromise is the bigger the header gets, the harder they are going to be to install and the more intrusive they become in the engine bay. The key piece of information that is usually missing is just how much of a difference in performance is gained or lost with a given header choice. If a 1⅞-inch header will put you within a few odd horsepower of a 2⅛-inch header, most guys would see the smaller header as the sensible choice. If on the other hand, there is 10, 20, 30, or even more horsepower dependent upon stepping up the header size, at some point it is going to be worth the effort to get the bigger pipes under the hood.

The swapping began with a set of Hooker 1¾-inch pipes. The full-length headers showed a decided advantage over the short tubes.

The swapping began with a set of Hooker 1¾-inch pipes. The full-length headers showed a decided advantage over the short tubes.

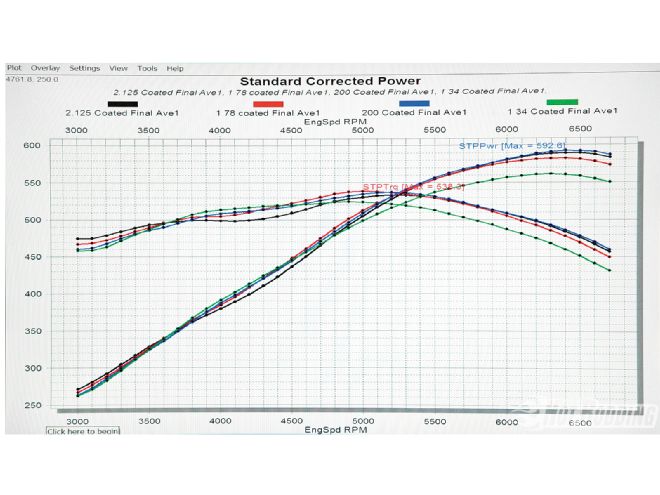

To get a handle on the variations in power output with a typical high-output street engine, we gathered a wide range of popular big-block Chevy headers from Hooker. Represented were 1¾-, 1⅞-, 2.00-, and 2⅛-inch full length headers, all with Hooker's factory silver ceramic metallic coating. To judge the effect of the header coating, we also had on hand a set of plain black painted 1⅞-inch headers identical to the coated version for a back-to-back test. We completed the lineup with a set of Hooker Block Hugger shorty headers, also in a 1⅞-inch primary tube diameter. Our test engine is a high-performance street big-block Chevy based upon a stock stroke 427. The engine was built with just under 10:1 compression, a pair of AFR 305 "as-cast" cylinder heads, a Crane 246/254 duration-at-.050-inch Street Roller cam, an Edelbrock Victor single-plane intake, and a Holley 950-cfm Ultra HP 4150 carb. Here is how the various pipes stacked up.

As the numbers show, there was quite a lot of power to separate the various header configurations, with as much as a 39hp spread in peak-to-peak horsepower, between the shorty header and the best performing long-tube, the 2.00-inch. The shorty header certainly did not provide the same exhaust tuning and scavenging effect of any of the long-tube headers, with a significant loss in torque and power throughout the curve. Our smallest full-length header, the 1¾-primary pipes produced substantially more power throughout the rpm range, and a particular advantage in torque in the 3,500-4,000 rpm range. For all-out power, the long-tubes win, but in many installations the shorty headers are a much easier fit.

Moving to larger 1⅞-inch headers proved to be much closer to what the engine needed at this power level, eclipsing the smaller pipes through most of the power curve. The 1⅞-inch size represents a good compromise between fit and performance for engines in the 500-600hp zone.

Moving to larger 1⅞-inch headers proved to be much closer to what the engine needed at this power level, eclipsing the smaller pipes through most of the power curve. The 1⅞-inch size represents a good compromise between fit and performance for engines in the 500-600hp zone.

Getting into the various full-length headers, bolting on the 1⅞-inch headers brought into focus the shortcomings of the smaller headers. The larger pipes showed a healthy increase in top end power of 21 peak horsepower, while even managing a torque advantage right from the bottom of our test range of 3,000 rpm. The smaller pipes had a short-lived advantage in the 4,000-rpm range, but the average power gives the nod to the larger pipes. Stepping up another level to the 2-inch headers showed another gain in top end power, this time a more modest increase of 11 hp at the top of the power curve. At the lower rpm levels, these two headers swapped the torque advantage depending upon the engine speed. Moving to our largest header, the 2⅛-inch primary, we seemed to be reaching the point of diminishing returns. As with our previous test, these headers swapped for torque advantage through the lower rpm range, while at the top end the larger tubes were actually slightly down on peak power. Overall, the big pipes were an overkill, sacrificing fit and packaging for no real gain.

Coatings: Are They Worth It?

As a part of our test, we wanted to quantify the benefits of a coated header versus a plain uncoated black painted header. A thermal barrier ceramic coating adds considerably to the price of any header, often doubling the price. We tested two otherwise identical Hooker 1⅞-inch headers with surprising results. Running on the dyno, we found the power numbers virtually unchanged (see Average Power table on next page). Where the ceramic coating made a remarkable difference is in the heat transferred by the header. We tested the header temperature immediately after a run, and then one minute after shutdown. The coated headers measured 258 degrees F dropping to 195 degrees F a minute after shutdown. In contrast, the uncoated header measured a scalding 870 degrees, retaining 520 degrees a minute after shutdown. We didn't need a heat gun to tell the difference in the test cell.

Our next test loaded the engine to 60 lb-ft of torque at 2,800 rpm, simulating a high-speed cruise situation. We gauged the surface temp of the header once fully stabilized. Once again, the difference was huge, with the coated header showing 288 degrees, while the uncoated header recorded 850 degrees. While the dyno run didn't show much difference in output, an engine breathing air from under the hood will definitely feel the effects of that extra 562 degrees F pumping into the engine bay. Taking account the effects of heat on engine component life and passenger comfort, the coated headers are definitely a winner.

Moving up again to the 2-inch header, an argument could be made that the top end power gains make this a worthwhile step up, though the averages showed only a modest change.

Moving up again to the 2-inch header, an argument could be made that the top end power gains make this a worthwhile step up, though the averages showed only a modest change.

Swapping on the big 2⅛-inch headers proved to actually hurt output slightly. At this power level the engine just didn’t require the bigger pipes. These headers would be more appropriate on a higher-powered 700-plus horsepower engine.

Swapping on the big 2⅛-inch headers proved to actually hurt output slightly. At this power level the engine just didn’t require the bigger pipes. These headers would be more appropriate on a higher-powered 700-plus horsepower engine.

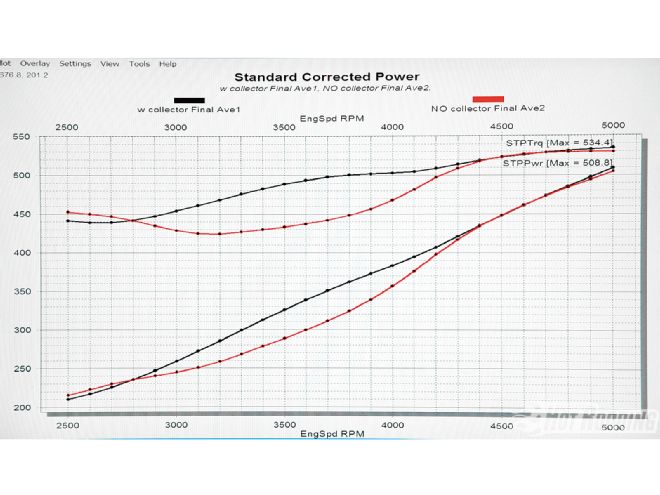

Collector Extensions: What Do They Do

For years we have been told of the value of collector extensions when running open headers. No serious drag race car would be running without them. It was simple enough to quantify the benefit of collector extensions while on the dyno, so we ran the 1⅞-inch headers with and without an 18-inch collector extension to have a look. Those old drag racer tales certainly held up, with the extensions producing a tremendous boost in torque. In the 3,000- to 4,000-rpm range, there was more than 50 lb-ft of torque added by the collector extensions. The extensions add to the secondary tuned length of the header, adding heavily to torque at an rpm range that counts. If your plans are to uncork the exhaust at the track, it is definitely worth packing a set of collector extensions.

DYNO RESULTS Hooker Header Test 427ci Big-Block Chevy The Torque Numbers RPM Shorty 1¾ 1⅞ 2.00 2⅛ 3,000 446.4 458.1 466.9 460.2 474.5 3,100 446.5 458.3 468.5 461.8 474.9 3,200 449.7 463.3 472.4 467.5 478.8 3,300 455.2 471.3 478.2 474.6 484.1 3,400 460.8 479.9 484.4 481.2 489.1 3,500 464.2 487.5 489.7 485.8 493.0 3,600 466.9 493.9 494.8 489.8 495.6 3,700 470.3 500.8 499.9 494.8 497.7 3,800 473.7 507.3 503.4 500.7 499.4 3,900 477.2 511.2 504.4 505.6 499.3 4,000 480.9 513.5 504.8 508.3 498.6 4,100 486.2 515.1 506.6 510.2 498.2 4,200 493.1 516.5 510.2 511.8 499.1 4,300 500.8 518.1 514.4 513.3 501.2 4,400 507.9 519.2 518.3 515.3 504.8 4,500 512.8 519.9 522.2 518.3 509.2 4,600 515.6 520.8 526.2 522.3 514.1 4,700 516.9 522.3 530.4 526.0 520.4 4,800 517.8 523.8 534.9 529.3 525.1 4,900 517.8 524.5 537.6 532.2 528.3 5,000 517.1 524.2 538.3 534.7 530.6 5,100 516.2 523.0 537.8 536.3 532.4 5,200 515.1 521.2 536.4 536.9 533.0 5,300 513.2 519.0 534.6 536.1 533.0 5,400 510.4 516.3 532.3 534.0 532.0 5,500 506.1 512.6 529.3 531.4 529.5 5,600 501.2 508.1 525.6 527.9 526.1 5,700 495.6 503.1 521.4 523.6 522.0 5,800 489.6 498.2 516.3 518.3 517.4 5,900 483.8 492.9 511.0 513.0 513.1 6,000 478.4 487.3 505.0 508.8 508.2 6,100 473.0 481.3 498.5 504.0 503.1 6,200 467.3 475.0 492.4 498.8 497.6 6,300 461.9 468.0 485.4 492.8 491.1 6,400 455.0 460.0 477.9 486.3 483.6 6,500 446.7 451.3 469.4 478.6 476.1 6,600 436.9 441.4 459.7 470.2 467.2 6,700 423.7 431.5 449.4 460.1 457.1

THE HORSEPOWER NUMBERS RPM Shorty 1¾ 1⅞ 2.00 2⅛ 3,000 255.0 261.7 266.7 262.8 271.0 3,100 263.5 270.5 276.5 272.6 280.3 3,200 274.0 282.3 287.8 284.8 291.7 3,300 286.0 296.1 300.4 298.2 304.2 3,400 298.3 310.6 313.6 311.5 316.6 3,500 309.3 324.9 326.3 323.7 328.5 3,600 320.1 338.6 339.2 335.7 339.7 3,700 331.3 352.8 352.2 348.6 350.6 3,800 342.7 367.0 364.2 362.2 361.3 3,900 354.4 379.6 374.6 375.4 370.8 4,000 366.3 391.1 384.5 387.1 379.7 4,100 379.5 402.1 395.5 398.2 388.9 4,200 394.3 413.0 408.0 409.3 399.1 4,300 410.0 424.2 421.1 420.3 410.4 4,400 425.5 434.9 434.2 431.7 422.9 4,500 439.4 445.4 447.4 444.1 436.3 4,600 451.6 456.1 460.9 457.5 450.3 4,700 462.6 467.4 474.7 470.7 465.7 4,800 473.3 478.7 488.9 483.8 479.9 4,900 483.1 489.3 501.6 496.6 492.9 5,000 492.3 499.0 512.5 509.0 505.2 5,100 501.2 507.9 522.2 520.8 517.0 5,200 510.0 516.0 531.1 531.6 527.7 5,300 517.9 523.7 539.5 541.0. 537.8 5,400 524.7 530.9 547.3 549.1 547.0 5,500 530.0 536.8 554.3 556.5 554.5 5,600 534.4 541.8 560.4 562.9 561.0 5,700 537.9 546.0 565.8 568.3 566.5 5,800 540.7 550.1 570.2 572.3 571.3 5,900 543.4 553.8 574.0 576.3 576.4 6,000 546.5 556.7 577.0 581.2 580.5 6,100 549.4 559.0 579.0 585.4 584.3 6,200 551.6 560.8 581.2 588.8 587.4 6,300 554.1 561.3 582.2 591.1 589.1 6,400 554.4 560.5 582.4 592.6 589.3 6,500 552.9 558.5 581.0 592.3 589.2 6,600 549.0 554.7 577.7 590.8 587.1 6,700 540.5 550.4 573.3 586.9 583.2

AVERAGE POWER Test RPM range Avg. HP Avg. TQ Shorty 1⅞-inch 3,000-6,700 446.1 482.9 1¾-inch coated 3,000-6,700 456.7 495.8 1⅞-inch coated 3,000-6,700 466.6 505.0 1⅞-inch uncoated 3,000-6,700 465.8 504.4 2.00-inch coated 3,000-6,700 467.7 505.3 2⅛-inch coated 3,000-6,700 465.7 503.6 1⅞-inch no extension 2,500-5,000 340.4 469.9 1⅞ 18-inch extension 2,500-5,000 354.8 490.6