Mini Mouse has seen more than her fair share of dyno time. After the introduction, we installed a cam then tested a pair of carbureted intake manifolds. We followed that up with a top-end change that included wilder cam timing and a set of CNC-ported Gen X 205 heads. Next, we ushered in the age of boost with a single-turbo system running 7 psi. In addition to the turbo, we also individually tested the merits of a cam and cylinder head upgrade under boost. This helped answer questions about turbo cam timing and whether ported heads offer any power under boost. Because of the positive experience with the turbo combination, we decided to duplicate that test with another form of forced induction. We now know that a cam and head swap play a major role in power production on the turbo engine, so, how do they work with a positive displacement blower? Enter the Whipple twin-screw supercharger.

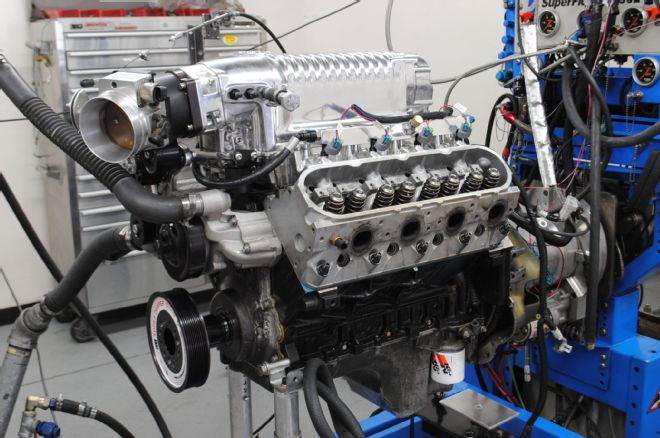

While Whipple offers supercharger kits for dedicated applications, we decided to try one of their 2.9L “Tuner” kits. The Tuner kit lacked components like the flash tool, air filter, and miscellaneous hardware, which wasn’t an issue for our engine dyno testing. The centerpiece of the Whipple kit was obviously the front-feed, 2.9L W175ax twin-screw supercharger. Capable of supporting 1,000 hp, it was more than enough blower for the little 4.8L. Even with an efficient twin-screw supercharger, heat is a natural byproduct of compression, so the Whipple kit also included an integrated air-to-water intercooler core. The higher the boost pressure, the higher the associated inlet air temperature, so intercooling becomes increasingly important. Passing the heated charge air through a heat exchanger (intercooler) dramatically reduces the air temperature and risk of harmful detonation. The twin-screw system from Whipple utilized an air-to-water intercooler core positioned directly below the discharge of the supercharger. The cooler really came in handy at the elevated boost levels run on the stock engine.

Unlike the turbo run in part 3, boost supplied by a supercharger was a function of two things. Since boost pressure is really just a measurement of backpressure created by the engine, boost is a function of blower speed (relative to engine speed) and the power output of the naturally aspirated engine. Like any blower, the rotor speed of the Whipple was controlled by the engine speed multiplied by the drive ratio between the crank and blower pulleys. Increasing the size of the crank pulley or decreasing the size of the blower pulley will increase the speed of rotors and increase the boost pressure supplied to the engine. Since we planned on running the oversized blower on the stock 4.8L, we requested a variety of different blower pulleys to work with the supplied ATI crank pulley. This gave us the ability to adjust the boost pressure supplied to the engine. We liked the fact that the kit came with a 10-rib pulley system to eliminate any chance of belt slippage. There is nothing more frustrating than having belt slippage during a test session. The dedicated fuel rails required short, 85-pound (LS3-style) injectors, which we sourced from FAST, along with one of their massive, 102mm Big Mouth throttle bodies.

Back in part 3, we subjected Mini Mouse to a single-turbo kit in stock and modified trim and decided to duplicate that procedure with the Whipple supercharger. To do so, the first order of business was to put the 4.8L engine back to stock. This meant removal of the TFS Gen X 205 heads and Crane 224 cam. Loyal readers will remember that the LR4 had been augmented with a set of JE forged pistons that featured 7.2cc domes, but the combination was otherwise stock. The naturally aspirated baseline was run with a set of 1 3/4-inch headers feeding 3-inch exhaust that included a set of Bassani mufflers. Also present was a Meziere electric water pump, Accufab throttle body, and Holley Dominator EFI management system. Run with 4.5 fresh quarts of Lucas synthetic oil, Mini Mouse produced peak numbers of 342 hp and 341 lb-ft of torque. All the time spent on the dyno had improved ring seal as the baseline power was up slightly from parts 1 and 2. Despite its minimal displacement and mild cam timing, torque production from the little 4.8L managed to exceed 325 lb-ft from 3,900 to 5,500 rpm.

As impressed as we always were with the power output of the stock 4.8L, we couldn’t wait to see the boosted power numbers. Off came the stock truck intake to make way for the Whipple supercharger. First to be installed was the lower intake manifold and fuel rail assembly. We installed the 85-pound FAST injectors in the rail then secured the injectors in place in the lower manifold. The upper manifold included the supercharger and intercooler assembly, and the upper and lower manifolds (and bypass valve) were sealed using supplied O-rings. Once the blower was bolted in place, we attached the (late-model Camaro) ATI damper and spring-loaded belt tensioner. Next came the 45-degree throttle body adapter and FAST 102mm throttle body followed by the belt and throttle cable. Installation of the supercharger required the use of a manual (late-model Camaro) water pump to replace the Meziere electric pump. We tried the Meziere Camaro electric pump but the water neck interfered with the blower bracket. Installation of the Whipple on Mini Mouse was no more difficult than a simple intake swap.

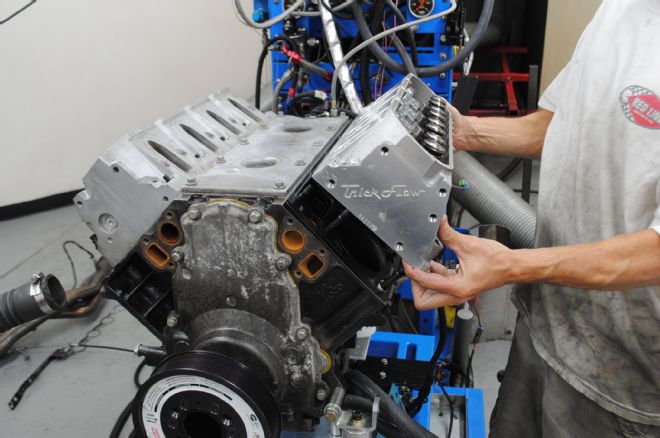

1. Steve Brule and Troy Goldie from Westech show the Trick Flow Specialties heads and Crane cam that go along with the Whipple supercharger.

2. As always, our test procedure started by establishing a baseline with Mini Mouse in naturally aspirated trim. Tuned with the Holley Dominator EFI and run with the stock heads, cam, and intake, the 4.8L produced 342 hp and 341 lb-ft of torque.

3. In preparation for the Whipple supercharger, off came the factory truck intake and Accufab throttle body.

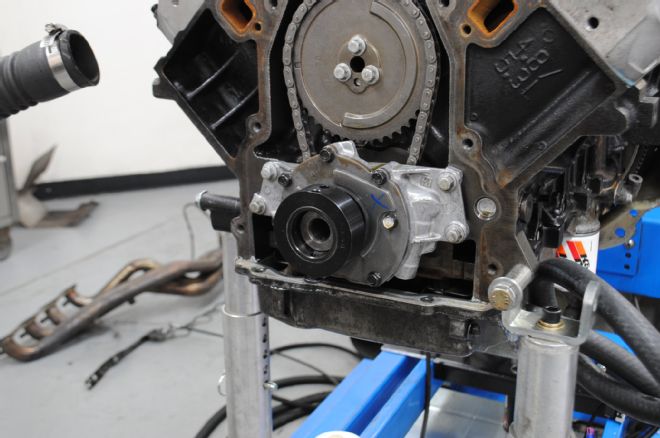

4. Next, we installed the Whipple lower intake and fuel rail. The lower manifold featured O-ring sealing for the supercharger and bypass valve.

5. Next, we installed the Whipple 2.9L twin-screw supercharger and air-to-water intercooler assembly. Located below the supercharger, the intercooler was used to lower the inlet air temps.

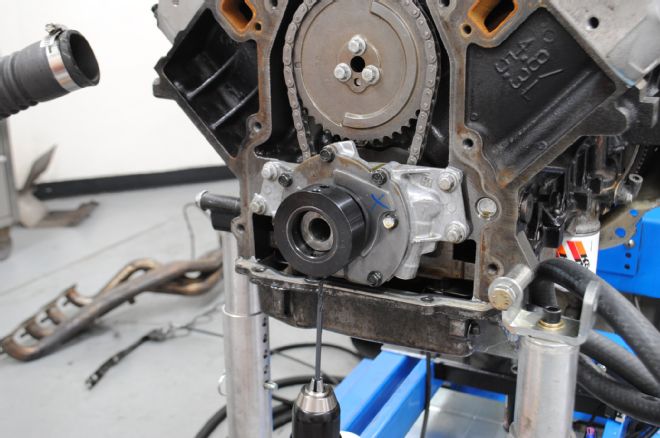

6. In addition to the 10-rib Super Damper, ATI supplied a kit to pin the factory crank. Since the factory damper is not keyed, it may spin on the crank from the load imposed by the supercharger. The kit included a locating sleeve, drill bits, and dowel pin.

7. After positioning the sleeve, we drilled the first hole, then switched over to the supplied reaming tool to finish the job.

8. We then tapped the dowel pin in place. The factory (or ARP) damper bolted ensured the dowel pin did not slide into the center of the crank. We had no damper or belt slippage issues once this system was in place.

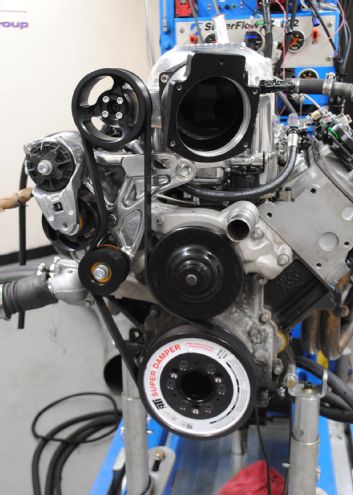

9. The spring-loaded tensioner/drive system used for the blower testing included the 7.5-inch ATI Super Damper, a manual water pump, and the 4.0-inch blower pulley. Note the 45-degree elbow used to keep the 102mm throttle body away from the blower pulley. Run on the stock engine, the 2.9L supercharger produced 577 hp and 503 lb-ft of torque at a whopping 19 psi.

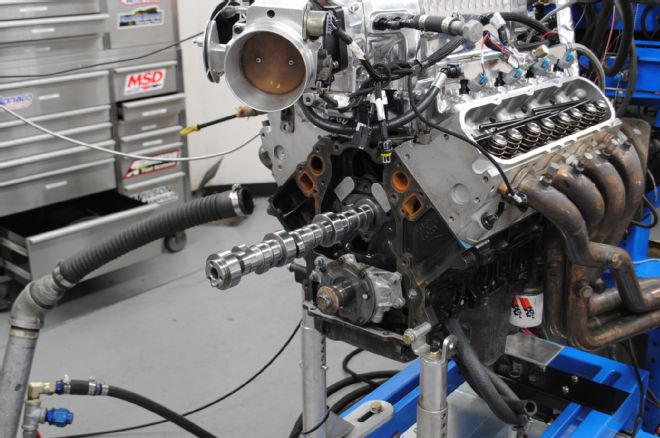

10. To help reduce the boost and increase power, we decide to swap out the stock cam. Off came the valve covers and out came the stock rockers and pushrods. In anticipation of the many cam swaps, the stock heads had been previously upgraded with Comp beehive springs (PN 26918).

11. Out came the wimpy stock cam and in went a Crane performance grind that offered 0.590-inch lift, a 224/232-degree duration split, and a 115-degree LSA. The cam swap increased the peak numbers to 670 hp and 540 lb-ft and reduced the peak boost pressure to 14.1 psi.

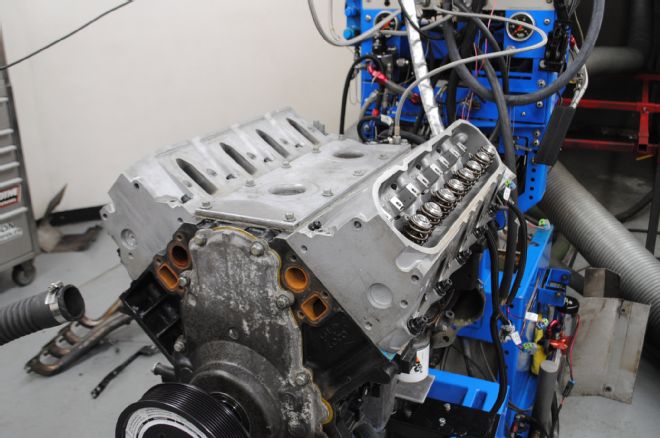

12. The head swap required the removal of the twin-screw supercharger and lower manifold assembly.

13. Off came the stock 706 heads and on went fresh Fel-Pro head gaskets. The new gaskets were used in conjunction with a set of ARP head studs.

14. Having worked so well on the naturally aspirated and turbo combinations, we were naturally excited about installing the TFS Gen X 205 heads on the supercharged 4.8L.

15. After torquing the heads in place, we installed the lower intake, rockers, and valve covers.

16. With the blower installed, we were surprised by the results. As expected, the peak boost was down to 12.7 psi, but the power changed very little.

For the first test on the stock LR4 engine, we went with the largest blower pulley we had available, the 4.00 inch. This kept blower speed and boost to a minimum, but we made sure to switch over to 110-octane Rocket Brand race fuel just to be safe. After all, the boost pressure would be highest on this stock combination. The combination of the ATI damper and 4.0-inch blower resulted in a peak boost pressure of 19.0 psi at 6,700 rpm. Knowing we had plans to add a cam and heads, we purposely ran the engine with more boost than you might in stock trim. Equipped with the intercooled Whipple supercharger pumping out a peak boost pressure of 19 psi, the supercharged 4.8L produced 577 hp at 6,700 rpm and 503 lb-ft of torque at 4,600 rpm. True to form, the positive displacement blower supplied plenty of boost down low (9.7 psi at 3,100 rpm), then continued to climb with engine speed. Truth be told, we’d like to see the engine make more power with less boost than the other way around and this next test was all about doing just that. Enter the camshaft.

Out came the stock LR4 cam and in went the same Crane 224 cam run on the NA and turbo combinations. Significantly more stout than the wimpy stock cam, the Crane 224 cam offered 0.590 lift, a 224/232-degree duration split, and 115-degree LSA. This represented a significant step up from the stock specs (0.466/0.457 lift, 190/191 duration, 116 LSA). Tested on this supercharged LR4, this cam offered significant power gains, increasing the peak numbers from 577 hp and 503 lb-ft of torque to 670 hp and 540 lb-ft of torque. In addition to the extra power, the cam swap also decreased the peak boost pressure. We wanted more power with less boost and that is exactly what we got, as the cam swap dropped the peak boost pressure from 19.0 psi to just 14.1 psi. We know you are thinking we have to crank up the boost but we like keeping the pulley the same and beneficially adjusting the power level and boost pressure. Remember, boost pressure is really backpressure and lower boost pressures also decrease the all-important inlet charge temperature.

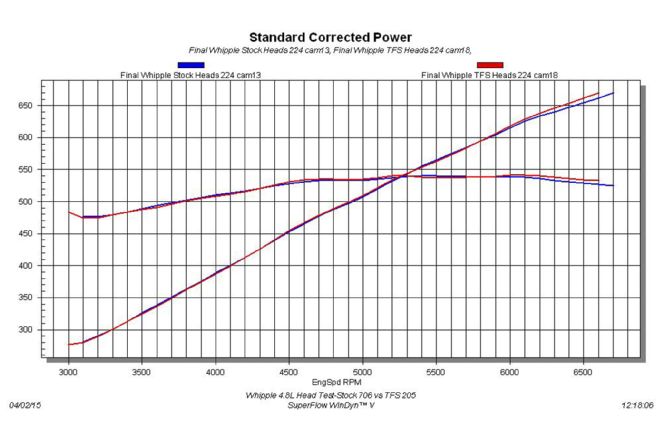

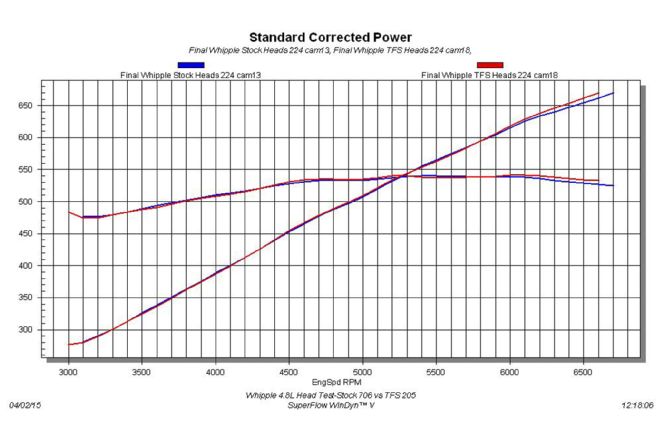

The final test was the most surprising of the day. Fresh after seeing the TFS heads add nearly 50 hp to the turbo combination (with the same cam), we had high hopes installing them on this supercharged application. The Gen X 205 heads flowed enough to support over 550 naturally aspirated horsepower, so we knew they were more than sufficient for our little 4.8L. After the cam test, off came the stock 706 heads (with Comp (PN 26918) valvesprings) and on went the TFS Gen X 205 heads. All we can say is that we were shocked by the results. At first, we were excited about seeing the drop in boost pressure from the peak of 14.1 with the stock heads and Crane cam to just 12.7 psi. Unfortunately, the drop in boost did not correspond with the expected increase in power, the as head swap netted just 10 hp, and only at the very top of the rev range. With all of the variables accounted for, we scratched our collective heads and called it a day but not before promising to revisit the supercharged head test in the future. After all, why would the head swap increase power both naturally aspirated and turbocharged but show no gains with the blower, especially after seeing the expected drop in boost? Having subjected Mini to both a turbo and twin-screw, was it time for a centrifugal, or maybe some nitrous? Stick around; Mini’s got some more tricks up her sleeve.

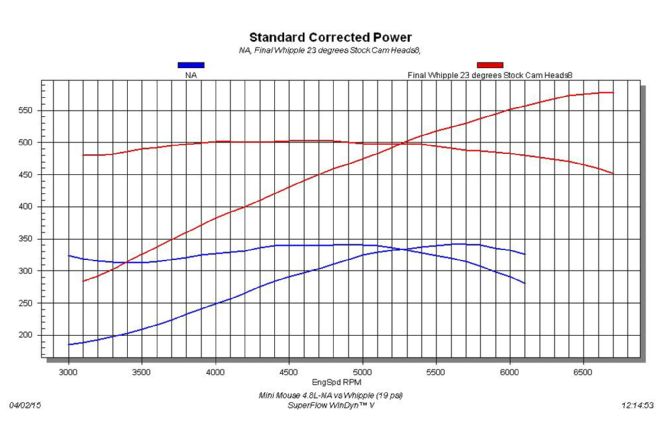

Mini Mouse 4.8L. NA vs 2.9L Whipple (19 psi)

Adding a supercharger makes a dramatic difference in the power as illustrated by this graph. Run with the stock heads, cam, and intake, the naturally aspirated 4.8L produced 342 hp and 341 lb-ft of torque. After adding the Whipple supercharger to the mix, the power numbers jumped to 577 hp and 503 lb-ft of torque. Unfortunately, the boost pressure of 19 psi was much too high to safely run on this engine for any length of time. Even using the largest blower pulley we had, the boost supplied by the 2.9L Whipple was just too much for the stock 4.8L. What we needed was a drop in boost and a jump in power.

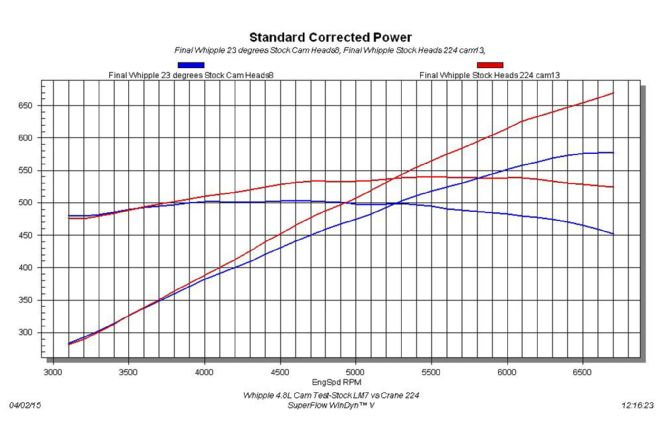

Cam Swap. Less Boost and More Power

Replacing the stock LR4 (LM7) cam with the Crane 224 cam resulted in some impressive power gains. Despite not being designed specifically for a blower application, the Crane cam upgrade increased the power output of the supercharged 4.8L from 577 hp and 503 lb-ft of torque to 670 hp and 540 lb-ft of torque. Every bit as important was the fact that the cam swap reduced the peak boost pressure from 19.0 psi to just 14.1 psi.

Head Swap. Stock vs TFS Gen X 205

This was a real head scratcher, as replacing the stock 706 heads with the TFS Gen X 205 heads resulted in very little power gain. The head swap netted just 10 hp at the very top of the rev range. We expected much more given the fact that the TFS heads were good for 30 hp on the naturally aspirated 4.8L and 50 hp on the turbo version (at just 7 psi). We might revisit this test to verify there were no mistakes, but all the variables and data checked out.

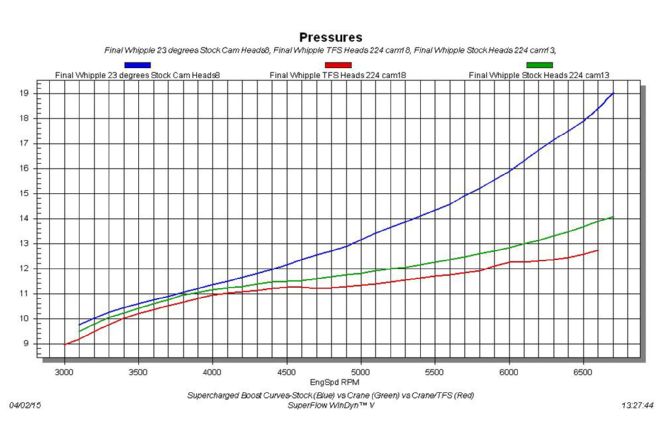

Boost Curves

Despite running the same pulley combinations, changing the cam and heads on the 4.8L resulted in decidedly different boost curves. Equipped with the stock heads and cam, the 2.9L Whipple supercharger produced 19 psi of boost at 6,700 rpm. Obviously, the blower speed was excessive on this stock, small-displacement application. Installation of the Crane 224 cam dropped the peak boost to just 14.1 psi, while the head swap dropped it even further to 12.7 psi.