In 1997 former President Clinton began his second term, scientists cloned Dolly the sheep, the spacecraft Pathfinder landed on Mars, and the Spice Girls released Spiceworld-their second Number One album-making the group the first British band since The Beatles to have two albums on the U.S. charts at the same time. Rock aficionados around the world mourned. That year, I was in the Bay Area, taking pictures and scribbling notes for an engine story that would appear in the August 1997 issue of Hot Rod magazine. Mike Blackstone was caressing a big-block Chevy to pump out what was some serious pump-gas horsepower for the day. Fastest street car racing was starting to get crazy and people were losing sight of the street aspect of fun, go-fast cars. This 557ci engine coming together in Blackstone's shop was designed for both street and dragstrip duty.

Nearly 15 years later, the engine has seen more than a dozen dyno pulls topping out at 893 hp and 740 lb-ft of torque, countless trips down the strip with and without nitrous, and thousands of street miles, including a drive from Los Angeles to Detroit. The concessions made in favor of more power in this big brute eventually created durability issues. First, we lost a lifter driving the car through Chicago. We tossed in a new set of lifters, changed the oil, and kept driving. Within a year, though, a mystery valvetrain noise developed.

After years of abuse on the street, this race-bred big-block Chevy developed a nasty valvetrain noise and demanded some attention. At Kurt Urban Performance, the top end of the engine was disassembled so the whole valvetrain could be inspected. This engine was built to perform really well on the dragstrip and be tolerated on the street. As such, the valvetrain required more maintenance and simply didn't last as long as a more docile setup would have.

After years of abuse on the street, this race-bred big-block Chevy developed a nasty valvetrain noise and demanded some attention. At Kurt Urban Performance, the top end of the engine was disassembled so the whole valvetrain could be inspected. This engine was built to perform really well on the dragstrip and be tolerated on the street. As such, the valvetrain required more maintenance and simply didn't last as long as a more docile setup would have.

We do need to explain something about this specific engine that drove the original and the replacement valvetrain components. This was never about building a docile street engine that will deliver 50,000 miles of service by just changing the oil and spark plugs. It's not about a smooth idle or having vacuum to operate power brakes. This is about big, nasty power that scares Toyota Prius drivers when we pass them in the HOV lane. Even in our quest to replace key pieces of the valvetrain, we wanted to maintain as much of the power as possible. Our true interest was to only make compromises required for higher durability on the street. Make no mistake, these are still race-inspired designs, but thanks to nearly 15 years of technical advancements, this valvetrain should require less maintenance and deliver better endurance on the street than the previous generation.

We recently took the engine to Kurt Urban Performance to tear it down and rebuild it. Urban normally builds LS engines these days, but in the early days of fastest street car racing, he built hundreds of big-block Chevys. He was very familiar with the parts we had in this engine and what the engine was built to do. We worked with COMP Cams to update the old valvetrain and solve some of the age-old problems with running a radical cam profile on the street. Quite a bit of new technology has developed for demanding applications like this. Even though this engine is on the radical side for the street, nearly all of the components are identical in function to any big-block Chevy, and the technology is similar for any cam-in-block engine. So if you have one of these old faithful engines in your street car, there's most likely a new trick for it in this article.

Why Can't These Parts Get Along?

The challenge in using race-bred valvetrain parts on the street boils down to the individual parts being at odds with each other. To make maximum power, a roller camshaft snaps the valves open and closed very quickly. This places immense side-loading force on the lifters, literally forcing them up by squeezing them against their bores. In addition, the valvespring pressure is very high in order to control the valves as the cam cycles them. If the springs aren't matched to the cam profile and the maximum rpm of the engine, the valves can actually bounce when they close, and the lifters won't stay on the cam lobes. This is bad for power, and it can be catastrophic for the engine. Even with the latest technology, a huge race cam on the street will eventually kill a set of lifters. In fact, Kurt Urban recommends we replace the lifters in this engine after 5,000 street miles or immediately if we find that the valve lash loosens up. While we're at it, the valvesprings should be checked each year, and replacing them before seeing hard racing use is a wise choice. How big is too big? It's best to work with a knowledgeable team like the folks at COMP Cams to make that determination for your specific application.

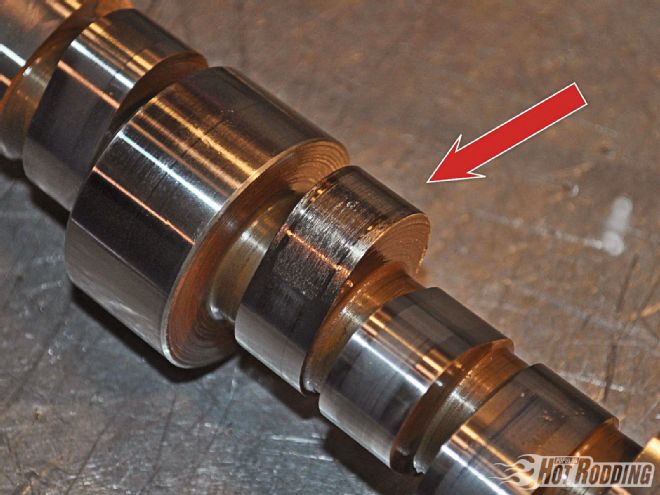

One of the roller lifters had failed. Most of the time when a roller lifter breaks, the bearings have failed and the wheel locks. Once the wheel stops turning, the engine becomes a lathe, grinding down the lobe on the camshaft. Not only does this trash the cam and potentially damage the rocker arm, pushrod, and valve when excess lash is introduced, it also sends metal throughout the engine. That's what we call a bad day.

One of the roller lifters had failed. Most of the time when a roller lifter breaks, the bearings have failed and the wheel locks. Once the wheel stops turning, the engine becomes a lathe, grinding down the lobe on the camshaft. Not only does this trash the cam and potentially damage the rocker arm, pushrod, and valve when excess lash is introduced, it also sends metal throughout the engine. That's what we call a bad day.

Hydraulic Versus Solid

Most engine builders opt for more moderate cam specs on an engine that will spend most of its life on the street. Sure, you'll give up some power, but you have to weigh the pleasure of hassle-free street driving with maximum horsepower at wide-open throttle. Just as important as the cam specs is the basic type. A roller camshaft will make more power because of the steep ramps that are possible, but should you use a solid roller or hydraulic? A long time ago, a roller lifter cam meant constantly checking the valve lash-the clearance between the rocker and the valve tip. In a solid lifter setup today, that's still true. The advantage of a solid lifter, in addition to maximum power, is that the valve lash is a great canary in the coal mine. If you find more clearance, something is wearing or broken, and you need to inspect the rocker, rocker mount, valve tip, and lifter. If you suddenly have less clearance, you probably have a valve that's mushrooming, and it's time to pull the heads. Hydraulic lifters absorb some of the beating within the valvetrain, especially the bearings in the roller lifters themselves. They also alleviate having to periodically check and adjust the valve lash. Matt Summerfield at COMP really would have preferred that we use a hydraulic roller cam with 266/274 degrees of duration at .050 and .646-/.646-inch lift for this engine. This would have greatly extended the life expectancy of the lifters and would make the valvetrain virtually maintenance free.

With the valvetrain completely disassembled, we called COMP Cams to get the skinny on the latest valvetrain technology for these older engines. In addition to quite a few solutions for our situation, the company also just introduced some very cool die-cast aluminum, black-wrinkle big-block Chevy valve covers, and their own blend of break-in oil that address the needs of bearings and rings as well as sensitive new valvetrain components.

With the valvetrain completely disassembled, we called COMP Cams to get the skinny on the latest valvetrain technology for these older engines. In addition to quite a few solutions for our situation, the company also just introduced some very cool die-cast aluminum, black-wrinkle big-block Chevy valve covers, and their own blend of break-in oil that address the needs of bearings and rings as well as sensitive new valvetrain components.