Every year we get reader mes-sages asking about the fate of a potential breakthrough engine technology developed by late legendary racing engine builder and high-perf tuner Henry "Smokey" Yunick with his longtime collaborator Ralph Johnson. HOT ROD first reported on this adiabatic, "hot vapor" (or "hot air") engine in the June '84 issue. "The Next Step" by C.J. Baker fully explained how Smokey developed a 2.5L (151ci) Iron Duke four-cylinder Fiero engine that met all '80s emissions standards (with a carburetor and no computer), made 250 hp and 250 lb-ft of torque (compared with about 90 hp and 125 lb-ft stock), went 0 to 60 mph in 6.5 seconds (stock was 12 to 13 seconds), and managed to get as high as 51 mpg on the highway running 93-octane pump unleaded premium gas (the stocker got about 35 mpg on 87-octane). The hot-vapor engine did all this running unheard of high temperatures at an extremely lean air/fuel ratio, in seeming violation of accepted internal-combustion-engine physics.

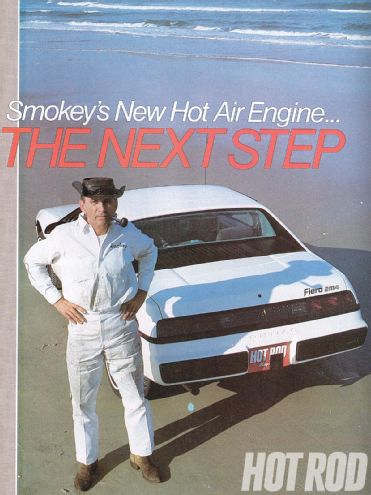

This is the original lead photo for HOT ROD's June '84 article on Smokey Yunick's adiabatic engine technology (the complete article is now posted on HotRod.com). At the time, it seemed this breakthrough engine had the potential to revolutionize internal combustion engine science as we know it.

This is the original lead photo for HOT ROD's June '84 article on Smokey Yunick's adiabatic engine technology (the complete article is now posted on HotRod.com). At the time, it seemed this breakthrough engine had the potential to revolutionize internal combustion engine science as we know it.

Normally, different parts of a standard nonhomogeneous air/fuel mixture burn at different rates within the same cylinder, creating turbulence and colliding flame fronts. Under such "normal" conditions, cooling the intake charge to create higher mixture density is beneficial to keep some of the fuel molecules from undergoing spontaneous combustion (aka detonation). But a standard Otto-cycle four-stroke internal-combustion engine utilizes only about 25 percent of its potential energy to make power. The remaining 75 percent is lost out the exhaust or transferred as heat into the cooling system and radiator. Hot-vapor technology attempts to recapture this heat energy, using it to superheat the incoming air/fuel mixture to more than 450 degrees F going into the cylinder, thereby achieving a homogeneous, perfectly vaporized condition that's said to prevent detonation while ensuring complete combustion.

To completely vaporize the fuel, Smokey used heat from the water in the engine's cooling system plus exhaust heat to progressively warm the system's induction flow to the required temperature. There was a heat exchanger under the carburetor that used hot engine coolant exiting the motor to warm the mixture to around 200 degrees. The air/fuel charge then flowed through a second-stage generator, an exhaust-driven turbine wrapped with exhaust-gas ducting. Smokey called this device a homogenizer, but it really was a turbocharger underneath the fancy ducting. Not only did the device generate boost, it also served as a one-way check valve to keep the expanded, hot mixture from back-flowing out the carburetor. From the turbine the mixture flowed through an intake manifold also wrapped by exhaust ducting to reach its final, super-hot induction temperature.

Two surviving key players still keeping hot-vapor engine tech alive: Tony Allers (left) dropped the original Smokey Fiero drivetrain into another Fiero restored to look and run exactly like Smokey's original. Ralph Johnson (right) built a hot-vapor engine at GM almost 60 years ago and collaborated with Smokey for more than three decades on a variety of projects.

Two surviving key players still keeping hot-vapor engine tech alive: Tony Allers (left) dropped the original Smokey Fiero drivetrain into another Fiero restored to look and run exactly like Smokey's original. Ralph Johnson (right) built a hot-vapor engine at GM almost 60 years ago and collaborated with Smokey for more than three decades on a variety of projects.

Although this technology seemingly was revolutionary and brand-new, Smokey and Ralph (who's still around today) had actually been puttering around with the concept for more than three decades. Ralph says, "I got the idea on my own and did the first vapor engine when I was 21 years old" back in the early '50s in his spare time during lunch hours while working as a GM dyno technician. It was a 235ci Chevy straight-six with a one-barrel carb that made 35 hp more than the 3x1-barrel setup on the '53 Corvette-all while using less fuel. Unfortunately, no official records or photos of this first effort are known to exist.

Ralph went on to become a tuning wiz and carburetor field service engineer for Holley and is generally credited with developing the 850-cfm double-pumper carburetor and LeMans-style racing fuel bowls that propelled Holley's rise to racing dominance. Ralph directly contradicts the original article's assertion that the engine was not a lean-burn system. "It was a lean-burn. I calibrated the carburetor." Although today's computer-managed engines are designed to run at a stoichiometric air/fuel ratio of 14.6:1, Ralph points out that carbureted OE econo six-cylinders were successfully running 18:1 ratios as far back as 1960. The '80s vapor motor's A/F ratio was well over 20:1.

Throughout the '80s, Smokey and Ralph continued to develop the technology. "Although I had been talking to Smokey for years about it," Ralph says, "Smokey was the push behind it. He paid me for my time and effort, and for whatever knowledge I contributed to our outcome. Smokey and I could work together without drawings or photos. It was all in our heads."

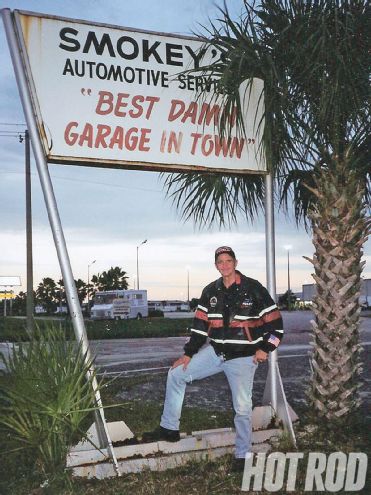

Tony Allers had been a friend and customer of Smokey for years. A true believer in hot-vapor technology, he's contemplating a number of personal vehicle builds using the tech with help from Ralph.

Tony Allers had been a friend and customer of Smokey for years. A true believer in hot-vapor technology, he's contemplating a number of personal vehicle builds using the tech with help from Ralph.

Eventually, there was a three-cylinder Buick (half a V-6), a Ford project, and a Mopar Omni/Horizon. Every application got more than 45 mpg and made at least 1.8 hp/ci. The Detroit OE boys and nationally certified independent labs verified all the claims and performance figures. It was on the verge of going into production (one application, for the '90 S-10 truck, got very close). Crane Cams was given a license to develop aftermarket retrofit kits. Then everything fell apart.

It was the "not invented here syndrome" rearing its ugly head again. How could a couple of gearhead hot rodders know more than all of Detroit's best engineering talent? By this time, Detroit was committed to the computer, fuel injection, and the catalytic converter. Traditional theory was to get rid of or manage heat; Smokey was channeling heat for improved performance, the exact opposite of conventional engineering science. True, he had allies in Detroit, but his cantankerous personality had also generated plenty of enemies over the decades. The shifting political tides of OE politics eventually left Smokey out in the cold.

Meanwhile, durability concerns led Crane to back off on the boost levels and temperatures for its projected retrofit kits. Smokey's original motors had trick rings, forged pistons, and Carrillo rods, but the retro kits would be bolt-ons for econo four-cylinders. The kit cost kept going up, even as performance declined. Bickering started. In marched the lawyers, and lawsuits inevitably followed. The project collapsed under a pile of recrimination.

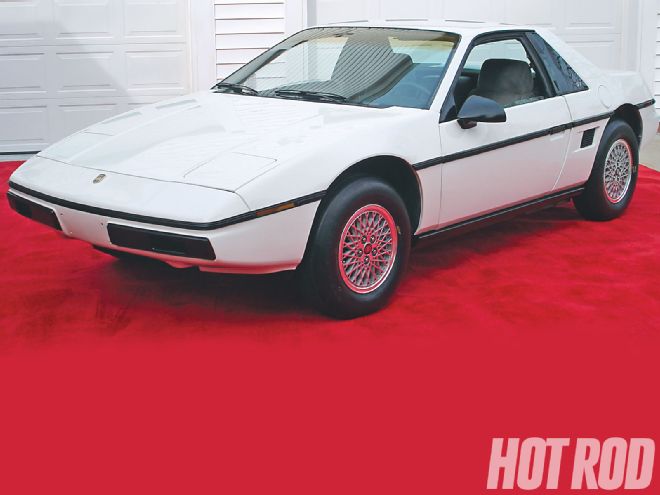

The original Fiero was ultimately crushed by Pontiac, which demanded Smokey return the long-term loner when GM pulled the plug on the initial project. Smokey returned the car, but not before removing the entire drivetrain. This is Allard's duplicate Fiero built in 2006 using the original salvaged Smokey drivetrain.

The original Fiero was ultimately crushed by Pontiac, which demanded Smokey return the long-term loner when GM pulled the plug on the initial project. Smokey returned the car, but not before removing the entire drivetrain. This is Allard's duplicate Fiero built in 2006 using the original salvaged Smokey drivetrain.

Smokey did take out patents on the basic hot vapor technology; the Yunick family allowed the patents to enter the public domain back in '03. Still, Smokey took much of the knowledge with him to the grave. As Smokey's daughter Trish Yunick puts it, "A patent application is a balance between disclosure versus secrets. You want to reveal just enough information to get the patent, but not so much that people can reverse-engineer your ideas. Smokey is gone, and some of the secrets went with him."

One of the key secrets is the exact tune-up or technique used to get the engine past the detonation threshold into the super-hot, super-lean running condition. Ralph provides some intriguing hints. He points out that "any good race driver that ever had a meltdown, he'll tell you the car never ran as well in its whole life as it did just before it let go." In short, an engine makes its most power running on the verge of detonation. For example, a typical small-block Chevy runs reliably at a 1,750-degree F stabilized exhaust temperature. At 2,250 degrees, you're definitely in trouble from engine-destroying detonation. But Ralph says "if you can take it to 2,600 degrees F, you can control the burn rate of the hydrogen molecule in the fuel, the major radical in the gas that's causing detonation. Control this burn rate at that temperature and you'll make more power without detonation." So the key seems to be getting safely past 2,250 degrees. Not only is the tune-up critical, but there may have been some special camshaft timing wizardry involved as well.

Smokey's original hot-vapor 2.5L Pontiac in Allers' Fiero: "It had been in storage for almost 22 years but fired right up on the five-year anniversary of Smokey's death," Allers says. "I only get 40 mpg because I can't keep from stepping on it! It smokes the tires at 60 mph, and it passed Tennessee emissions tests-twice. The only problem was burned plug wires from the heat. I rerouted them."

Smokey's original hot-vapor 2.5L Pontiac in Allers' Fiero: "It had been in storage for almost 22 years but fired right up on the five-year anniversary of Smokey's death," Allers says. "I only get 40 mpg because I can't keep from stepping on it! It smokes the tires at 60 mph, and it passed Tennessee emissions tests-twice. The only problem was burned plug wires from the heat. I rerouted them."

All of which brings us to another limiting factor in the context of the '80s: Internal changes are required to get the engine to reliably survive long-term at elevated temperatures in the hands of the average, nonautomotive-savvy consumer. There is some question as to whether the metallurgy of that era was up to the task, and if it was, would the cost be affordable in a mass-produced car? Also, any system malfunction (the wrong air/fuel ratio or temperature, for example) could lead to instant engine failure.

But technology has continued to evolve in the 20 years since the engine was built. Ceramic engine parts or even an entire engine made from ceramics (which are stable to 4,000 degrees F) could be an answer, but the material remains expensive. Cast or molded ceramics are subject to random voids and flaws, which are very hard to detect by conventional inspection methods. Ceramics can be extruded from solid stock (some fighter jet engines have ceramic parts), but the technology and manufacturing process at present is too costly for consumer use (extruded ceramics can only be cut by diamond tooling). Carbon-carbon technology (ultralight and stable to 5,000 degrees F) is another possibility, but again, costs must decline significantly.

All the gauges in the otherwise stock interior are Smokey's originals, except for two that Smokey sold at a garage sale. Allers: "The only real change was instead of laying the gauges on the seat and floor as Smokey did, I placed them in a panel on the dash."

All the gauges in the otherwise stock interior are Smokey's originals, except for two that Smokey sold at a garage sale. Allers: "The only real change was instead of laying the gauges on the seat and floor as Smokey did, I placed them in a panel on the dash."

Although the original hot-vapor engines relied on a carb with no computer, modern 21st century fuel injection and computer enhancements could be used to fail-safe the engine in event of system malfunction. For example, present engine management systems still rely on an oxygen sensor and a knock sensor to provide feedback to correct the air/fuel ratio and timing, respectively, but this a catch-up game, subject to a potentially deadly time lag on an engine always operating close to the limit. It is theoretically possible to put an inductive pickup on a spark plug wire that can be used by the computer to measure the ionization gap across the spark plug in real time. A change in the ionization gap indicating a problem in the cylinder would manifest itself as a slight change in electrical current read in milliamps. "If there's going to be a failure from temperature or heat, you'll know it instantaneously," Ralph says. "I worked on the genesis of this at Ethyl Corp. [using analog milliamp meters] all the way back in the '50s when I was still a student. With real-time feedback, the computer could then change the spark, the fuel ratio, and someday the compression ratio or the displacement to compensate before catastrophic failure occurs."

The computer could be programmed to fire fuel injector nozzles multiple times on a single firing stroke, each time with a different pulse width to slightly change the effective in-cylinder air/fuel ratio depending on where the flame front is in the cylinder compared with the piston position in relation to TDC. "This is what diesels do now," Ralph points out. "They fire six to seven times on one firing stroke. You don't hear the diesel anymore and it puts out more horsepower. I foresee 44:1 diesel engine compression ratios and as high as 35:1 on gasoline once the metallurgy catches up."

The Fiero's Bald Eagle tires are a whole story in themselves. 100 tires were made by Goodyear to Smokey's specs using a Smokey-patented secret rubber compound with cut treads. Reportedly, the ride was so smooth you couldn't hear any road noise. Smokey was willing to guarantee them for 100,000 miles. Allers still has some; they're 20 years old with no rot or apparent aging.

The Fiero's Bald Eagle tires are a whole story in themselves. 100 tires were made by Goodyear to Smokey's specs using a Smokey-patented secret rubber compound with cut treads. Reportedly, the ride was so smooth you couldn't hear any road noise. Smokey was willing to guarantee them for 100,000 miles. Allers still has some; they're 20 years old with no rot or apparent aging.

Meanwhile, Detroit is once again heavily involved in hot-vapor technology. The OEs have to be, what with fuel economy standards scheduled to really ratchet up in the next 10 years. GM has received a big grant for new research in this area under the economic stimulus plan. Secret research is rumored to be under way at Parker Hannifin. Activity is also said to be going on in Sweden.

As to the fate of the original Smokey hot-vapor engines, Trish Yunick still retains four different prototypes in long-term storage; the others have been sold. One is said to be in the custody of the Smithsonian Institution. Tony Allers, a longtime friend and customer of Smokey, has the only known good running engines. He built a Fiero that's identical to the original car, using the original drivetrain salvaged from the HOT ROD Fiero by Smokey before he returned the car to Pontiac for crushing. Allers drove the car daily for 21/2 years before he donated it in Christmas '09 to Don Garlits' museum where it is currently on display.

Perhaps Ralph sums it up best, "Hot-vapor technology won't die. Other kids are coming along that are smarter than me. It will continue to develop along with the technology needed to support it. The time will come when engines will be fully accepted as a heat pump."